This technical summary is based on the academic paper "Analysis of Mechanical Properties and Microstructure of Multiple Die Cavity Products Produced in Vertical and Horizontal Arrangement by Gravity Die Casting" by Ong Chin Yee, published by UTHM, Batu Pahat (2012). It was analyzed and summarized for HPDC experts by CASTMAN experts with the help of LLM AI such as Gemini, ChatGPT, and Grok.

![Figure 1.1: Gravity die mold [3].](https://castman.co.kr/wp-content/uploads/image-2682.webp)

Keywords

- Primary Keyword: Gravity Die Casting Multiple Cavities

- Secondary Keywords: Vertical arrangement, Horizontal arrangement, A356 alloy, Mechanical properties, Microstructure analysis, Porosity, Tensile strength

Executive Summary

- The Challenge: Manufacturers assume identical quality across products from multiple cavity molds, yet variations in mechanical properties and defects (e.g., porosity, cracks) persist due to cavity arrangement.

- The Method: The study compares A356 aluminum alloy castings from vertical and horizontal mold arrangements, analyzing mechanical properties (tensile strength, hardness, impact strength) and microstructure (porosity, grain structure).

- The Key Breakthrough: Vertical arrangement castings exhibit superior mechanical properties, with 5.55% higher hardness, 11.8-46.15% higher impact strength, and 11.81% higher ultimate tensile strength compared to horizontal arrangements.

- The Bottom Line: Vertical mold arrangements significantly enhance casting quality, offering actionable insights for optimizing production.

The Challenge: Why This Research Matters for HPDC Professionals

In gravity die casting (GDC), manufacturers often assume that products from multiple cavity molds—whether arranged vertically or horizontally—yield identical quality. However, real-world issues like porosity, cracks, and inconsistent mechanical properties challenge this assumption (Ref. [24]). These defects can compromise product performance, leading to costly rework or failures in critical applications like automotive or aerospace components. This research addresses a critical industry pain point: understanding how mold arrangement impacts casting quality, enabling manufacturers to make informed decisions to improve product reliability and consistency.

The Approach: Unpacking the Methodology

The study utilized A356 aluminum alloy castings produced in mild steel molds with multiple cavities arranged vertically and horizontally (Ref. [24], Section 3.1). The methodology included:

- Mold Design and Fabrication: Molds were designed with multiple cavities (Figure 3.1, 3.6) and preheated using silicon spray and K-type thermocouples (Figure 4.1, 4.2).

- Casting Process: Molten A356 was poured at temperatures of 800°C, 850°C, and 900°C (Section 4.1).

- Mechanical Testing: Tests included Izod impact (Section 3.2.1), Vickers microhardness (Section 3.2.2), and tensile testing (Section 3.2.3) to evaluate strength and toughness.

- Microstructural Analysis: Density tests (Section 3.3.1), porosity tests (Section 3.3.2), optical microscopy (Section 3.3.3), and SEM (Section 3.3.4) assessed internal defects and grain structure.

This rigorous approach ensures a comprehensive comparison of casting quality across arrangements.

The Breakthrough: Key Findings & Data

The study revealed significant differences in mechanical properties and microstructure between vertical and horizontal arrangements (Section 4.3):

- Hardness: Vertical arrangement castings showed 5.55% higher Vickers hardness than horizontal ones (Figure 4.9), attributed to faster cooling and finer grain structures.

- Impact Strength: Vertical castings had 11.8-46.15% higher impact strength (0-1.9 J) compared to horizontal castings (2-1.1 J) (Figures 4.10, 4.11, 4.12).

- Tensile Strength: Ultimate tensile strength (UTS) for vertical castings ranged from 121.82 MPa, 11.81% higher than horizontal castings (101.78 MPa) (Figures 4.13, 4.15; Table 4.12).

- Porosity: Microporosity in vertical arrangements was 5.35% lower than in horizontal arrangements (Tables 4.15, 4.16; Figures 4.17, 4.18), indicating better internal soundness.

These findings highlight the superior performance of vertical arrangements, likely due to improved molten metal flow and reduced turbulence (Section 4.3.6).

Practical Implications for HPDC Products

The research offers actionable insights for optimizing gravity die casting operations:

- For Process Engineers: Adjusting to vertical cavity arrangements could reduce microporosity by 5.35% (Table 4.15), enhancing casting integrity and reducing defects like shrinkage porosity (Figure 2.10).

- For Quality Control: The higher hardness (Figure 4.7) and tensile strength (Figure 4.13) in vertical castings provide reliable metrics for quality assurance, enabling earlier defect detection.

- For Die Design: Vertical mold designs promote directional solidification, minimizing macroporosity (Figures 4.13-4.18) and improving mechanical properties, as detailed in the study’s conclusion (Section 5.1).

By adopting vertical arrangements, manufacturers can achieve stronger, more reliable castings, reducing scrap rates and improving cost-efficiency.

Paper Details

1. Overview:

- Title: Analysis of Mechanical Properties and Microstructure of Multiple Die Cavity Products Produced in Vertical and Horizontal Arrangement by Gravity Die Casting

- Author: Ong Chin Yee

- Year of Publication: 2012

- Journal/Academic Society of Publication: UTHM, Batu Pahat

- Keywords: Gravity die casting, A356 alloy, vertical arrangement, horizontal arrangement, mechanical properties, microstructure, porosity

2. Abstract:

Multiple cavity gravity die casting in vertical and horizontal mold arrangements is common, but manufacturers often assume identical product quality. This study investigates A356 alloy castings, revealing that vertical arrangements yield superior hardness (5.55% higher), impact strength (11.8-46.15% higher), tensile strength (11.81% higher), and lower microporosity (5.35%) compared to horizontal arrangements.

3. Introduction:

The introduction outlines gravity die casting as a process for producing complex, high-volume metal parts with better dimensional accuracy than sand casting (Ref. [1]). It highlights the industry’s assumption that multiple cavity products are identical, despite potential variations in mechanical properties and defects (Section 1.2).

4. Summary of the Study:

- Background of the Research Topic: Gravity die casting is widely used for producing aluminum alloy parts like gears and automotive components (Section 1.1).

- Status of Previous Research: Prior studies focused on single-cavity casting or defect analysis but lacked detailed comparisons of multiple cavity arrangements (Section 2).

- Purpose of the Study: To compare mechanical properties and microstructure of A356 alloy castings from vertical and horizontal multiple cavity molds (Section 1.3).

- Core Study: The research examines hardness, impact strength, tensile strength, and porosity using standardized tests and microscopy (Section 3).

5. Research Methodology

- Research Design: Comparative study of A356 alloy castings in vertical and horizontal mold arrangements (Section 3.1).

- Data Collection and Analysis Methods: Mechanical tests (Izod, Vickers, tensile) and microstructural analysis (density, porosity, OM, SEM) at pouring temperatures of 800°C, 850°C, and 900°C (Sections 3.2, 3.3).

- Research Topics and Scope: Focuses on A356 alloy, mild steel molds, and multiple cavity arrangements (Section 1.4).

6. Key Results:

- Key Results: Vertical arrangements outperform horizontal ones in hardness (5.55% higher, Figure 4.9), impact strength (11.8-46.15% higher, Figures 4.10-4.12), tensile strength (11.81% higher, Table 4.12), and microporosity (5.35% lower, Table 4.15).

Figure Name List:

![Figure 1.2: principle of gravity die casting [3].](https://castman.co.kr/wp-content/uploads/image-2683.webp)

![Figure 2.6: Example of gas porosity defect [10].](https://castman.co.kr/wp-content/uploads/image-2685.webp)

![Figure 2.12: Cooling curve depicting undercooling and subsequent recalescence [1].](https://castman.co.kr/wp-content/uploads/image-2686.webp)

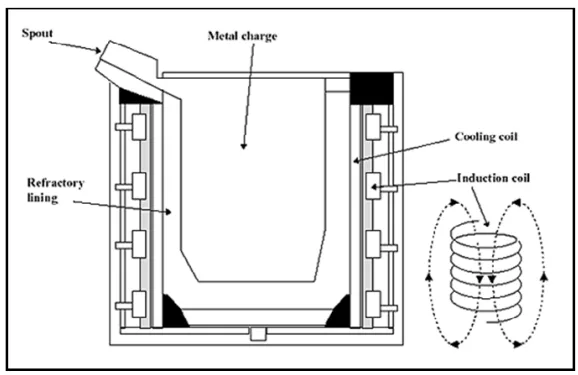

- Figure 1.1: Gravity die mold

- Figure 1.2: Principle of gravity die casting

- Figure 1.3: Example of multiple die cavities

- Figure 2.1: Electric Induction Furnace (Coreless)

- Figure 2.2: Typical Cupola Furnace

- Figure 2.3: Direct Arc Furnace

- Figure 2.4: Crucible Furnace

- Figure 2.5: Rotating Furnace

- Figure 2.6: Example of gas porosity defect

- Figure 2.7: Example of misrun defect

- Figure 2.8: Example of cold shut defect

- Figure 2.9: Example of hot tear defect

- Figure 2.10: Example of shrinkage porosity

- Figure 2.11: Cooling curve for a pure metal or eutectic-composition

- Figure 2.12: Cooling curve depicting undercooling & subsequent recalescence

- Figure 2.13: Schematic illustration of three shrinkage regimes

- Figure 2.14: Solidification model for an unfed sphere

- Figure 2.15: Hydrogen solubility in aluminum and two of its alloys

- Figure 2.16: Hydrogen content of liquid aluminum

- Figure 2.17: Two types of ladle used to pour casting

- Figure 2.18: Multi-cavity Core Box for Core Shooters

- Figure 2.19: The height of sprue

- Figure 2.20: Pouring basin design

- Figure 2.21: Proper sprue design

- Figure 2.22: Sprue base

- Figure 2.23: Runner

- Figure 2.24: Runner extension

- Figure 2.25: Molten metal flowing from the runner to the gate

- Figure 2.26: The ratio of runner for each gate

- Figure 2.27: Top riser and side riser (blind riser)

- Figure 2.28: SEM micrographs showing as-cast microstructure of alloys

- Figure 2.29: SEM micrographs showing as-cast microstructure of alloys

- Figure 3.1-3.10: Mold designs for vertical and horizontal arrangements

- Figure 3.11: Crucible furnace

- Figure 3.12-3.34: Testing equipment and procedures

- Figure 4.1-4.39: Casting process, defects, and microstructure results

7. Conclusion:

Vertical arrangement castings demonstrate superior mechanical properties and lower porosity due to better molten metal flow and solidification control. The study recommends vertical arrangements for enhanced casting quality (Section 5.1).

8. References:

- [1] Degagmo, E. P., Black, J. T. & Kohser, R. A. (2003). Materials and Processes in Manufacturing. 9th ed. USA: Wiley.

- [2] Gravity Die Casting: Introduction. Retrieved 2011. from Zhejiang Dongrun Casting Industry&Trade Co. Ltd.

- [3] Gravity Die Casting. Retrieved Dec 3, 2011, from IndiaMART InterMESH Limited.

- [4] Lumley, R. (2011). Fundamentals of Aluminum Metallurgy. Cambridge: Woodhead Publishing Limited.

- [10] Apelian, D. (2009). Aluminum Cast Alloys: Enabling Tools for Improved Performance. Wheeling, Illinois: North American Die Casting Association.

- [24] Ong Chin Yee (2012). Analysis of Mechanical Properties and Microstructure of Multiple Die Cavity Products Produced in Vertical and Horizontal Arrangement by Gravity Die Casting, UTHM, Batu Pahat.

Expert Q&A: Your Top Questions Answered

Q1: What was the single most critical factor identified in this study for improving casting quality?

A1: The study concluded that mold arrangement (vertical vs. horizontal) was the most influential factor. Vertical arrangements improved hardness, impact strength, and tensile strength, as detailed in Section 4.3 and supported by Figures 4.9, 4.10, and 4.13.

Q2: How does this research compare to traditional methods for addressing casting defects?

A2: The paper’s Introduction (Section 1.2) notes that traditional methods assume identical quality across multiple cavity molds. This research introduces a comparative analysis of arrangements, showing vertical molds reduce defects like microporosity by 5.35% (Table 4.15).

Q3: Is this finding applicable to all types of alloys, or a specific one?

A3: The research, as described in Section 1.4, was conducted using A356 aluminum alloy. Applicability to other alloys requires further investigation.

Q4: What specific measurement or simulation technique did the researchers use to arrive at this conclusion?

A4: The researchers utilized Izod impact tests, Vickers microhardness tests, tensile tests, density tests, porosity tests, optical microscopy, and SEM, as explained in Sections 3.2 and 3.3.

Q5: According to the paper, what is the main limitation or area for future research?

A5: The authors state in Section 5.2 that a key limitation was the focus on A356 alloy and mild steel molds. Future work should explore other alloys and mold materials.

Q6: What is the direct, practical takeaway from this paper for a die casting facility?

A6: The core takeaway is that adopting vertical cavity arrangements can enhance mechanical properties and reduce porosity, as supported by the results in Section 4.3 of the paper.

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing casting quality in gravity die casting. By adopting vertical mold arrangements, manufacturers can achieve stronger, more reliable components with fewer defects, directly addressing industry challenges like porosity and inconsistent mechanical properties.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers' most challenging die casting problems. If the issues discussed in this paper resonate with your operational goals, contact our engineering team to discuss how we can help you implement these advanced principles in your components.

Copyright

- This material is a paper by "Ong Chin Yee". Based on "Analysis of Mechanical Properties and Microstructure of Multiple Die Cavity Products Produced in Vertical and Horizontal Arrangement by Gravity Die Casting".

- Source of the paper: Not publicly available (UTHM, Batu Pahat).

- This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.