Unlocking High-Value Wrought Aluminum Recycling from ELVs: A Technical Deep Dive

This technical summary is based on the academic paper "Present situation and problems on recycling of aluminum wrought alloy scrap materials recovered from end of life vehicle" by Mitsuhiro Otaki, published in the Proceedings of the 12th International Conference on Aluminium Alloys (2010). It has been analyzed and summarized for technical experts by CASTMAN.

![Fig.2 Simulated result for the amount of aluminum scrap in Japan [1]](https://castman.co.kr/wp-content/uploads/image-3057.webp)

Keywords

- Primary Keyword: Wrought Aluminum Recycling

- Secondary Keywords: aluminum alloy scrap, end-of-life vehicle (ELV) recycling, aluminum shredding, paint removal from aluminum, secondary aluminum ingot

Executive Summary

- The Challenge: Recycling aluminum wrought alloy scrap from End-of-Life Vehicles (ELVs) back into high-quality wrought ingots is hindered by metallic impurities and thick paint coatings.

- The Method: The study conducted dismantling, shredding, and paint removal experiments on actual ELV components to evaluate recovery rates and process effectiveness.

- The Key Breakthrough: A combined process of shredding and heating in a rotary kiln is the most effective method for removing paint, resulting in a high melting yield (95%) and a safe working environment.

- The Bottom Line: A dedicated, multi-step process involving selective dismantling and advanced pre-treatment is essential to upgrade ELV-derived wrought aluminum scrap for high-value, product-to-product recycling.

The Challenge: Why This Research Matters for HPDC Professionals

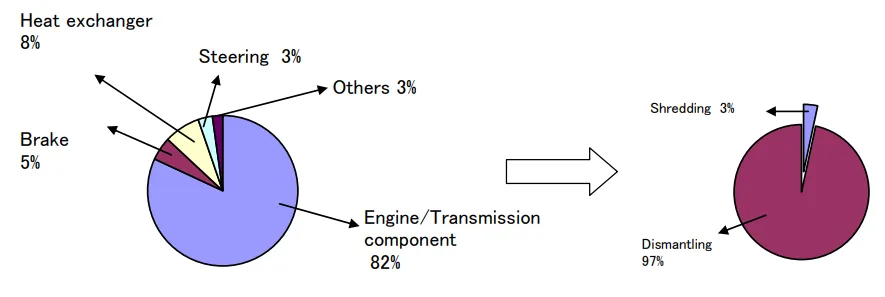

As automotive manufacturers increasingly use aluminum wrought alloys for components like hoods and heat exchangers to reduce vehicle weight, a new recycling challenge emerges. Historically, aluminum recovered from End-of-Life Vehicles (ELVs) has been dominated by casting alloys from engine blocks and transmissions. This scrap is readily recycled into secondary casting ingots (e.g., ADC12), which have a high tolerance for impurities like iron (Fe).

However, wrought alloys demand a much higher level of purity. Recycling wrought alloy scrap from ELVs directly into new wrought alloy ingots is difficult due to two major problems:

1. Metallic Contamination: Steel parts, such as bolts and reinforcements, are often attached to aluminum components. During shredding, these introduce Fe contamination that is difficult to remove and severely degrades the properties of wrought alloys.

2. Paint and Coatings: Body panels like hoods have thick, hard paint coatings. When melted without pre-treatment, these coatings create a hazardous working environment (smoke and fumes) and reduce the overall metal yield.

This research was conducted to identify practical, economical methods to overcome these hurdles and create a viable pathway for high-value, product-to-product Wrought Aluminum Recycling.

The Approach: Unpacking the Methodology

The study employed a series of practical tests using actual ELVs and components to simulate real-world recycling scenarios.

Dismantling Time Study: The researchers used two identical ELVs (Mazda roadsters from 1995 and 2000) to measure the time required to manually dismantle specific aluminum wrought alloy parts. This test determined the economic feasibility of recovering parts like hoods, radiators, condensers, and beams before the vehicle is shredded.

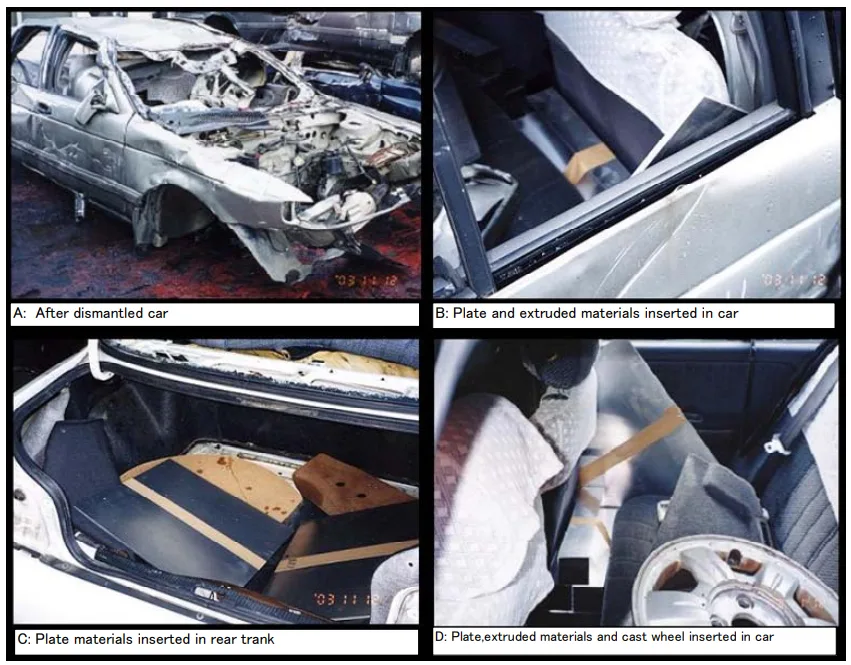

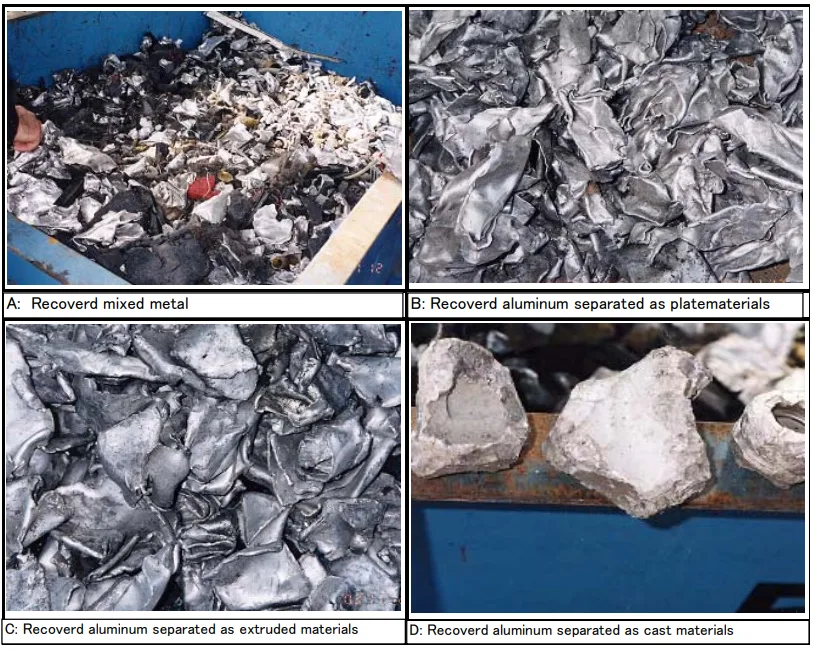

Shredding and Separation Test: To simulate a future scenario with more wrought aluminum in the scrap stream, researchers added known quantities of 6000-series alloy plate, 6063 extruded alloy, and AC4CH cast wheels to 10 cars before shredding. The shredded material then underwent air classification, magnetic separation, and hand-sorting to assess the feasibility of separating the mixed aluminum scrap back into its original forms (plate, extruded, cast).

Paint Removal Pre-Treatment Study: Using 61 painted aluminum hoods dismantled from ELVs, several pre-treatment methods were tested and compared:

- None (control group)

- Shredding only

- Rolling only

- Heating in a rotary kiln

- A combination of shredding and heating in a rotary kiln

The effectiveness of each method was evaluated based on the working environment during melting (smoke/smell), the final melting yield (%), and the chemical composition of the resulting aluminum.

The Breakthrough: Key Findings & Data

The experiments yielded critical data on the most effective strategies for recovering and processing wrought aluminum from ELVs.

Finding 1: The Economics of Dismantling Wrought Components

Not all parts are created equal when it comes to recovery. The study found a clear link between a component's size, accessibility, and the economic viability of dismantling it. As shown in Table 1, large parts over 1kg were easily recovered.

- Economical to Dismantle: The front hood (8.1 kg average), condenser (2.0 kg), and radiator (2.2 kg) each took only 1 minute to dismantle, making them highly economical for pre-shredder recovery.

- Not Economical to Dismantle: The evaporator (1.6 kg) and heater core (0.7 kg) were deemed difficult to dismantle due to their deep mounting positions within the vehicle, with a negative time value (-37 minutes) indicating the complexity of the task.

This finding suggests that a targeted dismantling strategy focusing on large, accessible wrought alloy parts is the most practical first step in the recycling chain.

Finding 2: The Critical Role of Pre-Treatment for Paint Removal

Melting painted aluminum parts without proper pre-treatment is inefficient and hazardous. The study demonstrated that a combination of mechanical and thermal treatment is the optimal solution.

As detailed in Table 6, the results were stark:

- Without Pre-treatment ("None"): The melting process produced bad smoke and smell, and the melting yield was only 87.4%.

- With Shredding + Heating: The combination of shredding and heating in a rotary kiln resulted in a good working environment (no smoke/smell) and dramatically increased the melting yield to 95%. This yield is comparable to that of a standard ADC12 ingot (94.8%).

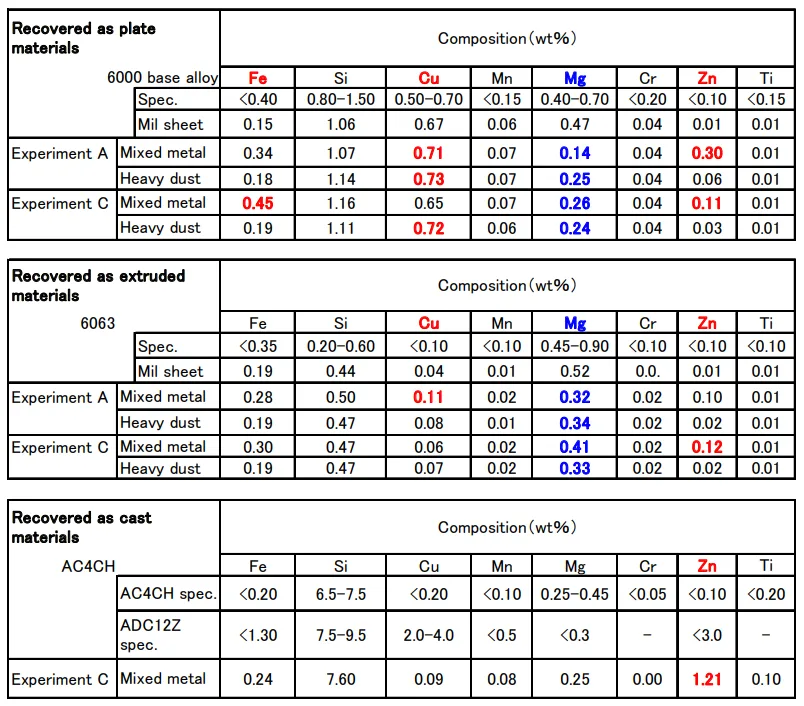

This pre-treatment also produced a cleaner final material, with Fe content at 0.11% and Si at 0.08%, demonstrating its effectiveness in preparing the scrap for high-quality remelting.

Practical Implications for R&D and Operations

The findings from this paper offer actionable insights for professionals across the manufacturing and recycling spectrum.

- For Process Engineers: This study suggests that adjusting the front-end of the recycling process is critical. For painted wrought alloy scrap, implementing a pre-treatment step involving shredding and heating in a rotary kiln can significantly improve melt-shop safety and increase metal yield from 87.4% to 95%.

- For Quality Control Teams: The data in Table 5 shows the typical levels of Fe, Cu, and Zn contamination found in aluminum scrap after shredding. This can serve as a baseline for developing more robust inspection criteria for incoming secondary raw materials. Furthermore, Table 6 illustrates how different pre-treatments directly impact the final chemical composition of the melted ingot.

- For Design Engineers: The findings indicate that large aluminum components (>1kg) that are easily accessible, like hoods and radiators, have a much higher probability of being properly dismantled and recycled. This underscores the importance of Design for Disassembly principles, as component placement can directly influence its end-of-life value.

Paper Details

Present situation and problems on recycling of aluminum wrought alloy scrap materials recovered from end of life vehicle

1. Overview:

- Title: Present situation and problems on recycling of aluminum wrought alloy scrap materials recovered from end of life vehicle

- Author: Mitsuhiro Otaki

- Year of publication: 2010

- Journal/academic society of publication: Proceedings of the 12th International Conference on Aluminium Alloys, The Japan Institute of Light Metals

- Keywords: aluminum alloy scrap, end life of vehicle, recycling, dismantling, shredding

2. Abstract:

Aluminum products for the automobile use in Japan are mainly the pressure die-casting and/or casting products as engine block, transmission case, and wheel et al., though aluminum wrought alloy products for the automobile use as front hood, heat exchanger increase gradually. Aluminum material recovered by dismantling and shredding from end of life vehicle (ELV) was recycled mainly to the secondary aluminum alloy ingot for the die-casting and/or casting use. In future, aluminum wrought alloy scrap will be desired to recycle for the aluminum wrought alloy ingot. Several dismantling and shredding methods were studied to separate the aluminum wrought alloy materials from the mixed aluminum scrap products and/or shredded chips recovered from ELV. Experimental results show that technical problems are prevention of metallic impurity element from the steel, copper and zinc parts in ELV and optimization of the removal method of paint. It is important to adapt the secondary dismantling process to separate the steel part from the aluminum alloy products. Shredding and heating process is recommended to remove efficiently the paint at the front food in order to keep the safety of working environment at melting process. The large aluminum wrought alloy products over 1kg as front food, radiator and condenser were easy to dismantle and possible to recycle by only the technology now on use.

3. Introduction:

Aluminum products for the automobile use in Japan are mainly the pressure die-casting and/or casting products as engine block, transmission case, and wheel et al., though aluminum wrought alloy products for the automobile use as front hood, heat exchanger increase gradually. Aluminum material recovered by dismantling, shredding and separating from end of life vehicle (ELV) was recycled mainly to the secondary aluminum alloy ingot for the die-casting and/or casting use. In future, aluminum wrought alloy scrap will be desired to recycle for the aluminum wrought alloy ingot. Several dismantling and shredding methods were studied to separate the aluminum wrought alloy materials from the mixed aluminum scrap products and/or shredded chips recovered from ELV.

4. Summary of the study:

Background of the research topic:

The use of aluminum wrought alloys in automobiles is increasing. While aluminum casting alloys from ELVs are easily recycled into secondary casting ingots, recycling wrought alloys back into high-purity wrought ingots presents challenges. This is due to stricter limits on impurities (like Fe from steel attachments) and the need to remove thick paint from body panels.

Status of previous research:

Aluminum from ELVs is primarily recycled for casting applications. A predicted surplus of aluminum scrap in Japan starting around 2018 necessitates the development of new recycling systems, particularly for product-to-product recycling of wrought alloys.

Purpose of the study:

To study and identify effective dismantling and shredding methods to separate aluminum wrought alloy materials from mixed scrap recovered from ELVs. The study aimed to address the technical problems of metallic impurity prevention and paint removal to enable the recycling of wrought scrap into wrought ingots.

Core study:

The study involved three main experimental parts:

1. A dismantling test to measure the time and economic feasibility of recovering specific aluminum wrought alloy parts from ELVs.

2. A shredding test with mixed wrought and cast aluminum parts to evaluate the separability and contamination of different alloy types after a typical shredding process.

3. A paint removal test comparing various pre-treatment methods (shredding, rolling, heating) on painted aluminum hoods to optimize melting yield and working environment safety.

5. Research Methodology

Research Design:

The research was designed as a series of empirical tests using actual ELVs and representative aluminum alloy materials. The study compared different recovery and pre-treatment processes to quantify their effectiveness in terms of time, yield, and material purity.

Data Collection and Analysis Methods:

- Dismantling Test: Time taken to remove specific parts from two Mazda roadsters (1995 and 2000 models) was measured in minutes.

- Shredding Test: Known weights of 6000-series plate, 6063 extruded sections, and AC4CH cast wheels were added to 10 cars. After shredding and separation, the recovered weights of each material type were measured. The chemical composition of the recovered materials was analyzed.

- Paint Removal Test: For 61 aluminum hoods, the remaining paint after pre-treatment was visually assessed. During melting, the working environment (smoke, smell) was observed. The melting yield was calculated as a percentage, and the final chemical composition (Fe, Si, Cu) of the melt was determined.

Research Topics and Scope:

The research focused on the recovery and pre-treatment of aluminum wrought alloys from ELVs. The scope included:

- Recovery of parts via dismantling.

- Separation of shredded aluminum scrap.

- Removal of paint from aluminum body panels.

The study did not cover the final refining processes of the molten metal.

6. Key Results:

Key Results:

- Large aluminum wrought alloy parts over 1kg (front hood, radiator, condenser) were easy and economical to dismantle, taking only 1 minute each.

- It was possible to separate shredded mixed aluminum scrap into plate, extruded, and cast materials via hand-sorting, with almost all aluminum alloy scrap being recovered.

- Recovered shredded materials showed contamination from Fe, Cu, and Zn. Fe powders were observed on the surface of the materials.

- Melting painted aluminum hoods without pre-treatment resulted in a poor working environment (bad smoke and smell) and a low melting yield of 87.4%.

- A combined pre-treatment process of shredding followed by heating in a rotary kiln was the most effective method for paint removal, leading to a good working environment and a high melting yield of 95%.

Figure Name List:

- Fig.1 Experimental result of the dismantling test

- Fig.2 Simulated result for the amount of aluminum scrap in Japan [1]

- Fig.3 Flow of the shredding test

- Fig.4 Appearance of the inserted materials at the shredding test

- Fig.5 Appearance of the recovered aluminum alloy materials

- Fig.6 Appearance of the melting furnace without any pre-treatment

- Fig.7 Recommended aluminum material recycling flow by ELV

7. Conclusion:

To effectively separate and recycle aluminum wrought alloy materials from ELVs, several technical challenges must be addressed. The primary problems are the prevention of metallic impurity contamination (from steel, copper, zinc) and the optimization of paint removal. The study concludes that it is important to use a secondary dismantling process to separate steel parts from aluminum products. For painted parts like the front hood, a combination of shredding and heating is recommended to efficiently remove the paint, which ensures safety in the melting environment. Large wrought alloy products over 1kg, such as the front hood, radiator, and condenser, are easy to dismantle and can be recycled using current technology.

8. References:

- [1] M. Otani et.al. : Pre-print of JILM 107 (2004) 331.

- [2] M.Otaki et.al.: JSAE 35, 5 (2005) 241.

- [3] M.Yanagawa et.al: Pre-print of JILM 107 (2004) 329.

Expert Q&A: Your Top Questions Answered

Q1: Why were cars from 1995 and 2000 specifically chosen for the dismantling test?

A1: The paper states that the "same kind of ELV (Mazda roadster) produced at the 1995 year and the 2000 year was prepared." This was done specifically "to measure the effect of the product year on the dismantling time of aluminum parts." By using the same model from different production years, the researchers could assess if manufacturing changes over time impacted the ease of disassembly.

Q2: Table 5 shows Fe contamination in the recovered materials. What is the likely source of this iron?

A2: The paper notes that after shredding, "Fe powders and /or particles were observed at the surface of recovered aluminum materials." This suggests that the contamination is not just from attached steel parts that failed to be magnetically separated, but also from the physical shredding process itself, where iron from the shredder mechanism or other steel components in the mix can be smeared onto the softer aluminum surfaces.

Q3: What makes the evaporator and heater core so difficult to dismantle compared to the radiator and condenser?

A3: According to the paper, the evaporator and heater core were "difficult to dismantle because of the deep mounting position." Unlike radiators and condensers, which are typically located at the front of the engine bay for easy access, these components are usually buried deep within the dashboard and HVAC system, requiring extensive labor to reach and remove.

Q4: The melting yield for "Shredding" alone was the same as "None" (87.4%) in Table 6. Why didn't shredding by itself improve the yield?

A4: Table 6 shows that shredding alone did not effectively remove the paint; the "Remaining paint after pre-treatment" was still rated as "bad." The low yield is primarily caused by the organic paint material burning off during melting. Shredding breaks the parts into smaller pieces but does not remove the coating, so the mass loss from the paint remains the same, resulting in an equally low metal yield.

Q5: The paper proposes a recycling flow in Figure 7. What is the key difference in the proposed processing for cast vs. wrought alloy parts?

A5: In the recommended flow, dismantled cast alloy parts (engine, transmission, wheels) are routed directly to remelting to produce aluminum cast/die-cast alloy ingots. In contrast, wrought alloy parts undergo a more complex flow. Large parts like heat exchangers are separated, while painted parts like hoods, fenders, and doors are specifically targeted for a "Remove the paint (Shredder + heating)" step before they can be remelted into higher-purity aluminum wrought alloy ingots. This additional pre-treatment step is the critical difference.

Conclusion: Paving the Way for Higher Quality and Productivity

The transition to a circular economy demands that we not only recycle materials but also preserve their inherent value. This research provides a clear, data-driven roadmap for upgrading the recycling stream for automotive aluminum. The core takeaway is that a one-size-fits-all approach is insufficient. To achieve high-value Wrought Aluminum Recycling, a sophisticated strategy combining targeted dismantling of large components with advanced pre-treatment of painted scrap is essential. By implementing processes like shredding and thermal paint removal, recyclers can overcome the critical barriers of contamination and low yields, turning a challenging waste stream into a valuable resource for new, high-quality products.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Present situation and problems on recycling of aluminum wrought alloy scrap materials recovered from end of life vehicle" by "Mitsuhiro Otaki".

- Source: Proceedings of the 12th International Conference on Aluminium Alloys, September 5-9, 2010, Yokohama, Japan, pp. 199-205.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.