This article introduces the paper ['The Impact of Increased Recycle Content on Microstructure, Tensile Properties and Hemming Capability in Automotive Al-Mg-Si Alloys'] submitted to the ['University of Pittsburgh']

1. Overview:

- Title: The Impact of Increased Recycle Content on Microstructure, Tensile Properties and Hemming Capability in Automotive Al-Mg-Si Alloys

- Author: Brian Thomas Kelley

- Publication Year: 2024

- Publishing Journal/Academic Society: University of Pittsburgh, Swanson School of Engineering (Master of Science Thesis)

- Keywords: Aluminum scrap utilization, Al-Mg-Si alloys, automotive applications, scrap-tolerant alloys, recycle content, microstructure, mechanical properties, tensile properties, hemming capability, thermomechanical processing, constituent phases, grain size, formability.

2. Research Background:

Background of the Research Topic:

The automotive industry's trend towards mass aluminization, starting in the mid-to-late 1980s, has led to increased use of aluminum alloys like 5XXX (Al-Mg) and 6XXX (Al-Mg-Si) series. 6XXX panels are utilized for applications requiring local formability and surface quality, such as body side and door outer panels, while high copper 6XXX alloys are used for components needing higher strength. The Ford F-series switch to an all-aluminum body solidified aluminum's widespread use. With increasing focus on recycling and scrap usage for cost and energy savings, understanding the impact of scrap utilization on aluminum alloy properties is crucial.

Status of Existing Research:

First-generation automotive aluminum alloys, adapted from aircraft and packaging alloys, offered satisfactory global formability and elongation but lacked local formability for sharp corners and bends, particularly in hemming operations. Modern hemming grades employ high levels of cold work and lower magnesium and silicon content to improve local formability. However, incorporating scrap introduces impurities like iron and manganese, which form intermetallic phases (e.g., Al12(Fe,Mn)3Si (a-phase) and Al9Fe2Si (β-phase)) that can negatively impact material properties. While pre-consumer scrap is generally high purity, post-consumer scrap is often contaminated, necessitating research into high recycle alloys.

Necessity of the Research:

The automotive industry's drive for sustainability and lower costs necessitates increased aluminum scrap utilization. However, the sensitivity of aluminum alloys to impurities in scrap streams poses challenges. This research is needed to elucidate the effects of increased recycle content, specifically iron and manganese, on the microstructure, mechanical properties, and hemming capability of automotive Al-Mg-Si alloys. Understanding how thermomechanical processing can mitigate negative impacts is crucial for developing scrap-tolerant alloys.

3. Research Purpose and Research Questions:

Research Purpose:

The primary objective of this study is to elucidate the effect of increased recycle content on the microstructure and mechanical properties of wrought Al-Mg-Si alloys intended for automotive applications. A further aim is to determine whether modifications in thermomechanical processing schedules can enhance the scrap tolerance of these alloys.

Key Research:

This research seeks to address the following key questions:

- How does increasing recycled scrap utilization affect the volume fraction of constituent phases and global ductility properties, specifically elongation to failure, in relation to Ford specifications?

- Can increasing the extent of cold work for a given scrap utilization level improve local formability properties, such as hem-ability?

- Will increasing the volume fraction of constituent phases, through particle stimulated nucleation, improve hem performance despite decreased ductility, due to decreased grain size?

- At high levels of scrap utilization, will decreased ductility outweigh the benefits of decreased grain size, resulting in decreased hem performance?

Research Hypotheses:

- Increasing the amount of recycled scrap utilization will increase the volume fraction of constituent phases, resulting in a reduction in global ductility properties, such as elongation to failure, below the Ford specification for the highest recycle content alloy.

- Increasing the extent of cold work for a given scrap utilization level will improve the local formability properties, such as hem-ability.

- Increasing volume fraction of constituent phases will result in particle stimulated nucleation in addition to decreased ductility. Moderate levels of scrap utilization will result in improved hem performance due to the decreased grain size.

- High levels of scrap utilization will result in decreased hem performance as the decreased ductility will outweigh the benefits of decreased grain size.

4. Research Methodology

Research Design:

This study employed an experimental design using three Al-Mg-Si alloys with varying recycle content: 0% (6XX0), 33% (6XX1), and 67% (6XX2). These alloys were derived from a hypothetical Ford F-150 post-consumer 6XXX scrap mixture. Each alloy was processed with three levels of cold reduction (70%, 80%, and 90%) and two heat treatment practices ("Equivalent Strength" and "Peak Strength").

Data Collection Method:

Data was collected through the following methods:

- Microscopy and Characterization: Optical metallography, Scanning Electron Microscopy (SEM), and Electron Backscatter Diffraction (EBSD) were used to evaluate alloy microstructure, phase distribution, and grain size.

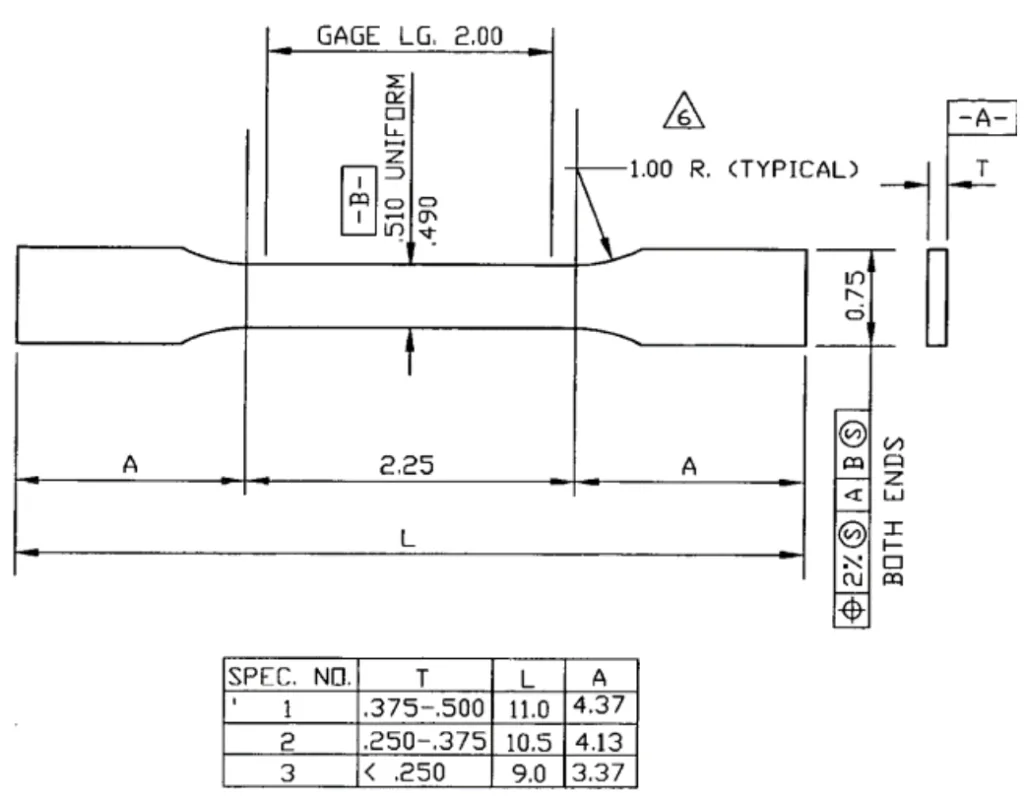

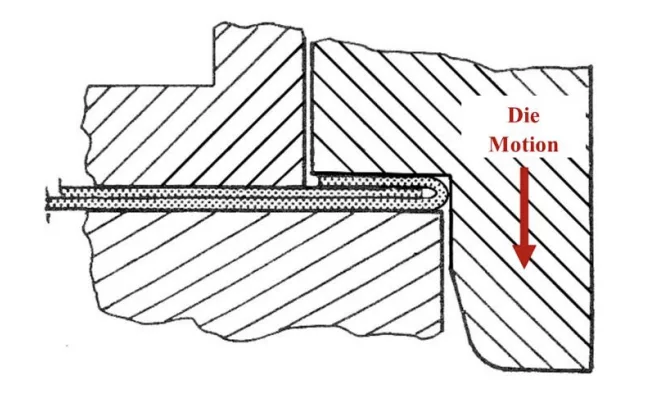

- Mechanical Testing: Uniaxial tensile testing (ASTM B557M) was conducted to measure tensile properties (Yield Strength, Tensile Strength, Uniform Elongation, Total Elongation, r-value, n-value). Ford flat hem testing and VDA bend testing were performed to assess formability and hemming capability.

Analysis Method:

- Microstructural Analysis: Optical microscopy and SEM images were used for qualitative and quantitative analysis of constituent phases and Mg2Si precipitates. EBSD data was used to determine grain size and texture. Image analysis software was used for phase quantification according to ASTM E1245-03.

- Tensile Data Analysis: Tensile test data was analyzed to determine yield strength, tensile strength, elongation, plastic strain ratio (r-value), and strain hardening exponent (n-value). Regression analysis was used to model the relationship between solution heat treatment time and yield strength.

- Formability Assessment: Ford flat hem test ratings were assigned based on a detailed rating scale (Table 8). VDA bend test results were quantified by measuring the bend angle at peak load.

Research Subjects and Scope:

The research focused on wrought Al-Mg-Si alloys designed for automotive exposed applications requiring hemming operations, specifically targeting a low copper 6XXX aluminum alloy grade meeting Ford WSS-M2A174-A2 specification. The scope included investigating the impact of 0%, 33%, and 67% recycle content, three levels of cold work (70%, 80%, 90%), and two heat treatment conditions on microstructure, tensile properties, and hemming performance over a natural aging period of up to 180 days.

5. Main Research Results:

Key Research Results:

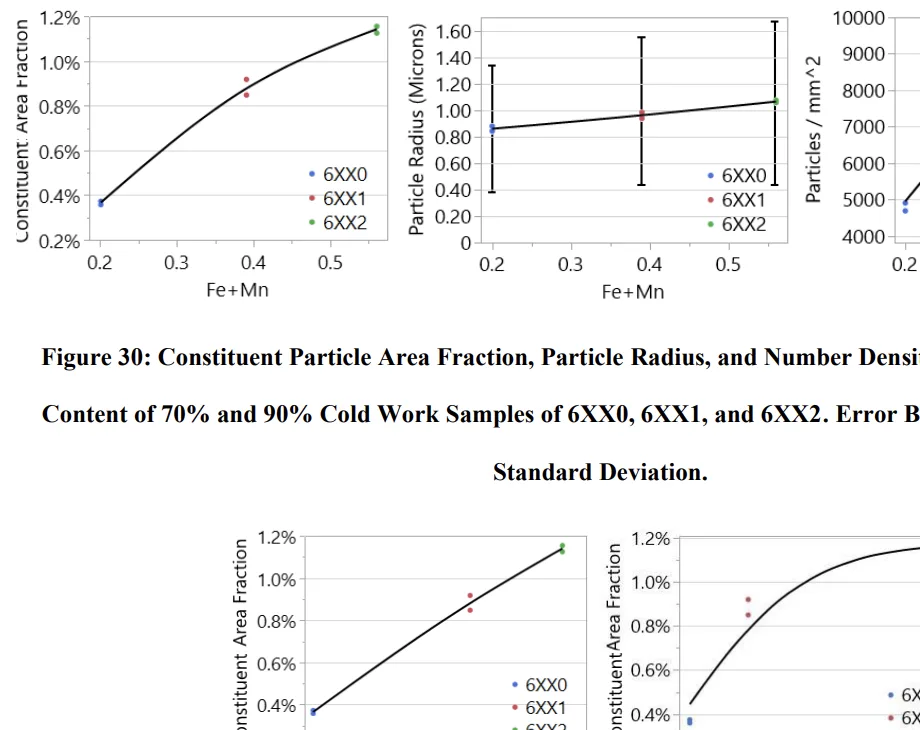

- Microstructure: Increased recycle content led to a linear increase in insoluble constituent phases (Al9Fe2Si and Al12(Fe,Mn)3Si). Grain size was refined with increasing scrap content up to 33%, with less refinement at 67%. Mg2Si precipitate levels were higher in 90% cold work samples compared to 70% cold work samples for all alloys.

- Tensile Properties: Yield strength decreased with increasing scrap utilization and cold work. Moderate scrap content alloy (6XX1) met Ford WSS-A175-A2 tensile specifications. High scrap content alloy (6XX2) showed reduced global formability, particularly in elongation and r-value, approaching or falling below Ford specification limits for certain properties. Control alloy (6XX0) exhibited more variability in yield strength compared to scrap-containing alloys.

- Hemming and Bend Performance: Control alloy (6XX0) showed the worst hem performance in Ford flat hem testing. Moderate and high scrap alloys (6XX1 and 6XX2) performed better in flat hemming, with 6XX2 typically performing best. VDA bend test results were contrary to hem test results, with control alloy outperforming scrap alloys. Increased cold work generally improved VDA bend angle.

Data Interpretation:

- Microstructure and Recycle Content: Increased recycle content directly increased the volume fraction of constituent particles, contributing to grain refinement, particularly at moderate scrap levels. The non-linear grain refinement with increasing scrap suggests a saturation effect in particle-stimulated nucleation. Variations in Mg2Si levels between cold work conditions indicate processing variations during hot rolling.

- Tensile Properties and Formability: While moderate scrap content (6XX1) maintained acceptable tensile properties and improved hemming, high scrap content (6XX2) negatively impacted global formability (elongation, r-value), potentially hindering stamping applications. The improved hem performance with scrap alloys, despite reduced global formability, suggests that local formability, influenced by grain refinement, is enhanced. The discrepancy between Ford flat hem and VDA bend test results highlights the influence of pre-strain in VDA testing, favoring alloys with better global formability metrics. The poorer hem performance of the control alloy, despite better tensile properties in VDA, suggests that grain refinement due to constituent particles in scrap alloys is beneficial for flat hemming.

Figure Name List:

- Figure 1: Various hem geometries, including the "3t" rope hem common in early door/closure design and the "3t" flat hem that is common in modern vehicles. [21]

- Figure 2: Ingot Homogenization Thermal Trace.

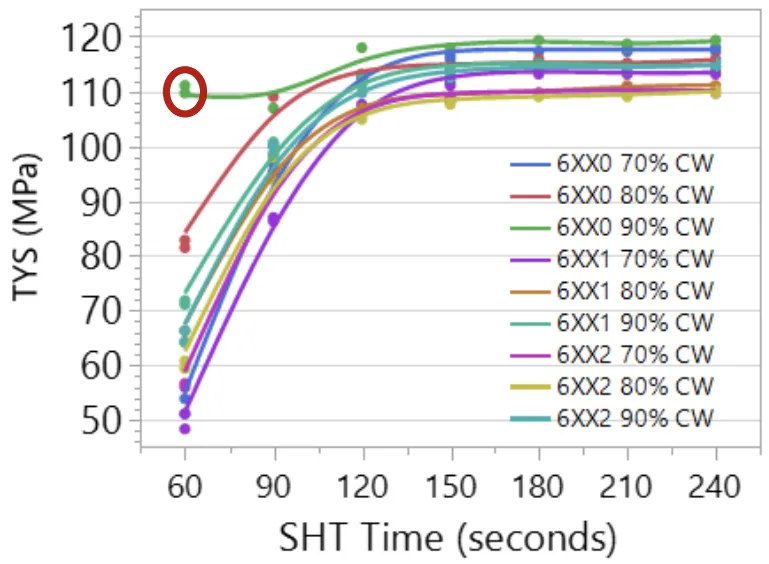

- Figure 3: Yield Strength vs Solution Heat Treatment Time Plot for HT Regression Trial.

- Figure 4: ASTM B557M 50mm Gauge Length r&n Tensile Specimen.

- Figure 5: Ford Flat Hem Down Flange Step

- Figure 6: Ford Flat Hem Pre-Hem Step

- Figure 7: Ford Flat Hem Test Final Step…

- Figure 8: Ford Flat Hem Rating Scale from 1 to 4 per Ford BB 115-01

- Figure 9: Schematic of VDA Bend Test Performed on 6XX0, 6XX1, and 6XX2 Samples ..

- Figure 10: 100X Optical Micrograph of L-ST Plane of 6XX0-T4, 80% CW in As-Polished Condition (top) and Etched Condition (bottom)

- Figure 11: 100X Optical Micrograph of L-ST Plane of 6XX0-T4, 80% CW in Electropolished and Anodized Condition…

- Figure 12: 1000X Electron Micrograph of L-ST Plane of 6XX0-T4, 70% CW.

- Figure 13: Representative inverse pole figure map of 6XX0-T4, 80% CW

- Figure 14: 100X Optical Micrographs of As-Cast Samples of 6XX0, 6XX1, and 6XX2 in Etched Condition

- Figure 15: 500X L-ST images at T/2 of F-temper Samples in As-Polished Condition. Scale Bars Indicate 50 μm..

- Figure 16: 500X L-ST Images at T/2 in As-Polished Condition of Equivalent Strength Samples. Scale bars indicate 50 microns. Contrast increased 25% to improve particle visibility.

- Figure 17: 100X L-ST Images at T/2 in Electro-polished and Anodized Condition of Equivalent Strength Samples. Scale bars indicate 200 m.

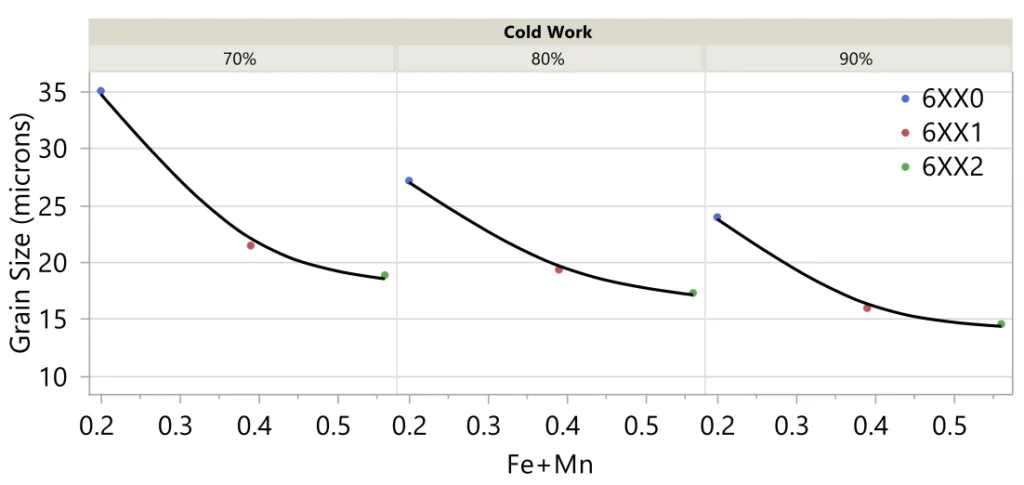

- Figure 18: Number-Weighted Average Grain Size of "Equivalent Strength" Lots as measured by Electron Backscatter Diffraction. Error Bars Reflect Number Weighted Grain Size Standard Deviation

- Figure 19: Yield Strength Natural Aging Curves of "Equivalent Strength" Lots in L and LT Directions. Ford Specification Limit Indicated by the Dashed Lines.

- Figure 20: Yield Strength Natural Aging Curves of "Peak Strength" Lots in L and LT Directions. Ford Specification Limit Indicated by the Dashed Lines.

- Figure 21: Tensile Strength Natural Aging Curves of "Equivalent Strength" Lots in L and LT Directions. Ford Specification Limit Marked by Dashed Lines.

- Figure 22: Tensile Strength Natural Aging Curves of "Peak Strength" Lots in L and LT Directions. Ford Specification Limit Marked by Dashed Lines.

- Figure 23: Average Uniform Elong. by Lot and Direction. Ford Spec. Marked by Dashed Line….

- Figure 24: Average Total Elongation by Lot and Direction.

- Figure 25: Average r-value (plastic strain ratio) @ 10% Elongation by Lot and Direction. Ford Specification Limit Marked by Dashed Line.

- Figure 26: Average n-value (strain hardening exponent) from 10% to 20% Elongation by Lot and Direction. Ford Specification Limit Marked by Dashed Line………………

- Figure 27: Flat Hem Simulation Results for each lot at 30 Days, 90 Days, and 180 Days Natural Age. Labeled Direction Indicated direction in which samples were cut. Ford Specification Limits marked by Dashed Line.

- Figure 28: Flat Hem Simulation Sample Images of Equivalent Strength Lots, Tested at 30 Days, 90 Days, and 180 Days of Natural Age. Samples were cut in Longitudinal Direction…

- Figure 29: VDA Bend Test Results of Equivalent Strength Samples, Tested at 30 Days, 90 Days, and 150 Days of Natural Age. Labeled Direction indicates the direction in which were cut.

- Figure 30: Constituent Particle Area Fraction, Particle Radius, and Number Density vs. Total Fe and Mn Content of 70% and 90% Cold Work Samples of 6XX0, 6XX1, and 6XX2. Error Bars Mark Particle Size Standard Deviation.

- Figure 31: Constituent Particle Area Fraction vs. separated Fe, Mn Content of 70% and 90% Cold Work Samples of 6XX0, 6XX1, and 6XX2.

- Figure 32: Magnified SEM Image of 6XX2 with a Dispersoid and Constituent Phases Labeled

- Figure 33: Number Weighted Grain size vs. Combined Fe and Mn content by Cold work Percentage.

- Figure 34: Uniform Elongation and Total Elongation of Equivalent Strength Lots Showing Large Impact of Increased Scrap Usage on Total Elongation.

- Figure 35: L and LT Stress Strain curves from Equivalent Strength Lots with OGL failure of E3370 LT Specimen.

6. Conclusion:

Summary of Main Results:

This study concludes that increasing recycle content in Al-Mg-Si alloys leads to increased insoluble phases and grain refinement, particularly at moderate levels. While moderate recycle content (33% scrap) alloys maintained acceptable tensile properties and improved hemming performance in Ford flat hem testing, high recycle content (67% scrap) alloys exhibited reduced global formability, potentially limiting their use in stamping applications. Ford flat hem testing indicated improved hem performance with increased scrap content, contrary to VDA bend test results which favored the control alloy. Moderate cold work (80% and 90%) in the 33% scrap alloy (6XX1) demonstrated the best balance of properties, meeting Ford specifications and showing improved hem performance.

Academic Significance of the Research:

This research contributes to the understanding of the complex interplay between recycle content, microstructure, mechanical properties, and formability in automotive Al-Mg-Si alloys. It highlights the non-linear effects of scrap additions on grain refinement and the contrasting performance in different formability tests, providing valuable insights for designing scrap-tolerant alloys and optimizing thermomechanical processing.

Practical Implications:

The findings suggest that moderate levels of scrap utilization (e.g., 33%) in Al-Mg-Si alloys can be implemented in automotive applications, particularly for components requiring good local formability like hemming, without compromising tensile properties. However, high levels of scrap utilization (e.g., 67%) may be detrimental for applications requiring high global formability, necessitating careful consideration of alloy composition and processing parameters. Thermomechanical processing modifications, particularly cold work, can be used to optimize the performance of moderate scrap content alloys.

Limitations of the Research

Limitations of this study include the use of laboratory-scale processing, which may introduce variations not representative of plant-scale production. Variability in the Ford flat hem test was observed. Phase quantification was limited to 70% and 90% cold work conditions. Texture evolution was not explicitly investigated.

7. Future Follow-up Research:

- Directions for Follow-up Research

Future research should focus on: - Investigating the effect of recycle content on texture evolution during thermomechanical processing to better understand its impact on formability, particularly in relation to directional properties.

- Refining thermomechanical processing strategies, including hot rolling and heat treatment cycles, to further optimize the properties of high recycle content alloys and mitigate negative impacts on global formability.

- Optimizing alloy composition, specifically Mg, Si, and Cu content, in conjunction with varying Fe and Mn levels from scrap, to achieve improved property balance in high recycle content alloys.

- Areas Requiring Further Exploration

Further exploration is needed in: - Plant-scale processing of high recycle content alloys to validate laboratory findings and assess process variability in industrial settings.

- Detailed analysis of texture evolution and its correlation with formability performance in scrap-containing alloys.

- Investigating the role of dispersoid phases in grain refinement and their impact on overall alloy properties.

8. References:

- [1] Aiura, T., & Sakurai, T. (2010). Development of Aluminum Alloys and New Forming Technology for Automotive Parts.

- [2] ALCOA ALLOY 6022. (2009). Alloy Digest, 58(4). https://doi.org/10.31399/asm.ad.al0421

- [3] Burger, G. B., Gupta, A. K., Jeiirey, ? W, & Lloyd, D. J. (1995). Microstructural Control of Aluminum Sheet Used in Automotive Applications.

- [4] Choate, W. T., & Green, J. A. S. (2003). U.S. energy requirements for aluminum production: Historical perspective, theoretical limits and new opportunities. TMS Annual Meeting.

- [5] Das, S. K., Green, J. A. S., & Kaufman, J. G. (2007). The development of recycle-friendly automotive aluminum alloys. In JOM (Vol. 59, Issue 11). https://doi.org/10.1007/s11837-007-0140-2

- [6] Dewang, Y., & Sharma, V. (2019). A study on sheet metal hemming process. Materials Today: Proceedings, 27. https://doi.org/10.1016/j.matpr.2019.09.074

- [7] Engler, O., Marioara, C. D., Hentschel, T., & Brinkman, H. J. (2017). Influence of copper additions on materials properties and corrosion behaviour of Al-Mg alloy sheet. Journal of Alloys and Compounds, 710. https://doi.org/10.1016/j.jallcom.2017.03.298

- [8] Furu, T., Telioui, N., Behrens, C., Hasenclever, J., & Schaffer, P. (2010). Trace elements in aluminium alloys: their origin and impact on processability and product properties. Proceedings of the 12 ICAA, 282–289. http://www.icaa-conference.net/ICAA12/pdf/KL-10.pdf

- [9] Hatch, John E. (1984). Aluminum: Properties and Physical Metallurgy ASM International. In Aluminum Science and Technology.

- [10] Hirsch, J. (2006). Virtual fabrication of aluminium products : microstructural modeling in industrial aluminum production. Wiley-VCH.

- [11] Ji, S., Yang, W., Gao, F., Watson, D., & Fan, Z. (2013). Effect of iron on the microstructure and mechanical property of Al-Mg-Si-Mn and Al-Mg-Si diecast alloys. Materials Science and Engineering: A, 564, 130–139. https://doi.org/10.1016/j.msea.2012.11.095

- [12] Kaffl, R. (2023, December 28). FORD F-SERIES: AMERICA'S BEST-SELLING TRUCK FOR 47 YEARS AND COUNTING. Ford Media Center.

- [13] Khan, M. H., Das, A., Li, Z., & Kotadia, H. R. (2021). Effects of Fe, Mn, chemical grain refinement and cooling rate on the evolution of Fe intermetallics in a model 6082 Al-alloy. Intermetallics, 132, 107132. https://doi.org/10.1016/j.intermet.2021.107132

- [14] Kishchik, M. S., Mochugovskiy, A. G., Cuda, M., Kishchik, A. A., & Mikhaylovskaya, A. v. (2023). Particle Stimulated Nucleation Effect for Al-Mg-Zr-Sc Alloys with Ni Addition during Multidirectional Forging. Metals, 13(8), 1499. https://doi.org/10.3390/met13081499

- [15] Laughlin, D. E., Miao, W. F., Karabin, L. M., & Chakrabarti, D. J. (1998). Effects of Cu and Mn content and processing on precipitation hardening behavior in Al-Mg-Si-Cu alloy 6022. TMS Annual Meeting.

- [16] Mracna, C. (2014). Engineering Material Specification: Aluminum Alloy, Sheet, Heat Treatable, Enhanced Bake Response. www.gma.ford.com

- [17] Mracna, C. (2014). Flat Hem Test Procedure for Aluminum Alloy Sheet. www.gma.ford.com

- [18] Mracna, C., Sinclair, L., & Wetekamp, L. (2022). Engineering Material Specification, Heat Treatable, Structural, High Strength, Thick Gauge. www.gma.ford.com

- [19] New sorting system for separating aluminium alloys. (2016, October 17). Recycling-Magazine. https://www.recycling-magazine.com/2016/10/17/new-sorting-system-for-separating-aluminium-alloys/

- [20] Raabe, D., Ponge, D., Uggowitzer, P. J., Roscher, M., Paolantonio, M., Liu, C., Antrekowitsch, H., Kozeschnik, E., Seidmann, D., Gault, B., de Geuser, F., Deschamps, A., Hutchinson, C., Liu, C., Li, Z., Prangnell, P., Robson, J., Shanthraj, P., Vakili, S., Pogatscher, S. (2022). Making sustainable aluminum by recycling scrap: The science of "dirty" alloys. Progress in Materials Science, 128, 100947. https://doi.org/10.1016/j.pmatsci.2022.100947

- [21] Shang, J., Wilkerson, L., & Hatkevich, S. (2011). Hemming of aluminum alloy sheets using electromagnetic forming. Journal of Materials Engineering and Performance, 20(8). https://doi.org/10.1007/s11665-011-9988-y

- [22] VDA Empfehlung 238-100 / VDA Recommendation 238-100 Plättchen-Biegeversuch für metallische Werkstoffe Plate bending test for metallic materials VDA 238-100. (2017). www.vda.de

- [23] Zhu, Y., Chappuis, L. B., de Kleine, R., Kim, H. C., Wallington, T. J., Luckey, G., & Cooper, D. R. (2021). The coming wave of aluminum sheet scrap from vehicle recycling in the United States. Resources, Conservation and Recycling, 164. https://doi.org/10.1016/j.resconrec.2020.105208

9. Copyright:

- This material is "Brian Thomas Kelley"'s paper: Based on "The Impact of Increased Recycle Content on Microstructure, Tensile Properties and Hemming Capability in Automotive Al-Mg-Si Alloys".

- Paper Source: DOI URL (Note: DOI URL might not be available as this is a thesis document. University repository URL can be used if available).

This material was summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.