Unlocking Peak Hardness in ADC12 Alloys: A Two-Step Aging Strategy for HPDC

This technical summary is based on the academic paper "AGING METALLURGY AND MECHANICAL PRPERTIES ON Al-Si-Cu-Mg DIE CASTING ALLOY" by T. Ando et al., published in the Proceedings of the 16th International Aluminum Alloys Conference (ICAA16) (2018). It has been analyzed and summarized for technical experts by CASTMAN.

![Figure 3. TEM image and corresponding diffraction patterns of die casting Al–Si–Cu–Mg alloy aged at 558 K for 600 s: (a) STEM image, (b) EDS map of silicon, (c) EDS map of copper, and (d) SAD pattern of [100]Al; small spots correspond to β′ precipitates](https://castman.co.kr/wp-content/uploads/image-2899-1024x265.webp)

Keywords

- Primary Keyword: Al-Si-Cu-Mg Die Casting Alloy

- Secondary Keywords: Artificial Aging, T5 Treatment, Automotive Aluminum, Precipitate Hardening, HPDC, JIS ADC12

Executive Summary

A 30-second overview for busy professionals.

- The Challenge: To reduce the significant CO2 emissions associated with traditional heat treatments for Al-Si-Cu-Mg die casting alloys without compromising their mechanical properties.

- The Method: The study investigated single-step and two-step isothermal aging treatments (T5 treatment) on a JIS ADC12 alloy, analyzing the resulting microstructures and mechanical properties using Vickers hardness tests, TEM, and DSC.

- The Key Breakthrough: A two-step aging process—a short preliminary aging at a higher temperature (458 K) followed by a longer secondary aging at a lower temperature (423 K)—achieved a peak hardness of 130 HV, which is significantly higher than that achieved by any single-step isothermal aging process.

- The Bottom Line: An optimized, low-energy two-step T5 heat treatment can produce superior mechanical properties in ADC12 alloys, offering a pathway to reduce manufacturing energy consumption and CO2 emissions.

The Challenge: Why This Research Matters for HPDC Professionals

Al-Si-Cu-Mg die casting alloys are the backbone of the automotive industry's lightweighting efforts, prized for their excellent balance of mechanical properties, machinability, and castability. To meet demanding performance requirements, these components often undergo heat treatments like T6 (solution treatment + artificial aging) or T5 (artificial aging after casting). However, these processes, along with the holding furnace, account for over 80% of the CO2 discharged during the casting process.

As the industry faces increasing pressure to reduce its carbon footprint, the key challenge is to develop lower-energy heat treatment strategies that not only maintain but enhance the final properties of the cast product. This research directly addresses this issue by exploring how to optimize the T5 treatment, a process whose hardening mechanism in actual die-cast materials has been inconsistent and not fully understood. The goal is to control the alloy's mechanical properties through a more efficient, low-energy heat treatment.

The Approach: Unpacking the Methodology

The researchers conducted a systematic investigation into the aging behavior of a common Al-Si-Cu-Mg die casting alloy (JIS ADC12).

- Material: Samples were cut from an actual cylinder block produced on a 2000-ton-class high pressure die casting machine. The alloy composition was Al-11.0 mass%Si-1.8 mass%Cu-0.2 mass%Mg.

- Heat Treatment: Two aging strategies were employed:

- Isothermal (Single-Step) Aging: Samples were aged at three different temperatures—423 K, 488 K, and 558 K—for various durations to map out the hardness evolution.

- Two-Step Aging: Samples underwent a short preliminary aging treatment for 600 seconds at temperatures ranging from 443 K to 563 K, followed by a secondary, long-duration aging treatment at 423 K.

- Analysis & Characterization: A suite of advanced analytical techniques was used to correlate microstructure with mechanical properties:

- Vickers Hardness Tests: To measure the change in mechanical strength.

- Transmission Electron Microscopy (TEM/STEM): To observe the morphology, composition (via EDS), and crystal structure (via SAD) of the nanoscale precipitates responsible for hardening.

- Differential Scanning Calorimetry (DSC): To analyze the thermal stability of precipitates and the thermodynamics of their formation.

The Breakthrough: Key Findings & Data

The study yielded crucial insights into how different aging strategies control the formation of strengthening precipitates and, consequently, the final hardness of the alloy.

Finding 1: Lower Temperatures Yield Higher Hardness in Single-Step Aging

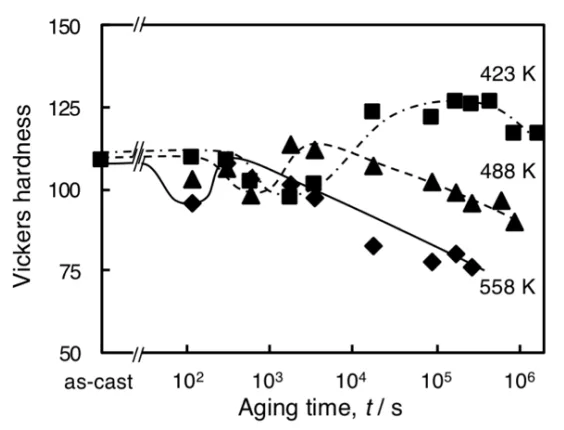

In the single-step aging process, the temperature had a profound effect on the peak hardness achieved. As shown in Figure 1, while higher temperatures (558 K and 488 K) led to faster aging, they resulted in a lower peak hardness that was approximately the same as the as-cast material. In contrast, aging at a lower temperature of 423 K produced a remarkable increase in strength.

- The peak hardness for samples aged at 423 K reached 125 HV, substantially higher than the peak hardness observed at 488 K and 558 K.

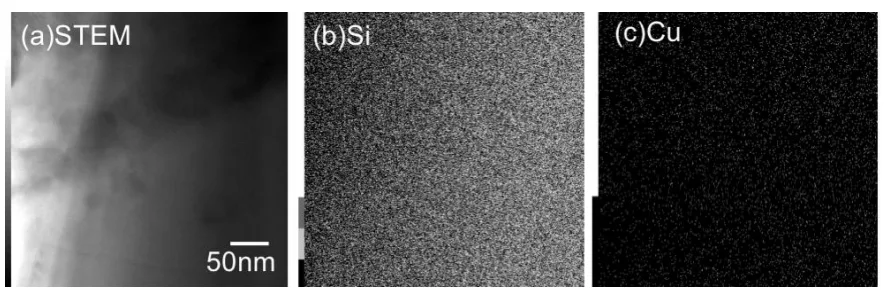

- TEM analysis revealed that the predominant strengthening precipitates were different depending on the temperature. At 558 K, rod-shaped β' phase (silicon compounds) were observed. At 423 K, the hardening was attributed to the formation of fine, disk-shaped copper compounds.

Finding 2: Two-Step Aging Unlocks Superior Hardness of 130 HV

The most significant breakthrough was the discovery that a two-step aging process could outperform any single-step treatment. By combining a short, high-temperature preliminary aging step with a long, low-temperature secondary step, the researchers could strategically form a combination of precipitates that delivered maximum strength.

- As detailed in Figure 5, the highest hardness of 130 HV was achieved using a preliminary aging treatment at 458 K for 600 s, followed by secondary aging at 423 K.

- This two-step process reached a hardness of 125 HV in a much shorter time (approx. 100 ks) than the single-step 423 K process.

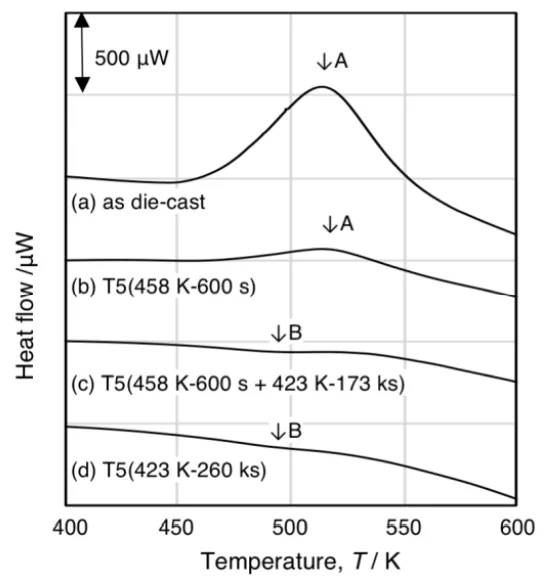

- DSC and TEM analysis suggested this enhanced strengthening is due to the combined effect of β" phase precipitates formed during the preliminary aging and other undefined copper-based compounds that form during the final low-temperature aging step.

Practical Implications for R&D and Operations

- For Process Engineers: This study demonstrates that a two-step T5 aging process (e.g., 458 K for 600s + 423 K) can be a powerful, low-energy alternative to traditional treatments. It offers a pathway to achieve higher mechanical strength while potentially reducing furnace time and energy consumption compared to a single, very long low-temperature cycle.

- For Quality Control Teams: The data in Figure 1 and Figure 5 provide valuable process maps linking aging time and temperature directly to Vickers hardness. These curves can be used to establish more precise quality inspection criteria and predict the final properties of components based on their thermal history.

- For Design Engineers: The finding that a T5-treated ADC12 alloy can reliably achieve a hardness of 130 HV provides critical data for material selection. This allows for greater confidence when designing lightweight components for high-performance applications, knowing that superior mechanical properties are achievable through an optimized, energy-efficient post-casting process.

Paper Details

AGING METALLURGY AND MECHANICAL PRPERTIES ON Al-Si-Cu-Mg DIE CASTING ALLOY

1. Overview:

- Title: AGING METALLURGY AND MECHANICAL PRPERTIES ON Al-Si-Cu-Mg DIE CASTING ALLOY

- Author: T. Ando, S. Onuki, R. Enomoto, M. Tejima, and Y. Okada

- Year of publication: 2018

- Journal/academic society of publication: Proceedings of the 16th International Aluminum Alloys Conference (ICAA16)

- Keywords: Al-Si-Cu-Mg alloy, Artificial aging, Automotive industries, Die casting, Precipitates

2. Abstract:

Al-Si-Cu-Mg die casting alloys are widely used in the automotive industry, and recent advancements in high pressure die casting technology enable heat treating products to achieve desirable properties. However, CO2 emissions associated with die-casting production lines should be reduced to address the global warming issue. In this study, the relation between the microstructures and thermal stability of precipitates formed during isothermal aging at 423, 485, and 558 K of Al-11.0 mass%Si-1.8 mass%Cu-0.2 mass%Mg (JIS ADC12) was investigated using Vickers hardness tests and transmission electron microscopy (TEM). The hardness tests and TEM results showed that Si compounds and Al-Cu compounds enhanced the mechanical properties of the alloy and that the predominant compound affecting the mechanical properties differed between specimens treated at 423 K and those treated at 558 K. Moreover, additional aging at 423–458 K resulted in a material with a Vickers hardness higher than that of the isothermally single-aged material. Differential scanning calorimetry, differential elemental analysis, and selected-area diffraction analysis using TEM suggested that the combination of Al-Cu compounds precipitated at low aging temperatures and Si compounds precipitated during preliminary aging increased the mechanical strength, resulting in a maximum hardness of 130 HV.

3. Introduction:

Al-Si-Cu-Mg die casting alloys possess well-balanced mechanical properties, machinability, and castability, making them widely used in the automotive industry and accounting for over 90% of aluminum in die casting. They are crucial for developing lightweight vehicles. While heat treatments are effective for improving properties, they are a source of CO2 emissions. Both T6 (aging after solution treatment) and T5 (aging after casting) treatments contribute significantly to the CO2 discharged during the casting process. With stricter fuel efficiency regulations, reducing CO2 from production lines is as important as reducing it from vehicle operation. This research aims to control mechanical properties via a low-energy heat treatment by investigating the relationship between microstructures and the thermal stability of precipitates formed during isothermal artificial aging (T5 treatment).

4. Summary of the study:

Background of the research topic:

The automotive industry relies heavily on Al-Si-Cu-Mg die casting alloys for lightweighting, but the associated heat treatments are energy-intensive and produce CO2. There is a need for low-energy heat treatments that still yield desirable mechanical properties.

Status of previous research:

Previous studies on the aging of die-cast aluminum alloys have reported inconsistent results regarding the hardening mechanism during T5 treatment. Some studies reported hardening from S' or S" phases, while others showed that precipitation-hardening did not occur in T5-treated material but did in T6-treated material. The mechanism remains unclear for actual die-cast parts.

Purpose of the study:

To investigate the relationship between microstructures and the thermal stability of precipitates formed during isothermal artificial aging of a JIS ADC12 alloy, with the objective of controlling mechanical properties via a low-energy heat treatment. The study also investigates the effect of two-step artificial aging.

Core study:

The study characterizes the evolution of hardness and precipitate formation in an Al-11.0 mass%Si-1.8 mass%Cu-0.2 mass%Mg alloy during single-step and two-step T5 aging treatments. It correlates mechanical properties with specific precipitate phases (e.g., Si compounds, Al-Cu compounds) identified using TEM, EDS, SAD, and DSC.

5. Research Methodology

Research Design:

The study employed an experimental design to compare the effects of different heat treatment schedules on the mechanical properties and microstructure of a die-cast alloy. It compared single-temperature isothermal aging with a two-step aging process.

Data Collection and Analysis Methods:

Mechanical properties were measured using Vickers hardness tests. Microstructural analysis was performed using transmission electron microscopy (TEM), scanning transmission electron microscopy (STEM), energy-dispersive X-ray spectrometry (EDS), and selected-area diffraction (SAD). Thermal analysis was conducted using differential scanning calorimetry (DSC).

Research Topics and Scope:

The research focuses on the T5 artificial aging behavior of a specific Al-Si-Cu-Mg die casting alloy (JIS ADC12). The scope includes isothermal aging at 423, 488, and 558 K, and two-step aging with preliminary treatments from 443-563 K followed by secondary aging at 423 K.

6. Key Results:

Key Results:

- Single-step aging at a lower temperature (423 K) resulted in a significantly higher peak hardness (125 HV) compared to aging at higher temperatures (488 K and 558 K).

- The primary strengthening precipitates differed with temperature: Si compounds (β' phase) dominated at 558 K, while Al-Cu compounds dominated at 423 K.

- A two-step aging process, specifically preliminary aging at 458 K for 600 s followed by secondary aging at 423 K, achieved the highest hardness of 130 HV.

- DSC analysis suggests that the preliminary aging step accelerates the formation of the β" phase, which, combined with precipitates formed during secondary aging, leads to enhanced strengthening.

Figure Name List:

- Figure 1. Effects of aging temperature on the Vickers hardness curves of die cast Al-Si-Cu-Mg alloy

- Figure 2. TEM images and corresponding diffraction pattern of as-cast Al-Si-Cu-Mg alloy: (a) STEM image, (b) EDS map of silicon, (c) EDS map of copper, and (d) SAD pattern of [100]Al

- Figure 3. TEM image and corresponding diffraction patterns of die casting Al-Si-Cu-Mg alloy aged at 558 K for 600 s: (a) STEM image, (b) EDS map of silicon, (c) EDS map of copper, and (d) SAD pattern of [100]Al; small spots correspond to β' precipitates

- Figure 4. TEM image and corresponding diffraction pattern of die casting Al-Si-Cu-Mg alloy aged at 423 K for 260 ks: (a) STEM image, (b) EDS map of silicon, (c) EDS map of copper, and (d) SAD pattern; small spots correspond to precipitates

- Figure 5. Effects of the preliminary aging temperature on the Vickers hardness curves of die cast Al-Si-Cu-Mg alloy for specimens subjected to secondary aging at 423 K (each temperature in the figure represents the temperature of preliminary aging

- Figure 6. DSC thermograms of die casting Al-Si-Cu-Mg alloy: (a) as die-cast, (b) as aged at 458 K for 600 s, (c) as preliminarily aged at 458 K for 600 s and secondarily aged at 423 K for 173 ks, and (d) as aged at 423 K for 260 ks

- Figure 7. TEM images and the corresponding diffraction pattern of die casting Al-Si-Cu-Mg alloy aged at 458 K for 600 s: (a) STEM image, (b) EDS map of silicon, (c) EDS map of copper, and (d) SAD pattern of [110]Al; small spots correspond to β" precipitates

- Figure 8. TEM images of die casting Al-Si-Cu–Mg alloy preliminarily aged at 458 K of 600 s and secondarily aged at 423 K for 173 ks: (a) STEM image, (b) EDS map of silicon, and (c) EDS map of copper

- Figure 9. TEM image and corresponding diffraction pattern of die casting Al-Si-Cu-Mg alloy preliminarily aged at 458 K for 600 s and secondarily aged at 423 K for 173 ks: (a) TEM image and (b) SAD pattern of [110]Al; small spots correspond to undefined precipitates

![Figure 7. TEM images and the corresponding diffraction pattern of die casting Al–Si–Cu–Mg alloy aged at 458 K for 600 s: (a) STEM image, (b) EDS map of silicon, (c) EDS map of copper, and (d) SAD pattern of [110]Al; small spots correspond to β″ precipitates](https://castman.co.kr/wp-content/uploads/image-2901-1024x253.webp)

7. Conclusion:

The study clarified that the die-cast Al-Si-Cu-Mg alloy exhibits age-hardening when subjected to T5 treatment. The hardness is controlled by a combination of β' phase, β" phase, and Al-Cu compounds. By using a low-energy, two-step heat treatment—specifically, preliminary aging at 458 K followed by secondary aging at 423 K—the alloy can achieve a hardness of 130 HV, which is higher than that attainable through any single-step isothermal aging process. This provides a viable method for producing high-strength components with reduced energy consumption.

8. References:

- Cayron, C., & Buffat, P. A. (2000). Transmission electron microscopy study of the β'-phase (Al-Mg-Si alloys) and QC phase (Al-Cu-Mg-Si alloys): Ordering mechanism and crystallographic structure. Acta Materialia, 48(10), 2639–2653. https://doi.org/10.1016/S1359-6454(00)00057-4

- Dong, S., Iwata, Y., Sugiyama, Y., & Iwahori, H. (2014). Reports of the JFS Meeting, 165, 92.

- Ikeno, S., Matsui, H., Matsuda, K., Terayama, K. & Uetani, Y. (2001). DSC measurement and HRTEM observation of precipitates in an Al-1.6 mass Mg2Si alloy. Japan Institute of Metals, Journal, 65(5), 404-408. https://doi.org/10.2320/jinstmet1952.65.5_404

- Inoue, T., Goto, M., Yamaguchi, A., Otake, T., Kuroda, A., & Yoshida, M. (2011). Effect of pre-aging conditions on T5 heat treatment behavior of Al-9%Si-0.3%Mg die-casting alloy. Keikinzoku/Journal of Japan Institute of Light Metals, 61(10), 507-512. https://doi.org/10.2464/jilm.61.507

- Konno, T. J., Sasaki, S., & Hamaoka, T. (2016). Transmission electron microscopic observation of precipitates in age-hardening die-cast aluminum alloys. Journal of the Japan Institute of Light Metals, 66, 291–297. https://doi.org/10.2464/jilm.66.291

- Mishra, R. K., Smith, G. W., Baxter, W. J., Sachdev, A. K., & Franetovic, V. (2001). The sequence of precipitation in 339 aluminum castings. Journal of Materials Science, 36(2), 461-468. https://doi.org/10.1023/A:1004888831537

- Wang, S.C., Starink, M.J., & Gao, N. (2006). Precipitation hardening in Al-Cu-Mg alloys revisited. Scripta Materialia, 54(2), 287-291. https://doi.org/10.1016/j.scriptamat.2005.09.010

- Yamagata, H. & Kitsunai, T. (2006). Strength improvement of high-quality die-casting part by T5 heat-treatment. 2006 Japan Die Casting Congress Transactions, 237-246.

- Zhu, Z. & Starink, M.J. (2008). Age hardening and softening in cold-rolled Al-Mg-Mn alloys with up to 0.4 wt% Cu. Materials Science and Engineering: A, 489(1-2), 138-149. https://doi.org/10.1016/j.msea.2007.12.019

Expert Q&A: Your Top Questions Answered

Q1: Why was the T5 treatment (aging after casting) investigated instead of the more common T6 treatment (solution treatment + aging)?

A1: The primary motivation of the study was to find ways to reduce CO2 emissions from production lines. T6 treatment involves an additional, high-temperature solution treatment step before aging, which is highly energy-intensive. By focusing on optimizing the T5 treatment, which only involves aging after casting, the research aims to enhance mechanical properties using a lower-energy, and therefore lower-emission, heat treatment pathway.

Q2: Figure 1 shows an initial drop in hardness (age-softening) for all samples before hardening begins. What causes this?

A2: The paper attributes this initial age-softening to the annihilation of dislocations. These dislocations are introduced into the material during the high-pressure die casting manufacturing process. At the beginning of the aging treatment, the thermal energy allows these defects to rearrange and annihilate, causing a slight decrease in hardness before the strengthening effect of precipitate formation becomes dominant.

Q3: The paper states that different precipitates cause hardening at different temperatures. Can you elaborate?

A3: Yes, the TEM and EDS analyses showed a clear difference. For samples aged at a high temperature of 558 K, the strengthening precipitates were identified as rod-shaped β' phase silicon compounds (Figure 3). In contrast, for samples aged at the lower temperature of 423 K, which achieved higher hardness, the precipitates were observed to be fine, disk-shaped, and exhibited a high copper concentration (Figure 4), indicating they are Al-Cu compounds.

Q4: How did the researchers determine that 600 seconds was an appropriate time for the preliminary aging step in the two-step process?

A4: The paper bases the choice of 600 s on the results from the single-step aging curves in Figure 1. For the preliminary aging temperatures of 443 K and 458 K, an aging time of 600 s is near the critical point where the material has just begun to soften but before significant hardening or over-aging occurs. This allows the treatment to nucleate the initial precipitates (like the β" phase) without exhausting the potential for further hardening in the second, low-temperature step.

Q5: What does the DSC thermogram in Figure 6 reveal about why the two-step aging process is so effective?

A5: The DSC thermograms show a key difference between the samples. The as-cast sample (a) and the preliminary aged sample (b) both show an exothermic peak around 520 K, which is associated with the formation of the β" phase. However, the peak is smaller for the sample that underwent preliminary aging, indicating that this process has already initiated or accelerated the formation of the β" phase. This pre-conditioning allows for a more effective combination of precipitates to form during the final aging step, leading to the superior hardness observed.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of reducing the carbon footprint of manufacturing while improving product performance is a critical issue in the HPDC industry. This research provides a significant step forward by demonstrating that the properties of Al-Si-Cu-Mg Die Casting Alloy can be substantially enhanced through an intelligent, low-energy T5 heat treatment. The key breakthrough is the use of a two-step aging process that cultivates a synergistic mix of strengthening precipitates, achieving a peak hardness of 130 HV—a level unattainable with conventional single-step aging. This strategy offers a clear path for manufacturers to produce stronger, more reliable components with lower energy consumption and reduced CO2 emissions.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "AGING METALLURGY AND MECHANICAL PRPERTIES ON Al-Si-Cu-Mg DIE CASTING ALLOY" by "T. Ando, S. Onuki, R. Enomoto, M. Tejima, and Y. Okada".

- Source: Published in the Proceedings of the 16th International Aluminum Alloys Conference (ICAA16) 2018, ISBN: 978-1-926872-41-4.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.