This article introduces the paper "Improving Electrical Conductivity of Commercially Pure Aluminium: The Synergistic Effect of AlB8 Master Alloy and Heat Treatment" presented at the "MDPI Materials"

1. Overview:

Title: Improving Electrical Conductivity of Commercially Pure Aluminium: The Synergistic Effect of AlB8 Master Alloy and Heat Treatment

Authors: Yusuf Zeybek, Cemile Kayış, and Ege Anıl Diler

Publication Year: 2025

Publishing Journal: Materials (MDPI)

Keywords: commercially pure aluminium, electrical conductivity, aluminium-boron master alloy, grain-coarsening heat treatment, efficiency of electrical motor

2. Research Background:

In the context of escalating global energy demands and the imperative to mitigate greenhouse gas emissions, enhancing energy efficiency has become a paramount concern. Electric motors, extensively utilized across industrial and commercial sectors, present a significant opportunity for efficiency improvements. Commercially pure aluminium (CP-Al) is frequently employed in the fabrication of squirrel cage rotors for induction motors owing to its advantageous low density and cost-effectiveness. However, the inherent electrical conductivity of aluminium, while substantial, can be further optimized to enhance motor performance.

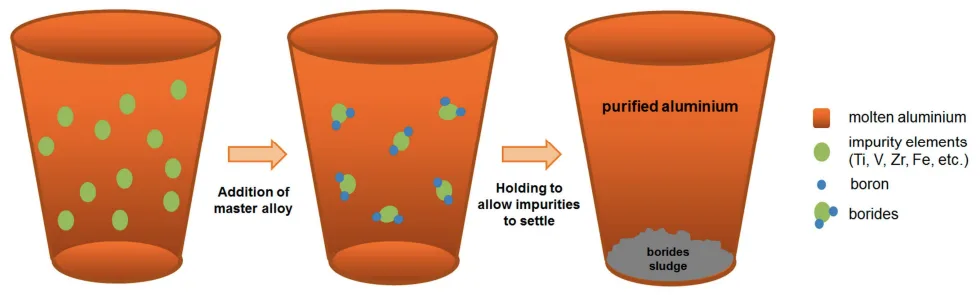

Existing methodologies for improving the electrical conductivity of aluminium often involve the utilization of rare earth elements. While effective, these approaches are associated with considerable cost implications. Aluminium-boron (Al-B) master alloys offer a more economical alternative for impurity reduction in aluminium. Nevertheless, the application of Al-B master alloys can induce grain refinement, potentially counteracting the desired enhancement in electrical conductivity due to increased grain boundary scattering. Therefore, a critical need exists for a cost-effective strategy that not only leverages the impurity removal capabilities of Al-B master alloys but also mitigates the grain refining effect to maximize the electrical conductivity of CP-Al for electric motor applications.

3. Research Purpose and Research Questions:

This research endeavors to significantly improve the electrical conductivity of commercially pure aluminium. The primary objective is to minimize both impurities and grain boundaries within the aluminium microstructure, thereby enhancing the efficiency of electric motors utilizing squirrel cage rotors made from this material.

The key research questions addressed in this study are:

- How does the incorporation of an AlB8 master alloy influence the purity level and electrical conductivity of commercially pure aluminium?

- What is the effect of a grain-coarsening heat treatment on the grain size and electrical conductivity of commercially pure aluminium?

- Does a synergistic effect exist between the addition of AlB8 master alloy and grain-coarsening heat treatment in enhancing the electrical conductivity of commercially pure aluminium?

- To what extent does the improvement in electrical conductivity translate to enhanced efficiency in electric motors?

The central research hypothesis posits that the combined application of AlB8 master alloy addition and a subsequent grain-coarsening heat treatment will synergistically and significantly elevate the electrical conductivity of commercially pure aluminium, ultimately leading to a measurable improvement in the efficiency of electric motors.

4. Research Methodology

This study employed a rigorous research methodology based on statistical experimental design and response surface methodology, utilizing the Box–Behnken design.

- Research Design: A Box–Behnken experimental design was implemented to investigate the effects of three factors: boron addition level, heat treatment temperature, and holding time, on the electrical conductivity of commercially pure aluminium.

- Data Collection Method: Electrical conductivity measurements were performed using a SIGMASCOPE® SMP10 instrument, employing the eddy current method as per DIN EN 2004–1 and ASTM E1004-17 standards. Microstructural characterization was conducted via optical microscopy, with grain size analysis performed using ImageJ software. Motor performance evaluations were carried out using KISTLER motor testing equipment. Chemical composition analysis was achieved through optical emission spectrometry.

- Analysis Method: Analysis of Variance (ANOVA) and regression analysis, facilitated by Design Expert Version 13 software, were utilized to assess the statistical significance of the factors and their interactions on electrical conductivity. Response surface plots and contour plots were generated to visualize the relationships between variables and the response.

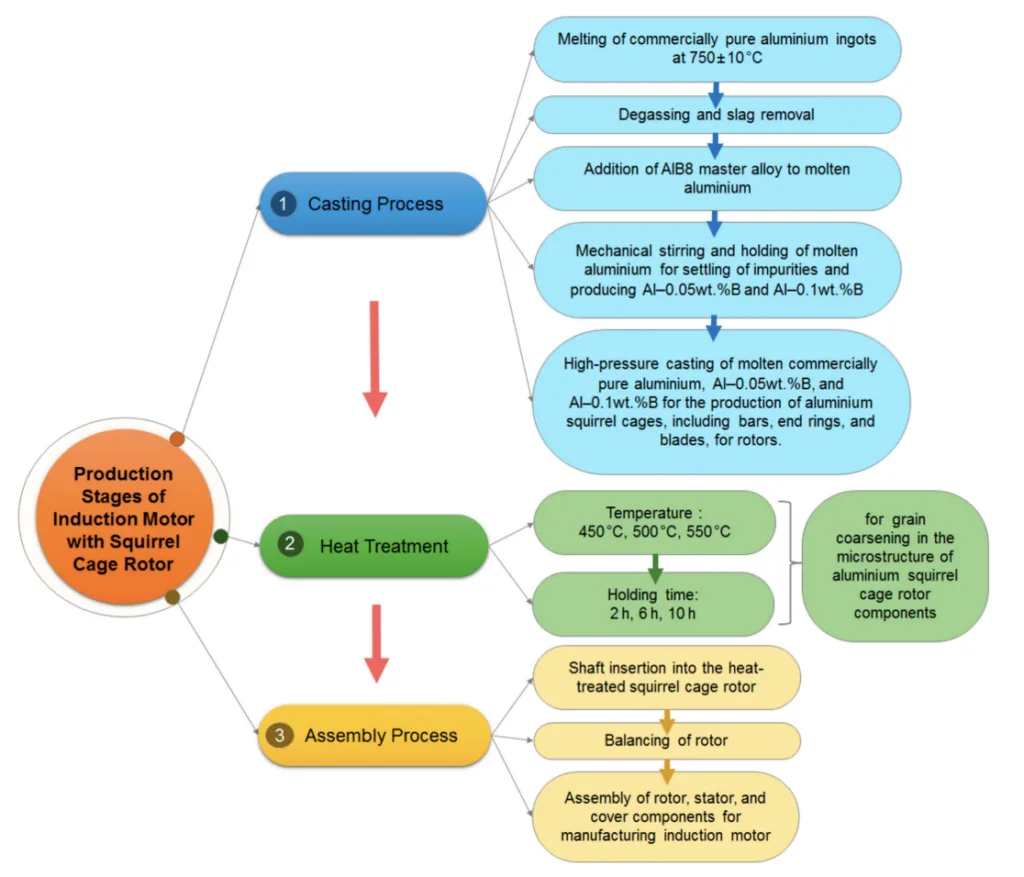

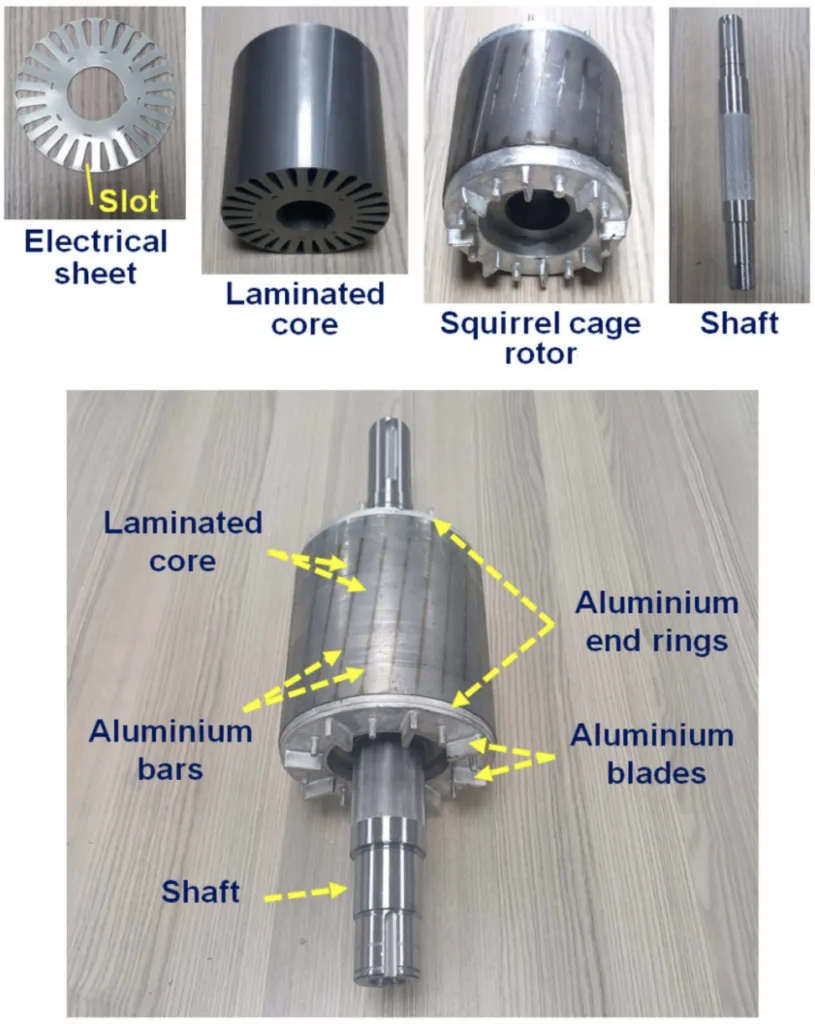

- Research Subjects and Scope: The study focused on commercially pure aluminium with a purity of 99.7%. An AlB8 master alloy was introduced to achieve boron additions of 0.05 wt.% and 0.1 wt.%. Squirrel cage rotors were manufactured using high-pressure die-casting. Grain-coarsening heat treatments were conducted at temperatures of 450 °C, 500 °C, and 550 °C, with holding times of 2 h, 6 h, and 10 h.

5. Main Research Results:

The experimental results demonstrated a significant enhancement in the electrical conductivity of commercially pure aluminium through the synergistic application of AlB8 master alloy addition and grain-coarsening heat treatment.

- Key Research Results: The most significant improvement in electrical conductivity was achieved with a combination of 0.05 wt.% boron addition and a grain-coarsening heat treatment at 550 °C for 10 h. This hybrid approach increased the electrical conductivity from an initial 60.62% IACS to 63.1% IACS. Correspondingly, the efficiency of electric motors fabricated with rotors produced using this method increased from 90.35% to 91.53%. Spectral analysis confirmed that boron addition effectively reduced impurities, particularly transition metals like Titanium (Ti), Vanadium (V), and Zirconium (Zr). Microstructural analysis revealed that heat treatment effectively promoted grain coarsening, reducing grain boundary density.

- Statistical/Qualitative Analysis Results: ANOVA indicated that boron addition, heat treatment temperature, holding time, and their quadratic and interaction effects (excluding the interaction between boron addition and holding time) significantly influenced electrical conductivity (p < 0.05). The regression model exhibited a high coefficient of determination (R² = 0.9859), indicating a strong model fit.

- Data Interpretation: The enhanced electrical conductivity is attributed to the combined effects of impurity removal by boron addition and the reduction of grain boundary scattering through grain coarsening heat treatment. The synergistic effect underscores the importance of optimizing both material purity and microstructure for achieving superior electrical performance.

Figure Name List:

- Figure 1. Diagram illustrating the production stages of squirrel cage rotors, heat treatment application, and subsequent manufacturing stages of induction electric motors.

- Figure 2. Schematic illustration of impurity removal through boron addition.

- Figure 3. Squirrel cage rotor and its components manufactured from commercially pure aluminium via the high-pressure casting method.

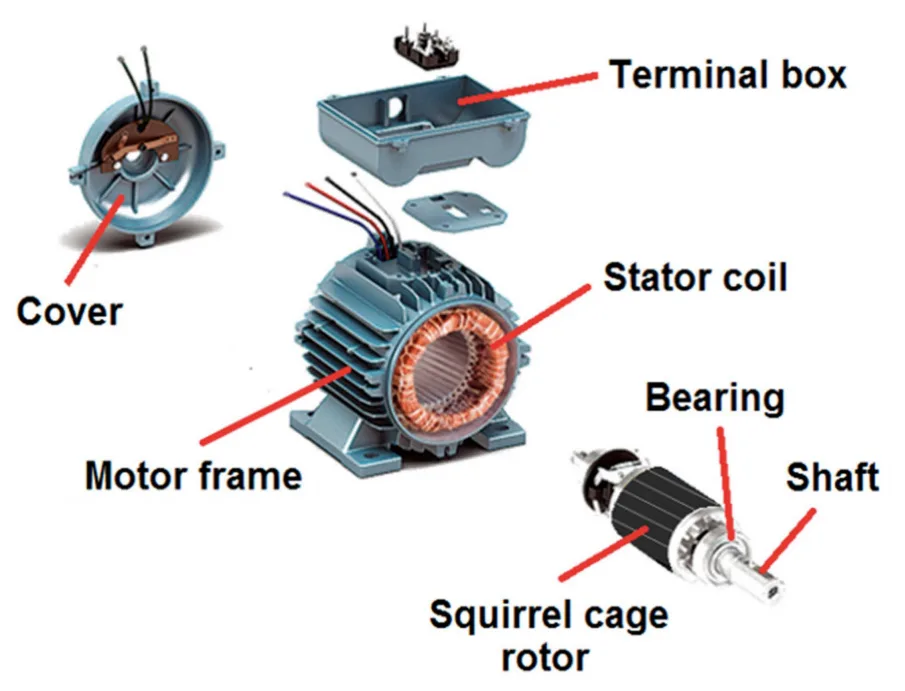

- Figure 4. Assembly of induction motor with a squirrel cage rotor.

- Figure 5. Electrical conductivity measurement for the aluminium specimens.

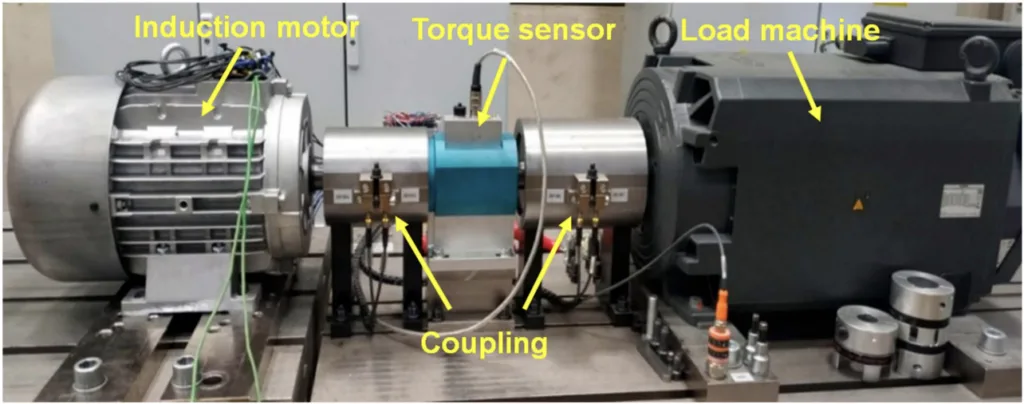

- Figure 6. Performance testing of induction motors.

- Figure 7. Box-Behnken design cube with the centre point (0,0,0) and twelve factorial points of three factors, each at three levels.

- Figure 8. Optical micrographs of the non-treated and heat-treated aluminium specimens.

- Figure 9. Grain size analysis of the non-heat-treated aluminium specimens.

- Figure 10. Grain size analysis of the heat-treated Al-0.05B specimens.

- Figure 11. Contributions of linear, quadratic, and interaction terms affecting electrical conductivity.

- Figure 12. Correlation graph between the predicted and experimental values of electrical conductivity.

- Figure 13. Main effect plots of boron addition, heat treatment temperature, and holding time on electrical conductivity.

- Figure 14. Two-dimensional contour plot and 3D response surface plot showing the effect of interactions on electrical conductivity.

- Figure 15. Relation between the motor efficiency and electrical conductivity of non-treated and heat-treated aluminium specimens.

6. Conclusion and Discussion:

- Summary of Main Results: This study successfully demonstrated that a hybrid approach combining AlB8 master alloy addition and grain-coarsening heat treatment is an effective method for enhancing the electrical conductivity of commercially pure aluminium, leading to a notable improvement in electric motor efficiency.

- Academic Significance of the Research: The research contributes to the fundamental understanding of synergistic material processing techniques for optimizing metal conductivity. It highlights the interplay between impurity control and microstructure engineering in achieving enhanced electrical properties.

- Practical Implications: The findings offer a viable and cost-effective methodology for improving the performance of electric motors utilizing commercially pure aluminium. This approach has significant practical implications for enhancing energy efficiency in various industrial applications and promoting sustainable manufacturing practices.

- Limitations of the Research: While the study effectively addressed electrical conductivity enhancement, it did not primarily focus on the mechanical properties of the modified aluminium. The applicability of pure aluminium, even with enhanced conductivity, may be limited in scenarios demanding high mechanical strength.

7. Future Follow-up Research:

- Directions for Follow-up Research: Future research should focus on further enhancing the mechanical properties of commercially pure aluminium while maintaining or improving the achieved electrical conductivity. This could involve exploring different alloying additions or alternative heat treatment regimes.

- Areas Requiring Further Exploration: Further investigation is warranted to assess the impact of this hybrid approach on other critical material properties, such as thermal conductivity and corrosion resistance. Exploring the broader industrial applications of this enhanced commercially pure aluminium in diverse sectors, including automotive and energy, is also recommended.

8. References:

- [1] De Almeida, A.T.; Ferreira, F.J.T.E.; Fong, J. Perspectives on electric motor market transformation for a net zero carbon economy. Energies 2023, 16, 1248.

- [2] Li, Z.; Hamidi, A.S.; Yan, Z.; Sattar, A.; Hazra, S.; Soulard, J.; Guest, C.; Ahmed, S.H.; Tailor, F. A circular economy approach for recycling electric motors in the end-of-life vehicles: A literature review. Resour. Conserv. Recycl. 2024, 205, 107582.

- [3] Mahale, M.D.; Patra, B.B. Efficient design, materials and specifications of electric motors used in electric vehicle challenges. In Energy Efficient Vehicles: Technologies and Challenges, 1st ed.; Singh, V.P., Kumar, A., Meena, C.S., Dwivedi, G., Eds.; CRC Press: Boca Raton, FL, USA, 2024; pp. 126–155.

- [4] Paul, K.; Sharma, D.; Konda, K.R.; Xie, T.; Höschler, K. Comprehensive review on cooling of permanent magnet synchronous motors and their qualitative assessment for aerospace applications. Energies 2023, 16, 7524.

- [5] Grassmann, R.M.; Shentu, C.; Hamoda, T.; Dewi, P.T.; Burgner-Kahrs, J. Open continuum robotics-one actuation module to create them all. Front. Robot. Al 2024, 11, 1272403.

- [6] Sun, B.; Zhang, Q.; Mao, H.; Li, Z. Validation of a statistical-dynamic framework for predicting energy consumption: A study on vehicle energy conservation equation. Energy Convers. Manag. 2024, 307, 118330.

- [7] Krzysztof, P.; Wnęk, H. Analysis of energy flow in hybrid and electric-drive vehicles. Energies 2024, 17, 1915.

- [8] Krishnamoorthy, S.; Panikkar, P.P.K. A comprehensive review of different electric motors for electric vehicles application. Int. J. Power Electron. Drive Syst. 2024, 15, 74–90.

- [9] Tong, W. Mechanical Design and Manufacturing of Electric Motors, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2022; pp. 1–94.

- [10] Gobbi, M.; Sattar, A.; Palazzetti, R.; Mastinu, G. Traction motors for electric vehicles: Maximization of mechanical efficiency—A review. Appl. Energy 2024, 357, 122496.

- [11] Kumar, P.; Channi, H.K.; Singh, H. A Comprehensive Review of Electrical Motors for Electric Mobility. In Proceedings of 2024 IEEE International Conference for Women in Innovation, Technology & Entrepreneurship (ICWITE), Bangalore, India, 16–17 February 2024; pp. 130–135.

- [12] Manohar, V.J. Advantages and disadvantages of brushless DC motor. In Electrical Devices & Systems; Reddy, K.S., Ed.; CIIR Research Publications: Uttar Pradesh, India, 2023; pp. 20–22.

- [13] Mishra, A.; Agarwal, P.; Srivastava, S.P. A comprehensive analysis and implementation of vector control of permanent magnet synchronous motor. Int. J. Power Energy Convers. 2014, 5, 1–23.

- [14] Pindoriya, R.M.; Rajpurohit, B.S.; Kumar, R.; Srivastava, K.N. Comparative Analysis of Permanent Magnet Motors and Switched Reluctance Motors Capabilities for Electric and Hybrid Electric Vehicles. In Proceedings of 2018 IEEMA Engineer Infinite Conference (eTechNxT), New Delhi, India, 13–14 March 2018.

- [15] Jape, S.R.; Thosar, A. Comparison of electric motors for electric vehicle application. Int. J. Res. Eng. Technol. 2017, 6, 12–17.

- [16] Dimitrios, R.; Kaminaris, S.D.; Piromalis, D.D.; Vokas, G.; Arvanitis, K.G.; Karavas, C.S. Comparative review of motor technologies for electric vehicles powered by a hybrid energy storage system based on multi-criteria analysis. Energies 2023, 16, 2555.

- [17] Basma, B.; Cheghib, H.; Chrenko, D.; Delgado, M.T.; Hamoudi, Y.; Rodriguez, J.; Abdelrahem, M. Sliding mode control of an electric vehicle driven by a new powertrain technology based on a dual-star induction machine. World Electr. Veh. J. 2024, 15, 155.

- [18] Kurt, M.Ş. The use of induction motors in electric vehicles. In Induction Motors—Recent Advances, New Perspectives and Applications; El-Shahat, A., Ed.; IntechOpen: London, UK, 2023; pp. 1–10.

- [19] Thirugnanam, P. Advances, new perspective and applications in induction motors. In Induction Motors—Recent Advances, New Perspectives and Applications; El-Shahat, A., Ed.; IntechOpen: London, UK, 2023; pp. 1–15.

- [20] Su, H.; Wen, H.; Zheng, X.; Su, J. Development of a super high efficiency motor with boron aluminum alloy rotor. Procedia Eng. 2017, 174, 1221–1228.

- [21] Shadfari, H.; Izadfar, H.R. A new squirrel cage rotor structure to improve the dynamic performance of the single-phase induction motor. Int. J. Ind. Electron. Control. Optim. 2022, 5, 279–286.

- [22] Nandagopal, S.; Chokkalingam, L.N. Influence of squirrel cage induction rotor geometry in battery C-rating. Eng. Sci. Technol. 2023, 39, 101336.

- [23] Luthfiyah, H.; Qowiy, O.A.; Malakani, A.I.; Arthanto, D.H.; Setiawan, F.D.; Ramanel, T.A.; Putra, G.M.; Kamar, S.; Suryandi, A.A. An optimized stator and rotor design of squirrel cage induction motor for EMU train. J. Mechatron. Electr. Power Veh. Technol. 2023, 14, 35–46.

- [24] Wang, L.; Bao, X.; Di, C.; Zhou, Y. Influence on vibration and noise of squirrel-cage induction machine with double skewed rotor for different slot combinations. IEEE Trans. Magn. 2016, 52, 8104404.

- [25] Balcı, M.Ş.; Dalcalı, A. The effect of rotor slot number on the performance of asynchronous motors in light electric vehicle. Aintelia Sci. Notes 2023, 2, 40–46.

- [26] Dinh, B.M. Efficiency Improvement of Squirrel Cage Induction Motor by Rotor Slot Designs. In Proceedings of 13th International Conference on Industrial Engineering and Operations Management, Manila, Philippines, 7–9 March 2023; IEOM Society International: Manila, Philippines, 2023; pp. 615–623.

- [27] Konda, R.Y.; Ponnaganti, V.K.; Reddy, P.V.S.; Singh, R.R.; Mercorelli, P.; Gundabattini, E.; Solomon, D.G. Thermal analysis and cooling strategies of high-efficiency three-phase squirrel-cage induction motors—A review. Computation 2024, 12, 6.

- [28] Özsoy, M.; Kaplan, O.; Akar, M. FEM-Based Analysis of rotor cage material and slot geometry on double air gap axial flux induction motors. Ain Shams Eng. J. 2024, 15, 102393.

- [29] Marfoli, A.; Nardo, M.D.; Degano, M.; Gerada, C.; Jara, W. Squirrel cage induction motor: A design-based comparison between aluminium and copper cages. IEEE Open J. Ind. Appl. 2021, 2, 110–120.

- [30] Liu, Y.; Han, P.; Bazzi, A.M. A Comparison of Rotor Bar Material of Squirrel-Cage Induction Machines for Efficiency Enhancement Purposes. In Proceedings of 2015 17th European Conference on Power Electronics and Applications (EPE’15 ECCE-Europe), Geneva, Switzerland, 8–10 September 2015.

- [31] Ocak, C. A FEM-based comparative study of the effect of rotor bar designs on the performance of squirrel cage induction motors. Energies 2023, 16, 6047.

- [32] Agapiou, J.S. Development of manufacturing technology for a hybrid induction rotor. Manuf. Lett. 2023, 35, 277–288.

- [33] Mallard, V.; Parent, G.; Demian, C.; Brudny, J.-F.; Delamotte, A. Increasing the energy efficiency of induction machines by the use of grain-oriented magnetic materials and die casting copper squirrel cage in the rotor. IEEE Trans. Ind. Appl. 2019, 55, 1280–1289.

- [34] Peters, D.T.; Cowie, J.G.; Brush, E.F. Die casting copper motor rotors: Mold materials and processing for cost-effective manufacturing. In Energy Efficiency Improvements in Electronic Motors and Drives; Bertoldi, P., De Almeida, A.T., Falkner, H., Eds.; Springer: Berlin, Germany, 2000; pp. 39–51.

- [35] Peters, D.T.; Cowie, J.G.; Brush, E.F.; Midson, S.P. Die-cast copper motor rotors: Die materials and process considerations for economical copper rotor production. In Energy Efficiency in Motor Driven Systems; Parasiliti, F., Bertoldi, P., Eds.; Springer: Berlin, Germany, 2003; pp. 128–135.

- [36] Feng, Y.N.; Apsley, J.; Williamson, S.; Smith, A.C.; Ionel, D.M. Reduced losses in die-cast machines with insulated rotors. IEEE Trans. Ind. Appl. 2010, 46, 928–936.

- [37] Varghese, S.T.; Singh, B.; Rajagopal, K.R. Fault investigations on die-cast copper rotors. IEEE Trans. Ind. Appl. 2018, 54, 184–194.

- [38] Agapiou, J.S. Development on die-cast copper motor rotors—Casting considerations. Manuf. Lett. 2022, 33, 310–321.

- [39] Cowie, J.G.; Brender, D.T. Die-Cast Copper Rotors for Improved Motor Performance. In Proceedings of the Conference Record of the 2003 Annual Pulp and Paper Industry Technical Conference, Charleston, SC, USA, 16–20 June 2003; pp. 42–49.

- [40] Passarini, F.; Ciacci, L.; Nuss, P.; Manfredi, S. Material Flow Analysis of Aluminium, Copper, and Iron in the EU-28. EUR 29220 EN; Publications Office of the European Union: Luxembourg, 2018; ISBN 978-92-79-85744-7.

- [41] Lin, G.; Li, L.; Guo, Z.; Jia, X.; Wang, X.; Yuan, Z.; Zhang, G.; Zhan, Y.; Shan, Q.; Li, Z. Influence of cerium and yttrium addition on strength and electrical conductivity of pure aluminum alloys. J. Rare Earth. 2024, 42, 600–611.

- [42] Zhang, Y.; Wei, F.; Mao, J.; Niu, G. The difference of La and Ce as additives of electrical conductivity aluminum alloys. Mater. Charact. 2019, 158, 109963.

- [43] Medvedev, A.E.; Murashkin, M.Y.; Enikeev, N.A.; Valiev, R.Z.; Hodgson, P.D.; Lapovok, R. Enhancement of mechanical and electrical properties of Al-RE alloys by optimizing rare-earth concentration and thermo-mechanical treatment. J. Alloys Compd. 2018, 745, 696–704.

- [44] Murashkin, M.Y.; Sabirov, I.; Medvedev, A.E.; Enikeev, N.A.; Lefebvre, W.; Valiev, R.Z.; Sauvage, X. Mechanical and electrical properties of an ultrafine grained Al–8.5wt. % RE (RE=5.4wt.% Ce, 3.1wt.% La) alloy processed by severe plastic deformation. Mater. Des. 2016, 90, 433–442.

- [45] Cui, X.; Wu, Y.; Liu, X.; Zhao, Q.; Zhang, G. Effects of grain refinement and boron treatment on electrical conductivity and mechanical properties of AA1070 aluminum. Mater. Des. 2015, 86, 397–403.

- [46] Cui, X.; Wu, Y.; Cui, H.; Zhang, G.; Zhou, B.; Liu, X. The improvement of boron treatment efficiency and electrical conductivity of AA1070Al achieved by trace Ti assistant. J. Alloys Compd. 2018, 735, 62–67.

- [47] Karabay, S.; Uzman, I. Inoculation of transition elements by addition of AlB2 and AlB12 to decrease detrimental effect on the conductivity of 99.6% aluminium in CCL for manufacturing of conductor. J. Mater. Process. Technol. 2005, 160, 174–182.

- [48] Xu, X.; Feng, Y.; Fan, H.; Wang, Q.; Dong, G.; Li, G.; Zhang, Z.; Liu, Q.; Fan, X.; Ding, H. The grain refinement of 1070 alloy by different Al-Ti-B mater alloys and its influence on the electrical conductivity. Results Phys. 2019, 14, 102482.

- [49] Wang, T.; Chen, Z.; Fu, H.; Gao, L.; Li, T. Grain refinement mechanism of pure aluminum by inoculation with Al-B master alloys. Mater. Sci. Eng. A 2012, 549, 136–143.

- [50] Wang, T.; Chen, Z.; Fu, H.; Xu, J.; Fu, Y.; Li, T. Grain refining potency of Al-B master alloy on pure aluminum. Scr. Mater. 2011, 64, 1121–1124.

- [51] Dong, L.; Yang, F.; Yu, T.; Zhang, N.; Zhou, X.; Xie, Z.; Fang, F. Contribution of grain boundary to strength and electrical conductivity of annealed copper wires. J. Mater. Res. Technol. 2023, 26, 1459–1468.

- [52] Bakonyi, I. Accounting for the resistivity contribution of grain boundaries in metals: Critical analysis of reported experimental and theoretical data for Ni and Cu. Eur. Phys. J. Plus 2021, 136, 410.

- [53] Zheng, Q.; Zhang, B.; Chen, T.; Wu, J. Achieving superior grain refinement efficiency for Al-Si casting alloys through a novel Al-La-B grain refiner. J. Mater. Res. Technol. 2024, 30, 52–60.

- [54] Liu, G.; Ren, Y.; Ma, W.; Morita, K.; Lei, Y.; Zhan, S.; Lv, G.; Li, S.; Zeng, Y.; Li, R. Development process and future trends of chemical refining agents' influence on grain refinement in aluminum alloys. J. Mater. Res. Technol. 2024, 29, 242–257.

- [55] Sigworth, G.K. Grain refinement of Al-Si-Cu alloys by AlB2 and (Al,Ti)B2. Inter. Metalcast. 2024, 18, 2778–2782.

- [56] Birol, Y. Grain Refining Aluminium foundry alloys with commercial Al-B master alloys. Mater. Sci. Technol. 2014, 30, 277–282.

- [57] Khaliq, A.; Rhamdhani, M.A.; Brooks, G.A.; Grandfield, J. Analysis of boron treatment for V removal using AlB2 and AlB12 based master alloys. In Light Metals 2014; Grandfield, J., Ed.; Springer: Cham, Switzerland, 2014; pp. 963–968.

- [58] Yabiku, R.; Fialho, R.; Teran, L.; Santos, A.; Rangel, E.; Dutra, D. A Comparative Study between Copper and Aluminum Induction Squirrel Cage Constructions. In 2010 Record of Conference Papers Industry Applications Society 57th Annual Petroleum and Chemical Industry Conference (PCIC), San Antonio, TX, USA, 20–22 September 2010; pp. 1–9.

- [59] Czerwinski, F. Aluminum alloys for electrical engineering: A review. J. Mater. Sci. 2024, 59, 14847–14892.

- [60] Aboraia, M.; Elrab, H.G.G.; Abdalla, G. Joint addition of zirconium, titanium and chromium to commercial pure aluminium. J. P. Min. Eng. 2020, 22, 58–64.

- [61] Liu, J.; Wang, Y.; Cui, X. Study about the forming mechanism of boron in Al-1B alloy. Met. Mater. Int. 2024, in press.

- [62] Khaliq, A.; Rhamdhani, M.A.; Mitchell, J.B.; Davidson, C.J. Analysis of Transition Metal (V, Zr) Borides Formation in Aluminium Melt. In Proceedings of European Metallurgical Conference (EMC) 2011, Dusseldorf, Germany, 26–29 June 2011.

- [63] Khaliq, A.; Rhamdhani, M.A.; Brooks, G.A.; Grandfield, J. Performance Evaluation of AlB12 and AlB2 for the Boron Treatment of Molten Aluminium. In Proceedings of the 6th Annual High Temperature Processing Symposium 2014, Melbourne, Australia, 3–4 February 2014; pp. 75–78.

- [64] Barta, J.; Uzhegov, N.; Losak, P.; Ondrusek, C.; Mach, M.; Pyrhönen, J. Squirrel-cage rotor design and manufacturing for high-speed applications. IEEE Trans. Ind. Electron. 2019, 66, 6768–6778.

- [65] Gerada, D.; Mebarki, A.; Brown, N.L.; Bradley, K.J.; Gerada, C. Design aspects of high-speed high-power-density laminated-rotor induction machines. IEEE Trans. Ind. Electron. 2011, 58, 4039–4047.

- [66] Jo, S.H.; Lee, S.H. Changes in microstructure, mechanical properties, and electrical conductivity of severely drawn AA1070 wire with annealing. Korean J. Met. Mater. 2024, 62, 749–756.

- [67] Wang, Q.; Yang, P.; Zhang, B.; Fan, H.; Xu, X.; Li, W.; Fan, X.; Wang, J.; Ding, H. Microstructure and texture evolution of cold rolled 1070 Al alloy during the subsequent annealing treatment. Results Phys. 2019, 13, 102178.

- [68] DIN EN 2004-1; Aerospace Series; Test Methods for Aluminium and Aluminium Alloy Products; Part 1: Determination of Electrical Conductivity of Wrought Aluminium Alloys; German Institute for Standardisation: Berlin, Germany, 1993.

- [69] ASTM E1004-17; Test Method for Determining Electrical Conductivity Using the Electromagnetic (Eddy-Current) Method; ASTM International: West Conshohocken, PA, USA, 2017.

- [70] IACS. International Annealed Copper Standard (IACS); United States Department of Commerce: Washington, DC, USA, 1914.

- [71] TS EN 60034-2-1; Rotating Electrical Machines - Part 2-1: Standard Methods for Determining Losses and Efficiency from Tests (Excluding Machines for Traction Vehicles); Turkish Standards Institution: Ankara, Turkey, 2014.

- [72] ISO/IEC 17025:2017; General Requirements for the Competence of Testing and Calibration Laboratories; International Organization for Standardization and International Electrotechnical Commission: Geneva, Switzerland, 2017.

- [73] Olabinjo, O.O. Response surface techniques as an inevitable tool in optimization process. In Response Surface Methods—Theory, Applications and Optimization Techniques; Silva, V., Cardoso, J.S., Eds.; IntechOpen: London, UK, 2024; pp. 1–11.

- [74] Ferreira, S.L.C.; Bruns, R.E.; Ferreira, H.S.; Matos, G.D.; David, J.M.; Brandão, G.C.; da Silva, E.G.P.; Portugal, L.A.; dos Reis, P.S.; Souza, A.S.; et al. Box-Behnken design: An alternative for the optimization of analytical methods. Anal. Chim. Acta 2007, 597, 179–186.

- [75] Myers, R.H.; Montgomery, D.C.; Anderson-Cook, C.M. Response Surface Methodology: Process and Product Optimization Using Designed Experiments, 4th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2016; pp. 1–825.

- [76] Iwundu, M.P.; Cosmos, J. The efficiency of seven-variable Box-Behnken experimental design with varying center runs on full and reduced model types. J. Math. Stat. 2022, 18, 196–207.

- [77] Elkady, E.F.; Fouad, M.A.; Mozayad, A.N. Application of Box-Behnken experimental design and response surface methodology for selecting the optimum RP-HPLC conditions for the simultaneous determination of methocarbamol, indomethacin and betamethasone in their pharmaceutical dosage form. BMC Chem. 2022, 6, 114.

- [78] Draper, N.R. Center points in second-order response surface designs. Technometrics 1982, 24, 127–133.

- [79] Hemavathi, M.; Varghese, E.; Shekhar, S.; Jaggi, S.; Bhowmik, A.; Sathianandan, T.V. Run order consideration for sequential third order rotatable designs. Commun. Stat. Simul. Comput. 2024, 53, 1068–1081.

- [80] Cooper, P.S.; Kearns, M.A. Removal of transition metal impurities in aluminium melts by boron additives. Mater. Sci. Forum 1996, 217-222, 141–146.

- [81] Khaliq, A. Thermodynamics and Kinetics of Transition Metal Borides Formation in Molten Aluminium. Ph.D. Thesis, Swinburne University of Technology, Melbourne, Australia, 2013.

- [82] Khaliq, A.; Rhamdhani, M.A.; Brooks, G.A.; Grandfield, J. Thermodynamic analysis of Ti, Zr, V and Cr impurities in aluminum melt. In Light Metals 2011; Lindsay, S.J., Ed.; Springer: Cham, Switzerland, 2011; pp. 751–756.

- [83] Gao, J.W.; Shu, D.; Wang, J.; Sun, B.D. Effect of boron on removal of iron from aluminium melts. Mater. Sci. Technol. 2009, 25, 1462–1466.

- [84] Imam, M.A. Phase Equilibria and Reaction Kinetics of Borides Based High-Temperature Thermoelectric Materials. Ph.D. Thesis, The University of Alabama, Tuscaloosa, AL, USA, 2018.

- [85] Gao, J.W.; Xie, M.X.; Xia, M.X. Effects of boron and lanthanum on the impurity iron in aluminium melts. Miner. Process. Extr. Metall.: Trans. Inst. Min. Metall. 2011, 120, 172–176.

- [86] Hatch, J.E. Aluminium: Properties and Physical Metallurgy, 1st ed.; ASM International: Metals Park, OH, USA, 1984; pp. 1–397.

- [87] Bishara, H.; Lee, S.; Brink, T.; Ghidelli, M.; Dehm, G. Understanding grain boundary electrical resistivity in Cu: The effect of boundary structure. ACS Nano 2021, 15, 15397–16946.

- [88] Subedi, K.N.; Kappagantula, K.; Kraft, F.; Nittala, A.; Drabold, D.A. Electrical conduction processes in aluminum: Defects and Phonons. Phys. Rev. B 2022, 105, 104114.

- [89] Samuel, E.; Tahiri, H.; Samuel, A.M.; Samuel, F.H. Heterogenous grain nucleation in Al-Si alloys: Types of nucleant inoculation. Metals 2024, 14, 271.

- [90] Park, S.B. Heterogeneous nucleation models to predict grain size in solidification. Prog. Mater. Sci. 2022, 123, 100822.

- [91] Burke, J.E.; Turnbull, D. Recrystallization and grain growth. Prog. Phys. Met. 1952, 3, 220–244.

- [92] Chen, Q.; Chen, R.; Su, J.; He, Q.; Tan, B.; Xu, C.; Huang, X.; Dai, Q.; Lu, J. The mechanisms of grain growth of Mg Alloys: A review. J. Magnes. Alloy. 2022, 10, 2384–2397.

- [93] Stange, H.; Brunken, S.; Greiner, D.; Heinemann, M.D.; Kaufmann, C.A.; Schmidt, S.S.; Bäcker, J.P.; Klaus, M.; Genzel, C.; Mainz, R. Diffusion-induced grain boundary migration as mechanism for grain growth and defect annihilation in chalcopyrite thin films. Acta Mater. 2016, 111, 377–384.

- [94] Tavakkoli, V.; Boltynjuk, E.; Scherer, T.; Mazilkin, A.; Ivanisenko, Y.; Ungar, T.; Kübel, C. Precipitate-mediated enhancement of mechanical and electrical properties in HPTE-processed Al-Mg-Si alloy. Mater. Sci. Eng. A 2024, 906, 146556.

- [95] Gaber, A.; Afify, N.; El-Halawany, S.M.; Mossad, A. Studies on Al-Mg solid solutions using electrical resistivity and microhardness measurements. EPJ Appl. Phys. 1999, 7, 103–109.

- [96] Hou, J.P.; Wang, Q.; Zhang, Z.J.; Tian, Y.Z.; Wu, X.M.; Yang, H.J.; Li, X.W.; Zhang, Z.F. Nano-scale precipitates: The key to high strength and high conductivity in al alloy wire. Mater. Des. 2017, 132, 148–157.

- [97] Vončina, M.; Paulin, I.; Medved, J.; Petrič, M. Predicting the quality of grain refiners from electrical resistance measurements of aluminum. Metals 2023, 13, 717.

- [98] Murashkin, M.; Medvedev, A.; Kazykhanov, V.; Krokhin, A.; Raab, G.; Enikeev, N.; Valiev, R.Z. Enhanced mechanical properties and electrical conductivity in ultrafine-grained Al 6101 alloy processed via ECAP-conform. Metals 2015, 5, 2148–2164.

- [99] Yang, Z.; Mallow, S.; Banhart, J.; Kessler, O. Probing precipitation in aluminium alloys during linear cooling via in-situ differential scanning calorimetry and electrical resistivity measurement. Thermochim. Acta 2024, 739, 179815.

- [100] Eivani, A.; Ahmed, H.; Zhou, J.; Duszczyk, J. Correlation between electrical resistivity, particle dissolution, precipitation of dispersoids, and recrystallization behavior of AA7020 aluminum alloy. Metall. Mater. Trans. A 2009, 40, 2435–2446.

- [101] Wang, M.; Wu, J.; Yang, S.; Knezevic, M.; Huang, Z.; Zhao, Y.; Liu, T.; Shen, B.; Wang, J. Processing of an as-cast Al-7.5 wt%Y eutectic alloy by rolling and annealing to improve the tradeoff between strength and electrical conductivity. Mater. Sci. Eng. A 2024, 890, 145950.

- [102] Vandersluis, E.; Ravindran, C.; Bamberger, M. Mechanisms affecting hardness and electrical conductivity in artificially-aged B319 aluminum alloy. J. Alloys Compd. 2021, 867, 159121.

- [103] Li, Y.F.; Qin, J.; Yu, J.M.; Liu, Y.; Li, Z.; Nagaumi, H.; Zhang, B. A novel approach to improve conductivity of 1XXX Al alloy by in situ synthesis of Al-X-B grain refiner. Metall. Mater. Trans. A 2024, 55, 1707–1712.

- [104] Belov, N. Multicomponent Phase diagrams: Applications for Commercial Aluminum Alloys; Elsevier: Amsterdam, The Netherlands, 2005; pp. 1-413.

- [105] Sauvage, X.; Bobruk, E.V.; Murashkin, Y.M.; Nasedkina, Y.; Enikeev, N.A.; Valiev, R.Z. Optimization of electrical conductivity and strength combination by structure design at the nanoscale in Al-Mg-Si alloys. Acta Mater. 2015, 98, 355–366.

- [106] De Souza, D.F.; Salotti, F.A.M.; Sauer, I.L.; Tatizawa, H.; De Almeida, A.T.; Kanashiro, A.G. A performance evaluation of three-phase induction electric motors between 1945 and 2020. Energies 2022, 15, 2002.

9. Copyright:

This material is Yusuf Zeybek, Cemile Kayış, and Ege Anıl Diler's paper: Based on "Improving Electrical Conductivity of Commercially Pure Aluminium: The Synergistic Effect of AlB8 Master Alloy and Heat Treatment".

Paper Source: https://doi.org/10.3390/ma18020364

This material was summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.