Mastering HPDC: A Deep Dive into the Causes and Cures for Porosity Defects in Aluminum Parts

This technical summary is based on the academic paper "ANALYZE OF THE POSSIBLE CAUSES OF POROSITY TYPE DEFFECTS IN ALUMINIUM HIGH PRESSURE DIECAST PARTS" by Ferencz Peti and Lucian Grama, published in the Scientific Bulletin of the „Petru Maior" University of Târgu Mureş (2011). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: HPDC Porosity Defects

- Secondary Keywords: high pressure diecasting, aluminium casting defects, gas porosity, shrinkage porosity, casting simulation, FEA simulation, diecast quality control

Executive Summary

- The Challenge: Porosity defects—including gas porosity, shrinkage porosity, and leakers—are the most common issues in high-pressure diecast aluminum parts, compromising their structural integrity, tightness, and overall quality.

- The Method: The paper analyzes the distinct visual characteristics of different porosity types and systematically maps the process-related root causes for each, while also reviewing modern control methods like X-ray, microscopy, and FEA simulation.

- The Key Breakthrough: The research provides a comprehensive categorization of the root causes for gas, shrinkage, and leaker porosities, linking them directly to specific process parameters such as shot end settings, metal conditions, and die design.

- The Bottom Line: Proactively controlling key process parameters and leveraging advanced simulation tools during the design phase are the most effective strategies for preventing and reducing costly HPDC Porosity Defects.

The Challenge: Why This Research Matters for HPDC Professionals

In the world of high-pressure die casting (HPDC), porosity is the most common and persistent defect. For engineers and managers striving for zero-defect production, these internal voids represent a significant challenge. As this paper highlights, porosity directly "reduces the quality of the casting usually it's tightness and strenght." Whether it's a critical automotive component that must withstand high pressure or a complex housing requiring perfect integrity, porosity can lead to part failure, costly recalls, and damage to a manufacturer's reputation. This research is vital because it moves beyond simply identifying porosity and provides a structured analysis of its root causes, offering a clear roadmap for prevention and control.

The Approach: Unpacking the Methodology

The study employs a multi-faceted approach to analyze and understand porosity defects in aluminum diecast parts. The core of the methodology involves:

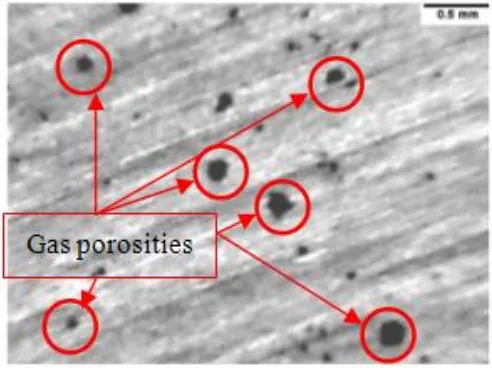

- Visual and Microscopic Analysis: The researchers prepared polished sections of diecast parts to examine defects under a microscope. This allowed for the clear identification and characterization of different porosity types based on their unique shapes, sizes, and shades, as documented in Figures 1, 2, and 3.

- Systematic Cause-and-Effect Mapping: The paper systematically categorizes the numerous process parameters that can lead to porosity. It groups these causes under logical headings such as "Shot end parameters," "Metal volume," "Die construction," and "Metal," creating a diagnostic framework for troubleshooting.

- Review of Advanced Control and Prevention Technologies: The study reviews both traditional and state-of-the-art methods for defect detection and prevention. This includes established quality control methods like X-Ray and sectioning, as well as advanced analytical tools like Computerized Tomography (CT). Critically, it highlights the role of Finite Element Analysis (FEA) simulation software like Flow3D for predicting and mitigating defects during the product and process development phase.

The Breakthrough: Key Findings & Data

The paper delivers several critical findings that are immediately applicable for HPDC professionals.

Finding 1: Distinct Visual Signatures for Gas vs. Shrinkage Porosity

A key breakthrough is the clear visual differentiation between the two primary types of porosity, which is essential for accurate root cause analysis.

- Gas Porosity: As shown in Figure 1, gas porosity is characterized by a "specific shape mostly regular - globular and the opaque shade." This appearance points to trapped air or gas from various sources during the injection process.

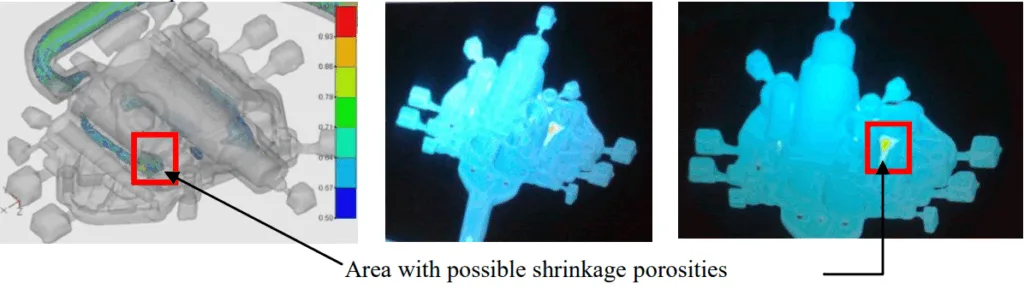

- Shrinkage Porosity: In contrast, Figure 2 illustrates that shrinkage porosity has a "specific shape mostly iregular - longitudinal and the bright shade." This dendritic, crack-like appearance is caused by a volume deficit as the metal solidifies, particularly in thick-walled sections.

Finding 2: Predictive Defect Mitigation Using FEA Simulation

The research underscores the power of simulation in preventing defects before a single tool is cut.

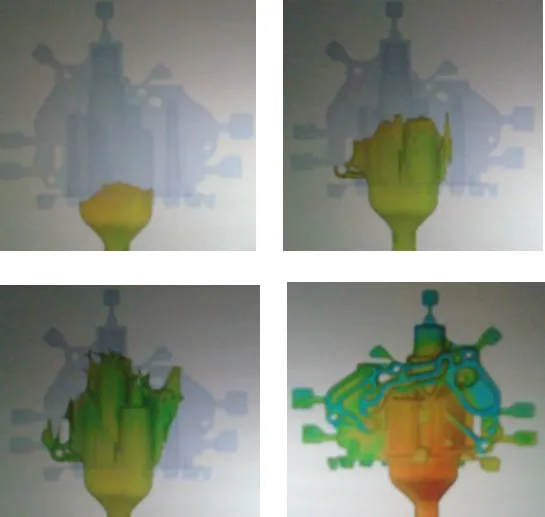

- Flow Simulation for Gas Porosity: Figure 6 demonstrates how flow simulation can "identify the last filled areas where the overflows have to be placed in order to assure good wenting of the cavities and minimize gas porosity defects."

- Solidification Simulation for Shrinkage Porosity: As shown in Figure 7, solidification simulation identifies "areas where the part presents areas with liquid fractions after the optimum solidification time which can cause shrinkage porosities." This allows designers to address potential hot spots and thick sections that are prone to shrinkage.

Practical Implications for R&D and Operations

The findings from this paper provide actionable insights for various technical teams involved in the HPDC process.

- For Process Engineers: This study suggests that adjusting specific process parameters, such as first and second stage shot velocities, changeover points, and intensification pressure, is critical for reducing both gas and shrinkage porosity. The detailed cause lists in Section 3 serve as an excellent troubleshooting guide.

- For Quality Control Teams: The data in Figure 1 and Figure 2 of the paper illustrates the distinct visual differences between gas and shrinkage porosity, which can inform new visual inspection criteria for sectioned parts. The mention of standards like ASTM E505 and VDG P 201 provides a reference for establishing objective quality specifications.

- For Design Engineers: The findings indicate that "Poor gating and runner design" and "Difficult casting geometry" are direct causes of porosity. The use of FEA simulation (Figures 6 & 7) is a valuable tool in the early design phase to optimize part geometry and runner systems, thereby designing out the potential for defects.

Paper Details

ANALYZE OF THE POSSIBLE CAUSES OF POROSITY TYPE DEFFECTS IN ALUMINIUM HIGH PRESSURE DIECAST PARTS

1. Overview:

- Title: ANALYZE OF THE POSSIBLE CAUSES OF POROSITY TYPE DEFFECTS IN ALUMINIUM HIGH PRESSURE DIECAST PARTS

- Author: Ferencz Peti, Lucian Grama

- Year of publication: 2011

- Journal/academic society of publication: Scientific Bulletin of the „Petru Maior" University of Târgu Mureş, Vol. 8 (XXV) no. 1

- Keywords: High pressure diecasting, aluminium, porosity, mold, casting deffects

2. Abstract:

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminium, magnesium. Depending on the type of metal being cast, a hot- or cold-chamber machine is used. Die castings are characterized by a very good surface finish (by casting standards) and dimensional consistency. The most common deffect that appear in castings is the porosity type of deffect, which can be gas porosity, shrinkage porosity or leaker.

3. Introduction:

This paper presents the porosity type of deffects in the high pressure diecast parts and the main causes that have influence on the porosity type of deffects. Also this paper presents the most common control methods for the detection of the porosity type of deffects and the way to prevent and to reduce the porosity since the product / process development phase. In the paper are presented the standards in terms of porosity of the most important car's and components manufacturers.

4. Summary of the study:

Background of the research topic:

High pressure die casting is a widely used process for producing non-ferrous metal parts with good surface finish and dimensional consistency. However, the process is susceptible to defects, with porosity being the most common type, affecting the quality, tightness, and strength of the final product.

Status of previous research:

The paper references established industry standards for porosity inspection, such as ASTM E505 (American Standard) and VDG Specification P 201 (German Standard), indicating a pre-existing body of knowledge and quality specifications used by major automotive manufacturers like Ford, Renault, and Volkswagen.

Purpose of the study:

The study aims to present the different types of porosity defects in high-pressure diecast aluminum parts, identify their main causes, describe common methods for detection and control, and outline ways to prevent or reduce these defects starting from the product development phase.

Core study:

The core of the study is the characterization of gas porosity, shrinkage porosity, and leakers. It provides a detailed breakdown of the potential process-related causes for each defect type, covering shot end parameters, metal volume, die conditions, and die design. The study also reviews control methods, from traditional sectioning and X-ray to advanced Computerized Tomography and predictive FEA simulations (Flow3D) for flow and solidification.

5. Research Methodology

Research Design:

The study is a descriptive and analytical review. It analyzes the physical characteristics of porosity defects, systematically catalogs their potential causes, and evaluates various methods for their control and prevention.

Data Collection and Analysis Methods:

The methods include visual analysis of polished sections of diecast parts via microscopy, review of established industry standards (ASTM E505, VDG P 201), and discussion of advanced analytical techniques such as Computerized Tomography and Finite Element Analysis (FEA) simulation using software like Flow3D.

Research Topics and Scope:

The research is focused on porosity type defects (gas porosity, shrinkage porosity, and leakers) specifically within aluminum parts produced by the high-pressure die casting process.

6. Key Results:

Key Results:

- Porosity defects are categorized into gas porosity, shrinkage porosity, and leakers, each with distinct causes and characteristics.

- Gas porosity appears as regular, globular voids, while shrinkage porosity is irregular, longitudinal, and often bright in polished sections.

- A comprehensive list of process parameters causing these defects is provided, including shot velocities, intensification, metal temperature, die temperature, and die design (gating, runners, venting).

- FEA simulation is presented as a powerful tool to predict and mitigate porosity during the design phase by analyzing metal flow and solidification patterns.

- Industry standards from ASTM and VDG are used by major automotive manufacturers to specify acceptable porosity levels.

Figure Name List:

- Fig. 1. Air Porosity in the section of an aluminium diecast part

- Fig. 2. Shrinkage porosity in the section of an aluminium diecast part

- Fig. 3. Analize of the dimensions of shrinkage porosities with microscope

- Fig. 4. Leaker in the section of an aluminium diecast part

- Fig. 5. Reconstruction of the numerical 3D model of an Oil Pump component with Computerized Tomography

- Fig. 6. Analyze of the cavities filling with Flow3D software

- Fig. 7. Solidification simulation with Flow3D software

- Fig. 8. Fluids flow equation

7. Conclusion:

The simplest way to reduce porosity type defects is to establish a good process definition and setup from the beginning and maintain it under control by ensuring process stability. This stability can be achieved by monitoring and controlling process parameters, either automatically by the die casting cell or through frequent controls defined in process failure mode analysis and control plans.

8. References:

- [1]. Ernst Brunhuber Praxis der Druckgussfertigung, Ed. Schiele & Schön, Berlin, 1991

- [2]. Herbert Rees - Mold Engineering, Ed. Carl Hanser Verlag, Munich, 2002

- [3]. Montes Jose Revision Tecnica del Producto, CIE C. Vilanova, 2008

- [4]. Street Arthur, The diecasting handbook, Portcullis Press LTD, 1977

- [5]. Şeres I. Matrițe de injectat, Ed. Imprimeriei de Vest, Oradea, 1999

- [6]. Zirbo, Gh., Dan V. Turnarea sub presiune. Elemente de proiectare a formelor metalice, Ed. U.T. Pres, Cluj-Napoca, 1997

- [7]. *** - Company documentation Buhler

- [8]. http:// www.buhlergroup.com

- [9]. http:// www.diecastingengineer.org

- [10]. http://eb-cat.ds-navi.co.jp/enu/jtekt/tech/ej/

- [11]. http://www.flow3d.com/

- [12]. http://www.springerlink.com

- [13]. http://ciepedia.cie.lan/ciepedia/index.php

- [14]. http://en.wikipedia.org/wiki/Die_casting

- [15]. http://www.diecasting.org

- [16]. http://www.xviewct.com/industrial-ct-video/die-casting-video

- [17]. http://www.regal-aluminium.ca

Expert Q&A: Your Top Questions Answered

Q1: Why is it so important to visually distinguish between gas and shrinkage porosity?

A1: According to the paper, the visual distinction is critical for effective troubleshooting. Gas porosity (globular, opaque) as seen in Figure 1 points to issues like trapped air from poor venting or incorrect shot parameters. Shrinkage porosity (irregular, longitudinal) shown in Figure 2 indicates problems with solidification, such as insufficient feeding in thick sections or hot spots. Identifying the correct type leads engineers to the right set of potential causes listed in Section 3, saving time and resources.

Q2: The paper lists many potential causes for gas porosity. Which are the most critical to control?

A2: While the paper doesn't explicitly rank the causes, the "Shot end parameters" category is listed first and is the most detailed. This suggests that parameters like "First stage velocity too low/high," "Change over point too early/late," and "Second stage velocity too low" are fundamental to controlling turbulence and preventing air from being trapped during the filling of the mold cavity.

Q3: How does the FEA solidification simulation in Figure 7 specifically help prevent shrinkage porosity?

A3: The simulation in Figure 7 identifies areas with "liquid fractions after the optimum solidification time." These areas are essentially hot spots that cool down last. As the paper explains, shrinkage is caused by metal reducing its volume during solidification without enough molten metal to feed the void. By pinpointing these potential hot spots in the design phase, engineers can modify the part geometry (e.g., reduce wall thickness) or add cooling channels to the die to ensure more uniform solidification, thereby preventing shrinkage voids from forming.

Q4: What is the primary cause of a "leaker" defect, and how does it differ from simple porosity?

A4: According to Section 2, a leaker is not caused by a single void but by a combination of defects. The paper states it can be "oxide folds and/or inclusion and/or porosity in conjunction with a surface defect which completes the part for a leak." This means an internal defect (like a line of porosity or an inclusion) creates a continuous path to the outer surface of the part, compromising its pressure tightness.

Q5: The paper mentions industry standards like ASTM E505 and VDG P 201. What is their practical role in production?

A5: As stated in Section 5, these standards are used by major automotive and component manufacturers (like Ford, Renault, TRW, and Volkswagen) to define the acceptable limits for porosity. They provide standardized reference radiographs and criteria for "Volume Deficits." In practice, they serve as the basis for the quality agreement between the die caster and the customer, ensuring that parts meet the required level of internal health and integrity for their application.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of minimizing HPDC Porosity Defects is central to achieving high quality and efficiency in aluminum die casting. This research provides a clear and structured framework for understanding the distinct causes of gas, shrinkage, and leaker porosities. The key takeaway is that a proactive approach, combining rigorous process control with the predictive power of FEA simulation, is the most effective strategy. By identifying potential issues in the design phase and ensuring process stability during production, manufacturers can significantly reduce scrap rates, improve part performance, and deliver superior components.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "ANALYZE OF THE POSSIBLE CAUSES OF POROSITY TYPE DEFFECTS IN ALUMINIUM HIGH PRESSURE DIECAST PARTS" by "Ferencz Peti and Lucian Grama".

- Source: Scientific Bulletin of the „Petru Maior" University of Târgu Mureş, Vol. 8 (XXV) no. 1, 2011, ISSN 1841-9267

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.