This technical summary is based on the academic paper "Rotary Valve 4-Stroke Engines for General Purpose Power Equipment and Unmanned Systems" published by Brian Mason, Keith Lawes (RCV Engines Limited), and Koichi Hirakawa (KAAZ Corporation) in SETC2022 New Product Technology Session (2022). It was analyzed and summarized for HPDC experts by CASTMAN experts with the help of LLM AI such as Gemini, ChatGPT, and Grok.

![Figure 1. Small powered two-wheeler technology trends in Taiwan 2002 to 2022 [3].](https://castman.co.kr/wp-content/uploads/image-2745.webp)

Keywords

- Primary Keyword: Rotary Valve 4-Stroke Engines

- Secondary Keywords: High-Pressure Die Casting (HPDC), Small Engine Technology, UAV Engines, Multi-fuel Engines, Net-zero Carbon Fuels, Power-to-weight Ratio, ADC12 Die Casting

Executive Summary

- The Challenge: Small engine applications, from professional power tools to long-range UAVs, demand alternatives to battery power that meet tightening emissions regulations, deliver high power-to-weight, and can operate on future net-zero carbon fuels.

- The Method: Researchers developed and tested an advanced Rotary Valve (RCV) 4-stroke engine system. This included the multi-fuel "DF" engine range for UAVs and the high-power, volume-manufactured "CK1" engine, whose cylinder is produced using high-pressure die casting (HPDC) of ADC12 alloy.

- The Key Breakthrough: The RCV engine design delivers exceptional power-to-weight (the 25cc CK1 engine produces 60% more power than typical 4-stroke competitors), true multi-fuel capability (including JP8 and synthetic fuels), and low emissions, all within a scalable and manufacturable framework.

- The Bottom Line: Rotary valve technology is a proven, viable path for the future of the internal combustion engine in professional and unmanned applications where performance, range, and fuel flexibility are non-negotiable.

The Challenge: Why This Research Matters for HPDC Professionals

For decades, the small engine market has been defined by a trade-off between the power of 2-stroke engines and the emissions profile of 4-stroke engines. Today, this landscape is further complicated by the push towards battery-electric (BE) systems and the global goal of net-zero carbon emissions by 2050.

While BE systems are viable for many consumer products, they fall short in demanding professional applications where power, weight, range, and rapid refueling are critical. Unmanned Air Vehicles (UAVs) requiring long flight durations and professional-grade handheld tools used in remote locations cannot be tethered to a charging station.

This creates a critical engineering challenge: to develop a new generation of internal combustion engines (ICE) that are not only powerful and lightweight but also have low tailpipe emissions, high fuel efficiency, and the capability to run on a range of fuels, including the sustainable synthetic fuels of the future. This paper presents a compelling solution that meets these demanding criteria.

The Approach: Unpacking the Methodology

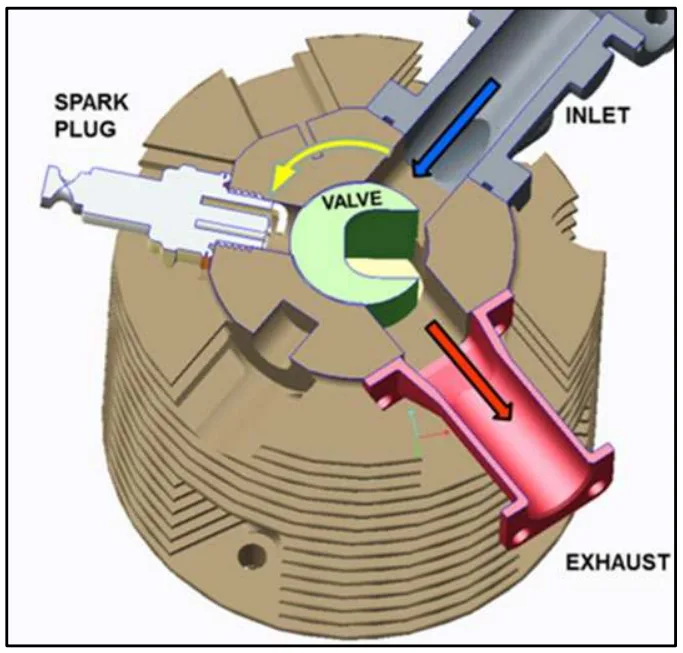

To address this challenge, researchers focused on an innovative "rotary valve" 4-stroke engine design. Unlike a conventional engine with poppet valves, cams, and springs, the RCV concept uses a single rotating valve to control both intake and exhaust flow events (see Figure 4). This core technology was developed into two distinct product lines:

- The DF Engine Range: Tailored for high-performance UAV applications, these engines (35cc to 140cc) are designed for multi-fuel capability, particularly heavy fuels like JP8, and feature electronic fuel injection.

- The CK1 Engine: A 25cc engine developed for general-purpose, high-volume applications like brushcutters. Critically for the manufacturing industry, the CK1 was designed for mass production. Its cylinder is diecast in ADC12 aluminum alloy with a Nickel Silicon Carbide coating on the cylinder and valve bores (Figure 19), demonstrating a practical, cost-effective path to market.

The development process combined physical testing with advanced simulation, including thermal finite element analysis (FEA) to manage heat in the valve system (Figure 6) and computational fluid dynamics (CFD) to optimize the cooling system (Figure 18).

The Breakthrough: Key Findings & Data

The research yielded powerful results, demonstrating the RCV technology's clear advantages in power, fuel flexibility, and manufacturability.

- Finding 1: Unprecedented Power-to-Weight Ratio: The 25cc CK1 engine dramatically outperforms its competitors. It produces over 1.2 kW, which is 60% more power than typical 25cc 4-stroke engines on the market. As shown in Figure 21, it sustains high power across a wide speed range (8000-11500 rpm). This results in a power-to-weight ratio of 0.35 kW/kg, significantly better than other 4-stroke engines (Table 3).

- Finding 2: True Multi-Fuel and Net-Zero Capability: The DF engine range has proven its ability to operate reliably on a wide variety of fuels. It runs not only on gasoline but also on low-octane, kerosene-based "heavy fuels" like JP8 without suffering from detonation or "knock." Crucially, the DF35 engine was used in the UK Royal Air Force's first drone flight powered by net-zero carbon synthetic aviation fuel (Figure 13, Ref. [21]), proving its viability for a sustainable future.

- Finding 3: Designed for High-Volume HPDC Manufacturing: The research proves that this advanced engine architecture is not just a theoretical concept. The CK1 engine's cylinder is explicitly designed to be diecast in ADC12, a workhorse alloy for the HPDC industry. The ability to cast this complex component, which houses both the piston and the rotary valve, and then apply a durable Nickel Silicon Carbide coating (Figure 19), confirms the technology is ready for cost-effective, scalable production.

- Finding 4: Low Emissions without Complex Aftertreatment: The CK1 engine achieves compliance with stringent EU Stage V and US EPA Phase 3 exhaust emissions regulations. Test results show CO emissions of 118.0 g/kW.h and HC+NOx emissions of 20.8 g/kW.h, well below the legislative limits (Table 4), without needing a catalytic converter.

Practical Implications for HPDC Products

This research is more than an academic exercise; it signals a significant new market opportunity for high-quality, precision die castings. The findings have direct implications for manufacturers.

- For Process Engineers: The paper validates a manufacturing pathway for complex, high-performance engine components using ADC12 die casting followed by a specialized surface coating (Figure 19). This successful application opens doors for HPDC in producing parts that require intricate internal geometries, high thermal stability, and wear-resistant surfaces, moving beyond traditional component designs.

- For Quality Control: The RCV engine's reliability hinges on maintaining a precise sliding clearance between the rotary valve and the diecast cylinder bore. This requirement places a premium on the dimensional accuracy, stability, and integrity of the ADC12 casting. It underscores the critical importance of robust process controls and stringent quality assurance in HPDC to meet the demands of such advanced, high-performance applications.

- For Die Design: The successful casting of the integrated CK1 cylinder and valve bore unit (Figure 19) serves as a powerful case study for using HPDC to create highly consolidated, multi-functional components. This approach can reduce part counts, streamline assembly, and lower overall system costs, offering a competitive advantage for forward-thinking product designers and die casters.

Paper Details

Rotary Valve 4-Stroke Engines for General Purpose Power Equipment and Unmanned Systems

1. Overview:

- Title: Rotary Valve 4-Stroke Engines for General Purpose Power Equipment and Unmanned Systems

- Author: Brian Mason and Keith Lawes (RCV Engines Limited), Koichi Hirakawa (KAAZ Corporation)

- Year of publication: 2022

- Journal/academic society of publication: SETC2022 New Product Technology Session

- Keywords: Rotary valve, 4-stroke, UAV, heavy fuel, general purpose engine, emissions, power to weight

2. Abstract:

A rotary valve 4-stroke combustion system has been applied to engines for unmanned air vehicles (UAVs) and general-purpose power equipment. The RCV rotary valve system can operate on a range of fuels and at high levels of power, together with typical 4-stroke exhaust emissions and fuel economy. The DF35 and DF70 engines, for UAVs and unmanned hybrids, are based around a 35 cc cylinder configured as a single or boxer twin, with either air or liquid cooling. The fuel injected DF engines achieve 63 kW/litre on either gasoline or kerosene-based fuels such as JP8. The 25 cc multi-position general purpose CK1 engine is configured into a brushcutter package. CK1 has completed development for volume production, achieves 48 kW/litre. Recent small engine developments are application specific. Combining the multi-fuel capability of the DF engine with volume production technology of the CK1 engine, the RCV rotary valve combustion system provides a viable technology for future small engine applications.

3. Introduction:

Small internal combustion engines (ICE) are used on lightweight two wheeled vehicles, portable lawn and garden equipment, and unmanned air vehicles. These applications have traditionally favoured 2-stroke over 4-stroke engines for cost and power to weight reasons. However, this position has changed over the last 30 years with legislation to reduce toxic tailpipe exhaust emissions for improved air quality. The market today includes a mix of low emissions 2-stroke and 4-stroke engines, with an increasing uptake of battery/electric (BE) systems. With the global effort to reduce carbon emissions to net-zero by 2050, it is necessary to consider attributes that small engine need to have where BE systems are not viable. The introduction of exhaust emissions legislation has led to shifts in engine technology in two-wheeler and small off-road engine (SORE) markets, with a future challenge being the control of particulate emissions.

4. Summary of the study:

Background of the research topic:

The need for high-performance, low-emission, and fuel-flexible small internal combustion engines persists in applications where battery-electric systems are not viable, such as long-range UAVs and professional handheld equipment. This research addresses the challenge of meeting future requirements, including operation on net-zero carbon fuels.

Status of previous research:

Previous developments in small engines have focused on transitioning from 2-stroke to 4-stroke engines to meet emissions regulations, and more recently, the introduction of battery-electric systems. For specific applications like UAVs, efforts have been made to convert small engines to run on heavy fuels (HF), often with a performance penalty. This paper builds on over 20 years of RCV Engines' experience in rotary valve technology.

Purpose of the study:

The study aims to demonstrate that the RCV (Rotary Valve) 4-stroke combustion system is a viable and superior technology for future small engine applications. It showcases the system's benefits through two distinct engine lines: the multi-fuel DF range for unmanned systems and the high-power, volume-production CK1 engine for general-purpose equipment.

Core study:

The core of the study is the design, development, testing, and characterization of the RCV engine technology. This involves detailing the engine architecture, materials (including diecast ADC12), and manufacturing processes. Performance metrics such as power output, fuel consumption (BSFC), emissions, and multi-fuel capability are measured and compared against conventional engines and legislative standards.

5. Research Methodology

Research Design:

The research involved the parallel development of two engine platforms based on the same core RCV technology: the specialist DF range for UAVs and the general-purpose CK1. This dual approach allowed for the demonstration of both high-end multi-fuel capabilities and suitability for cost-effective volume production.

Data Collection and Analysis Methods:

Data was collected through extensive dynamometer testing to measure power, torque, and BSFC across various engine speeds and fuel types (gasoline, JP8). Emissions were measured by an independent body for EU homologation. Durability was assessed through a 400-hour test cycle, and real-world performance was confirmed via field testing. Engineering analysis tools like FEA and CFD were used to optimize thermal and cooling system designs.

Research Topics and Scope:

The research covers the engine's mechanical design, combustion system, heavy fuel operation, manufacturing methods (including HPDC for the CK1 cylinder), performance characteristics, emissions compliance, and application in both UAV/hybrid systems and handheld power tools.

6. Key Results:

Key Results:

- The RCV DF engines achieve high power density (63 kW/litre) and operate effectively on both gasoline and heavy fuels like JP8.

- The RCV combustion system exhibits low detonation sensitivity, enabling efficient operation on low-octane fuels without performance loss.

- The 25cc CK1 engine produces 1.25 kW, 60% more power than comparable 25cc 4-stroke engines, with a superior power-to-weight ratio of 0.35 kW/Kg.

- The CK1 engine, utilizing a diecast ADC12 cylinder, is designed for volume production and meets stringent EU Stage V and EPA Phase 3 emissions limits.

- The technology has been successfully tested with net-zero carbon synthetic aviation fuel in a UAV application.

Figure Name List:

- Figure 1. Small powered two-wheeler technology trends in Taiwan 2002 to 2022 [3].

- Figure 2. Future small engine application scenarios towards 2050.

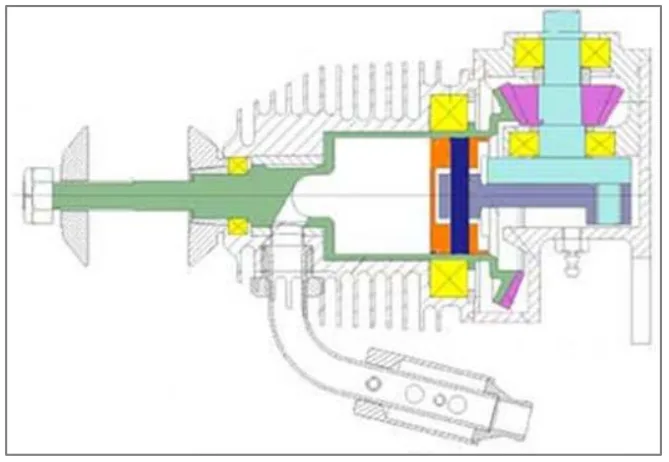

- Figure 3. Section through the RCV SP “Rotating Cylinder Valve" model aircraft engine.

- Figure 4. RCV rotary valve timing drive.

- Figure 5. RCV DF engine – section through the rotary valve, ports, and sparkplug.

- Figure 6. Valve thermal analysis example showing temperature distribution.

- Figure 7. Rotary valve — effective exhaust valve area compared to a mini-4-stroke.

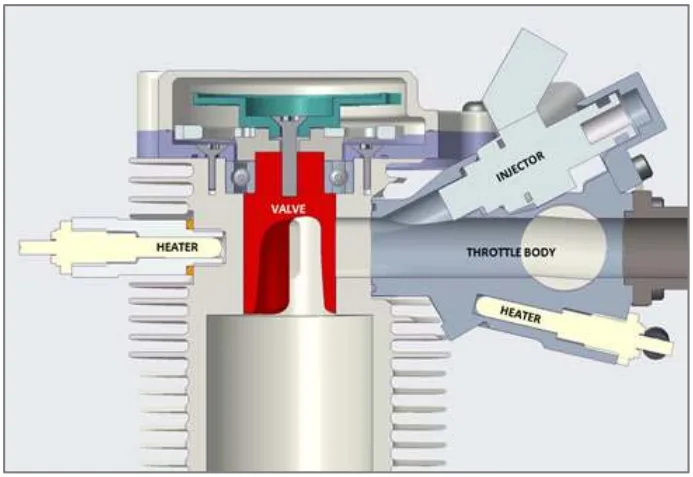

- Figure 8. Section through the DF35 throttle body.

- Figure 9. RCV DF70 combustion system response to AFR on JP8 fuel tested with a 12 x 8 propeller.

- Figure 10. RCV DF Engine Range.

- Table 1. DF35 and DF70 general Specification

- Figure 11. DF35 full load power and BSFC on JP8 fuel.

- Figure 12. RCV EFI Engine Control Unit.

- Figure 13. DF35 flight test on net-zero carbon synthetic aviation fuel.

- Figure 14. DF70 2 kW hybrid module installed an electric motorcycle.

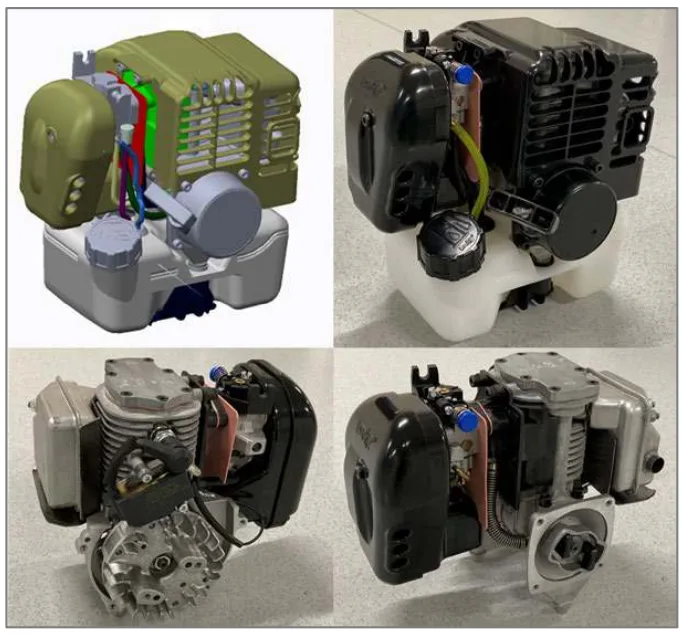

- Figure 15. CK1 engine – external views.

- Table 2. CK1 engine specifications.

- Figure 16. Section through the ports of the CK1 engine.

- Figure 17. Section through the CK1 airbox.

- Figure 18. CFD example from CK1 engine cooling system development.

- Figure 19. Section through the CK1 cylinder with plated surfaces shown in green.

- Table 3. Comparison of general-purpose engine dimensions and power to weight.

- Figure 20. CK1 engine - main dimensions.

- Figure 21. CK1 power and BSFC with catalogue power levels for 25cc and 35cc 4-strokes.

- Table 4. CK1 exhaust emissions compared to current EU and EPA limits

- Figure 22. CK 4-stroke compared to manufacturers catalogue power data for 2-stroke and 4-stroke brushcutter engines.

- Figure 23. CK1 field testing in South Korea.

7. Conclusion:

The RCV rotary valve combustion system demonstrates benefits through ICE product applications for UAVs and small general-purpose engines. The multi-fuel DF engine range is established as an ICE option for UAVs and unmanned systems with increased use in hybrid applications. The CK1 engine shows strong power, sustained at high engine speeds with 4-stroke emissions and fuel economy. The combination of the DF multi-fuel combustion system with volume production technology for the CK1 engine demonstrates that RCV rotary valve technology is a viable candidate for future small engines.

8. References:

- [List the references exactly as cited in the paper, Do not translate, Do not omit parts of sentences.]

- Kamakaté, F., and Gordon, D., “Managing Motorcycles: Opportunities to Reduce Pollution and Fuel Use from Two- and Three-Wheeled Vehicles”, www.ict.org, 2009.

- Ricardo UK, “Challenges for Future Motorcycle Emissions Control”, https://cdn.ricardo.com/motorcycle/media/events/rmc%207.0/motorcycle-emission.pdf, 2022.

- Taiwan Transportation Vehicle Manufacturers Association, https://www.ttvma.org.tw/en/statistics#2, June 2022.

- Favrere, C., May, J., Bosteels, D., Tromayer, J., and Neumann, G., “A Demonstration of Emissions’ Behaviour of Various Handheld Engines Including Investigations on Particulate Matter”, SAE Technical Paper 2013-32-9130, 2013.

- California Air Resources Board, “CARB approves updated regulations requiring most new small off-road engines to be zero emission by 2024”, https://ww2.arb.ca.gov/news/carb-approves-updated-regulations-requiring-most-new-small-road-engines-be-zero-emission-2024, December 2021.

- Ausserer, J., Polanka, M., Baranski, J., and Litke, P., “Mapping of Fuel Anti-Knock Requirements for a Small Remotely Pilot Aircraft Engine”, SAE Technical Paper 2016-32-0045, 2016.

- Cathcart, G., Dickson, G., and Ahern, S., “The Application of Air-Assist Direct Injection for Spark-ignited Heavy Fuel 2-Stroke and 4-Stroke Engines”, SAE Technical Paper 2005-32-0065, 2005.

… [Full reference list from paper] … - "RAF’s First Synthetic Fuel Drone Flight", https://www.gov.uk/government/news/rafs-first-synthetic-fuel-drone-flight, March 2022.

Expert Q&A: Your Top Questions Answered

Q1: Why is this rotary valve technology a significant step forward for small engines?

A1: It addresses the key limitations of both traditional poppet-valve engines and battery systems. It delivers significantly higher power-to-weight ratios (as shown in Figure 21), runs on future-proof net-zero carbon fuels, and maintains low emissions. This makes it ideal for professional applications where performance, range, and operational flexibility are critical. [Source: "Summary" and "Conclusions" sections].

Q2: Can this technology really handle heavy fuels like JP8 without a major performance loss?

A2: Yes. The paper explicitly states the "RCV rotary valve combustion system is not knock limited on HF and produces similar power and BSFC to gasoline operation." This is attributed to its compact central combustion chamber and uniform surface temperatures, which prevent detonation. [Source: Page 5, "In terms of abnormal combustion, detonation or knock…"].

Q3: Is this technology just for high-end, specialist applications like military UAVs?

A3: No. While the DF engine range is tailored for specialist UAVs, the CK1 engine was specifically developed for high-volume general-purpose applications. The paper highlights that the CK1 was designed for "low cost through volume production" and its core cylinder component is a die casting in ADC12 alloy, demonstrating its suitability for cost-effective, mass-market products. [Source: "CK1 General Purpose Engine" section, Page 7 and "Low cost through volume production" on Page 10].

Q4: From a manufacturing standpoint, what's the key innovation in the CK1 engine's cylinder?

A4: The key innovation is the successful mass-production design of a complex cylinder made from diecast ADC12, which integrally includes both the main cylinder bore and the separate valve bore. This diecast part is then finished with a durable Nickel Silicon Carbide coating (Figure 19). This proves that high-pressure die casting is a commercially viable method for producing the core components of this advanced engine technology at scale. [Source: Page 8, "From a manufacturing perspective…"].

Q5: What makes the RCV engine's combustion chamber so resistant to detonation with low-octane fuels?

A5: The paper attributes this characteristic to the "compact central combustion chamber" and "uniform combustion chamber surface temperatures," both inherent features of the rotary valve design. This low sensitivity to detonation was confirmed in evaluations on n-Heptane fuel, showing ignition could be advanced 20° beyond best torque without knock. [Source: Page 5, "In terms of abnormal combustion, detonation or knock…"].

Conclusion & Next Steps

This research provides a valuable roadmap for the future of the internal combustion engine. By moving beyond conventional designs, the RCV rotary valve technology offers a clear, data-driven path toward developing engines that are more powerful, more efficient, fuel-flexible, and manufacturable at scale using established processes like high-pressure die casting.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers' most challenging die casting problems. The successful use of an ADC12 diecast cylinder in this high-performance application is a testament to the potential of HPDC. If the challenges of manufacturing complex, durable, and precise components resonate with your goals, contact our engineering team to discuss how we can help you turn advanced designs into reality.

Copyright

- This material is a paper by "Brian Mason, Keith Lawes, and Koichi Hirakawa". Based on "Rotary Valve 4-Stroke Engines for General Purpose Power Equipment and Unmanned Systems".

- Source of the paper: SETC2022 New Product Technology Session, Paper NPT2022-028.

This material is for informational purposes only. Unauthorized commercial use is prohibited. Copyright © 2025 CASTMAN. All rights reserved.