Unlock 85%+ Accuracy in Die Casting Project Forecasting: A New Hybrid Model

This technical summary is based on the academic paper "Hybrid forecasting modelling of cost and time entities for planning and optimizing projects in the die-cast aluminium industry" by Muñoz-Ibañez, C., Chairez, I., Jimenez-Martinez, M., Molina, A., and Alfaro-Ponce, M., published in Advances in Production Engineering & Management (2023). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: Die Casting Project Forecasting

- Secondary Keywords: Cost Estimation Models, Aluminium Die Casting, Project Planning Optimization, Hybrid Forecasting, Time and Cost Entities

Executive Summary

- The Challenge: Accurately estimating project cost and time in the die casting industry is notoriously difficult due to large sets of parameters and poorly identifiable variables that increase project complexity.

- The Method: Researchers developed a data-driven hybrid forecasting model that deconstructs projects into "Cost and Time Entities" (CTEs) for raw materials, manufacturing, and tooling.

- The Key Breakthrough: The proposed hybrid model demonstrated an accuracy greater than 85% in predicting the time and cost of die casting projects, validated against real-world data.

- The Bottom Line: This entity-based modeling approach provides a structured and highly accurate tool for generating fast, reliable quotes, significantly improving project planning and competitive advantage in the die casting industry.

The Challenge: Why This Research Matters for HPDC Professionals

In the competitive die casting industry, the speed and precision of cost and time estimation are critical. Finalizing a purchase order often hinges on these initial quotes. However, traditional project planning models struggle with the sheer number of variables involved, from volatile raw material prices to the specific operational times of diverse manufacturing processes.

As the paper highlights, this complexity makes it difficult for designers and project managers to visualize necessary cost-reduction modifications. The lack of a transparent cost structure can lead to opaque negotiations and delays with customers. Indirect costs and the complex causal relationships between cost objects (like products and services) and the resources they consume further complicate accurate forecasting. This research directly addresses the need for a more precise, flexible, and data-driven model to overcome these long-standing challenges in Die Casting Project Forecasting.

The Approach: Unpacking the Methodology

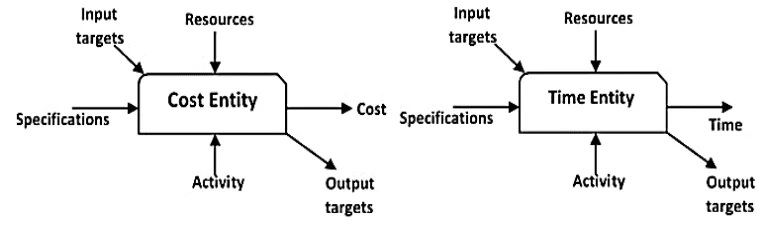

To build a more accurate forecasting tool, the researchers developed a data-driven hybrid model using a combination of analytical, parametric, and analog methods. The core innovation is the concept of Cost and Time Entities (CTE), which breaks down a project into two fundamental components:

1. Cost Entity (CE): Controls the cost of each project phase.

2. Time Entity (TE): Determines the time allocated for each activity.

These CTEs are then grouped into a macro-structure called the Cost and Time Entity Pattern (CTEP). The model is organized into three primary CTEPs:

- CTEP1 (Raw Materials): Forecasts the cost of aluminum using historical data from the London Metal Exchange (LME).

- CTEP2 (Product Manufacturing): Models the cost and time for manufacturing activities like die-casting, grinding, drilling, and packing, based on data from 25 real-world industrial projects.

- CTEP3 (Tooling Manufacturing): Estimates the cost and time for creating the die-cast tooling itself.

By structuring the project this way, the model can adapt to the specific characteristics of any given casting process. A binary matrix is used to identify which activities are included in a project, allowing for flexible and precise calculations of total cost and time.

The Breakthrough: Key Findings & Data

The study's primary success lies in the validated high accuracy of its hybrid model. By breaking the problem into manageable entities and applying the right modeling technique to each, the researchers achieved reliable predictive power.

Finding 1: Accurately Modeling Volatile Raw Material Costs

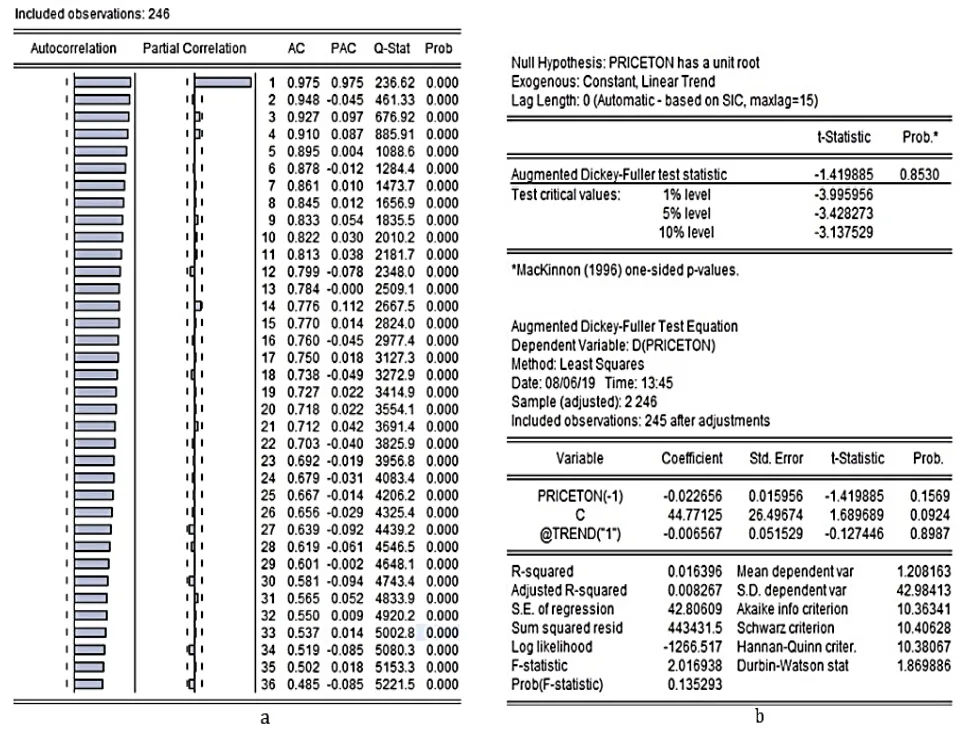

Forecasting the cost of aluminum is a major challenge due to market volatility. The researchers analyzed five years of LME price data and, through statistical tests like the Dickey-Fuller test (Fig. 2b), determined the time series was non-stationary. This insight led them to select an ARMA (2,2) model (Eq. 10) as the most effective tool for this specific forecast. This tailored approach allows the model to precisely adjust to the complex behavior of aluminum pricing, forming a reliable foundation for the total project cost.

Finding 2: Achieving Over 85% Reliability Across the Entire Project Scope

The ultimate test of the model was its overall accuracy when forecasting total project cost and time. The researchers validated each component of the CTEP framework using a chi-squared (χ²) test against real-world project outcomes. The results, summarized in Table 3, demonstrate exceptional reliability.

As shown in Table 3 (Model sensitivity analysis), the model achieved:

- 95% reliability for the Cost of raw material.

- 85% reliability for the Cost of the piece.

- 80% reliability for the Time of manufacture of the piece.

- 80% reliability for the Tooling cost.

This high degree of accuracy, consistently above 85% for key cost components, confirms that the entity-based hybrid model is a powerful and dependable tool for industrial application.

Practical Implications for R&D and Operations

The findings from this paper offer tangible benefits for various technical roles within a die casting operation.

- For Process Engineers: This study suggests that by using the model's specific equations for each manufacturing step (die-casting, grinding, etc.), it's possible to precisely quantify the time and cost impact of process changes. This enables data-driven optimization to reduce specific defects or improve overall efficiency.

- For Quality Control Teams: The data in the model, which links product weight to manufacturing time and cost, can inform new quality and efficiency metrics. For example, understanding the expected time for a part of a certain weight (as per the model) can help identify process deviations that may impact quality.

- For Project & Sales Engineers: The model provides a structured, fast, and efficient method for handling quotation data. The findings indicate that this entity-based approach facilitates user interaction and generates a solid, well-structured database, enabling the team to produce accurate quotes quickly and gain a competitive advantage.

Paper Details

Hybrid forecasting modelling of cost and time entities for planning and optimizing projects in the die-cast aluminium industry

1. Overview:

- Title: Hybrid forecasting modelling of cost and time entities for planning and optimizing projects in the die-cast aluminium industry

- Author: Muñoz-Ibañez, C.ª, Chairez, I.ª, Jimenez-Martinez, M.b, Molina, A.ª, Alfaro-Ponce, M.a,*

- Year of publication: 2023

- Journal/academic society of publication: Advances in Production Engineering & Management

- Keywords: Hybrid models; Entity modelling; Project planning; Forecasting models; Aluminium die-casting; Cost factors; Time factors; Optimization

2. Abstract:

The techniques employed to manage an industrial project are based on tools that aim to achieve the objectives set by an organization. Most of these techniques consider the development of operative and predictive models. The difficulty in developing project planning models relies on estimating large sets of parameters and the need to include model sections of poorly identifiable, that increase costs and time. This work develops a hybrid forecasting model for all the phases that make up die-casting projects through a series of parameters and sub-models that contemplate the particularities of each case, thereby achieving greater precision in the forecast. The model identifies the cost and time factors that affect project planning, specifically in the die-casting industry, and intends to predict their future behaviour when certain initially given conditions are modified. To estimate the parameters of the hybrid model, several factors in the processes were considered that interact in this industry, such as primary matter costs and activities associated to the process. The considered processes that have a substantial economic impact on the implementation of the project were selected. The criteria for this selection considered identifying the relevant parts of the design and manufacturing in the die-casting industry. Process factors such as the Cost of aluminium and its related activities, whose processes will be grouped into cost and time entities to build a set of metrics that allow better control over them. Finally, the proposed model is based on analytical, parametric, and analog methods that achieve accuracy greater than 85 % in predicting the time and Cost of the process.

3. Introduction:

Project planning is useful for improving time and costs in company projects involving management techniques. These models have motivated the implementation of several optimization strategies that have contributed to reducing operation costs and operative times. Developing valuable estimation models requires analyzing historical information. A main problem in the die casting production process is the lack of information about the cost structure and manufacturing processes, making it difficult for designers to reduce costs in quotation activities and causing delays with customers. This study presents a data-driven hybrid model to assess costs and process time in the die-cast aluminum industry, considering factors like raw material cost, processing time, and operational costs.

4. Summary of the study:

Background of the research topic:

Estimating manufacturing costs and time is crucial in many industrial sectors, including die casting. Existing models often focus on specific operational aspects like part geometry, porosity, or thermal fatigue but are not formally related to the economic aspects of the final product or its delivery time. Many companies use parametric or probabilistic methods that rely on synthetic data, which can be imprecise.

Status of previous research:

Previous research has developed specialized models for various sectors like software, construction, and automotive. In die casting, models exist for determining the number of cavities, simulating pores, and predicting thermal fatigue. However, these models often lack a direct link to the overall project cost and time. The use of hybrid models has shown significant advantages in other industries for process optimization, inventory control, and energy consumption, but their application to cost/time forecasting in die casting is novel.

Purpose of the study:

The study aims to develop a data-driven hybrid forecasting model to accurately assess costs and process time in the die-cast aluminum industry. The goal is to create a projection that allows for better control over the project plan, serving as an auxiliary tool for estimating costs and delivery times for customer products. The model is designed to be an integral formulation that adapts to the specific characteristics of the casting process.

Core study:

The core of the study is the construction of a model based on "Cost and Time Entities" (CTE). The researchers defined equations for CTEs related to raw material cost, part manufacturing time, part manufacturing cost, and tooling manufacturing cost and time. They used historical market data (LME) for aluminum prices and conducted extensive time-and-motion studies on 25 industrial projects to model the manufacturing processes. The model's accuracy was then rigorously tested and validated.

5. Research Methodology

Research Design:

The study employed a quantitative, model-building research design. It integrated three different modeling methods—analytical, parametric, and analog—to create a hybrid system. The research was structured around decomposing the die casting project into distinct cost and time entities (CTEs) and patterns (CTEPs) for raw materials, manufacturing, and tooling.

Data Collection and Analysis Methods:

Data was collected from multiple sources. For raw material costs, five years of monthly data (246 data points) were sourced from the London Metal Exchange (LME). For manufacturing time and cost, data was gathered from 25 real-world projects at Maquinados e Inyecciones Tecamac SA de CV. This involved conducting time and movement studies with 50 observation cycles per activity, generating over 7,000 data points. Statistical analysis, including time-series analysis (correlograms, Dickey-Fuller test) and regression, was used to develop forecasting equations. The final model's accuracy was validated using the chi-squared (χ²) test.

Research Topics and Scope:

The research focuses on cost and time forecasting for projects in the aluminum die casting industry. The scope includes:

- The cost of the raw material (aluminum).

- The cost and time of manufacturing the die-cast part, including processes like die-casting, grinding, drilling, shot blasting, and packing.

- The cost and time of manufacturing the die-cast tooling (mould).

6. Key Results:

Key Results:

- A hybrid forecasting model based on Cost and Time Entities (CTE) was successfully developed for the die casting industry.

- Time-series analysis of LME data identified an ARMA (2,2) model as the most accurate for forecasting aluminum raw material costs.

- The overall model demonstrated high accuracy, with a validated reliability of 95% for raw material cost estimation and 85% for final piece cost estimation.

- The model provides a structured, entity-based framework that simplifies the quotation process and improves planning precision.

Figure Name List:

- Fig. 1 Graphic representation of the CTE

- Fig. 2 (a) Aluminium price correlogram for LME, and (b) Dickey-Fuller test

7. Conclusion:

The results show that the developed model presents a degree of accuracy above 85 percent, allowing for quick forecasts with minimal information required for a quotation. This leads to an entity-based model that efficiently determines costs and time, providing certainty and a competitive advantage. Analyzing the model structure revealed that it facilitates fast and efficient handling of quotation data by the person in charge. The model increases accuracy and facilitates user interaction, helping to generate a solid and well-structured database. Future research could explore other modeling systems, like genetic algorithms or artificial intelligence, to further increase accuracy.

8. References:

- [1] Campero, M., Alarcón, L.F. (2018). Administración de proyectos civiles, Tercera edición, Ediciones UC, Valparaíso, Chile.

- [2] Gido, J., Clements, J., Baker, R. (2003). Administración exitosa de proyectos, Cengage Learning Editores, Santa Fe, México, from https://dspace.scz.ucb.edu.bo/dspace/bitstream/123456789/13442/3/9947.pdf, accessed April 26, 2023.

- [3] Turner, J.R. (2009). Handbook of project-based management: Leading strategic change in organizations, 3rd edition, Mc Graw Hill, New York, USA.

- [4] Wan, J. (2022). Demand prediction and optimization of workshop manufacturing resources allocation: A new method and a case study, Advances in Production Engineering & Management, Vol. 17, No. 4, 413-424, doi: 10.14743/apem2022.4.445.

- [5] Amaya Amaya, J. (2016). Toma de decisiones gerenciales: Métodos cuantitativos para la administración, 2nd edition, Ecoe Ediciones, Bogotá, Colombia, from Link, accessed April 26, 2023.

- [6] Heizer, J.H., Render, B. (2004). Principles of Operations Management, 5th edition, Pearson Educación, Ciudad de México, Mexico, from Link, accessed April 26, 2023.

- [7] Kerzner, H. (2013). Project management: A systems approach to planning, scheduling, and controlling, John Wiley, New York, USA, from Link, accessed April 27, 2023.

- [8] Goodpasture, J.C. (2004). Quantitative methods in project management, J. Ross Publishing, Fort Lauderdale, Florida, USA, from Link, accessed April 27, 2023,.

- [9] Saunders, M., Lewis, P. (2017). Doing research in business and management, 2nd edition, Pearson, Harlow, United Kingdom, from https://research.birmingham.ac.uk/en/publications/doing-research-in-business-and-management, accessed April 27, 2023.

- [10] Kramar, D., Cica, D. (2021). Modeling and optimization of finish diamond turning of spherical surfaces based on response surface methodology and cuckoo search algorithm, Advances in Production Engineering & Management, Vol. 16, No. 3, 326-334, doi: 10.14743/apem2021.3.403.

- [11] Turk, M., Pipan, M., Simic, M., Herakovic, N. (2020). Simulation-based time evaluation of basic manual assembly tasks, Advances in Production Engineering & Management, Vol. 15, No. 3, 331-344, doi: 10.14743/apem2020.3.369.

- [12] Kan, S.H. (2004). Metrics and models in software quality engineering, 2nd edition, Pearson Education, New York USA, from Link, accessed April 27, 2023.

- [13] Bryde, D., Broquetas, M., Volm, J.M. (2013). The project benefits of Building Information Modelling (BIM), International Journal of Project Management, Vol. 31, No. 7, 971-980, doi: 10.1016/J.IJPROMAN.2012.12.001.

- [14] Ofori, G. (2010). Indicators for measuring construction industry development in developing countries, Building Research & Information, Vol. 29, No. 1, 40-50, doi: 10.1080/09613210150208787.

- [15] Ward, Y., Graves, A. (2007). Through-life management: The provision of total customer solutions in the aerospace industry, International Journal of Services, Technology and Management, Vol. 8, No. 6, 455-477, doi: 10.1504/IJSTM.2007.013942.

- [16] Burgess, T.F., McKee, D., Kidd, C. (2005). Configuration management in the aerospace industry: A review of industry practice, International Journal of Operations and Production Management, Vol. 25, No. 3, 290-301, doi: 10.1108/01443570510581880.

- [17] Martínez Sánchez, A., Pérez Pérez, M. (2005), Supply chain flexibility and firm performance: A conceptual model and empirical study in the automotive industry, International Journal of Operations & Production Management, Vol. 25, No. 7, 681-700, doi: 10.1108/01443570510605090.

- [18] Han, X., Zhao, P.X., Kong, D.X. (2022). A bi-objective optimization of airport ferry vehicle scheduling based on heuristic algorithm: A real data case study, Advances in Production Engineering & Management, Vol. 17, No. 2, 183-192, doi: 10.14743/apem2022.2.429.

- [19] Vukelic, D., Simunovic, K., Kanovic, Z., Saric, T., Doroslovacki, K., Prica, M., Simunovic, G. (2022). Modelling surface roughness in finish turning as a function of cutting tool geometry using the response surface method, Gaussian process regression and decision tree regression, Advances in Production Engineering & Management, Vol. 17, No. 3, 367-380, doi: 10.14743/apem2022.3.442.

- [20] Blair, M., Hartong, A. (2012). Multidisciplinary design tools for affordability, In: Proceedings of 41st Structures, Structural Dynamics, and Materials Conference and Exhibit, Atlanta, USA, 350-360, doi: 10.2514/6.2000-1378.

- [21] Qian, L., Ben-Arieh, D. (2008). Parametric cost estimation based on activity-based costing: A case study for design and development of rotational parts, International Journal of Production Economics, Vol. 113, No. 2, 805-818, doi: 10.1016/J.IJPE.2007.08.010.

- [22] Wang, H.S., Wang, Y.N., Wang, Y.C. (2013). Cost estimation of plastic injection molding parts through integration of PSO and BP neural network, Expert Systems with Applications, Vol. 40, No. 2, 418-428, doi: 10.1016/J.ESWA.2012.01.166.

- [23] Verlinden, B., Duflou, J.R., Collin, P., Cattrysse, D. (2008). Cost estimation for sheet metal parts using multiple regression and artificial neural networks: A case study, International Journal of Production Economics, Vol. 111, No. 2, 484-492, doi: 10.1016/J.IJPE.2007.02.004.

- [24] Lallemand, H. (1999). Méthodes de chiffrage et indicateurs de la fonction devis, Travail et méthodes, No. 545, 35-44.

- [25] Madan, J., Rao, P.V.M., Kundra, T.K. (2007). System for early cost estimation of die-cast parts, International Journal of Production Research, Vol. 45, No. 20, 4823-4847, doi: 10.1080/00207540600789016.

- [26] Sung, B.S., Kim, I.S. (2008). The molding analysis of automobile parts using the die-casting system, Journal of Materials Processing Technology, Vol. 201, No. 1-3, 635-639, doi: 10.1016/J.JMATPROTEC.2007.11.185.

- [27] Srivastava, A., Joshi, V., Shivpuri, R. (2004). Computer modeling and prediction of thermal fatigue cracking in die-casting tooling, Wear, Vol. 256, No. 1-2, 38-43, doi: 10.1016/S0043-1648(03)00281-3.

- [28] Tsoukalas, V.D. (2008). Optimization of porosity formation in AlSi9Cu3 pressure die castings using genetic algorithm analysis, Materials & Design, Vol. 29, No. 10, 2027-2033, doi: 10.1016/J.MATDES.2008.04.016.

- [29] Kim, D.-H., Kim, H.-G., Kim, H.-S. (2015). Design optimization and manufacture of hybrid glass/carbon fiber reinforced composite bumper beam for automobile vehicle, Composite Structures, Vol. 131, 742-752, doi: 10.1016/J.COPSTRUCT.2015.06.028.

- [30] Singh, R., Sahay, A., Karry, K.M., Muzzio, F., Ierapetritou, M., Ramachandran, R. (2014). Implementation of an advanced hybrid MPC-PID control system using PAT tools into a direct compaction continuous pharmaceutical tablet manufacturing pilot plant, International Journal of Pharmaceutics, Vol. 473, No. 1-2, 38-54, doi: 10.1016/J.IJPHARM.2014.06.045.

- [31] Liou, F., Slattery, K., Kinsella, M., Newkirk, J., Chou, H., Landers, R. (2007). Applications of a hybrid manufacturing process for fabrication of metallic structures, Rapid Prototyping Journal, Vol. 13, No. 4, 236-244, doi: 10.1108/13552540710776188.

- [32] Rojek, I., Jagodziński, M. (2012). Hybrid artificial intelligence system in constraint based scheduling of integrated manufacturing ERP systems, In: Corchado, E., Snášel, V., Abraham, A., Woźniak, M., Graña, M., Cho, S.B. (eds.), In: Hybrid artificial intelligent systems, HAIS 2012, Lecture notes in computer science, Vol. 7209, Springer, Berlin, Germany, 229-240, doi: 10.1007/978-3-642-28931-6 22.

- [33] Liu, N., Zhang, Y.F., Lu, W.F. (2015). A hybrid approach to energy consumption modelling based on cutting power: A milling case, Journal of Cleaner Production, Vol. 104, 264-272, doi: 10.1016/J.JCLEPRO.2015.05.049.

- [34] Hao, Q., Shen, W. (2008). Implementing a hybrid simulation model for a Kanban-based material handling system, Robotics and Computer-Integrated Manufacturing, Vol. 24, No. 5, 635-646, doi: 10.1016/J.RCIM.2007.09.012.

- [35] Langmaak, S., Wiseall, S., Bru, C., Adkins, R., Scanlan, J., Sóbester, A. (2013). An activity-based-parametric hybrid cost model to estimate the unit cost of a novel gas turbine component, International Journal of Production Economics, Vol. 142, No. 1, 74-88, doi: 10.1016/J.IJPE.2012.09.020.

- [36] Zhu, Z., Dhokia, V.G., Nassehi, A., Newman, S.T. (2013). A review of hybrid manufacturing processes - state of the art and future perspectives, International Journal of Computer Integrated Manufacturing, Vol. 26, No. 7, 596-615, doi: 10.1080/0951192X.2012.749530.

- [37] Shehab, E.M., Abdalla, H.S. (2001). Manufacturing cost modelling for concurrent product development, Robotics and Computer-Integrated Manufacturing, Vol. 17, No. 4, 341-353, doi: 10.1016/S0736-5845(01)00009-6.

- [38] Shooter, S.B., Simpson, T.W., Kumara, S.R.T., Stone, R.B., Terpenny, J.P. (2005). Toward a multi-agent information management infrastructure for product family planning and mass customisation, International Journal of Mass Customisation, Vol. 1, No. 1, 134-155, doi: 10.1504/IJMASSC.2005.007354.

- [39] Montgomery, D.C., Jennings, C.L., Kulahci, M. (2008). Introduction to time series analysis and forecasting, 2nd edition, Jonh Wiley & Sons, Hoboken, New Jersey, USA, doi: 10.1111/jtsa.12203.

- [40] Rosato, D.V., Rosato, D.V., Rosato, M.G. (2012). Injection molding handbook, 3rd edition, Kluwer Academic Publishers, Norwell, Massachusetts, USA, doi: 10.1007/978-1-4615-4597-2.

Expert Q&A: Your Top Questions Answered

Q1: Why was a hybrid model using analytical, parametric, and analog methods chosen over a single approach?

A1: The paper explains that the advantage of a hybrid model lies in its flexibility and ability to adapt to a significant number of features. This allows the system to select the specific modeling technique that best suits the characteristics of the data being predicted. For example, a time-series model (analytical) was best for LME price data, while parametric equations were better for modeling manufacturing times based on part weight.

Q2: How did the model account for the volatility of raw material prices, which is a major pain point in quoting?

A2: The model directly tackled this by creating a dedicated sub-model (as part of CTEP1) for the cost of aluminum. It used five years of historical data from the London Metal Exchange (LME) and applied rigorous time-series analysis. The Dickey-Fuller test (Fig. 2b) confirmed the price data was non-stationary, which justified the selection of a more sophisticated ARMA (2,2) model (Eq. 10) to accurately forecast price behavior.

Q3: What makes the "Cost and Time Entity" (CTE) concept effective for practical use in a die casting facility?

A3: The CTE concept is effective because it deconstructs a highly complex project into logical, manageable, and homogeneous components (the Cost Entity and Time Entity). This allows for a granular analysis of each critical activity, from raw material procurement to specific finishing operations. This provides clear information on the value added at each stage and enables a precise, repeatable method for estimating cost per kilogram and manufacturing time.

Q4: The model claims >85% accuracy. How was this high level of reliability validated?

A4: The model's accuracy was validated using a chi-squared (χ²) statistical test, as shown in Equation 14. This test rigorously compared the model's expected or predicted values against the real, observed values from actual projects. The results of this validation are summarized in Table 3, which explicitly lists the degree of reliability for each sub-model, such as 95% for raw material cost and 85% for the cost of the piece.

Q5: What was the scope of the real-world data used to build the manufacturing time models?

A5: The manufacturing models were built on a robust and comprehensive dataset. Data was collected from 25 distinct projects, which collectively represented 87% of the sample company's annual production. For each activity within these projects, detailed time and movement studies were conducted, observing 50 cycles per activity. This methodology resulted in a dataset of more than 7,000 data points, providing a strong statistical foundation for the forecast equations.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of accurate and timely quoting in the die casting sector has long been a barrier to efficiency and customer satisfaction. This research introduces a powerful solution: a hybrid model for Die Casting Project Forecasting that deconstructs project complexity into manageable entities. The key breakthrough is its validated ability to predict project costs and timelines with over 85% accuracy, providing a reliable, data-driven alternative to traditional estimation methods. For R&D and operations teams, this translates into faster, more transparent quoting, better resource planning, and a significant competitive edge.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

- This content is a summary and analysis based on the paper "Hybrid forecasting modelling of cost and time entities for planning and optimizing projects in the die-cast aluminium industry" by "Muñoz-Ibañez, C., et al.".

- Source: https://doi.org/10.14743/apem2023.2.464

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.