Optimizing HPDC: A Deep Dive into Pressure Die Casting Tool Design for a Clutch Hub

This technical summary is based on the academic paper "Design and Manufacture a Pressure Die Casting Tool for the manufacturing of the Clutch hub" by Mr. Akshay K. Khandagale, published in the Journal Publication of International Research for Engineering and Management (JOIREM) (2022). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: Pressure Die Casting Tool Design

- Secondary Keywords: Clutch Hub Manufacturing, Die Casting Process, Mould Design, Casting Calculations, Die Casting Defects

Executive Summary

- The Challenge: To create a robust and efficient pressure die casting tool for the mass production of a complex automotive component, the clutch hub.

- The Method: The study outlines a comprehensive methodology involving detailed design calculations for machine tonnage, gate and runner systems, and overflow, coupled with CAD/UNIGRAPHICS for tool modeling.

- The Key Breakthrough: The paper provides a precise, step-by-step calculation framework that successfully determines critical machine and tool parameters, such as the required 255-ton locking force and a 58.25 mm² gate area, for manufacturing the specific clutch hub.

- The Bottom Line: A systematic, calculation-driven approach to tool design is essential for achieving accuracy, managing costs, and ensuring the successful production of complex die-cast components.

The Challenge: Why This Research Matters for HPDC Professionals

In the high-volume world of metalworking, die casting stands out for its ability to produce complex, mass-produced components for industries ranging from automotive to consumer goods. However, the process is not without its challenges. The quality and efficiency of die casting are fundamentally tied to the design of the tool, or die. Forcing molten metal into a mould at high velocity requires meticulous planning to control flow, manage solidification, and prevent defects.

This research addresses the core challenge of translating a component design—in this case, an automotive clutch hub—into a functional and efficient manufacturing tool. It tackles the critical questions that every die casting engineer faces: What machine tonnage is required? How should the gate and runner system be sized? How can we ensure the cavity fills completely and solidifies correctly? By providing a detailed case study, the paper offers a practical roadmap for moving from component specifications to a fully realized pressure die casting tool.

The Approach: Unpacking the Methodology

The study presents a systematic approach to designing and manufacturing a pressure die casting tool for a clutch hub. The methodology is rooted in a series of critical engineering calculations and a structured manufacturing workflow.

The process begins with the component's specifications, including its weight (387.27 gm), projected area (176.62 cm²), and volume (143.33 cm³). Using these inputs, the author performs a series of calculations to define the key parameters of the die casting process:

- Machine Tonnage: Calculated to determine the minimum locking force required to hold the die closed against the pressure of the injected molten metal.

- Gate and Runner System: The gate area, thickness, width, and length are calculated to control the velocity and flow of molten metal into the die cavity. Runner dimensions are determined based on established ratios to the gate area.

- Overflows: The size and number of overflows are calculated to ensure complete cavity filling, help vent air, and capture the initial, colder metal front.

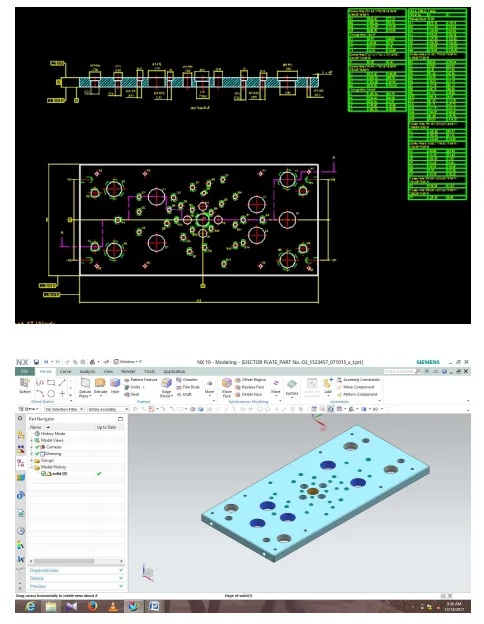

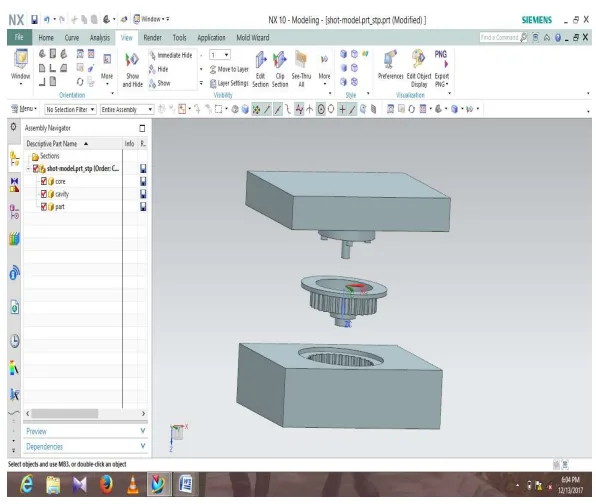

This calculation-driven design phase is followed by a structured manufacturing process flow, which includes raw material preparation, pre-machining, precision machining, heat treatment, and assembly. The tool components, including the core and cavity, were modeled using AUTO-CAD and UNIGRAPHICS.

The Breakthrough: Key Findings & Data

The paper's primary contribution is its detailed, transparent calculation of the essential parameters for the clutch hub tool. These calculations serve as a practical blueprint for engineers.

Finding 1: Precise Determination of Machine Tonnage and Locking Force

The study demonstrates how to calculate the required machine tonnage based on the component's projected area, the casting pressure, and a factor of safety. The total projected area (As), including the component, runner, and overflow, was calculated to be 264.92 cm².

- Using a casting pressure (Pc) of 800 kg/cm² and a factor of safety (fos) of 1.2, the machine tonnage (Tm) was calculated:

Tm = (As x Pc x fos) / 1000 = (264.62 x 800 x 1.2) / 1000 = 254.32 Ton - This result establishes that a machine with a minimum tonnage of 255 Tons (Approx.) is required for this specific component. The corresponding die locking force was calculated to be 255 Tons (Approx.).

Finding 2: Engineering the Gating and Overflow System

The paper meticulously calculates the dimensions of the gating system to achieve a target fill time and metal velocity. Based on a gate velocity of 40 m/sec and a fill time of 0.08 seconds, the critical dimensions were determined.

- Gate Area (Ag): Calculated to be 0.58 cm² (or 58.25 mm²).

- Gate Dimensions: With a gate thickness of 2 mm, the gate width was determined to be 29.125 mm, and the gate length was 44 mm.

- Overflow Volume: The total overflow area was specified as 5200 mm², distributed among five overflows, to ensure proper cavity filling and venting.

These specific, data-driven results provide a clear example of how theoretical principles are applied to create a functional die design for a real-world part.

Practical Implications for R&D and Operations

Based on the paper's conclusions and the author's training summary, the study offers several practical insights for HPDC professionals.

- For Process Engineers: This study suggests that a systematic calculation of machine tonnage, shot weight, and gating parameters is fundamental to process stability. Adhering to calculated ratios for runner-to-gate area (e.g., 3:1 used in the study) can help ensure consistent metal flow and part quality.

- For Quality Control Teams: The emphasis on calculating overflows (30% of component area) highlights their role in trapping cold metal and porosity. This reinforces the importance of inspecting overflows as an indicator of process health and complete cavity fill.

- For Design Engineers: The findings underscore the value of using integrated CAD/CAM software like UNIGRAPHICS for modeling the core, cavity, and other tool components (as shown in Figure 3). This approach allows for precise design and visualization before committing to expensive machining, ensuring better fit and function of the final die.

Paper Details

Design and Manufacture a Pressure Die Casting Tool for the manufacturing of the Clutch hub

1. Overview:

- Title: Design and Manufacture a Pressure Die Casting Tool for the manufacturing of the Clutch hub

- Author: Mr. Akshay K. Khandagale

- Year of publication: 2022

- Journal/academic society of publication: Journal Publication of International Research for Engineering and Management (JOIREM)

- Keywords: mould, casting

2. Abstract:

DIE CASTINGS are produced by forcing molten metal under pressure into metal mould called dies. Mould filling in permanent mould casting depends on the force of gravity, die casting involves metal flow at high velocities induced by the application of pressure. Because of this high velocity filling, die casting can produce shapes that are more complex than shapes that can be produced by permanent mould casting. In die casting, die has been closed and locked; molten metal is delivering through plunger or pump. The pump plunger is advanced to drive molten metal to quickly through the feeding system while the air in the die escapes through vents. Sufficient metal is introduced to over flow the die cavities, fill overflow wells and develop some flash. As the extraneous metal solidifies, pressure is applied to the remaining metal and is maintained through a specified dwell time to allow the casting to solidify. The die opens and the casting is then ejected. While the casting die is open, it is cleaned and lubricated as required. Then the die is closed and locked, and the cycle is repeated.

3. Introduction:

Die castings are among the highest volume, mass-produced items manufactured by the metalworking industry. They can be found in thousands of consumer, commercial and industrial products. Die cast parts are important components of products ranging from automotive to toys. Parts can be as simple as a handle or a complex engine block. A versatile process for producing engineered metal parts, die casting calls for forcing molten metal under high pressure into reusable steel molds. These molds, called dies, can be designed to produce complex shapes with a high degree of accuracy and repeatability. Parts can be sharply defined, with smooth or textured surfaces, and are suitable for a wide variety of attractive and serviceable finishes.

4. Summary of the study:

Background of the research topic:

The study is set against the backdrop of high-pressure die casting, a major manufacturing process for producing high-volume, complex metal parts. The process is characterized by injecting molten metal at high velocity into a steel die, enabling the creation of intricate shapes with high accuracy. The paper highlights the advantages of die casting, including improved microstructure, better accuracy than other forming methods, and cost-effective formation of complex shapes.

Status of previous research:

The paper does not contain a formal literature review section. However, it cites 14 previous studies, indicating that the work is built upon existing research in areas such as casting defects, flow modeling, die shape effects, and the influence of injection parameters on final product quality.

Purpose of the study:

The primary purpose is to present a detailed, practical case study on the design and manufacture of a specific pressure die casting tool for an automotive clutch hub. The study aims to provide a clear methodology, from initial calculations to final tool assembly, to guide the production of a successful die.

Core study:

The core of the study involves a step-by-step procedure for designing the die casting tool. This includes a detailed set of 21 design calculations covering component weight and area, machine tonnage, die opening force, locking force, shot weight, gating system dimensions (area, thickness, width, length), runner calculations, and overflow calculations. The study also presents a manufacturing process flowchart and illustrates the use of CAD software (UNIGRAPHICS) for modeling the core and cavity of the tool.

5. Research Methodology

Research Design:

The research follows a case study and engineering design methodology. It focuses on a single product (a clutch hub) and documents the entire process of designing and planning the manufacture of its die casting tool. The design is based on established engineering formulas and industry-standard practices.

Data Collection and Analysis Methods:

The primary data consists of the physical specifications of the clutch hub (weight, density, projected area, volume). The analysis involves applying a series of deterministic formulas to these inputs to calculate the required process and tool parameters. The results are presented as a sequence of calculated values for tonnage, forces, weights, and dimensions. The study also uses CAD modeling to visualize and design the tool components.

Research Topics and Scope:

The scope is focused specifically on the design calculations and manufacturing process planning for a pressure die casting tool for a clutch hub. It covers key design aspects such as machine selection (tonnage), gating, runners, and overflows. It also briefly touches upon the software tools (AUTO-CAD, UNIGRAPHICS) and the manufacturing workflow from raw material to tool assembly.

6. Key Results:

Key Results:

- Minimum required machine tonnage was calculated to be 255 Tons.

- Total shot weight, including component, overflow, runner, and biscuit, was calculated to be 677.3 gm.

- The gate area was calculated as 58.25 mm², with a thickness of 2 mm and a width of 29.125 mm.

- The runner area to gate area ratio was set at 3:1.

- The total overflow area was calculated to be 5200 mm².

- The study outlines a complete manufacturing flow chart, from design and part drawing release through machining, heat treatment, and final assembly.

- The use of UNIGRAPHICS software for the extraction and modeling of the core and cavity was demonstrated.

Figure Name List:

- Fig.-1: PROCESS FLOW (From Quotation to Dispatch)

- Fig -2: Drafting of plate

- Fig -3: Core &C Cavity Extraction of Clutch Hub

7. Conclusion:

Aluminum castings are very powerful and versatile techniques for manufacturing semi- or finished products with intricate shapes. Those techniques are continuously improved and developed to satisfy the user needs and to penetrate new markets. Innovations are mainly oriented to the automobile sector which is the most important market for castings. This continual improvement and development will ensure that aluminum castings continue to play a vital role in this field. The author also concludes by listing the skills and knowledge gained during a 6-month training period, which include design department processes, ISO procedures, quoting, and live project work on designing a Die-Casting Die (DCD).

8. References:

- [1] Avalle, M., Belingardi, G., Cavatorta, M.P., Doglione, R., 2002. Casting defects and fatigue strength of a die cast aluminium alloy: a comparison between standard specimens and production components. International Journal of Fatigue 24, 1–9.

- [2] Cleary, P.W., 2010. Extension of SPH to predict feeding, freezing and defect creation in low pressure die casting. Applied Mathematical Modelling 34, 3189–3201.

- [3] Cleary, P., Ha, J., Alguine, V., Nguyen, T., 2002. Flow modelling in casting processes. Applied Mathematical Modelling 26, 171–190.

- [4] Dorum, C., Laukli, H.I., Hopperstad, O.S., Langseth, M., 2009. Structural behavior of Al-Si die-castings: Experiments and numerical Simulations. European Journal of Mechanics A/Solids 28, 1–13.

- [5] González, R., Martínez, D.I, González, J.A., Talamantes, J., Valtierra, S., Colás, R., 2011. Experimental investigation for fatigue strength of a cast aluminium alloy. International Journal of Fatigue 33, 273– 278. Kong, L.X., She, F.H., Gao, W.M., Nahavandi, S., Hodgson, P.D. 2008.

- [6] Integrated optimization system for high pressure die casting processes. Journal of materials processing technology 201, 629–634.

- [7] Seo, P.K., Kim, D.U., Kang, C.G., 2006. Effects of die shape and injection conditions proposed with numerical integration design on liquid segregation and mechanical properties in semi-solid die casting process. Journal of Materials Processing Technology 176, 45–54. Sung, B.S., Kim, I.S., 2008.

- [8] The molding analysis of automobile parts using the die-casting system. Journal of materials processing technology 201, 635–639. Teng, X., Mae, H., Bai, Y., Wierzbicki, T., 2009.

- [9] Pore size and fracture ductility of aluminium low pressure die casting. Engineering Fracture Mechanics 76, 983–996.

- [10] Tian, C., Law, J., Van Der Touw, J., Murray, M., Yao, J. -Y., Graham, D., St. John, D., 2002. Effect of melt cleanliness on the formation of porosity defect in automotive aluminium high pressure die castings. Journal of Materials Processing Technology 122, 82–93. Verran, G.O., Mendes, R.P.K., Rossi, M.A., 2006.

- [11] Influence of injection parameters on defects formation in die casting All2Sil, 3Cu alloy: Experimental results and numeric simulation. Journal of Materials Processing Technology 179, 190–195.

- [12] Verran, G.O., Mendes, R.P.K., Dalla Valentina, L.V.O., 2008. DOE applied to optimization of aluminium alloy die castings. Journal of materials processing technology 200, 120–125. Wang, L., Turnley, P., Savage G., 2011.

- [13] Gas content in high pressure die castings. Journal of Materials Processing Technology 211, 1510–1515.

- [14] Yue, S., Wang, G., Yin, F., Wang, Y., Yang, J., 2003. Application of an integrated CAD/CAE/CAM system for die casting dies. Journal of Materials Processing Technology 139, 465–468

Expert Q&A: Your Top Questions Answered

Q1: What casting pressure value was used for the machine tonnage calculation, and why is this parameter important?

A1: The study used a casting pressure (Pc) of 800-900 kg/cm² in its calculations. Specifically, the value of 800 kg/cm² was used to determine the 255-ton machine tonnage. This pressure is critical because it is the force per unit area exerted by the molten metal on the die. The machine's locking force must be sufficient to counteract this pressure across the part's entire projected area to prevent the die halves from separating and causing flash.

Q2: The paper mentions a runner area to gate area ratio of 3:1. What is the significance of this ratio in die casting tool design?

A2: This ratio is a crucial design parameter for controlling metal flow. The runner is the channel that transports molten metal to the gate. By designing the runner to have a larger cross-sectional area than the gate (in this case, 3 times larger), the system ensures that metal flows with minimal pressure loss until it reaches the gate. The gate then acts as a restriction, increasing the metal's velocity as it enters the cavity, which is essential for achieving a quick fill and fine detail.

Q3: What role do overflows play in the die casting process according to the paper?

A3: The paper's abstract explains that overflows are intentionally designed features in the die. "Sufficient metal is introduced to over flow the die cavities, fill overflow wells and develop some flash." Their purpose is to provide a place for the initial, often colder and oxide-laden, front of the molten metal to flow past the part cavity. This helps prevent defects like cold shuts and ensures the part is formed from hotter, cleaner metal. They also assist in venting trapped air from the cavity.

Q4: What specific software was used for the design and modeling of the die components?

A4: The author states in the "In 6 months training I have studied following things" section that the tool was "Designed & constructed the tool using AUTO-CAD" and involved "Modeling of various component of mould, die-casting-dies & using UNIGRAPHICS." Figure 3 explicitly shows the core and cavity extraction being performed in UNIGRAPHICS (NX 10).

Q5: What are the main steps in the manufacturing process flow for the die itself?

A5: Figure 1 and the flow chart on page 2 outline the key manufacturing stages. The process begins with the design and release of the part drawing. This is followed by raw material procurement and preparation, pre-machining, bench work, precision machining (including conventional and CNC machining), heat treatment, grinding, and finally, assembly of the tool.

Conclusion: Paving the Way for Higher Quality and Productivity

The successful mass production of a complex component like a clutch hub hinges on a meticulous and data-driven Pressure Die Casting Tool Design. This study effectively demonstrates that a systematic approach, grounded in precise engineering calculations for machine tonnage, gating, and overflows, is not just theoretical but essential for practical application. By translating component requirements into concrete tool specifications, engineers can mitigate risks, optimize material flow, and lay the foundation for a stable, high-quality manufacturing process.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Design and Manufacture a Pressure Die Casting Tool for the manufacturing of the Clutch hub" by "Mr. Akshay K. Khandagale".

- Source: www.joirem.com

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.