The Surprising Truth About Conformal Cooling: A Deep Dive into Channel Performance

This technical summary is based on the academic paper "Analysis of cooling channels performance" published by A. J. Norwood, P. M. Dickens, R. C. Soar, R. Harris, G. Gibbons & R. Hansell in the International Journal of Computer Integrated Manufacturing (2004). It was analyzed and summarized for HPDC experts by CASTMAN experts with the help of LLM AI such as Gemini, ChatGPT, and Grok.

Keywords

- Primary Keyword: Conformal Cooling in Die Casting

- Secondary Keywords: Die Casting Cycle Time, Solidification Simulation, MAGMASOFT, Laminate Tooling, Cooling Channel Design, HPDC Performance, Aluminum Die Casting (LM24)

Executive Summary

- The Challenge: The die casting industry is under constant pressure to increase productivity, with die cooling being a critical factor in determining cycle times. Conformal cooling is proposed as a solution to reduce solidification time.

- The Method: Researchers compared a traditional cooling channel design against a conformal design for an aluminum (LM24) clutch housing. The study used MAGMASOFT® to simulate solidification times and then validated the results with physical casting trials using laminate H13 steel inserts.

- The Key Breakthrough: The simulation and physical trials both showed that the specific conformal cooling design, despite having 1.5 times the cooled surface area, offered no reduction in solidification time compared to the traditional design.

- The Bottom Line: This research proves that simply making a cooling channel "conformal" is not enough. The effectiveness of a cooling system is critically dependent on its specific geometry, placement, and thermal analysis, underscoring the need for careful design and simulation before manufacturing.

The Challenge: Why This Research Matters for HPDC Professionals

In the competitive world of high-pressure die casting (HPDC), every second counts. The cooling of mould tools is a crucial process that directly impacts both production rates and the final quality of the cast component (Xu 2001; Wayde 2000). Traditional cooling channels, typically machined as straight, interconnecting lines, are often suboptimal. They cannot always be placed in strategic areas that require the most cooling, leading to slower cycle times and potential "hot spots" that can cause defects.

Conformal cooling, where channels follow the exact contours of the mould cavity, promises a more uniform and efficient cooling process. This method has the potential to eliminate hot spots, reduce stress in parts, and significantly cut cycle times (Xu 2001). However, the real-world benefits depend entirely on the effectiveness of the channel design. This study was initiated to explore whether a conformal cooling design could demonstrably reduce the cycle time for an aluminum (LM24) pressure die-cast component.

The Approach: Unpacking the Methodology

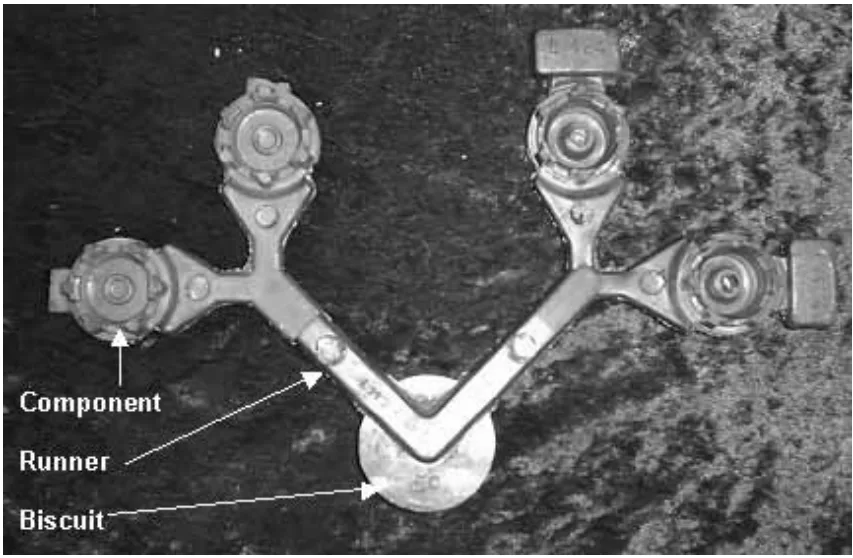

To test the efficiency of conformal cooling, researchers designed a direct comparison between two cooling strategies for the biscuit area of a die, which is typically the last area to solidify.

- Design: Two die insert designs were created using STL CAD files. The first featured a traditional straight cooling channel. The second featured a conformal channel with an 'M' profile that followed the runner and biscuit area, providing 1.5 times the cooled surface area of the traditional design (Figure 3).

- Simulation: Both designs were simulated using MAGMASOFT® software. The simulation ran for 10 cycles to achieve a near-steady state, with thermal data recorded on the 11th cycle to predict the time to solidification for the casting.

- Manufacturing: To create the complex internal channels, the die inserts were manufactured using a laminate tooling process. H13 tool steel sheets were laser-cut, stacked, and bonded via a brazing process in an inert Argon atmosphere to form the final inserts (Figure 11).

- Validation: The manufactured inserts were used in physical casting trials on a Frech 125 DAK cold chamber machine. Over 150 shots of LM24 aluminum were cast to bring the die to a stable operating temperature (200-250°C). The solidification time was then progressively reduced in 0.1-second increments until a "burst biscuit" occurred, indicating the minimum time required for the part to solidify sufficiently for ejection (Figure 7).

The Breakthrough: Key Findings & Data

The results from both the simulation and the physical trials provided a clear, and perhaps unexpected, outcome.

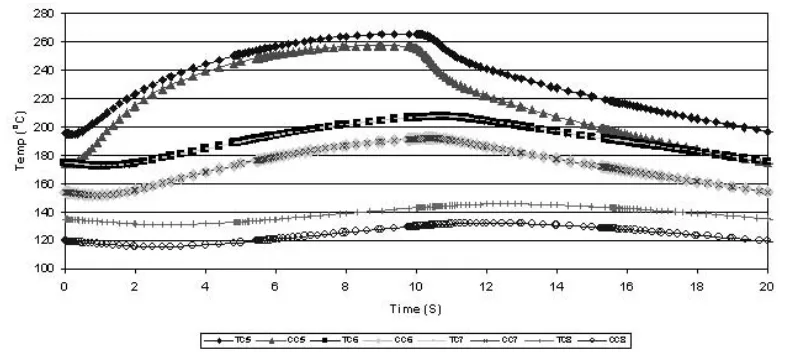

- Finding 1: Cooler Insert, Same Solidification Time: The MAGMASOFT simulation showed that the conformally cooled insert was indeed cooler—approximately 20°C cooler than the traditionally cooled insert at equivalent locations (Figure 15). However, this did not translate into faster solidification for the casting itself.

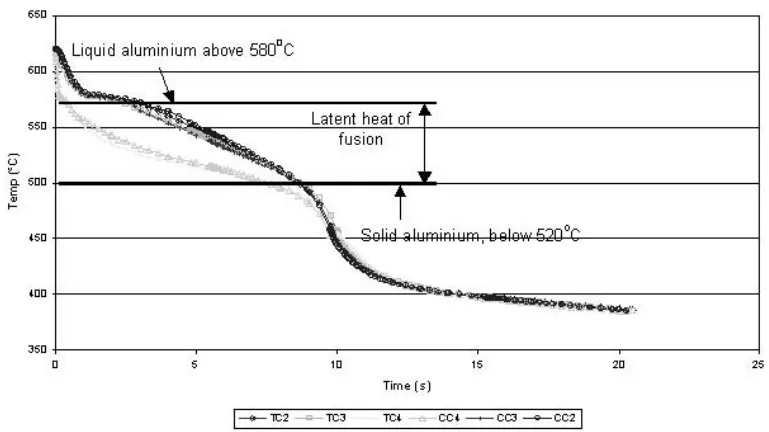

- Finding 2: Simulation Predicts No Improvement: The simulation data for the casting's biscuit area showed no significant difference in solidification time between the traditional and conformal designs. In both scenarios, the center of the biscuit required approximately 8-9 seconds to fully solidify (Figure 14).

- Finding 3: Physical Trials Confirm Simulation: The real-world casting trials validated the simulation's prediction. For both the traditionally cooled and conformally cooled inserts, the minimum successful solidification time was 1.0 second. Failure (a burst biscuit) occurred at 0.7 seconds for both designs. The conformal design offered no practical advantage in reducing the cycle time.

- Finding 4: Design is Paramount: The study concluded that although the conformal channel had a larger surface area and volume, it was "evidently was not enough to remove the heat." This highlights that the specific shape, placement, and flow characteristics of the channels are more critical than simply increasing the channel's length or proximity to the cavity.

Practical Implications for HPDC Products

This research provides critical, actionable insights for anyone involved in die casting design and production.

- For Process Engineers: The findings are a crucial reminder that implementing conformal cooling is not a "plug-and-play" solution for reducing cycle times. This study suggests that without proper thermal analysis (FEA), a significant investment in complex tooling may yield zero return in productivity. The specific design, not just the concept, is what matters.

- For Quality Control: The strong correlation between the MAGMASOFT simulation and the physical casting trials validates the use of such software as a reliable tool for comparative analysis. While the absolute solidification times differed between simulation and reality, the software accurately predicted that the new design would offer no improvement, potentially saving significant manufacturing costs.

- For Die Design: This study is a case-in-point for the importance of front-loading the design process with advanced simulation. As the paper concludes, the shape, surface area, volume, and location of cooling channels are all inadequate in this specific conformal design. A thorough finite element analysis must be conducted before manufacturing to optimize channel geometry and placement to ensure it effectively removes heat from critical areas.

Paper Details

Analysis of cooling channels performance

1. Overview:

- Title: Analysis of cooling channels performance

- Author: A. J. Norwood, P. M. Dickens, R. C. Soar, R. Harris, G. Gibbons & R. Hansell

- Year of publication: 2004 (Published online: 08 Nov 2010)

- Journal/academic society of publication: International Journal of Computer Integrated Manufacturing, 17:8, 669-678

- Keywords: Conformal cooling, die casting, cycle time, solidification, laminate tooling, MAGMASOFT, finite element analysis

2. Abstract:

The die casting industry is under increasing pressure to improve production rates to enable greater productivity. Employing conformal cooling channels could potentially improve a die performance through the reduction of solidification times. The paper reviews simulated solidification results from a traditional cooling channel design and a conformal cooling channel design. The paper continues by describing the construction of bonded laminate insert with integrated cooling channels. Casting trials were conducted using the inserts to validate the simulated results. Work to date has demonstrated the ability to manufacture laminate inserts quickly, the accuracy of finite element analysis and the importance of designing conformal cooling channels.

3. Introduction:

The cooling of mould tools is crucial to the performance of tooling, as it affects both production rates and component quality. Laminate tooling, a layer-by-layer manufacturing process, allows a die to be constructed from die steel with integrated conformal cooling, unlike a solid H13 die where only straight channels can be machined. Conformal cooling is achieved by creating a channel that follows the exact contours of the mould cavity, allowing for uniform cooling and eliminating hot spots. This has been reported to reduce stress in parts and decrease cycle times. Software like MAGMASOFT® now allows designers to model tools and place conformal channels exactly where required, reducing design compromises.

4. Summary of the study:

Background of the research topic:

The research addresses the need for increased productivity in the die casting industry. Cooling is a primary factor limiting production rates, and traditional straight-drilled cooling channels are often inefficient. Conformal cooling offers a potential solution by placing cooling channels in optimal locations to reduce solidification times.

Status of previous research:

Previous work has highlighted the benefits of conformal cooling in injection moulding for reducing cycle times and part stress (Xu 2001). Various rapid tooling methods exist, but laminate tooling offers the potential for higher strength and toughness, allowing for the creation of die steel tools with integrated complex cooling channels.

Purpose of the study:

The main objective was to explore the benefits of conformal cooling on the cycle time of an aluminium (LM24) pressure die-casting process. This was achieved by:

- Conducting a simulation to compare a traditional cooling design against a conformal cooling design.

- Validating the simulation results by conducting physical die casting trials with manufactured inserts.

Core study:

The study focused on the "biscuit" area of a die casting, as it is the last area to solidify and is heavily affected by temperature and pressure. Two die inserts were designed: one with traditional cooling and one with a conformal 'M' profile channel that had 1.5 times the cooled surface area. These designs were first simulated in MAGMASOFT® to predict solidification. Then, the inserts were manufactured from H13 steel laminates and used in real-world casting trials to measure the minimum possible solidification time before part failure.

5. Research Methodology

Research Design:

The research employed a comparative experimental design. A traditionally cooled die insert was used as a control against a conformally cooled insert. The performance metric was the minimum solidification time achievable before a "burst biscuit" occurred during ejection.

Data Collection and Analysis Methods:

- Simulation: MAGMASOFT® software was used to simulate die cycling and water-cooling. Ten theoretical thermocouples were placed in the model to record temperature changes and predict solidification time (Figure 6).

- Physical Trials: A Frech 125 DAK cold chamber die-casting machine was used. The die was heated, and 150 shots were cast to achieve a stable operating temperature. The solidification time was then reduced by 0.1 seconds every 10 shots, and the resulting castings were visually inspected for failure.

Research Topics and Scope:

The research was scoped to a single component—an aluminum (LM24) clutch housing—focusing specifically on the cooling of the runner and biscuit area. The study compared one specific conformal design against a traditional design to determine its effect on cycle time.

6. Key Results:

Key Results:

- The MAGMASOFT simulation showed the conformally cooled insert was approximately 20°C cooler than the traditional insert (Figure 15).

- Despite the cooler insert temperature, the simulation predicted no significant improvement in the solidification time of the casting between the two designs (Figure 14).

- Physical casting trials confirmed the simulation results. Both the traditional and conformal designs achieved a minimum successful solidification time of 1.0 second.

- The study demonstrated that the specific conformal design, despite having a larger surface area, was inadequate to provide a measurable reduction in cycle time.

Figure Name List:

- Figure 1. Cast aluminium (LM24) clutch housing component.

- Figure 2. Cold chamber machine. Diagram illustrates cold chamber pressure die, casting process.

- Figure 3. Designs for traditional cooling (left) and conformal cooling (right).

- Figure 4. Male and female STL CAD of inserts.

- Figure 5. 3D CAD models of the inserts and shot sleeve used for simulation.

- Figure 6. Section through the tool showing the location of thermocouple points.

- Figure 7. Burst biscuit.

- Figure 8. Insert location.

- Figure 9. Typical cycle time of the die.

- Figure 10. Heating and cooling profile of the brazing process.

- Figure 11. Insert after machining.

- Figure 12. Traditionally cooled solidification time.

- Figure 13. Conformal cooling solidification time.

- Figure 14. Traditional cooling (TC) verses conformal cooling (CC) (thermocouples 2–4).

- Figure 15. Traditional cooling (TC) verses conformal cooling (CC) (thermocouples 5–8).

7. Conclusion:

The results showed that the simulation was accurate at predicting no differences between the channel designs, which was verified by the casting trials. This proves that simply increasing the length of a channel does not necessarily improve cooling performance in an aluminum pressure die casting tool. The research has outlined the importance of conformal cooling geometry and placement, as the chosen conformal design did not reduce the solidification time in this case. The discrepancy between the simulated solidification time (8-10 seconds) and the actual achievable time (1 second) suggests the formation of a solid skin on the casting allows for early ejection.

8. References:

- DEGARMO, E. P., 1998, Material and Processes in Manufacturing, 7th edn (New York: Collier Macmillan Publishers).

- DICKENS, P. M., 1999, Rapid prototyping – past, present & future. Journal of the Institute of Engineering Designers, 25(1), 12–15.

- HALFORD, B., 1999, Rapid tooling. Journal of the Institute of Engineering Designers, May, 4–6.

- OBIKAWA, T., 1999, Sheet steel lamination for rapid manufacturing. Journal of Materials Processing Technology, 89–90, 171–176.

- SOAR, R. C., 2000, An examination of the feasibility and design limitations of laminate tooling for pressure die casting, PhD thesis, De-Montfort University.

- WAYDE, R., 2000, Conformal cooling vs. conventional cooling: an injection moulding, case study with 3-dimensional printing. Solid Freeform and Additive Fabrication, Materials Research Society Publications, 625, 51–56.

- XU, X., 2001, The design of conformal cooling channels in injection mould tooling. Polymer and Engineering Science, 41(7), 1265–1279.

Expert Q&A: Your Top Questions Answered

Q1: What was the main goal of this research?

A1: The primary goal was to determine if a conformal cooling channel design could reduce the solidification time, and therefore the overall cycle time, for an aluminum (LM24) pressure die-cast part compared to a traditional cooling design. [Source: Section 2. Aims and objectives]

Q2: Did the conformal cooling channel design actually improve the cycle time?

A2: No. The physical casting trials showed that both the traditional and the conformal cooling designs resulted in the exact same minimum solidification time of 1.0 second. The conformal design provided no improvement in productivity in this specific case. [Source: Section 5.2. Results from casting]

Q3: Why didn't the conformal cooling design work as expected?

A3: The paper concludes that the design of the conformal channel itself was "inadequate." Even though it had 1.5 times the surface area, its shape, volume, and location were not effective enough to remove heat more quickly than the traditional channel. This proves that the specific geometry and placement are more important than just being "conformal." [Source: Section 7. Conclusion, Section 6. Discussion]

Q4: How accurate was the MAGMASOFT simulation compared to the real-world casting trials?

A4: The simulation was very accurate in its comparative prediction. It correctly predicted that there would be little to no difference in solidification time between the two designs. While the absolute solidification time in the simulation (8-10 seconds) was much longer than in reality (1 second), its ability to accurately compare the performance of two designs was validated. [Source: Section 6. Discussion, Section 7. Conclusion]

Q5: What is the key takeaway for a die designer from this study?

A5: The most important takeaway is that you cannot assume a conformal cooling channel will automatically be better. A thorough finite element analysis (FEA) and simulation must be conducted before manufacturing to optimize the channel's geometry and placement. A poorly designed conformal channel is an expensive mistake that offers no performance benefit. [Source: Section 6. Discussion]

Q6: What are "laminate inserts" and why were they used?

A6: Laminate inserts are tool components built layer-by-layer from laser-cut sheets of tool steel (H13 in this case) that are then bonded together. This manufacturing method was used because it allows for the creation of complex internal features, like the conformal cooling channel, which would be impossible to machine in a solid block of steel. [Source: Section 1. Introduction, Section 4.4. Laminate die insert manufacture]

Conclusion & Next Steps

This research provides a valuable, data-driven roadmap for any organization looking to leverage conformal cooling in HPDC. It serves as a critical cautionary tale: the promise of reduced cycle times can only be realized through meticulous design and analysis. The findings offer a clear path toward de-risking the investment in advanced tooling by emphasizing the power of simulation to validate design choices before cutting steel.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers' most challenging die casting problems. If the issues discussed in this paper resonate with your operational goals, contact our engineering team to discuss how we can help you implement these advanced principles in your components.

Copyright

- This material is a paper by "A. J. Norwood, P. M. Dickens, R. C. Soar, R. Harris, G. Gibbons & R. Hansell". Based on "Analysis of cooling channels performance".

- Source of the paper: http://dx.doi.org/10.1080/0951192042000237528

This material is for informational purposes only. Unauthorized commercial use is prohibited. Copyright © 2025 CASTMAN. All rights reserved.