This introduction paper is based on the paper "TOWARDS THE MODELING OF FLUID-STRUCTURE INTERACTIVE LOST CORE DEFORMATION IN HIGH-PRESSURE DIE CASTING" published by "The 13th OpenFOAM Workshop (OFW13), June 24-29, 2018, Shanghai, China".

1. Overview:

- Title: TOWARDS THE MODELING OF FLUID-STRUCTURE INTERACTIVE LOST CORE DEFORMATION IN HIGH-PRESSURE DIE CASTING

- Author: SEBASTIAN KOHLSTÄDT¹, MICHAEL VYNNYCKY², JAN JÄCKEL³, LUDGER LOHRE⁴

- Year of publication: 2018

- Journal/academic society of publication: The 13th OpenFOAM Workshop (OFW13), June 24-29, 2018, Shanghai, China

- Keywords: compressible two-phase flow, fluid-structure interaction, high-pressure die casting, lost salt cores, solver development, experimental validation

2. Abstract:

This paper details the development and validation of a numerical model for simulating the fluid-structure interaction (FSI) of lost salt cores during the high-pressure die casting (HPDC) process. Utilizing the OpenFOAM C++ toolbox, a new solver class, FSI::compInterFluid, was implemented within the fsiFoam solver framework to handle compressible two-phase flow (molten metal and air) interacting with a deformable solid core. The solver was benchmarked against standard OpenFOAM solvers. The model was then applied to simulate the deformation of a salt core in a simplified casting geometry, with results showing core deformation and providing insights into the forces exerted by the melt. These simulation results were subsequently validated against experimental data obtained from actual die casting trials, demonstrating comparable core deformation and confirming the model's potential for assessing the viability of lost salt cores in HPDC.

3. Introduction:

High-pressure die casting (HPDC) is a critical manufacturing process for high-volume, low-cost automotive components like transmission housings and gearbox parts [1, 2]. In HPDC, liquid metal (typically aluminium or magnesium) is injected at high speed (50-100 m/s) and high pressure (up to 100 MPa) into a die. Employing lost salt cores to create undercuts or hollow sections (e.g., for cooling or oil-flow channels) has proven challenging [3, 4, 5, 6]. The use of salt as a material for lost cores has been proposed by machine manufacturers and automotive companies [7, 8]. Numerical simulation is identified as a method to determine the viability of this approach [9]. This paper focuses on modeling the deformation of such lost cores due to fluid-structure interaction during the HPDC process.

4. Summary of the study:

Background of the research topic:

The research is set against the backdrop of high-pressure die casting (HPDC), an essential process for automotive component manufacturing. There is an industrial interest in using lost salt cores to create complex internal geometries in cast parts, which can enhance design freedom for engineers. However, the successful implementation of salt cores in the harsh HPDC environment faces significant challenges.

Status of previous research:

Previous work and industrial experience indicate that it has been difficult to employ lost salt cores within the HPDC process [3]. While the idea of using salt cores has been put forward [7, 8], understanding their behavior under casting conditions is crucial. Numerical simulation is suggested as a key tool to evaluate the viability of lost salt cores [9].

Purpose of the study:

The primary purpose of this study is to develop and validate a numerical model capable of simulating the fluid-structure interactive deformation of lost salt cores during high-pressure die casting. This involves creating a solver that can accurately capture the complex physics of two-phase fluid flow and its interaction with the deformable core.

Core study:

The core of the study involves modeling the two-phase flow of molten metal and air and its interaction with a deformable salt core. This includes the development of a specific solver class within the OpenFOAM framework, FSI::compInterFluid, suitable for this fluid-structure interaction (FSI) problem. The study also includes benchmarking this new solver and validating the simulation results against experimental die casting trials.

5. Research Methodology

Research Design:

The research was designed in several stages:

- Mathematical modeling of the fluid (two-phase flow) and solid (salt core) domains.

- Development of a suitable numerical solver within the OpenFOAM framework by modifying existing libraries to handle the specific FSI problem.

- Benchmarking the newly developed solver against established solvers for verification.

- Application of the solver to a test case simulating lost core deformation in a simplified HPDC scenario.

- Experimental validation by conducting die casting experiments with salt cores and comparing the observed deformation with simulation predictions.

Data Collection and Analysis Methods:

Fluid Side Modeling:

The two-phase flow of molten metal and air was modeled using the Volume of Fluid (VOF) method [10]. The governing equations include:

- Continuity equation:

∂ρ/∂t + ∇·(ρU) = 0(1) - Momentum equation (Navier-Stokes):

∂(ρU)/∂t + ∇·(ρUU) = -∇p + ∇·{(μ + μ_tur)(∇U + (∇U)ᵀ)} + ρg + F_s(2) - VOF transport equation:

∂γ/∂t + ∇·(γU) + ∇·(γ(1-γ)U_r) = (γ/ρ_g) ∂ρ_g/∂t + (γ/ρ_g) U·∇ρ_g(3) (Note: The paper's equation (3) seems to have a typo on the right hand side regarding γ and ρg. The provided OCR is transcribed as accurately as possible. The text describes Ur as a supplementary velocity field for compressing the phase-interface by MULES [11,14]). - Material properties ρ (density) and μ (dynamic viscosity) are defined as:

ρ = γρ_l + (1-γ)ρ_g(4)μ = γμ_l + (1-γ)μ_g(5) - Air is treated as a barotropic fluid:

ρ_g = p/(R_sT) = pψ(6) - Turbulence was modeled using the Menter k-ω-SST model [15].

- Surface tension force

F_sis modeled by the Continuum Surface Force (CSF) method [13].

Solid Side Modeling:

The displacement D of the salt core is governed by the stress equation:

ρ_s ∂²D/∂t² - ∇·[(2μ_s + λ_s)∇D] = ∇·q(7)

whereρ_sis the solid density,λ_sandμ_sare Lamé parameters, andqis the load from fluid pressure and viscous forces.

Solver Development and Testing:

- The C++ toolbox OpenFOAM [17, 18] was used.

- The fsiFoam solver from the foam-extend project's fsi library [19] was chosen due to expected large deformations.

- A new solver class, FSI::compInterFluid, was developed by implementing the methodology of compressibleInterDyMFoam into a class compatible with the fsi fluid solver requirements. This involved modifying the standard PIMPLE algorithm.

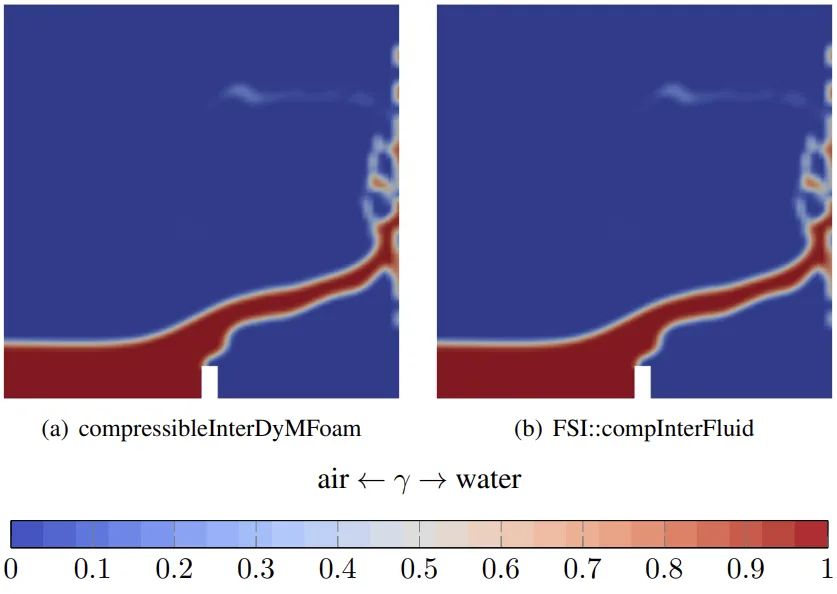

- The new solver class was benchmarked against the standard compressibleInterDyMFoam using a damBreak tutorial case.

Experimental Validation:

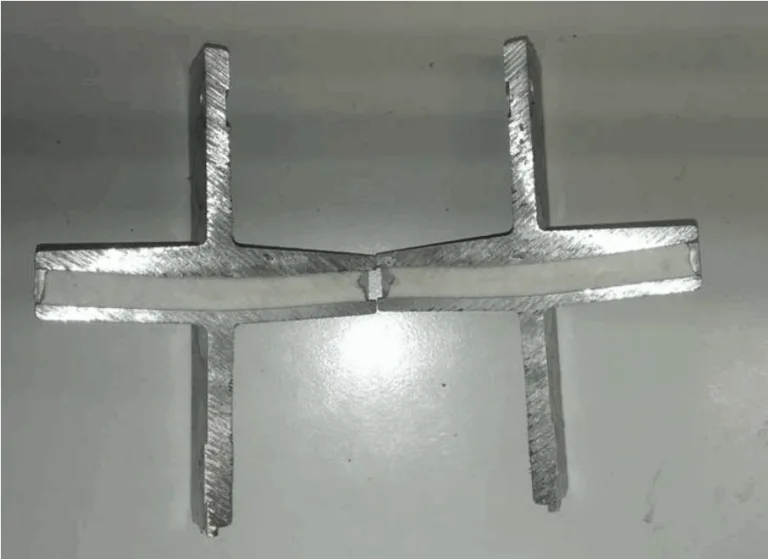

- An experimental die was constructed to resemble the geometry of the meshed body used in simulations (similar to a three-point bending test).

- The die was tested on a high-pressure die casting machine using the same process parameters as in the simulation.

- The deformation of the cast salt cores was observed and compared to simulation results.

Research Topics and Scope:

The research focuses on the modeling of fluid-structure interaction (FSI) involving compressible two-phase flow and a deformable lost salt core specifically within the context of high-pressure die casting. The scope includes the development, implementation, benchmarking, and experimental validation of a dedicated numerical solver for this purpose using OpenFOAM. The study aims to predict core deformation and understand the impact of melt flow on the core.

6. Key Results:

Key Results:

- A new solver class, FSI::compInterFluid, was successfully developed and implemented within the fsiFoam solver in OpenFOAM. This class adapts the methodology of compressibleInterDyMFoam for FSI applications.

- Benchmarking of FSI::compInterFluid against the standard compressibleInterDyMFoam for a damBreak case showed that both produce identical flow field results for the phase field (γ), validating the implementation of the fluid dynamics part of the new solver class (Figure 2).

- Simulations of a salt core in a simplified HPDC setup predicted a core deformation in the range of 2.5 mm shortly after the melt hit the core (Figure 3). The core was observed to vibrate initially and then get displaced constantly by the bypassing flow.

- Experimental validation was conducted using a specially designed die and actual HPDC process. The cast prototypes showed that the core gets symmetrically bent by the inflowing melt, with a displacement in the order of magnitude of more than 2 mm (Figure 4). This is comparable to the CFD simulation results.

- The study noted (citing unpublished research by the authors) that the highest expectable impact on the core occurs at the transition from the air phase to the melt phase at the core interface.

Figure Name List:

- Figure 1: Solving process scheme of fsiFoam Solver

- Figure 2: γ-field comparsion of compressibleInterDyMFoam and FSI::compInterFluid at 0,4 s

- Figure 3: The deformation of the salt core as result of the CFD simulation.

- Figure 4: The deformation of the salt core in a casting experiment.

7. Conclusion:

The research successfully demonstrated a methodology for modeling fluid-structure interactive lost core deformation in high-pressure die casting. A new solver class, FSI::compInterFluid, was developed within the OpenFOAM fsiFoam framework, enabling the simulation of compressible two-phase flow interacting with a deformable solid. The numerical simulations predicted core deformation that was found to be in good agreement with experimental results from actual die casting trials. This work provides a validated tool that can be employed to assess the viability of using lost salt cores in HPDC, potentially leading to greater design freedom in casting complex automotive components. The findings also highlight the critical impact on the core during the initial melt-air interface transition.

8. References:

- [1] B. Nogowizin, Theorie und Praxis des Druckgusses, 1. Edition ed. Berlin: Schiele und Schoen, 2010.

- [2] E. Brunnhuber, Praxis der Druckgussfertigung. Berlin: Schiele und Schoen, 1991.

- [3] B. Fuchs, H. Eibisch, and C. Körner, “Core viability simulation for salt core technology in high-pressure die casting," Int. J. Metalcasting, vol. 7, pp. 39–45, 2013.

- [4] E. Graf and G. Soell, “Vorrichtung zur Herstellung eines Druckgussbauteils mit einem Kern und einem Einlegeteil," 2003, dE Patent DE2,001,145,876.

- [5] E. D. I. Graf and G. D. I. Söll, “Verfahren zur Herstellung eines Zylinderkurbelgehäuses," 2008, dE Patent DE200,710,023,060.

- [6] S. Kohlstädt, U. Rabus, S. Goeke, and S. Kuckenburg, "Verfahren zur Herstellung eines metallischen Druckgussbauteils unter Verwendung eines Salzkerns mit integrierter Stützstruktur und hiermit hergestelltes Druckgussbauteil," 2016, dE Patent DE201,410,221,359.

- [7] P. Jelínek and E. Adámková, “Lost cores for high-pressure die casting," Archives of Foundry Engineering, vol. 14, no. 2, pp. 101–104, 2014.

- [8] T. Schneider, S. Kohlstädt, and U. Rabus, “Gehäuse mit Druckgussbauteil zur Anordnung eines elektrischen Fahrmotors in einem Kraftfahrzeug und Verfahren zur Herstellung eines Druckgussbauteils," 2016, dE Patent DE201,410,221,358.

- [9] B. Fuchs and C. Körner, "Mesh resolution consideration for the viability prediction of lost salt cores in the high pressure die casting process," Prog. Comp. Fluid Dyn., vol. 14, pp. 24–30, 2014.

- [10] C. W. Hirt and B. D. Nichols, "Volume of fluid (VOF) method for the dynamics of free boundaries,” J. Comp. Phys., vol. 39, pp. 201–225, 1981.

- [11] P. M. Ferrer, D. Causon, L. Qian, C. Mingham, and Z. Ma, “A multi-region coupling scheme for compressible and incompressible flow solvers for two-phase flow in a numerical wave tank," Computers & Fluids, vol. 125, pp. 116–129, 2016.

- [12] R. Mayon, Z. Sabeur, M.-Y. Tan, and K. Djidjeli, "Free surface flow and wave impact at complex solid structures," in 12th International Conference on Hydrodynamics, Egmond aan Zee, NL, 18 - 23 Sep 2016, 2016, p. 10pp.

- [13] J. Brackbill, D. B. Kothe, and C. Zemach, "A continuum method for modeling surface tension," Journal of computational physics, vol. 100, no. 2, pp. 335–354, 1992.

- [14] H. Rusche, “Computational fluid dynamics of dispersed two-phase flows at high phase fractions," Ph.D. dissertation, Imperial College London (University of London), 2003.

- [15] F. R. Menter, "2-equation eddy-viscosity turbulence models for engineering applications,” AIAA J., vol. 32, pp. 1598–1605, 1994.

- [16] E. Robertson, V. Choudhury, S. Bhushan, and D. Walters, "Validation of OpenFOAM numerical methods and turbulence models for incompressible bluff body flows," Computers & Fluids, vol. 123, pp. 122–145, 2015.

- [17] H. Jasak, A. Jemcov, and Z. Tukovic, “OpenFOAM: A C++ Library for Complex Physics Simulations," in International Workshop on Coupled Methods in Numerical Dynamics IUC, 2007.

- [18] H. G. Weller, G. Tabor, H. Jasak, and C. Fureby, “A tensorial approach to computational continuum mechanics using object-oriented techniques," Computers in Physics, vol. 12, no. 6, pp. 620–631, 1998.

- [19] P. Cardiff, Ž. Tuković, H. Jasak, and A. Ivanković, “A block-coupled finite volume methodology for linear elasticity and unstructured meshes,” Computers & structures, vol. 175, pp. 100–122, 2016.

9. Copyright:

- This material is a paper by "SEBASTIAN KOHLSTÄDT, MICHAEL VYNNYCKY, JAN JÄCKEL, LUDGER LOHRE". Based on "TOWARDS THE MODELING OF FLUID-STRUCTURE INTERACTIVE LOST CORE DEFORMATION IN HIGH-PRESSURE DIE CASTING".

- Source of the paper: Not provided in the source paper. (The paper is from The 13th OpenFOAM Workshop (OFW13) proceedings).

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.