Beyond the Shot Curve: How New Sensors are Revolutionizing Aluminum High Pressure Die Casting Quality Control

This technical summary is based on the academic paper "Correlation between process parameters and quality characteristics in aluminum high pressure die casting" by M. Winkler, L. Kallien, and T. Feyertag, presented at the 2015 NADCA Die Casting Congress & Exposition. It has been analyzed and summarized for technical experts by CASTMAN with the assistance of AI.

![Figure 1: reduction of weight using structural aluminum high

pressure die casting parts instead of joined steel parts [1]](https://castman.co.kr/wp-content/uploads/image-2879-1024x440.webp)

Keywords

- Primary Keyword: Aluminum High Pressure Die Casting

- Secondary Keywords: HPDC process parameters, cognitive system, casting defects, sensor network, quality control, scrap rate reduction

Executive Summary

A 30-second overview for busy professionals.

- The Challenge: High scrap rates in Aluminum High Pressure Die Casting, often reaching 10-25%, are driven by a vast number of interacting process parameters that are not centrally monitored.

- The Method: A special casting geometry was developed and instrumented with an innovative network of sensors to monitor previously unmeasured parameters like cavity pressure, evacuated air humidity, and air mass flow.

- The Key Breakthrough: The research established direct correlations between new sensor data and specific casting defects, proving that real-time process monitoring can predict part quality before it's even inspected.

- The Bottom Line: An intelligent cognitive system, powered by this rich sensor data, can predict and eventually auto-correct process deviations, paving the way for a significant reduction in scrap and post-production quality control costs.

The Challenge: Why This Research Matters for HPDC Professionals

The Aluminum High Pressure Die Casting (HPDC) process is renowned for its productivity and ability to create complex, near-net-shape parts with excellent surface quality. It's a cornerstone of modern manufacturing, particularly in the automotive industry where weight reduction is critical. For example, Audi achieved a 10.9 kg weight reduction by replacing a 10-part joined steel shock tower with a single casted aluminum component.

However, this productivity comes with a significant challenge: complexity. The quality of an HPDC part is influenced by an enormous number of parameters—from piston speeds and intensification pressure to die temperature and spraying parameters. These variables are often monitored by separate, disconnected systems (the machine, the furnace, the thermal regulator), making it impossible to get a holistic view of the process.

This lack of integrated control and the complex interaction of parameters lead to extremely high scrap rates, often between 10% and 25%. This is a major pain point for any HPDC operation, representing a significant loss of material, energy, and productivity. This research, part of the European project MUSIC, was initiated to tackle this problem head-on by developing an intelligent system to reduce scrap rates.

The Approach: Unpacking the Methodology

To build a system that can predict defects, researchers first needed to understand their root causes by intentionally producing them in a controlled environment.

They designed a special "horseshoe" casting geometry (Figure 4) specifically to generate common defects:

- A thin, 1 mm stepped wedge to induce cold shuts.

- Three thick-walled domes to provoke shrinkage porosity.

- Six round cores to entrap air and cause gas porosity.

- A long, unsupported shape to measure distortion.

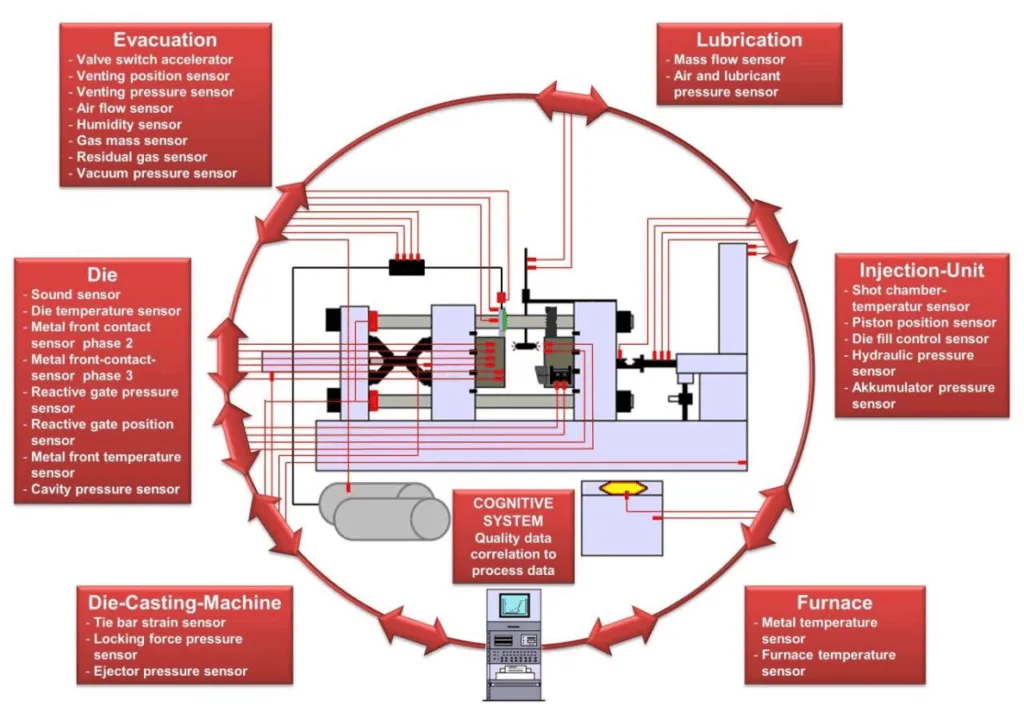

Crucially, the die was instrumented with a network of new and innovative sensors (Figure 3) to capture data far beyond the standard shot curve. This network included:

- Cavity Pressure Sensors: To measure the actual pressure on the molten metal inside the die during filling and intensification.

- Metal Front Temperature Sensors: To track the temperature on the die surface as it's contacted by the alloy.

- Multi-Airpipe-Sensor-System: An integrated unit in the vacuum channel to measure the humidity, residual gas composition, pressure, and mass of the evacuated air.

- Sound and Acceleration Sensors: To monitor vibrations and acoustic signals during the shot.

Data from these sensors, along with standard machine parameters, was collected for each casting and stored in a common database. The quality of each part was then meticulously evaluated and indexed. This created a rich dataset correlating specific process conditions with final part quality, which is essential for training a predictive cognitive system.

The Breakthrough: Key Findings & Data

[Based on the paper's Results section, present the 2-3 most significant findings with concrete data.]

Finding 1: Cavity Pressure Sensors Directly Predict Part Density and Porosity

Conventional process control relies on the machine's hydraulic pressure, but this doesn't guarantee that pressure is effectively transmitted to the solidifying casting. The study placed three cavity pressure sensors (P1, P2, P3) in different areas of the die.

As shown in Figure 8, a shot with high intensification pressure (orange curves) resulted in a significantly higher and more sustained pressure reading at sensor P3 (close to the gate) compared to a shot with no intensification (light green curve). This effective pressure transmission directly impacted part quality. The inset density chart in Figure 8 shows that the part made with intensification had a higher overall density. Specifically, the density in "area p3" was higher for the intensified part, demonstrating a direct link between measured cavity pressure and reduced shrinkage porosity. This proves that cavity pressure is a far more accurate indicator of feeding efficiency than machine pressure alone.

Finding 2: Air Mass and Humidity Sensors Reveal Hidden Process Flaws

The condition of the die cavity before the shot is critical. The study used a "Multi-airpipe-sensor-system" to analyze the air evacuated by the vacuum system, revealing two key insights.

1. Detecting Vacuum Leaks: Figure 10 shows a normal shot where the air mass signal (grey) rises as air is evacuated and drops to zero when the chill vent is blocked by metal. In contrast, Figure 11 shows a shot with a leak in the vacuum channel. The air mass signal does not return to zero, indicating a continuous flow of 3 g/s. This leak resulted in a lower final vacuum and, as the inset chart shows, a lower overall part density due to entrapped air. The air mass sensor provides a direct, real-time method for detecting costly vacuum system failures.

2. Optimizing Die Spraying: Excessive moisture from die lubricant can cause gas porosity. The humidity sensor measured the moisture in the evacuated air. As seen in Figure 12, a long spraying cycle (blue curve) resulted in significantly higher measured humidity compared to a short spraying cycle (yellow curve). This data provides a quantitative way to optimize spraying programs, ensuring adequate lubrication while minimizing residual humidity in the die, directly improving part quality.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting the intensification pressure based on real-time cavity pressure feedback may contribute to reducing shrinkage porosity. Furthermore, monitoring humidity and air mass signals can be used to optimize spray cycles and immediately detect vacuum system malfunctions, preventing entire batches of defective parts.

- For Quality Control Teams: The data in Figure 8 illustrates the direct effect of intensification on part density. This suggests that cavity pressure curves could serve as an in-process quality check, flagging potentially porous parts in real-time and reducing the reliance on costly and time-consuming X-ray or CT scanning.

- For Design Engineers: The findings indicate that the placement of cavity pressure sensors can validate the effectiveness of the gating and feeding system in different areas of a casting. The correlation between second-phase velocity (v2) and die surface temperature (T1) on cold shuts (Figure 13) provides quantitative data that can inform design rules for wall thickness and flow paths.

Paper Details

Correlation between process parameters and quality characteristics in aluminum high pressure die casting

1. Overview:

- Title: Correlation between process parameters and quality characteristics in aluminum high pressure die casting

- Author: M. Winkler, L. Kallien, T. Feyertag

- Year of publication: 2015

- Journal/academic society of publication: NADCA (North American Die Casting Association)

- Keywords: Aluminum high pressure die casting, process parameters, quality characteristics, cognitive system, sensor network, scrap rates

2. Abstract:

Aluminum high pressure die casting is a highly productive process, but the complexity and large number of influencing parameters lead to high scrap rates of 10-25%. Parameters are typically monitored by various separate systems. The European research project MUSIC aims to decrease scrap rates by developing an intelligent cognitive system that considers all quality-controlling parameters. A special casting geometry was designed to produce various defects. The die is instrumented with new, innovative sensors to monitor parameters like the sound of the shot. Sensor data, machine parameters, and peripheral device data are stored with the quality index of the castings in a common database. This allows a cognitive network to calculate the quality index for future parts based on measured sensor data.

3. Introduction:

The use of high pressure die cast aluminum parts in innovative car bodies is increasing to reduce weight. For example, Audi achieved a 10.9 kg weight reduction by replacing a 10-part joined steel shock tower with a single casted part. The rising complexity and quality requirements of these components present a challenge. The HPDC process involves an enormous number of parameters influencing part quality, and their interactions lead to high scrap rates. This research aims to address this by developing a cognitive system that takes all quality-controlling parameters into account.

4. Summary of the study:

Background of the research topic:

High scrap rates (10-25%) in aluminum HPDC are a major industrial problem, caused by the complex interplay of numerous process variables that are not centrally monitored.

Status of previous research:

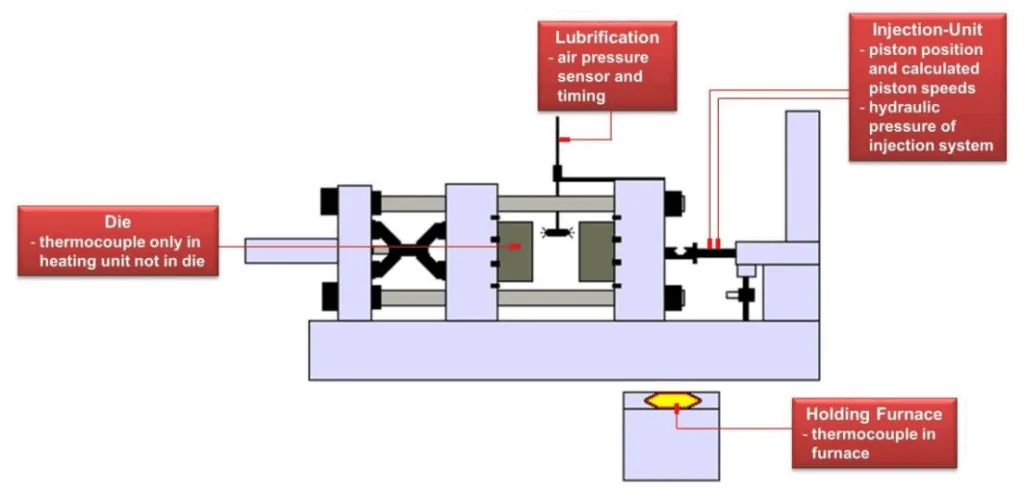

Conventional data acquisition in HPDC is fragmented, with different systems (injection unit, furnace, lubrication) monitoring parameters in isolation. Many critical parameters, like the humidity in the die or the actual quantity of evacuated air, are not measured at all.

Purpose of the study:

The study, as part of the MUSIC project, aims to decrease scrap rates in HPDC by developing an intelligent cognitive system. This involves instrumenting a die casting cell with a comprehensive network of innovative sensors, collecting correlated process and quality data, and using this data to train a system that can predict casting quality in real-time.

Core study:

A special casting geometry was designed to intentionally produce a range of defects. A die casting machine was equipped with numerous sensors to monitor both traditional and novel process parameters (e.g., cavity pressure, air mass, humidity). A Design of Experiments (DoE) was conducted by varying key process parameters. The resulting sensor data and the measured quality of each casting were stored in a database to analyze correlations and train a predictive cognitive model.

5. Research Methodology

Research Design:

The research employed an experimental design focused on creating a dataset for correlation analysis and training a cognitive system. A special casting geometry was created to produce defects intentionally. A Design of Experiments (DoE) was performed, varying key process parameters such as piston speed, switching point, intensification pressure, spraying time, and melt/die temperature.

Data Collection and Analysis Methods:

An innovative sensor network was installed on the die, machine, and vacuum unit. Data from all sensors (e.g., cavity pressure, metal front temperature, air mass, humidity, piston acceleration) and machine controllers were acquired at 1 kHz and stored in a common database. Each casting was assigned a unique ID for traceability. Quality investigations included visual inspection, density measurement (Archimedean principle), distortion measurement, X-ray, and CT scans. The collected data was analyzed using a correlation matrix and statistical software (Design-Expert®) to identify dependencies between process parameters, sensor signals, and quality outcomes.

Research Topics and Scope:

The scope was to establish and quantify the correlation between a wide range of process parameters (both standard and newly measured) and specific quality characteristics (cold shuts, porosity, distortion) in aluminum HPDC. The ultimate goal is to use these correlations to build a predictive cognitive system for real-time quality control.

6. Key Results:

Key Results:

- Cavity Pressure: Demonstrated a direct correlation between effective intensification pressure measured inside the cavity and the final density of thick sections, providing a more accurate measure of feeding efficiency than machine hydraulic pressure.

- Air Mass Sensor: Successfully detected leakages in the vacuum channel in real-time, which were shown to correlate with lower overall part density due to poor evacuation.

- Humidity Sensor: Quantified the amount of residual humidity in the die after spraying, confirming that longer spray cycles leave more moisture, which can be a source of gas porosity. The sensor provides a tool for optimizing spray programs.

- Correlation Analysis: A correlation matrix (Table 1) and 3D interaction plots (Figure 13) successfully identified strong dependencies, such as the link between higher second-phase piston speed (v2) and higher die surface temperature (T1) leading to a reduction in cold shuts.

Figure Name List:

- Figure 1: reduction of weight using structural aluminum high pressure die casting parts instead of joined steel parts [1]

- Figure 2: conventional data acquisition during HPDC process

- Figure 3: Innovative sensor network and cognitive system

- Figure 4: special casting geometry to produce defects

- Figure 5: Comparison of real cast part and simulation results regarding cold shuts [2]

- Figure 6: shot curve with additional sensor signals

- Figure 7: Comparison of the density of dome areas

- Figure 8: Shot curve with cavity pressure sensor signal with intensification pressure (orange color of sensor signals) and without intensification pressure (green color of sensor signals)

- Figure 9: Multi-airpipe-sensor-system assembled on the 750 t cold chamber machine of the foundry laboratory in Aalen [4]

- Figure 10: Shot curve with vacuum and air mass signal showing no leakage in the vacuum channel

- Figure 11: Shot curve with vacuum and air mass signal showing a leakage in the vacuum channel

- Figure 12: Shot curve with vacuum and humidity sensor signal showing measured after a long (blue) and a short (yellow) spraying cycle

- Figure 13: Interrelation between the quality index in area 'A', piston speed in the 2nd phase and temperature sensor signal T1

7. Conclusion:

The research successfully demonstrated that by instrumenting a die with an innovative sensor network, it is possible to capture critical process data that directly correlates with final part quality. Sensors for cavity pressure, air mass, and humidity provide new insights into the process that are not available from conventional machine parameters. The established correlations are the foundation for training a cognitive system capable of predicting casting quality during production. The ultimate aim is to create a closed-loop system that not only predicts but also automatically adjusts process parameters to optimize quality and significantly reduce scrap rates in HPDC.

8. References:

- Wanke, P., Innovative Strukturgusskonzepte bei AUDI, AUDI AG, Gießereikolloquium Hochschule Aalen, (May 9, 2012)

- Kallien, L., Winkler, M., Kognitives System zur Reduzierung der Ausschussrate im Druckguss, Horizonte, (April/May 2015)

- Bonollo, F., Gramegna, N., et al., The MUSIC guide to key-parameters in High Pressure Die Casting, MUSIC Consortium (2014)

- http://www.electronics-gmbh.de/electronics/english/produkt_multisensor.htm

Expert Q&A: Your Top Questions Answered

Q1: Why was a special casting geometry designed to intentionally create defects?

A1: The primary goal was to generate a wide spectrum of quality outcomes—from perfect parts to parts with specific, identifiable defects like cold shuts, shrinkage porosity, and distortion. This diverse dataset is essential for training the cognitive system. The system learns to predict failures by correlating the sensor and process data from a "bad" part with its known defect, and likewise for "good" parts. Without intentionally creating defects, it would be difficult to capture the signatures of these failure modes.

Q2: What is the significance of the "Multi-airpipe-sensor-system" compared to a standard vacuum sensor?

A2: A standard vacuum sensor only measures the pressure level achieved in the vacuum channel. The Multi-airpipe-sensor-system provides a much richer picture of the conditions inside the die before the shot. It measures not only pressure but also the total mass of evacuated air (detecting leaks), the humidity (quantifying residual spray), and the residual gas composition. This allows engineers to diagnose problems related to poor evacuation or excessive moisture, which are common sources of porosity.

Q3: How does the cavity pressure data in Figure 8 provide more insight than the machine's hydraulic pressure?

A3: Figure 8 shows that even with a set intensification pressure on the machine, the actual pressure transmitted to the casting can vary. The orange P3 curve shows a high, sustained pressure peak, indicating effective feeding to a thick section near the gate. The green P3 curve, without intensification, drops off immediately after filling. This direct measurement inside the die confirms whether the intensification phase is actually working to compress the metal and reduce shrinkage porosity, a level of insight the machine's hydraulic pressure curve cannot provide.

Q4: Table 1 shows many correlations. What is a key practical takeaway from the relationship between v2 max, T1, and the quality index 'A'?

A4: The correlation matrix in Table 1 and the 3D plot in Figure 13 highlight a critical interaction for preventing cold shuts (defect 'A'). There is a strong negative correlation between the quality index for defect 'A' and both the second phase piston speed (v2 max) and the metal front temperature (T1). This means that to get a good quality index (i.e., no defect), you need a high piston speed and a high die surface temperature. The plot visually confirms that low speeds and low temperatures result in incomplete filling, providing a clear operational window for process engineers.

Q5: What is the ultimate goal of the "cognitive system" mentioned in the paper? Is it just for prediction?

A5: Prediction is the first step, but not the final goal. The paper states a further aim is to create a closed-loop control system. By connecting all devices (machine, peripherals) via a common protocol (OPC-UA), the cognitive system will not only predict a potential defect based on incoming sensor data but will also be able to send commands back to the machine. It could then automatically adjust parameters like piston speed or die temperature within defined limits to correct the deviation and optimize the process in real-time, preventing the defect from ever occurring.

Conclusion: Paving the Way for Higher Quality and Productivity

The persistent challenge of high scrap rates in Aluminum High Pressure Die Casting stems from process complexity and a lack of integrated, real-time data. This research demonstrates a powerful solution: a comprehensive sensor network that looks beyond standard machine parameters to capture the true conditions inside the die. By correlating this rich data with final part quality, the path is cleared for an intelligent cognitive system that can move HPDC from reactive quality control to predictive, and ultimately, self-optimizing manufacturing.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Correlation between process parameters and quality characteristics in aluminum high pressure die casting" by "M. Winkler, L. Kallien, T. Feyertag".

- Source: NADCA 2015 Die Casting Congress & Exposition. Paper T15-011.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.