Optimizing Strength and Wear Resistance in Aluminum Composites: A Die Casting Breakthrough

This technical brief is based on the academic paper "Mechanical Properties of Al6061- Al₂O₃ Metal Matrix Composite Using Die Casting Technique" by Mahendra HM, Prakash GS, Prasad KSK, and Rajanna, published in the Journal of Material Science and Metallurgy (2018). It is summarized and analyzed for HPDC professionals by the experts at STI C&D.

Keywords

- Primary Keyword: Al6061-Al₂O₃ Metal Matrix Composite

- Secondary Keywords: Die Casting, Mechanical Properties, Wear Resistance, Tensile Strength, Microstructure Analysis, Alumina Reinforcement, MMC Manufacturing

Executive Summary

- The Challenge: To enhance the physical and mechanical properties of conventional 6061 Aluminum alloy for demanding aerospace, automotive, and marine applications where higher strength and wear resistance are critical.

- The Method: Researchers fabricated Al6061-Al₂O₃ metal matrix composites (MMCs) with varying reinforcement levels (0, 4, 8, 12, and 16wt%) of 40 µm alumina particles using a high-pressure die casting technique.

- The Key Breakthrough: The study identified an optimal reinforcement level of 12wt% Al₂O₃, which resulted in the maximum ultimate tensile strength (210 N/mm²), yield strength (186 N/mm²), and hardness (92 BHN).

- The Bottom Line: High-pressure die casting is an effective method for producing Al6061-Al₂O₃ MMCs. Adding alumina significantly improves mechanical properties and wear resistance, but exceeding a 12wt% threshold leads to particle agglomeration and a subsequent decline in performance.

The Challenge: Why This Research Matters for HPDC Professionals

Metal matrix composites (MMCs) are increasingly sought after for advanced applications in aerospace, automotive, and turbine manufacturing due to their superior properties compared to monolithic alloys. For engineers working with aluminum alloys like Al6061, the goal is often to improve strength, hardness, and wear resistance without compromising manufacturability.

While various methods exist to produce MMCs, many are complex or costly. This research focuses on high-pressure die casting, a process known for its ability to produce components in large quantities efficiently and cost-effectively [3]. The central challenge addressed is how to systematically enhance Al6061's performance by reinforcing it with ceramic particulates (Al₂O₃) and to understand the precise relationship between the amount of reinforcement and the final mechanical properties of the die-cast component.

The Approach: Unpacking the Methodology

To investigate the effects of alumina reinforcement, the researchers employed a robust and industrially relevant methodology:

- Material Preparation: The matrix material was standard 6061Al alloy. The reinforcement consisted of Al₂O₃ particulates with a 40 µm particle size. Composites were prepared with five different weight fractions of alumina: 0% (pure Al6061), 4%, 8%, 12%, and 16%.

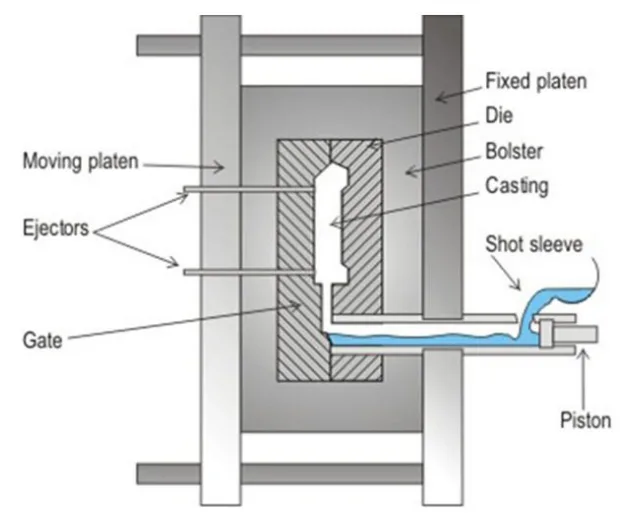

- Manufacturing Process: A high-pressure die casting machine was used to fabricate the composites (Figure 1). Molten metal, heated to 750 °C, was injected at high speed and pressure into a permanent mold to produce cylindrical rods (30mm diameter, 300mm length).

- Mechanical Testing:

- Tensile & Hardness: Tensile properties were measured according to the ASTM E8 standard using a computerized universal testing machine. Hardness was evaluated using a Brinell hardness tester as per the ASTM E10 standard.

- Wear Test: Dry sliding wear behavior was analyzed using a pin-on-disc tribometer under various loads (3, 4, and 5 kg) at a constant speed, following the ASTM D785-08 standard.

- Microstructural Analysis: The dispersion of Al₂O₃ particles within the aluminum matrix was examined using computerized optical microscopy and Scanning Electron Microscopy (SEM) to correlate the material's internal structure with its performance.

The Breakthrough: Key Findings & Data

The study yielded clear, data-driven insights into how alumina reinforcement transforms the properties of die-cast Al6061.

- Finding 1: Tensile Strength Peaks at 12% Reinforcement The addition of Al₂O₃ particulates progressively increased the ultimate tensile strength and yield strength of the composite. The maximum values were achieved at 12wt% reinforcement, with an ultimate tensile strength of 210 N/mm² and a yield strength of 186 N/mm². Beyond this point, at 16wt%, the strength began to decrease. This trend is clearly documented in Table 5 and visualized in Figures 9 and 10.

- Finding 2: Hardness Follows a Similar Trend The hardness of the composite material increased with the addition of hard ceramic Al₂O₃ particles. The Brinell hardness (BHN) rose from 72 for pure Al6061 to a peak of 92 for the 12wt% composite. At 16wt%, the hardness slightly decreased to 90 BHN, mirroring the trend seen in tensile strength (Table 6).

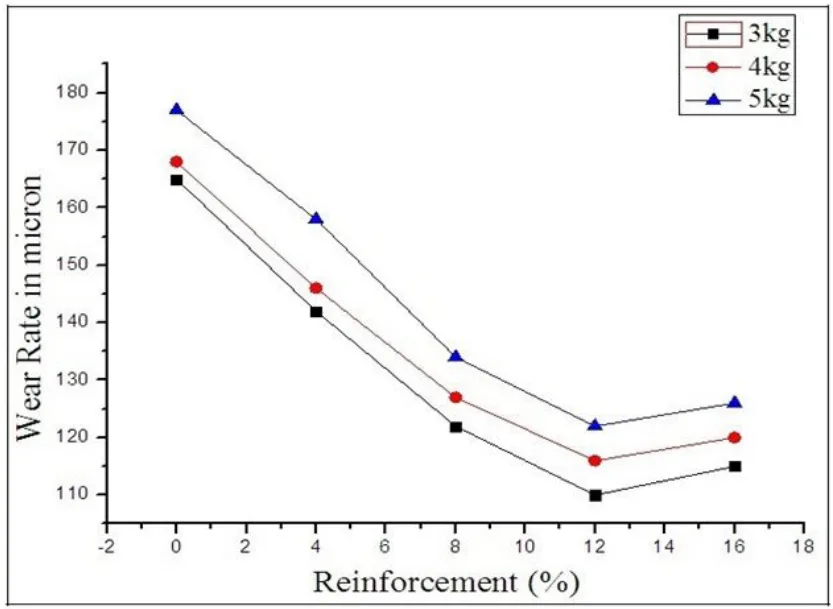

- Finding 3: Significant Improvement in Wear Resistance The reinforced composites demonstrated superior wear resistance compared to the base Al6061 alloy. Both the coefficient of friction and the wear rate (measured in microns) decreased as the percentage of Al₂O₃ increased. This indicates that the hard alumina particles help protect the matrix from wear. The results under different loads are presented in Figures 17 and 18.

- Finding 4: Microstructure Reveals the Cause of Property Decline The optical and SEM micrographs (Figures 12-16 and 19-23) were crucial in explaining the results. At lower concentrations (up to 12%), the Al₂O₃ particles were well-dispersed throughout the matrix. However, at 16wt% reinforcement, the images show clear evidence of particle "agglomeration," or clustering. This clumping creates weak points in the material, reducing the effectiveness of the reinforcement and causing the observed drop in tensile strength and hardness.

Practical Implications for Your HPDC Operations

The findings from this paper offer actionable insights for engineers and managers involved in die casting and material selection.

- For Process Engineers: This research confirms that high-pressure die casting is a viable method for manufacturing Al-Al₂O₃ MMCs. The data suggests that for maximizing strength and hardness, targeting a 12wt% alumina reinforcement level is the optimal strategy. Exceeding this can be counterproductive and lead to inferior mechanical properties.

- For Quality Control: The direct link between particle agglomeration (seen in Figure 16 and Figure 23) and the drop in mechanical properties (Table 5) underscores the critical need for process control. Monitoring the homogeneity of the molten mix before injection is essential to prevent clustering and ensure consistent, high-quality parts. Microstructural analysis can serve as a powerful tool for diagnosing issues in parts that fail to meet mechanical specifications.

- For Die and Material Design: For components requiring high wear resistance and strength, such as bearing materials or contact strips, Al6061-Al₂O₃ MMCs are a compelling choice. This study provides the specific data (Table 5, Table 7) needed to design with these materials, allowing engineers to balance the trade-offs between strength, ductility (which decreases with reinforcement, see Figure 11), and wear performance.

Paper Details

Mechanical Properties of Al6061- Al₂O₃ Metal Matrix Composite Using Die Casting Technique

1. Overview:

- Title: Mechanical Properties of Al6061- Al₂O₃ Metal Matrix Composite Using Die Casting Technique

- Author: Mahendra HM, Prakash GS, Prasad KSK and Rajanna

- Year of publication: 2018

- Journal/academic society of publication: Journal of Material Science and Metallurgy

- Keywords: Al6061; Al₂O₃; Die-Casting; Mechanical Properties; Wear Test

2. Abstract:

6061Al - Al₂O₃ Metal matrix composites are applied as conventional materials in the domain of aerospace, automotive and marine applications to enhance the physical properties. The present work aimed to prepare metal matrix composite using 6061Al as the matrix material. Particulates of Al₂O₃ with 40 µm were reinforced using die casting technique. Further level of reinforcement is being varied from 0-16wt% in steps of 4wt%. Microstructural characterization has been conducted for the resulting composites to check the homogeneous distribution of particles. Tensile properties of 6061 Al - Al₂O₃ composite have been analysed. Effect of reinforcement on the tensile properties was studied carefully. Enhancement in tensile properties was observed by the addition of particles in to the matrix and a maximum strength was observed for the composite with 12% fillers. Incorporation of Al₂O₃ into 6061 enhances the wear resistance up to a loading level 12%.

3. Introduction:

Metal matrix composites (MMCs) are becoming increasingly attractive for advanced applications in fields like aerospace, automobiles, and turbines, as adding suitable fillers can improve the properties of the matrix material. Die casting is presented as an effective, low-cost, and commercially viable method for producing MMCs in large quantities. The introduction reviews previous work on aluminum-based composites, noting that reinforcing with ceramic particles like Al₂O₃ or SiC generally enhances tensile strength, yield strength, and hardness, while often reducing ductility. The goal of this study is to build upon this knowledge by systematically investigating Al6061-Al₂O₃ composites made via die casting.

4. Summary of the study:

Background of the research topic:

The research is grounded in the need for advanced materials with enhanced physical properties for high-performance applications. Aluminum alloy 6061 is a common engineering material, but its properties can be insufficient for more demanding roles. Metal matrix composites (MMCs), specifically Al6061 reinforced with alumina (Al₂O₃), offer a promising solution.

Status of previous research:

Previous studies have confirmed that reinforcing aluminum alloys with ceramic particles like Al₂O₃ and SiC improves mechanical properties such as hardness and tensile strength [4, 5]. Various manufacturing methods like melt stirring and low-pressure die casting have been explored [4, 6]. Research has also shown that while strength increases, ductility often decreases, and particle clustering at higher concentrations can be a problem [6]. This study aims to use high-pressure die casting and systematically vary the Al₂O₃ content to find an optimal composition.

Purpose of the study:

The primary aim was to prepare an Al6061-Al₂O₃ metal matrix composite using the die casting technique and to comprehensively study the effect of varying the weight percentage of Al₂O₃ reinforcement (from 0% to 16%) on the resulting mechanical properties (tensile strength, hardness) and wear behavior.

Core study:

The core of the study involved fabricating five sets of composite samples with different Al₂O₃ concentrations (0, 4, 8, 12, 16 wt%). These samples were then subjected to a series of standardized tests: tensile testing (ASTM E8), Brinell hardness testing (ASTM E10), and pin-on-disc wear testing. The internal structure of the resulting composites was analyzed using optical microscopy and SEM to understand how particle distribution influenced the measured properties.

5. Research Methodology

Research Design:

The study was designed as a comparative experiment. The independent variable was the weight percentage of Al₂O₃ reinforcement (0, 4, 8, 12, 16 wt%). The dependent variables were the mechanical and tribological properties of the resulting composite, including ultimate tensile strength, yield strength, percentage of elongation, Brinell hardness, wear rate, and coefficient of friction.

Data Collection and Analysis Methods:

Data was collected through physical testing using calibrated laboratory equipment.

- Tensile Properties: A computerized universal testing machine (Extensometer) was used to generate stress-strain curves (Figures 4-8), from which yield strength, ultimate tensile strength, and % elongation were derived (Table 5).

- Hardness: A Brinell hardness testing machine was used to measure indentation on prepared specimens, with the results recorded in BHN (Table 6).

- Wear: A pin-on-disc apparatus was used to measure wear in microns and calculate the coefficient of friction under different loads (Table 7).

- Microstructure: An optical microscope (200x magnification) and a VEGA3 TESCAN SEM were used to capture images of the particle distribution within the matrix (Figures 12-23).

Research Topics and Scope:

The research was focused on Al6061 aluminum alloy as the matrix and 40 µm Al₂O₃ particles as the reinforcement. The manufacturing method was exclusively high-pressure die casting. The scope of the investigation was limited to the "as-cast" condition, without any subsequent heat treatment, and covered reinforcement levels from 0 to 16wt%.

6. Key Results:

Key Results:

The key results demonstrate a clear, non-linear relationship between the amount of Al₂O₃ reinforcement and the composite's properties.

- Tensile and Yield Strength: Both properties increased steadily with reinforcement up to 12wt%, reaching a maximum of 210 N/mm² (UTS) and 186 N/mm² (Yield Strength). At 16wt%, these values dropped to 192 N/mm² and 170 N/mm², respectively (Table 5).

- Ductility: The percentage of elongation, a measure of ductility, decreased as reinforcement was added, dropping from 14.8% for pure Al6061 to 7.8% for the 12wt% composite (Table 5).

- Hardness: Hardness increased from 72 BHN (0% Al₂O₃) to a peak of 92 BHN (12% Al₂O₃) before slightly decreasing to 90 BHN at 16% (Table 6).

- Wear Resistance: The addition of Al₂O₃ significantly improved wear resistance. The coefficient of friction and wear rate consistently decreased as the percentage of reinforcement increased across all tested loads (3, 4, and 5 kg), as shown in Figures 17 and 18.

- Microstructure: Micrographs confirmed a uniform dispersion of Al₂O₃ particles at lower concentrations, but showed particle agglomeration at 16wt%, which is cited as the reason for the decline in mechanical properties at that level.

Figure Name List:

- Figure 1: High Pressure Die casting Setup

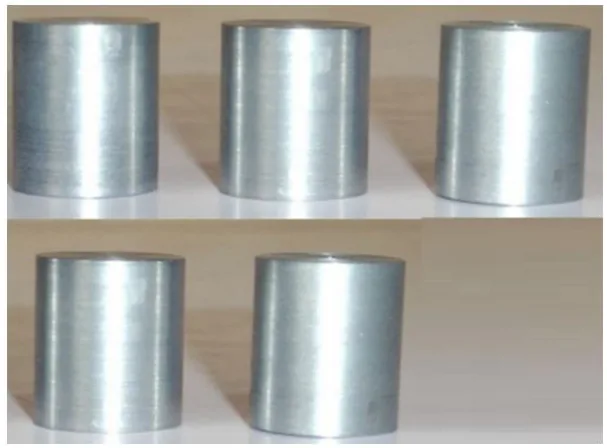

- Figure 2: Hardness Testing Specimen

- Figure 3: Wear Testing Specimen

- Figure 4: Stress v/s % of Elongation (0% Al₂O₃)

- Figure 5: Stress v/s % of Elongation (4% Al₂O₃)

- Figure 6: Stress v/s % of Elongation (8% Al₂O₃)

- Figure 7: Stress v/s % of Elongation (12% Al₂O₃)

- Figure 8: Stress v/s % of Elongation (16% Al₂O₃)

- Figure 9: Variation of Yield strength for Al6061 with percentage of Al₂O₃

- Figure 10: Variation of Ultimate Tensile strength for Al6061 with percentage of Al₂O₃

- Figure 11: Variation of Percentage of Elongation for Al6061 with percentage of Al₂O₃

- Figure 12: AL6061- Al₂O₃ -0%

- Figure 13: AL6061- Al₂O₃ -4%

- Figure 14: AL6061- Al₂O₃ -8%

- Figure 15: AL6061- Al₂O₃ -12%

- Figure 16: AL6061- Al₂O₃ -16%

- Figure 17: Variation of Co-efficient of friction with percentage of reinforcement for different loads

- Figure 18: Variation of Wear rate with percentage of reinforcement for different loads.

- Figure 19: Al6061- Al₂O₃ -0%

- Figure 20: Al6061- Al₂O₃ -4%

- Figure 21: Al6061- Al₂O₃ -8%

- Figure 22: Al6061 - Al₂O₃ -12%

- Figure 23: Al6061- Al₂O₃ -16%

7. Conclusion:

Composites of Al6061 Aluminium alloy has been successfully prepared by reinforcing Al₂O₃ particulates of 40-micron size with various loading levels. Microstructure studies showed that the composite shows better dispersion of particulates at lower loading levels. Tensile properties and hardness of the composite exhibited an increasing trend upon the addition of particulates in the matrix. Wear resistance studies showed a positive impact on the addition of Al₂O₃ in Al6061 matrix. Finally, it can be concluded that the resulting composite material can be used to manufacture materials with higher stability.

8. References:

- [1] Veerabhadrappa A, Balaraj V, Nagaraj K (2015) Effect of T6 type heat treatment on the Mechanical characterization of Al6061-Al₂O₃ particulate composites. Int J Emerging Trends Eng Dev 3: 5.

- [2] Hashim J, Looney L, Hashmi MSJ (1999) Metal Matrix Composites Production by the Stir Casting Method. J Mater Process Technol 92: 1-7.

- [3] A Chennakesava Reddy, Essa Ztioun (2011) Tensile Properties and Fracture Behavior of 6061/Al₂O₃ Metal Matrix Composites Fabricated by Low Pressure Die Casting Process. Int J Mater Sci 6: 147-57.

- [4] Bharath V, Madev Nagaral, V Auradi, Kori SA (2014) Preparation of 6061Al-Al₂O₃ MMC's by Stir Casting and Evaluation of Mechanical and Wear Properties. Procedia Mater Sci 6: 1658-67.

- [5] G Shaikshavali, E Venugopal goud, M Murali mohan (2016) Mechanical Properties of Al6061 Based Metal Matrix Composites Reinforced with Ceramic Particulates and Effect of Age Hardening on its Tensile Characteristics. Int J Eng Res Gen Sci 4.

- [6] A Chennakesava Reddy, Essa Ztioun (2011) Tensile Properties and Fracture Behavior of 6061/Al₂O₃ Metal Matrix Composites Fabricated by Low Pressure Die Casting Process. Int J Mater Sci 6: 147-57.

- [7] G Nagesh, Sukesha V, Rajeev Ranjan, K, Sekar (2014) Investigation of mechanical and tribological properties of A356/Al₂O₃/graphite by stir with squeeze casting method. 5th Int & 26th All India Manuf Technol, Des Res Conf (AIMTDR 2014) IIT Guwahati, Assam, India.

- [8] Mahalingegowda HB, Mahesh BS (2014) Mechanical and Wear Behaviour of Al60601- composites and Al6061Al₂O₃-Gr Hybrid Composites. Int J Innovative Res Sci Eng Technol 3: 6.

- [9] Bartakke Nikhil N, Chivelkar Amey A, Devrukhkar Vaibhav L, Jamsutkar Sahil R, Rajnitu Rakshaskar (2016) Mechanical Property Analysis of Aluminum Alumina Composite by Varing the Percentage of Alumina. Int J Mech Prod Eng 4.

- [10] Bharath V, Madev Nagaral, V Auradi, Kori SA (2014) Preparation of 6061Al-Al₂O₃ MMC's by Stir Casting and Evaluation of Mechanical and Wear Properties. Procedia Mater Sci 6: 1658-67.

- [11] M Dhanashekar, VS Senthil Kumar (2014) Squeeze Casting of Aluminium Metal Matrix Composites- An Overview. Procedia Eng 97: 412-20.

- [12] Himanshu Kala, KKS Mer, Sandeep Kumar (2014) A Review on Mechanical and Tribological Behaviors of Stir Cast Aluminum Matrix Composites. Procedia Mater Sci 6: 1951-60.

- [13] Bharath V, Mahadev Nagaral, V Auradi (2012) Preparation, Characterization and Mechanical Properties of Al₂O₃ Reinforced 6061Al Particulate MMC's. Inter J Eng Res Technol 1.

- [14] Karthick E, Joel Mathai, Michael Tony J, Senthil Kumar Marikkannan (2017) Processing Microstructure and Mechanical Properties of Al₂O₃ and SiC Reinforced Magnesium Metal Matrix Hybrid Composites. Mater Today Proc 4: 6750-6.

- [15] T Rajmohan, K Palanikumar, S Ranganathan (2013) Evaluation of Mechanical and Wear Properties of Hybrid Aluminium Matrix Composites. Trans Nonferrous Met Soc China 23: 2509-17.

- [16] BN Sarada, PL Srinivasa Murthy, G Ugrasen (2011) Hardness and wear characteristics of Hybrid Fabricated by stir casting. Mater Sci Eng A 528: 8765-71.

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing the mechanical properties of Al6061 using die casting. The findings offer a clear, data-driven path toward improving quality, reducing wear, and optimizing materials for high-stability applications.

STI C&D is committed to applying cutting-edge industry research to solve our customers’ most challenging technical problems. If the problem discussed in this white paper aligns with your research goals, please contact our engineering team to discuss how we can help you apply these advanced principles to your research.

Expert Q&A:

- Q1: What is the optimal percentage of Al₂O₃ reinforcement in Al6061 for maximizing tensile strength using die casting? A: According to the paper "Mechanical Properties of Al6061- Al₂O₃ Metal Matrix Composite Using Die Casting Technique," the optimal level is 12wt% reinforcement. At this level, the composite achieved a maximum ultimate tensile strength of 210 N/mm² and a yield strength of 186 N/mm². This is supported by the data in Table 5 and Figures 9 & 10.

- Q2: How does adding Al₂O₃ affect the wear resistance of the Al6061 composite? A: The addition of Al₂O₃ significantly improves the wear resistance of the Al6061 matrix. The study found that as the percentage of Al₂O₃ filler increases, the wear rate and the coefficient of friction both decrease. This is because the hard ceramic particles help to resist the abrasive forces during sliding contact, as detailed in Figures 17 and 18.

- Q3: Why do the mechanical properties of the composite decrease when the Al₂O₃ content exceeds 12wt%? A: The paper suggests that the decrease in tensile strength and hardness at 16wt% reinforcement is due to the "formation of agglomerates." The microstructural analysis, particularly the SEM images like Figure 23, shows that at this higher concentration, the Al₂O₃ particles begin to cluster together instead of dispersing uniformly. These clusters act as stress concentration points and defects, weakening the overall composite.

- Q4: What manufacturing process was used in this study, and was it effective? A: The study used a high-pressure die casting technique, as shown in Figure 1. The conclusion states that this method was successful in preparing the Al6061-Al₂O₃ composites and that the resulting materials can be used to "manufacture materials with higher stability," indicating the process was effective for this application.

- Q5: What was the effect of Al₂O₃ reinforcement on the ductility of the Al6061 composite? A: The addition of Al₂O₃ reinforcement led to a decrease in the ductility of the composite. The percentage of elongation at break, a measure of ductility, decreased from 14.8% for the unreinforced Al6061 to 7.8% for the composite with 12% Al₂O₃. This trade-off between increased strength and reduced ductility is a common characteristic of particle-reinforced metal matrix composites and is documented in Table 5 and Figure 11.

Copyright

- This material is an analysis of the paper "Mechanical Properties of Al6061- Al₂O₃ Metal Matrix Composite Using Die Casting Technique" by Mahendra HM, et al.

- Source of the paper: Journal of Material Science and Metallurgy, 2018, Vol 1, Issue 1. (A direct DOI is not provided in the paper, but it is published by ScholArena).

- This material is for informational purposes only. Unauthorized commercial use is prohibited.

- Copyright © 2025 STI C&D. All rights reserved.