This technical summary is based on the academic paper "MICROSTRUCTURE CHARACTERIZATION AND MECHANICAL PROPERTIES OF SEMI SOLID ADC12 AL ALLOY" by Sujeet K. Gautam, Himadri Roy, Aditya K. Lohar, Sudip K. Samanta, and Goutam Sutradhar, published in the International Journal of Modern Manufacturing Technologies (2019).

Keywords

- Primary Keyword: ADC12 Alloy Rheocasting

- Secondary Keywords: Semi-Solid Metal Processing, Cooling Slope Technique, ADC12 Mechanical Properties, Microstructure Control, HPDC Defects

Executive Summary

- The Challenge: Conventional die casting of ADC12 aluminum alloy often results in a dendritic microstructure, leading to defects like porosity and blowholes that compromise mechanical performance.

- The Method: The study employs a cooling slope rheocasting technique to transform the molten alloy into a semi-solid slurry before casting, precisely controlling the microstructure.

- The Key Breakthrough: An optimal process window was identified—a slope angle of 45° and a slope length of 500 mm—that produces a fine, highly spherical (non-dendritic) microstructure in the ADC12 alloy.

- The Bottom Line: ADC12 alloy rheocasting under optimized conditions significantly enhances both ultimate tensile strength and elongation compared to conventional gravity casting, offering a direct path to higher-performance components.

The Challenge: Why This Research Matters for HPDC Professionals

ADC12 is a workhorse aluminum alloy in the automotive industry, valued for its high corrosion resistance, low thermal expansion, and excellent castability. However, in conventional high-pressure die casting (HPDC), its performance is often capped by inherent process limitations. The rapid, often turbulent filling of the die can lead to a coarse, dendritic (tree-like) microstructure. This structure is prone to forming microporosity and entrapping gas, resulting in defects like surface blisters and blowholes. These defects not only weaken the final component but also make it unsuitable for heat treatment, limiting its potential applications. This research directly confronts this challenge by exploring a semi-solid metal (SSM) processing method to fundamentally change the alloy's structure before it ever enters the mold.

The Approach: Unpacking the Methodology

The researchers investigated a specific SSM technique known as the cooling slope process to refine the microstructure of ADC12 alloy. The methodology was designed to be systematic and directly comparable to conventional methods.

Method 1: Material Preparation and Thermal Analysis

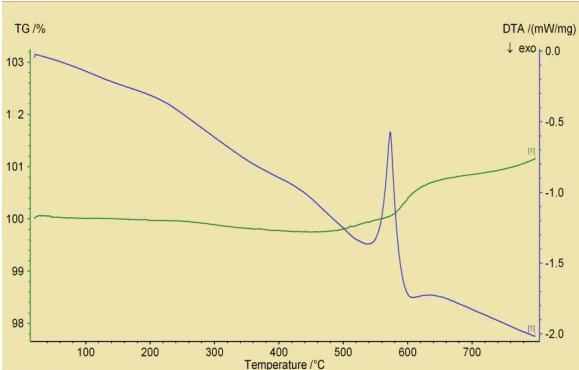

Commercial ADC12 alloy ingots were used. Differential Thermal Analysis (DTA) was first performed to precisely determine the alloy's liquidus (572°C) and solidus (520°C) temperatures, establishing the critical semi-solid processing window. The ingot was melted in a resistance furnace to 750°C and then transferred to a holding furnace maintained at a precise pouring temperature of 585°C.

Method 2: Cooling Slope Rheocasting

A stainless steel cooling slope plate was used to generate the semi-solid slurry. Stainless steel was chosen for its low thermal conductivity, which promotes gradual cooling and prevents the melt from adhering to the surface. The plate was preheated to 60°C and coated with boron nitride. The molten ADC12 was poured onto the slope, with two key variables being systematically altered:

* Slope Angle: 30°, 45°, and 60°

* Slope Length: 400 mm, 500 mm, and 600 mm

The resulting semi-solid slurry was collected at the end of the slope in a preheated (200°C) copper mold and allowed to cool.

Method 3: Characterization and Testing

Samples from both the rheocasting process and a conventional gravity cast process were prepared for comparison. Microstructure was analyzed using optical and field emission scanning electron microscopes (FESEM). Mechanical properties were measured by fabricating tensile specimens (per ASTM E8) and testing them at a displacement rate of 0.5 mm/sec. Finally, the fracture surfaces of the broken tensile samples were examined with FESEM to understand the failure mechanisms.

The Breakthrough: Key Findings & Data

The study delivered clear, data-driven evidence that the cooling slope process dramatically improves ADC12 alloy characteristics, with specific parameters yielding optimal results.

Finding 1: Slope Angle is a Critical Control for Particle Shape and Size

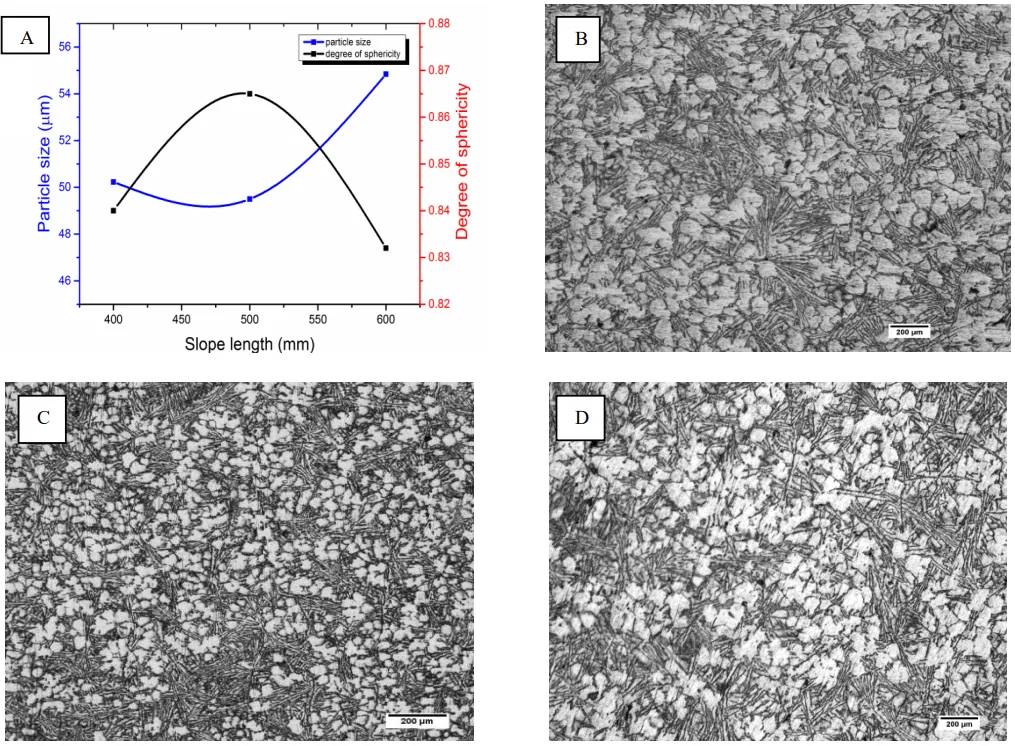

The angle of the cooling slope directly dictates the shear forces and residence time of the melt, which in turn controls the final microstructure. The study found that a 45° angle provides the ideal balance.

* At 30°, the shear force was too low to effectively break up dendrites, resulting in a less spherical structure.

* At 60°, the melt flowed too quickly, reducing heat extraction and resulting in a less refined microstructure.

* As shown in Figure 5(A), the 45° slope angle achieved the minimum average particle size (approx. 48 µm) and the maximum degree of sphericity (approx. 0.87).

Finding 2: Slope Length Determines the Degree of Grain Refinement

The length of the slope controls the total cooling and shearing time. The research identified 500 mm as the optimal length for producing the finest, most uniform microstructure.

* At 400 mm, the processing time was insufficient for full microstructural transformation.

* At 600 mm, the extended time led to a thickening of the solid layer on the slope, which insulated the flowing slurry, reduced the cooling rate, and caused the primary particles to coarsen.

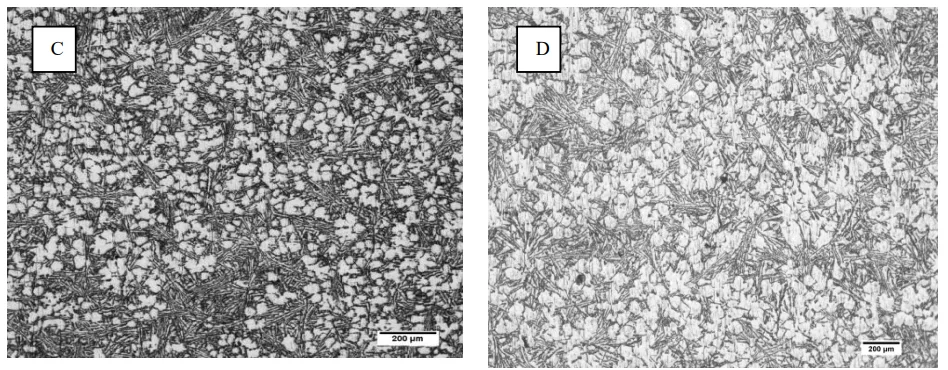

* As illustrated in Figure 6(A), the 500 mm slope length produced the finest particle size (approx. 48 µm) and the highest degree of sphericity (approx. 0.87) at a constant 45° angle.

Finding 3: Optimized Microstructure Translates to Superior Mechanical Properties

The refined, globular microstructure achieved through rheocasting directly resulted in significant improvements in mechanical performance compared to the coarse, dendritic structure of conventional gravity casting.

* As shown in Figure 7, the gravity cast sample exhibited an ultimate tensile strength (UTS) of approximately 100 MPa and an elongation of less than 2%.

* In stark contrast, the rheocast sample produced under optimal conditions (45° angle, 500 mm length, 585°C) achieved a UTS of nearly 180 MPa and an elongation of over 6%—an 80% increase in strength and a 200% increase in ductility.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that implementing a cooling slope process with a slope angle of 45° and a length of 500 mm can be a highly effective strategy for producing ADC12 components with superior and more consistent mechanical properties.

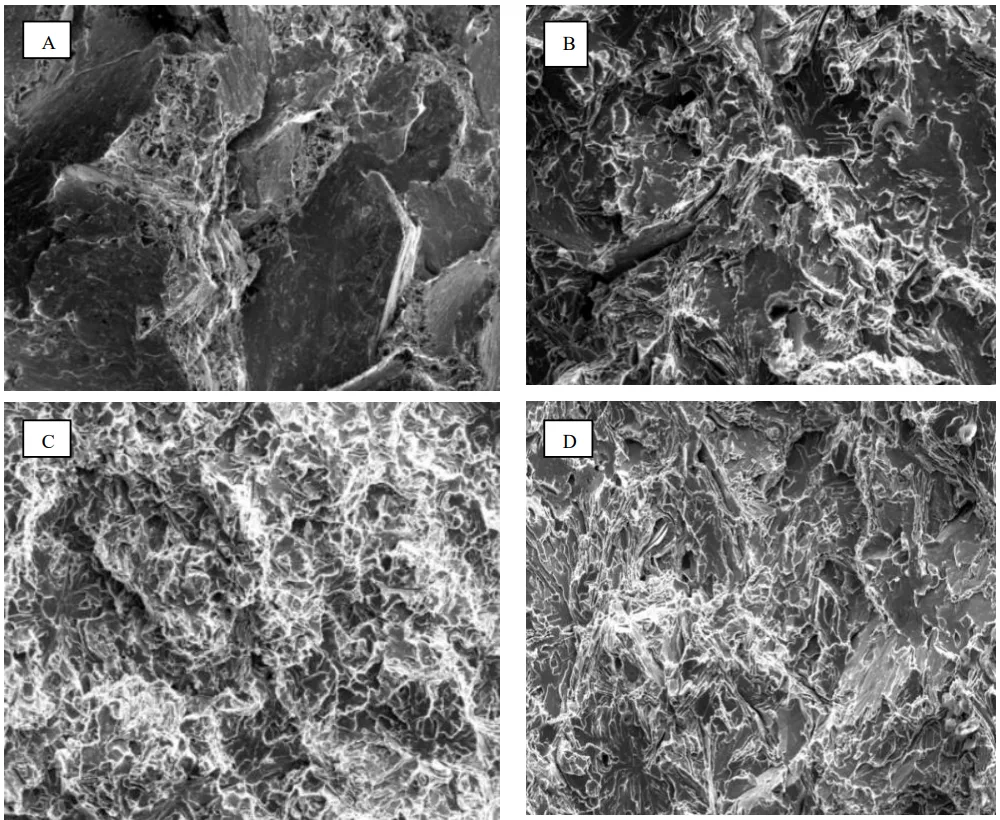

- For Quality Control Teams: The data in Figure 7 provides a new performance benchmark for ADC12 components. The distinct fracture surfaces shown in Figure 8 (brittle facets in gravity cast vs. mixed-mode fracture in rheocast) could inform new criteria for failure analysis and quality inspection.

- For Design Engineers: The findings indicate that the enhanced ductility and strength from rheocasting could allow for the design of more complex, lightweight, or thinner-walled ADC12 components that would be prone to failure if produced using conventional casting methods.

Paper Details

MICROSTRUCTURE CHARACTERIZATION AND MECHANICAL PROPERTIES OF SEMI SOLID ADC12 AL ALLOY

1. Overview:

- Title: MICROSTRUCTURE CHARACTERIZATION AND MECHANICAL PROPERTIES OF SEMI SOLID ADC12 AL ALLOY

- Author: Sujeet K. Gautam, Himadri Roy, Aditya K. Lohar, Sudip K. Samanta, Goutam Sutradhar

- Year of publication: 2019

- Journal/academic society of publication: International Journal of Modern Manufacturing Technologies

- Keywords: rheocasting, cooling slope; tensile properties; ADC12 aluminium alloy.

2. Abstract:

To investigatemicrostructural evolution and tensile properties of semi solidADC 12 Al alloy under the different input variablesof cooling slope technique in detail. Furthermore, comparisons between the conventional cast and cooling slope cast samples have been made at same pouring temperature. The ingot of ADC12 aluminium alloy was melted in resistance heating furnace at 750°C. Subsequently, the liquid metal alloy was poured in a holding furnace and set at the desired temperature (585°C). Liquid molten metal was flow through the cooling slope plate at a fixed temperature with varying slope angle (30°, 45°and 60°) and slope length (400, 500, 600mm). Obtained results infer that the slope angle and slope length are most significant input variablesof cooling slope techniques, which affects the morphological characteristics of semi solid cast material. From microstructure observation, at the optimum condition (45º and 500mm) of these input variables generates the high sphericity and minimum particle size of primary phase of Al alloy. Obtained results also infer that the cooling slope cast samples are having better mechanical properties than corresponding gravity cast samples. The fracture studies reveal the presence of mixed mode fracture to be predominant fracture mode in case of rheocast specimens.

3. Introduction:

Semi solid metal (SSM) processing is a significant manufacturing technology with advantages over conventional methods, including better mechanical properties and high dimensional precision. The core of SSM is the transformation of the microstructure from dendritic to non-dendritic, reducing segregation and porosity. Rheocasting, a popular SSM process, offers advantages over thixocasting, such as lower processing costs. The cooling slope process is an effective technique for generating the semi-solid slurry required for rheocasting by promoting the formation of a uniform, near-equiaxed grain microstructure. While extensive research exists for Al alloys like A356 and A380, the widely used automotive alloy ADC12 has been studied less in this context. Conventional die casting of ADC12 suffers from defects like porosity and surface blisters due to turbulent flow, which limits its properties and prevents heat treatment. This experimental work aims to resolve this problem by investigating the microstructural evolution and tensile properties of ADC12 Al alloy processed using the cooling slope technique with varying input parameters.

4. Summary of the study:

Background of the research topic:

Semi-solid metal (SSM) processing is a key technology for producing high-integrity components for industries such as automotive and aerospace. The cooling slope technique is a method within the rheocasting branch of SSM that uses a chilled, inclined plate to induce heterogeneous nucleation and shear, transforming a liquid metal into a semi-solid slurry with a globular, non-dendritic microstructure.

Status of previous research:

Significant work has been conducted on the semi-solid processing of common aluminum casting alloys like A356/A357 (low Cu) and A380 (high Cu). However, despite its widespread industrial use, ADC12 Al alloy has received comparatively less attention in the literature regarding semi-solid processing via the cooling slope method.

Purpose of the study:

The primary purpose of this study was to investigate the microstructural evolution and mechanical properties of ADC12 Al alloy when processed using the cooling slope technique. The study aimed to identify the effects of varying input parameters—specifically slope angle and slope length—and determine the optimal conditions for achieving a refined microstructure and enhanced tensile properties compared to conventionally gravity-cast ADC12.

Core study:

The core of the study involved an experimental investigation where ADC12 aluminum alloy was melted and poured at 585°C onto a cooling slope. The slope angle was varied (30°, 45°, 60°) and the slope length was varied (400, 500, 600 mm). The resulting semi-solid slurry was cast and solidified. The microstructure of these rheocast samples was characterized for primary phase particle size and sphericity and compared to a baseline gravity-cast sample. Subsequently, tensile tests were performed on all samples to evaluate ultimate tensile strength and elongation, and fracture surfaces were analyzed to understand the failure mechanisms.

5. Research Methodology

Research Design:

The study employed a comparative experimental design. A baseline was established using a conventional gravity cast ADC12 sample. This was compared against a series of rheocast samples produced using a cooling slope apparatus. The experimental matrix was designed to isolate the effects of two key independent variables: cooling slope inclination angle and cooling slope length.

Data Collection and Analysis Methods:

- Material Analysis: The liquidus and solidus temperatures of the commercial ADC12 alloy were determined using Differential Thermal Analysis (DTA). The chemical composition was confirmed via analysis.

- Microstructural Characterization: Samples were metallographically prepared and examined using an optical microscope and a Field Emission Scanning Electron Microscope (FESEM) to analyze the morphology, size, and sphericity of the primary α-Al phase.

- Mechanical Testing: Rounded tensile specimens were machined according to ASTM E8 standard. Tensile tests were conducted at ambient temperature at a displacement rate of 0.5 mm/sec to determine ultimate tensile strength (UTS) and percent elongation.

- Fractography: The fracture surfaces of the tested tensile specimens were analyzed using FESEM to identify the fracture modes and initiation sites.

Research Topics and Scope:

The research was focused exclusively on commercial ADC12 aluminum alloy. The scope was limited to the investigation of two process parameters of the cooling slope technique: inclination angle (30°, 45°, 60°) and slope length (400, 500, 600 mm). The study's outputs were the characterization of the resulting microstructure (particle size and sphericity) and mechanical properties (UTS and elongation).

6. Key Results:

Key Results:

- The cooling slope process successfully transformed the dendritic morphology of the primary α-Al phase in gravity-cast ADC12 into a non-dendritic, globular morphology in the rheocast samples.

- The slope angle was identified as a significant variable, with an angle of 45° yielding the optimal microstructure characterized by the highest sphericity and minimum particle size. Angles of 30° and 60° resulted in less ideal microstructures.

- The slope length also significantly influenced the microstructure. A length of 500 mm was found to be the optimum condition for generating fine, globular grains. Shorter lengths (400 mm) were insufficient, while longer lengths (600 mm) led to grain coarsening.

- The rheocast sample produced at the optimum parameters (45° angle, 500 mm length) exhibited markedly superior mechanical properties, with a significant increase in both ultimate tensile strength and elongation compared to the gravity-cast sample.

- Fracture analysis showed a transition in failure mechanism. The gravity-cast sample failed due to cracking of coarse, needle-like eutectic and Fe-based intermetallic phases. The rheocast samples exhibited a mixed-mode fracture, with void initiation at globular eutectic silicon particles.

Figure Name List:

- Fig. 1. Differential thermal analysis graph of ADC 12 Al alloy

- Fig. 2. Experimental setup of cooling slope techniques

- Fig. 3. Dimensions of tensile samples

- Fig. 4. Gravity cast microstructure

- Fig. 5. Micrographs of cooling slope cast samples at constant pouring temperature (585°C) and slope length (500mm): (A) variation in (slope angle); (B) 30°; (C) 45°; and (D) 60°

- Fig. 6. Microstructure of cooling samples at constant pouring temperature (585°C) and slope angle (45°): (A) direct effect of processing parameter (slope length); (B) 400mm; (C) 500mm; and (D) 600mm

- Fig. 7. Tensile strength and % elongation of ADC12 alloy of gravitycast and cooling slope cast at different processing conditions

- Fig. 8. FESM fractographs of tensile fracture surfaces at different magnification 1000x. (A) gravity cast. cooling slope cast at different processing condtions (B) angle 30 degree, length 500mm and pouring temperature 585°C. (C) angle 45 degree, length 500mm and pouring temperature 585°C. (D) angle 60 degree, length 500mm and pouring temperature 585°C

7. Conclusion:

The investigation concludes that the morphology of the α-Al phase in ADC12 alloy can be effectively transformed from dendritic to non-dendritic by flowing the melt through a cooling slope channel. The slope angle and length are critical parameters that control the heat extraction rate and thus the final microstructure. The most favorable condition for generating a fine grain size and high globular structure was found to be a slope angle of 45° at a constant length of 500 mm, and a slope length of 500 mm at a constant angle of 45°. Samples produced under these optimum conditions (45°, 500 mm, 585°C) demonstrated a significant increase in both tensile strength and elongation compared to conventionally processed gravity cast samples.

8. References:

- Apelian, D., (2006). SSM and Squeeze Casting: Principles & Opportunities. North American Die Casting Association Transactions.

- Birol, Y., (2007). A357 thixoforming feedstock produced by cooling slope casting, J. of Mater. Proces. Technol., 186(1-3), 94-101.

- Birol, Y., (2008). Cooling slope casting and thixoforming of hypereutectic A390 alloy, J. of Mater. Proces. Technol., 207(1-3), 200-203.

- Bălțătescu, O., Florea, R. M., Buzăianu, A., Roman, C., and Carcea, I., (2013). Manufacturing and characterization of stabilized aluminum foams. International Journal of Modern Manufacturing Technologies, V(1), 17-24.

- Ćosić, M., Aćimović-Pavlović, Z., Terzić, A., Dojčinović, M., Pavlović, L., (2012). The possibility of obtaining composite All8wt% si/sic by compocasting process. International Journal of Modern Manufacturing Technologies, 4(2), 23-26.

- Das, P., Samanta, S. K., Ray, T., Venkatpathi, B. R. K., (2012). Mechanical properties and tensile fracture mechanism of rheocast A356 Al alloy using cooling slope. Advan. Mater. Resear., 585, 354-358.

- Das, P., Samanta, S. K., Ray, T., Venkatpathi, B. R. K., (2012). Mechanical properties and tensile fracture mechanism of rheocast A356 Al alloy using cooling slope. Advan. Mater. Resear., 585, 354-358.

- Das, P., Samanta, S. K., Das, R., and Dutta, P., (2014). Optimization of degree of sphericity of primary phase during cooling slope casting of A356 Al alloy: Taguchi method and regression analysis, Measure, 55, 605-615.

- Gencalp, S., Saklakoglu, N., (2010). Semisolid microstructure evolution during cooling slope casting under vibration of A380 aluminum alloy. Mater.Manufact.Proce., 25(9), 943-947.

- Flemings, M. C., (1991). Behavior of metal alloys in the semisolid state. Metallurg. trans. A., 22(5), 957-981.

- Gautam, S. K., Mandal, N., Roy, H., Lohar, A. K., Samanta, S. K. and Sutradhar, G., (2018). Optimization of processing parameters of cooling slope process for semi-solid casting of ADC 12 Al alloy. J. of the Brazi. Society of Mech. Sci. and Engin., 40(6), 291.

- Haga, T., and Suzuki, S., (2001). Casting of aluminum alloy ingots for thixoforming using a cooling slope. J. of Mater. Proces. Technol., 118(1-3), 169-172.

- Istrate, B., Crimu, C. I., Munteanu, C., (2015). Microstructural analysis of mg-ca and mg-si-ca biodegradable alloys. International Journal of Modern Manufacturing Technologies, 7(1), 36-41.

- Jorstad, J., Apelian, D. (2008). Pressure assisted processes for high integrity aluminum castings. Int. J.of Metalcast., 2(1), 19-39.

- Liu, D., Atkinson, H. V., and Jones, H., (2004). MTDATA thermodynamic prediction of suitability of alloys for thixoforming. S2P, International Conference on Semi-Solid Processing of Alloys and Composites, 8, 335-346.

- LÜ, S. L., Wu, S. S., Zhu, Z. M., Ping, A. N., and Mao, Y. W., (2010). Effect of semi-solid processing on microstructure and mechanical properties of 5052 aluminum alloy. Trans. of Nonfer.Met. Soc. of China, 20, s758-s762.

- Nedelcu, D., Comaneci, R., Chelariu, R., and Tabacaru, L., (2009). Overview of composite material technology with Si-C particles, reinforcement. International Journal of Modern Manufacturing Technologies, I(1), 57-62.

- Nedelcu, D., Milosevic, O., Chelariu, R., and Roman, C., (2010). Some experimental aspects concerning the stratified composite materials with metallic matrix, International Journal of Modern Manufacturing Technologies, II(2), 65-71.

- Nourouzi, S., Baseri, H., Kolahdooz, A., and Ghavamodini, S. M., (2013). Optimization of semi-solid metal processing of A356 aluminum alloy. J. of Mech. Sci. and Techn., 27(12), 3869-3874.

- Park, C., Kim, S., Kwon, Y., Lee, Y., and Lee, J., (2005). Mechanical and corrosion properties of rheocast and low-pressure cast A356-T6 alloy. Mater. Scien.Engine.: А., 391(1-2), 86-94.

- Saklakoğlu, N., Gencalp, S., Kasman, Ş., and Saklakoğlu, İ. E., (2011). Formation of globular microstructure in A380 aluminum alloy by cooling slope casting. Advan.Mater.Resear., 264, 272-277.

- Salarfar, S., Akhlaghi, F., and Nili-Ahmadabadi, M., (2004). Influence of pouring conditions in the inclined plate process and reheating on the microstructure of the semisolid A356 aluminum alloy, Proceedings of the 8th Int. Conf. on Semisolid Proc. of Alloys and Composites, Cyprus.

- Spencer, D. B., Mehrabian, R., and Flemings, M. C., (1972). Rheological behavior of Sn-15 pctPb in the crystallization range, Metallurg. Trans., 3(7), 1925-1932.

- Taghavi, F., and Ghassemi, A., (2009). Study on the effects of the length and angle of inclined plate on the thixotropic microstructure of A356 aluminum alloy, Mater. & Desig., 30(5), 1762-1767.

- Tian, C., Law, J., Van Der Touw, J., Murray, M., Yao, J. Y., Graham, D., and John, D. S., (2002). Effect of melt cleanliness on the formation of porosity defects in automotive aluminium high pressure die castings, J. of Mater. Proces. Technol., 122(1), 82-93.

- Vundavilli, P. R., Mantry, S., Mandal, A., and Chakraborty, M., (2014). A Taguchi optimization of cooling slope casting process parameters for production of semi-solid A356 alloy and A356-5TiB2 in-situ composite feedstock, Proced. Mater. Sci., 5, 232-241.

- Xu, J., Wang, T. M., Chen, Z. N., Zhu, J., Cao, Z. Q., Li, T. J., (2011). Preparation of semisolid A356 alloy by a cooling slope processing, In Mater. Sci. Foru., 675, 767-770.

- Zhao, H. D., Wang, F., Li, Y. Y., Xia, W., (2009). Experimental and numerical analysis of gas entrapment defects in plate ADC12 die castings, J. of Mater. Proces. Technol., 209(9), 4537-4542.

Expert Q&A: Your Top Questions Answered

Q1: Why was stainless steel chosen for the cooling slope instead of a more conductive material like copper?

A1: The paper states that stainless steel was chosen specifically because its thermal conductivity is very low compared to copper. A low thermal conductivity material ensures a more gradual heat extraction from the molten alloy. This prevents premature, excessive solidification on the plate surface and allows sufficient time for the shearing forces to effectively break down and spheroidize the dendritic structures as the slurry flows down the slope.

Q2: What is the significance of the 585°C pouring temperature?

A2: The pouring temperature of 585°C was selected based on the Differential Thermal Analysis (DTA) results, which identified the alloy's liquidus temperature as 572°C. Pouring at a temperature slightly above the liquidus ensures the alloy is fully molten at the start but enters the semi-solid (liquid + solid) range quickly upon contact with the cooler slope. This is essential for initiating the heterogeneous nucleation needed to form the globular primary phase.

Q3: How exactly does the fracture mechanism change between the gravity cast and rheocast samples?

A3: The fracture analysis in Figure 8 shows a clear difference. In the conventional gravity cast sample (Fig. 8A), the fracture surface is characterized by large, flat facets, indicating a brittle failure. This is caused by cracks initiating and propagating easily through the coarse, needle-like eutectic Al-Si and Fe-based intermetallic phases. In the rheocast samples (Fig. 8C), the fracture surface is more dimpled and complex, indicating a mixed-mode, more ductile fracture. Failure initiates from voids forming at the fine, globular eutectic silicon particles rather than catastrophic cracking along large brittle phases.

Q4: The study identifies 45° as the optimal slope angle. What specifically happens at 30° and 60° that makes them less effective?

A4: At a low angle of 30°, the gravitational force component pulling the melt down the slope is weaker. This results in a lower melt velocity and insufficient shear force to effectively break apart the forming dendrites, leading to incomplete transformation to a globular structure. Conversely, at a high angle of 60°, the melt flows too rapidly, which significantly reduces the residence time on the slope. This short duration does not allow for adequate heat extraction, resulting in a slurry with a low solid fraction and a less refined microstructure.

Q5: What is the practical consequence of using a slope length longer than the optimal 500 mm, such as 600 mm?

A5: According to the paper, increasing the slope length beyond the optimum leads to a thickening of the solid layer that forms between the flowing melt and the inclined plate. This thickened layer acts as an insulator, which reduces the rate of heat transfer from the slurry to the plate. As a consequence, the cooling rate of the melt decreases, which leads to a lower nucleation rate and coarsening (growth) of the existing primary solid particles, ultimately resulting in a less refined final microstructure.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a clear and actionable framework for overcoming the inherent limitations of conventional ADC12 casting. By implementing ADC12 Alloy Rheocasting using the cooling slope method, manufacturers can transition from a defect-prone dendritic microstructure to a robust, globular one. The key breakthrough is the identification of an optimal process window—a 45° slope angle and 500 mm slope length—that maximizes mechanical properties, delivering an 80% increase in strength and a 200% increase in ductility. These findings empower engineers to produce higher-performance, more reliable components, opening new possibilities for lightweighting and complex designs in the automotive sector and beyond.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

This content is a summary and analysis based on the paper "MICROSTRUCTURE CHARACTERIZATION AND MECHANICAL PROPERTIES OF SEMI SOLID ADC12 AL ALLOY" by "Sujeet K. Gautam, Himadri Roy, Aditya K. Lohar, Sudip K. Samanta, Goutam Sutradhar".

Source: International Journal of Modern Manufacturing Technologies, ISSN 2067-3604, Vol. XI, No. 1 / 2019

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.