Paper Title Metal vs. Sand Molds: How Cooling Rate Dictates Al-Si Alloy Microstructure and Performance

This technical summary is based on the academic paper "The Effect of Casting Mold Material on Microstructure of Al-Si Alloys" by Tomas Vlach and Jaromir Cais, published in MANUFACTURING TECHNOLOGY (2022). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: Al-Si Alloy Microstructure

- Secondary Keywords: Dendrite Arm Spacing (DAS), Casting Mold Material, Solidification Cooling Rate, Aluminum Alloy Segregation, Microhardness of Al-Si Alloys, AlSi7Mg0.3, AlSi7Cu4, Intermetallic Phases

Executive Summary

- The Challenge: Segregation in Al-Si alloys during solidification degrades mechanical properties, and its extent is highly dependent on casting conditions.

- The Method: Three distinct Al-Si alloys were cast into metal and sand molds to create different solidification conditions and compare the resulting microstructures and mechanical properties.

- The Key Breakthrough: Castings from metal molds exhibited significantly smaller Dendrite Arm Spacing (DAS) and higher microhardness in the α(Al) solid solution, directly linking faster cooling rates to superior material properties.

- The Bottom Line: The choice of mold material, by controlling the solidification cooling rate, is a critical factor in refining the microstructure and enhancing the mechanical properties of Al-Si alloy castings.

The Challenge: Why This Research Matters for HPDC Professionals

Aluminum-Silicon (Al-Si) alloys are foundational materials in the casting industry, prized for their excellent castability and performance. However, a persistent challenge is segregation—the non-uniform distribution of alloying elements that occurs during the gradual transformation from liquid to solid. This phenomenon directly compromises the mechanical, chemical, and physical properties of the final component.

The degree of segregation is heavily influenced by the cooling rate during solidification. Slower cooling allows more time for alloying elements to diffuse and concentrate, leading to a coarser microstructure and weaker properties. For engineers in high-performance sectors like automotive and aerospace, controlling this process is paramount to ensuring component reliability and performance. This research was undertaken to precisely quantify the effects of different cooling rates, as dictated by mold material, on the final structure and properties of select Al-Si alloys.

The Approach: Unpacking the Methodology

To investigate the influence of cooling rate, the researchers employed a comparative methodology using three different Al-Si alloys:

1. AlSi7Mg0.3 (EN AC-42100): A common casting alloy known for its hardening capabilities.

2. AlSi7Cu4 (EN AC-46300): An alloy used where high strength and stiffness are required.

3. AlSi10.5Cu1.2Mn0.8Ni1.2Pb0.5: A complex, non-standard alloy developed for high-performance applications.

Each alloy was melted and refined before being gravity cast into two distinct mold types to create different thermal environments:

* Metal Molds: To simulate a high cooling rate.

* Sand Molds: To simulate a slow cooling rate.

The molds were preheated to 200 °C, and the casting temperature was maintained at 730 °C ± 5°C. Samples were systematically extracted from the bottom, middle, and upper sections of each casting for comprehensive analysis.

The evaluation involved several key techniques:

* Confocal Microscopy: To examine the microstructure and measure the Dendrite Arm Spacing (DAS), a key indicator of segregation and cooling rate.

* Scanning Electron Microscopy (SEM) with EDX: To identify intermetallic phases and analyze elemental distribution.

* Vickers Microhardness Testing: To measure the hardness of the α(Al) solid solution, providing a direct link between microstructure and mechanical properties.

The Breakthrough: Key Findings & Data

The study produced clear, quantifiable data demonstrating the profound impact of cooling rate on the final cast product.

Finding 1: Mold Material Drastically Alters Microstructure and Dendrite Size

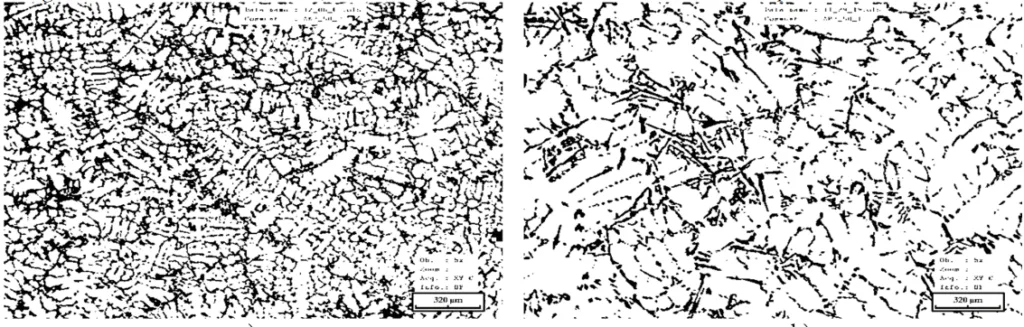

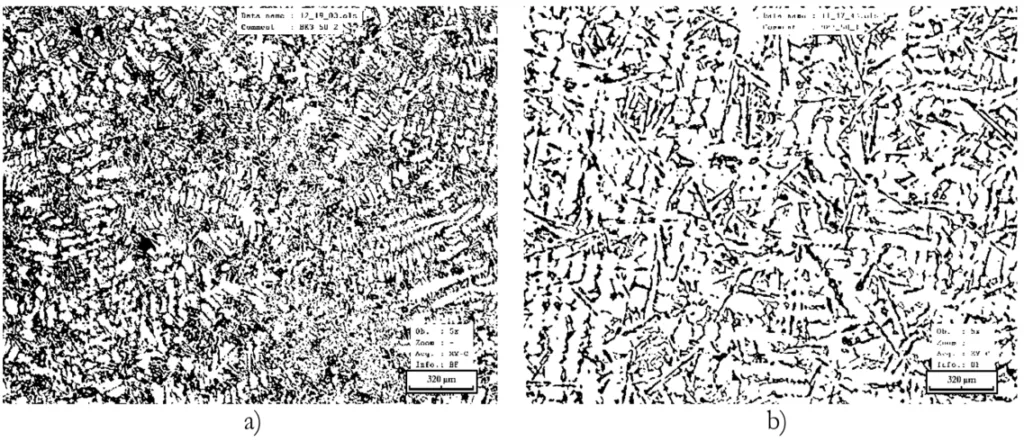

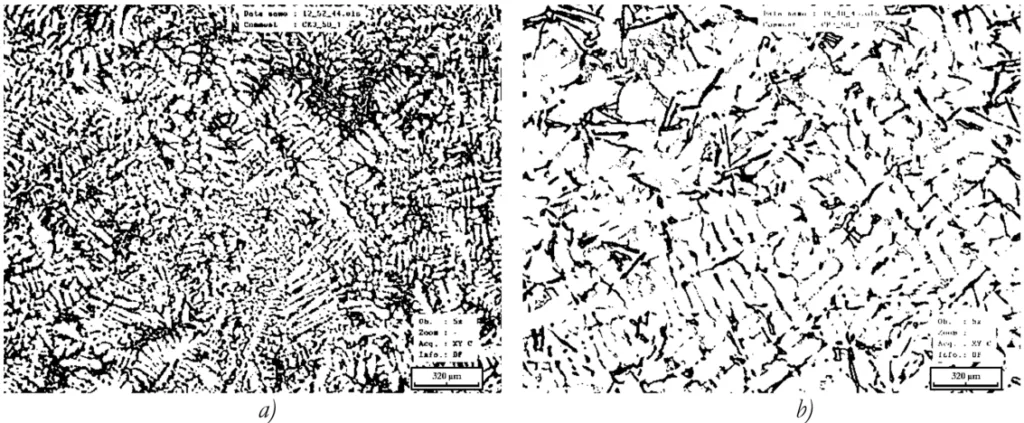

The most significant difference was observed in the size of the dendritic cells. As shown in Graph 1, the Dendrite Arm Spacing (DAS) for samples cast in sand molds was approximately three times larger than for those cast in metal molds across all three alloys. For the AlSi7Mg0.3 alloy, the average DAS increased from ~25-30 µm in the metal mold (samples AK1-AK3) to ~80-90 µm in the sand mold (samples AP1-AP3). This dramatic increase in dendrite size, visually confirmed in Figures 3, 4, and 5, is a direct result of the slower heat dissipation in sand molds, which facilitates segregation.

Finding 2: Faster Cooling Enhances Microhardness of the Solid Solution

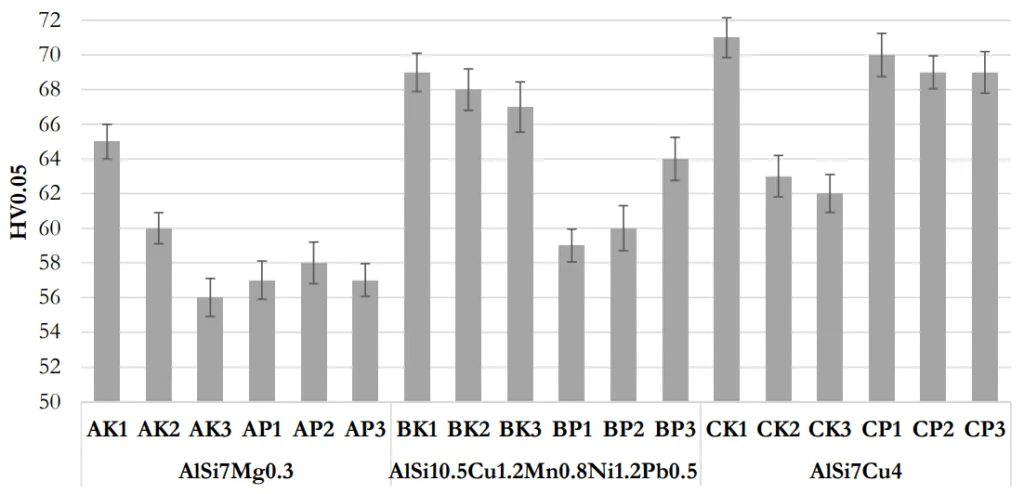

The refined microstructure achieved with metal molds translated directly to improved mechanical properties. Graph 2 shows that castings from metal molds consistently exhibited higher microhardness values for the aluminum solid solution.

* For the AlSi7Mg0.3 alloy, the increase was approximately 5%.

* For the AlSi7Cu4 alloy, the increase averaged 6%.

* For the complex AlSi10.5Cu1.2Mn0.8Ni1.2Pb0.5 alloy, the microhardness difference was most pronounced, increasing by up to 12%.

This data confirms that a finer, more homogenous microstructure resulting from rapid solidification leads to a harder, and therefore stronger, material.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting the cooling rate is a primary lever for controlling microstructure and reducing segregation. The paper states, "A metal mold has a higher cooling gradient than a sand mold. This significantly affected the process of segregation," reinforcing the importance of thermal management in any casting process to achieve desired material properties.

- For Quality Control Teams: The data in Graph 1 (DAS) and Graph 2 (Microhardness) of the paper illustrates a direct correlation between finer microstructure and higher hardness. This relationship could inform new quality inspection criteria, where DAS measurement is used as a rapid, predictive indicator of final mechanical performance.

- For Design Engineers: The findings indicate that the selection of casting process parameters, which directly influence solidification, has a critical impact on final component properties. The conclusion that the newly developed AlSi10.5Cu1.2Mn0.8Ni1.2Pb0.5 alloy achieves a grain refinement effect comparable to standard alloys when cast in metal molds provides valuable data for material selection in demanding applications.

Paper Details

The Effect of Casting Mold Material on Microstructure of Al-Si Alloys

1. Overview:

- Title: The Effect of Casting Mold Material on Microstructure of Al-Si Alloys

- Author: Tomas Vlach, Jaromir Cais

- Year of publication: 2022

- Journal/academic society of publication: MANUFACTURING TECHNOLOGY, Vol. 22, No. 5

- Keywords: segregation, heterogeinity, aluminium alloys, microstructure, DAS, microhardness

2. Abstract:

This article deals with the influence of the mold material on the segregation process in selected Al-Si alloys. Three types of Al-Si alloys were chosen in order to compare the segregation process while congealing. AlSi7Mg0.3, AlSi7Cu4 and AlSi10.5Cu1.2Mn0.8Ni1.2Pb0.5 alloys were cast by gravity casting in a metal and sand molds. Macroscopic and microscopic analysis of the internal structure of each of the alloys was also studied. The chemical composition within the lower, middle and upper parts of the casts were observe by using scanning electron microscope. All samples were subjected to the Vickers microhardness measurement of a solid solution of a(Al). The microhardness measurement was performed to verify the constancy of the mechanical properties of the solid solution a(Al) under different solidification conditions. The distance between the secondary axes of the dendrites DAS (Dendrite Arm Spacing) was used to evaluate the level of segregation.

3. Introduction:

Aluminum alloys are among the most widely used metal materials, with Al-Si alloys representing the largest portion of casting materials. Gravity casting into sand or metal molds is a common production method, particularly in the automotive industry. However, this process can lead to undesirable phenomena like segregation, where the gradual solidification of the grain causes a non-uniform distribution of alloying elements. This segregation negatively affects the alloy's mechanical, chemical, and physical properties. The degree of segregation is dependent on the cooling rate, which is directly related to the distance between the dendritic axes. Slower cooling (as in a sand mold) results in larger dendritic cells and facilitates segregation, while faster cooling (as in a metal mold) leads to a finer-grained structure. This study investigates these effects.

4. Summary of the study:

Background of the research topic:

Al-Si alloys are susceptible to segregation during solidification, a phenomenon that degrades material properties. The cooling rate during casting is a primary factor influencing the degree of segregation and the resulting microstructure.

Status of previous research:

Prior research has established the link between cooling rate, dendrite size, and chemical heterogeneity in aluminum alloys. It is known that slower cooling promotes segregation and that processes like homogenization annealing can be used to mitigate it.

Purpose of the study:

The purpose was to compare the influence of mold material (metal vs. sand) on the segregation process, microstructure, and microhardness of three distinct Al-Si alloys: AlSi7Mg0.3, AlSi7Cu4, and the complex AlSi10.5Cu1.2Mn0.8Ni1.2Pb0.5.

Core study:

The core of the study involved gravity casting the three alloys into both metal and sand molds to create different cooling conditions. The resulting castings were then analyzed for differences in microstructure (via confocal microscopy and SEM) and mechanical properties (via Vickers microhardness testing). The Dendrite Arm Spacing (DAS) was used as the primary metric to quantify the level of segregation.

5. Research Methodology

Research Design:

A comparative experimental design was used. Three different Al-Si alloys were subjected to two different casting conditions (metal mold vs. sand mold), representing fast and slow cooling rates, respectively. A total of 18 samples were prepared, with samples taken from the top, middle, and bottom of each casting to assess uniformity.

Data Collection and Analysis Methods:

- Microstructure Examination: A Laser Confocal Microscope (Olympus OLS 3100) was used to observe the microstructure and measure the Dendrite Arm Spacing (DAS).

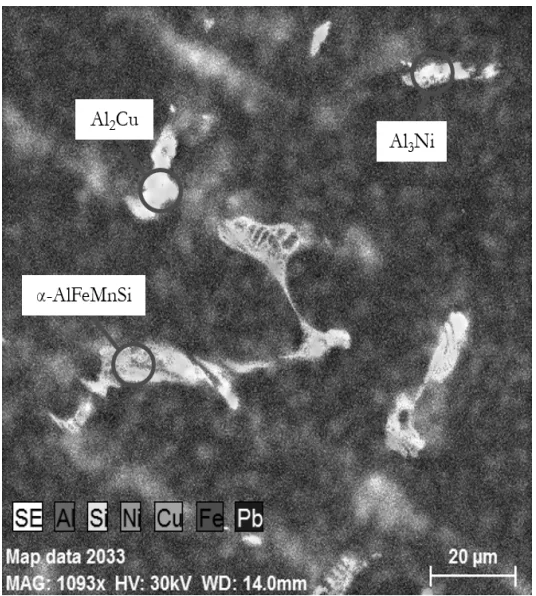

- Phase Identification: A Scanning Electron Microscope (Tescan VEGA 3) with an EDX detector was used to create elemental maps and identify intermetallic phases.

- Mechanical Property Measurement: A SHIMADZU HMV Micro Hardness Tester was used to conduct Vickers microhardness (HV0.05) measurements on the α(Al) solid solution.

Research Topics and Scope:

The research focused on the effect of mold material on the solidification of Al-Si alloys. The scope included the analysis of macrostructure, microstructure (dendritic cell size), the identification of intermetallic phases, and the measurement of microhardness in the resulting castings.

6. Key Results:

Key Results:

- Casts from metal molds have significantly higher microhardness of the α solid solution compared to sand mold casts (5% higher for AlSi7Mg0.3, 12% for AlSi10.5..., and 6% for AlSi7Cu4).

- Casts from sand molds exhibit significantly larger dendritic cells compared to metal mold casts. The dendrite size increased by an average of 68% for AlSi7Mg0.3, 65% for AlSi10.5..., and 67% for AlSi7Cu4.

- Specific intermetallic phases were identified in each alloy:

- AlSi7Mg0.3: Al5FeSi phases.

- AlSi10.5Cu1.2Mn0.8Ni1.2Pb0.5: Al5FeSi, Al3Ni, and Al2Cu phases.

- AlSi7Cu4: Al2Cu and Al5FeSi phases.

- The newly developed AlSi10.5Cu1.2Mn0.8Ni1.2Pb0.5 alloy demonstrated a grain refinement effect comparable to the other two standard alloys when cast in metal molds.

Figure Name List:

- Fig. 1 DAS measurement scheme

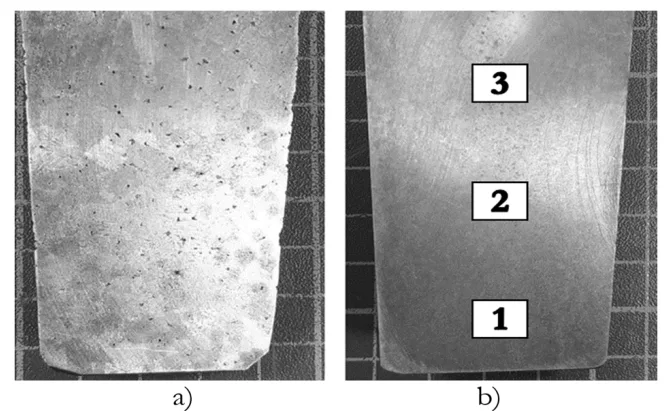

- Fig. 2 Macrostructure of AlSi10.5Cu1.2Mn0.8Ni1.2Pb0.5 alloy a) sand mold b) metal mold

- Fig. 3 Microstructure of the AlSi7Mg0.3 alloy – bottom part of the cast, a) metal mold b) sand mold

- Fig. 4 Microstructure of the AlSi10.5Cu1.2Mn0.8Ni1.2Pb0.5 alloy – bottom part of the cast, a) metal mold b) sand mold

- Fig. 5 Microstructure of the AlSi7Cu4 alloy – bottom part of the cast, a) metal mold b) sand mold

- Fig. 6 Element map of sample AK2

- Fig. 7 Element map of sample BK2

- Fig. 8 Element map of sample CK2

- Graph 1 Dendrite arm spacing of prepared samples

- Graph 2 Microhardness of solid solution a prepared samples

7. Conclusion:

Casting into different mold materials creates different solidification conditions. A metal mold provides a higher cooling gradient than a sand mold, which significantly affects the segregation process, macrostructure, and microstructure. The results confirm that metal mold castings yield higher microhardness values and significantly finer dendritic structures compared to sand mold castings. The study successfully identified the intermetallic phases present in each alloy and confirmed that the newly developed complex alloy exhibits grain refinement comparable to standard alloys under rapid cooling conditions.

8. References:

- [1] ROUČKA J., (2004). Metalurgie neželezných slitin, CERM s.r.o., Brno, ISBN 80-214-2790-6

- [2] DURAI, K.., SUNDAR, S., P., SUNDARLINGAM, HARSHAVARDHANA, N. (2021). Optimization of highspeed machining cutting parameters for end milling of AlSi7Cu4 using Taguchi based tech-nique of order preference similarity to the ideal solution, Materials Today: Proceedings, Vol. 47, No. 19, pp. 6799-6804, ISSN 2214-7853.

- [3] MICHNA, Š., MICHNOVÁ L. (2014). Neželezné kovy, PrintPoint s.r.o., Praha, ISBN 978-80-260-7132-7

- [4] TAYLOR, J.A. (2012). Iron-containing intermetallic phase in Al-Si based casting alloys. In: Procedia Materials Science. Vol 1, pp. 19-33.

- [5] DINNIS, C. M. et al., (2005). As-cast morphologyof iron-intermetallics in Al-Si foundry alloys, Scripta Materialia 53 (8), pp. 955-958.

- [6] TILLOVÁ, E., CHALUPOVÁ, M. (2009). Štruktúrna analýza zliatin Al-Si. EDIS Žilina. 191 s. ISBN 978-80-554-0088-4

- [7] BOLIBRUCHOVÁ, D., BRŮNA, M. (2017). Impact of the Elements Affecting the Negative IronBased Phases Morphology in Aluminium Alloys - Summary. Results In: Manufacturing Technology. ISSN 1213-2489. Vol. 17, No. 5, p. 675-679

- [8] WEISS, V., SVOBODOVÁ, J. (2015). The Use of Colour Metallography and EDS for Identification of Chemical Heterogeneity of Selected Aluminium Alloys Copper and Zinc Alloyed. Manufacturing Technology, vol. 15, iss. 6, p. 1048-1053.

- [9] WEISS, V., (2012). Hodnocení vlivu teploty a doby homogenizačního žíhání slitiny AlCu4MgMn z hlediska mikrostruktury, obrazové analýzy a metody EDX. Strojírenská technologie, vol. 17, iss. 5-6, p. 348-355.

- [10] WEISS, V., STŘIHAVKOVÁ, E. (2011). Optimalizace homogenizačního žíhaní slitiny AlCu4MgMn. Strojírenská technologie, vol. 16, iss. 5, p. 42-49.

- [11] WEISS, V. (2016). Research of the Chemical Heterogeneity during Crystallization for AlCu4MgMn Alloy and the Possibility of its Elimination. Manufacturing Technology, 2016, vol. 16, iss. 1, p. 289-294.

- [12] EN AC-42100 (AISi7Mg0.3) Cast Aluminum. (2022). MakeItFrom.com: Material Properties Database

- [13] AlSi7Mg0.3 – Aluminium Silicium Alloy. (2022). Jura-Guss Beilngries | Aluminium Gießerei, Sandguss, Kokillenguss, Modellbau [online]

- [14] MICHNA, Š. CAIS, J. (2016), Hliníková slitina, zejména pro výrobu odlitků segmentů forem pro lisování pneumatik, a způsob tepelného zpracování odlitků segmentů forem. UJEP, Usti nad Labem, Česká republika. Patentový spis CZ 306352 B6. 2.11.2016, EP306352

- [15] EN AC-46300 (AISi7Cu4) (2022) European Steel andAlloy Grades / Numbers, SteelNumber, steelnumber.com [online].

- [16] LM21.[online]. [Cit. 19.3. 2022]. Dostupné z: http://www.nortal.co.uk/LM21/

Expert Q&A: Your Top Questions Answered

Q1: Why were both metal and sand molds chosen for this study?

A1: The researchers used metal and sand molds to deliberately create two very different cooling environments. As stated in the introduction, "The cooling process is related to heat removal and is significantly affected by the material of the mold." A metal mold dissipates heat much faster, leading to a high cooling gradient, while a sand mold provides insulation, leading to a slow cooling gradient. This comparison allowed for a direct evaluation of how cooling rate impacts segregation, microstructure, and final properties.

Q2: What is the significance of measuring Dendrite Arm Spacing (DAS)?

A2: According to the paper, DAS was used "to evaluate the level of segregation." The distance between the secondary arms of the dendrites is directly related to the cooling rate during solidification. A larger DAS, which occurs during slower cooling, indicates a coarser microstructure and provides more opportunity for alloying elements to segregate, which can negatively impact mechanical properties.

Q3: The AlSi10.5Cu1.2Mn0.8Ni1.2Pb0.5 alloy is complex. What specific intermetallic phases were identified in it?

A3: The analysis identified several intermetallic phases in this alloy. As shown in the elemental map in Figure 7 and described in the text, the detected phases were α-AlFeMnSi, Al3Ni, and Al2Cu. The α-AlFeMnSi phase was noted for its skeletal "Chinese script" morphology.

Q4: How did the microhardness values differ between the top, middle, and bottom of the castings?

A4: The paper notes a distinct difference based on the mold type. For castings from a metal mold, the authors state that "Microhardness decreases with increasing distance from the bottom of the casting," indicating a gradient in properties due to slight variations in cooling. However, for castings from sand molds, "significant differences in microhardness values cannot be observed," suggesting a more uniform, albeit slower, cooling process throughout the casting.

Q5: Did the newly developed AlSi10.5... alloy show a finer grain structure than the standard alloys under the same conditions?

A5: The paper does not state that it was finer, but rather that it was comparable. The conclusion reports that the newly developed alloy "has the same grain refinement effect as AlSi7Mg0.3 alloy and AlSi7Cu4 alloy when using metal molds." This is a significant finding, as it shows this complex, highly-alloyed material can achieve a fine microstructure similar to more common alloys when subjected to rapid cooling.

Q6: What was the purpose of the ECOSAL refining salt treatment before casting?

A6: The paper mentions that "Before casting into molds, the melt was refined using ECOSAL refining salt." While not a focus of the study, this is a standard metallurgical practice. Refining salts are used to clean the molten aluminum by removing dissolved gases (like hydrogen) and solid impurities (like oxides), ensuring a higher quality melt and reducing the potential for defects like porosity in the final casting.

Q7: The paper mentions "Chinese script" morphology. Which phase exhibited this structure?

A7: This distinct morphology was observed in the complex AlSi10.5Cu1.2Mn0.8Ni1.2Pb0.5 alloy. The text accompanying Figure 7 specifies that "the α-AlFeMnSi phase was excluded in the form of a skeletal structure - they are so called „Chinese script“." This needle-like or script-like phase is a common morphology for iron-bearing intermetallics in Al-Si alloys.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a clear and compelling demonstration of a fundamental principle in casting: faster solidification leads to superior material properties. By quantitatively linking the high cooling rate of metal molds to a finer Al-Si Alloy Microstructure, smaller Dendrite Arm Spacing, and significantly higher microhardness, the study reinforces the critical importance of thermal management in producing high-performance components. For industries where strength, durability, and reliability are non-negotiable, controlling the solidification process is the key to unlocking the full potential of advanced aluminum alloys.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "The Effect of Casting Mold Material on Microstructure of Al-Si Alloys" by "Tomas Vlach, Jaromir Cais".

- Source: https://doi.org/10.21062/mft.2022.072

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.