This technical summary is based on the academic paper "Stir Casting Process Analysis and Optimization for Better Properties in Al-MWCNT-GR-Based Hybrid Composites" published by Kanchiraya Shivalingaiah, Vinayaka Nagarajaiah, et al. in Metals (2022). It was analyzed and summarized for casting experts by CASTMAN experts with the help of LLM AI such as Gemini, ChatGPT, and Grok.

Keywords

- Primary Keyword: Al-MWCNT-GR composite properties

- Secondary Keywords: Stir casting optimization, Hybrid metal matrix composites, Hardness and wear resistance, Taguchi-CRITIC-MOORA, Graphene reinforced aluminum, Process parameter optimization

Executive Summary

- The Challenge: Standard aluminum alloys often lack the hardness and wear resistance required for demanding, load-bearing applications in the automotive and aerospace sectors.

- The Method: Researchers developed a hybrid aluminum composite reinforced with multiwall carbon nanotubes (MWCNT) and graphene (GR) using a stir casting process. They applied a Taguchi L16 experimental design and advanced multi-objective optimization (Taguchi-CRITIC-MOORA) to pinpoint the ideal process parameters.

- The Key Breakthrough: The study successfully identified an optimal set of stir casting parameters that significantly enhanced material properties. The percent reinforcement of graphene was found to be the most dominant factor, contributing to over 76% of the change in hardness.

- The Bottom Line: The optimized process resulted in a 31.77% increase in hardness and a 36.33% decrease in wear rate compared to initial conditions, creating a high-performance, self-lubricating composite material suitable for industrial-scale applications.

The Challenge: Why This Research Matters for HPDC Professionals

In modern manufacturing, particularly for automotive and aerospace components, the push for lightweight, high-strength materials is relentless. While aluminum is a go-to choice for its low density, its inherent properties can be insufficient for high-wear, load-bearing parts [Ref. [12]]. This has led to the development of metal matrix composites (MMCs), where a base metal is enhanced with stronger reinforcement materials.

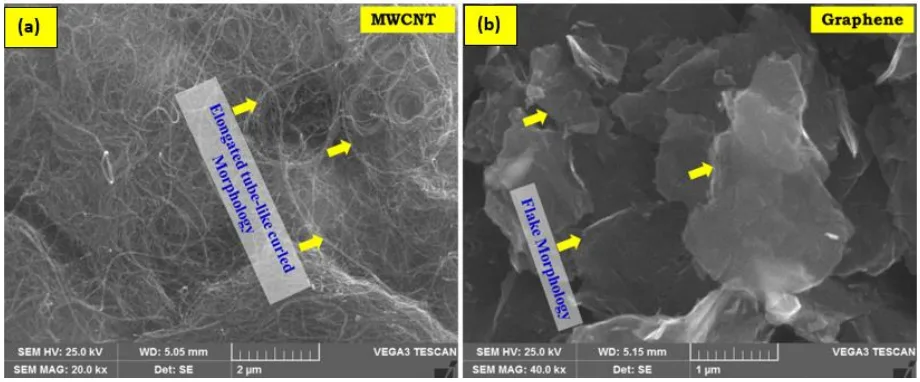

However, traditional reinforcements like carbides or oxides can be abrasive, hard to machine, and prone to cracking [Ref. [19], [20]]. The new frontier lies in carbon-based nano-reinforcements like multiwall carbon nanotubes (MWCNTs) and graphene (GR). These materials offer incredible strength, hardness, and unique self-lubricating properties [Ref. [22], [23]].

The primary challenge, as this paper addresses, is not just creating these composites but perfecting the manufacturing process to unlock their full potential. For any liquid-state casting process, including stir casting and HPDC, slight variations in parameters like melt temperature, die temperature, or mixing speed can lead to defects like particle agglomeration, gas entrapment, and porosity, severely compromising the final product's quality [Ref. [33-36]]. This research tackles that exact problem: how to systematically analyze and optimize the process to produce a superior, reliable composite.

The Approach: Unpacking the Methodology

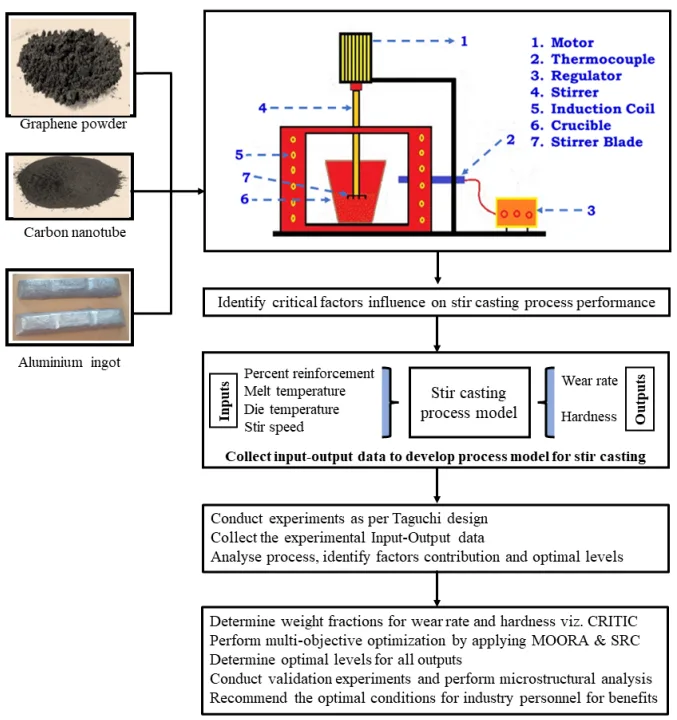

To find the ideal manufacturing recipe, the researchers employed a systematic and robust methodology combining physical experimentation with advanced statistical analysis.

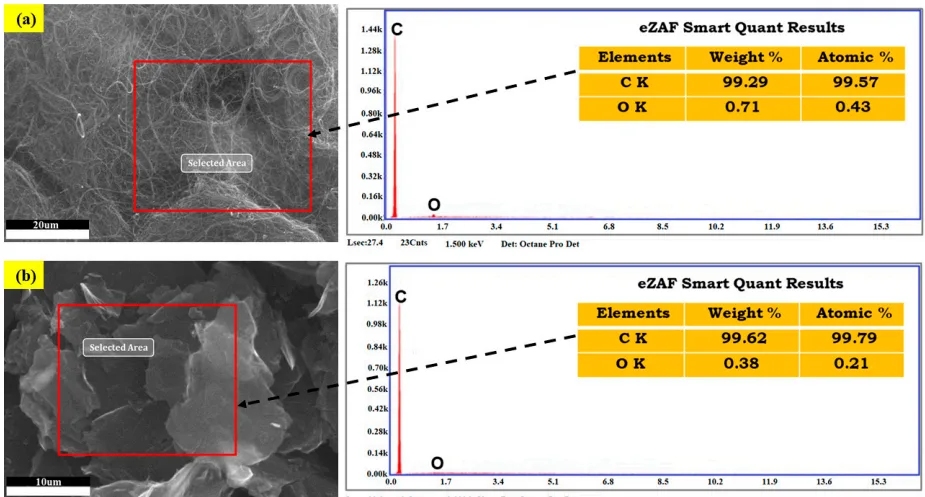

- Material Preparation: The team fabricated a hybrid composite by reinforcing a pure aluminum matrix (>98.5% purity) with a fixed 2.5 wt.% of MWCNTs and a variable amount (1, 2, 3, or 4 wt.%) of graphene.

- Process Route: A stir casting process was used, a liquid-state method where reinforcements are mechanically stirred into the molten metal before casting. This method was chosen for its flexibility, simplicity, and suitability for high-volume production [Ref. [7], [31], [32]].

- Experimental Design: A Taguchi L16 orthogonal array was used to efficiently study the process. This method allows for the analysis of multiple factors with a minimal number of experiments. The four key process variables (factors) studied were:

- Percent reinforcement of graphene (PR): 1, 2, 3, and 4 wt.%

- Die temperature (DT): 140, 180, 220, and 260 °C

- Melt temperature (MT): 680, 710, 740, and 770 °C

- Stir speed (SS): 480, 520, 560, and 600 rpm

- Optimization: Since the goal was to achieve two conflicting objectives simultaneously (higher hardness and lower wear rate), the researchers used multi-objective optimization techniques. They compared two hybrid methods: Taguchi-CRITIC-GRA and Taguchi-CRITIC-MOORA. The CRITIC method was critically used to assign scientific weightings to hardness (0.4752) and wear rate (0.5428), avoiding guesswork and ensuring the final result was balanced according to the data's inherent variability.

The Breakthrough: Key Findings & Data

The comprehensive analysis yielded clear, actionable results, with the Taguchi-CRITIC-MOORA method proving to be the superior optimization tool.

Finding 1: Graphene Reinforcement is the Dominant Factor.

Pareto ANOVA analysis revealed that the percentage of graphene reinforcement (PR) had the most profound impact on both hardness and wear rate. It accounted for 76.77% of the contribution to hardness and 80.31% of the contribution to wear rate. All other factors had a much smaller, though still significant, influence (Table 3, Table 4).Finding 2: The Single Optimal Process Recipe.

While optimizing for hardness and wear rate individually yielded different process settings, the Taguchi-CRITIC-MOORA method successfully identified a single set of optimal parameters for the best combined performance:- Percent Reinforcement (PR): 3 wt.%

- Die Temperature (DT): 180 °C

- Melt Temperature (MT): 740 °C

- Stir Speed (SS): 520 rpm

Finding 3: Quantified Performance Gains.

Confirmation experiments validated the model's prediction. Compared to the initial, non-optimized conditions (PR: 1%, DT: 140°C, MT: 680°C, SS: 480 rpm), the composite produced with the optimal parameters showed remarkable improvements (Table 13):- Hardness (HV): Increased from 85 to 112 HV (a 31.77% improvement).

- Wear Rate (WR): Decreased from 2.89 to 1.84 x 10⁻³ mm³/min (a 36.33% reduction).

Finding 4: Microstructural and Wear Surface Evidence.

SEM analysis provided visual proof of the optimization's success. The optimized sample (Figure 8b) exhibited a dense microstructure with minimal pores and evenly dispersed reinforcements, in stark contrast to the porous, clustered structure of the initial sample (Figure 8a). Furthermore, analysis of the worn surface (Figure 10c) showed thin, slender grooves and evidence of a self-lubricating layer, confirming its superior wear resistance.

Practical Implications for HPDC Products

While this study was conducted using stir casting, the fundamental principles and outcomes offer valuable insights for professionals working with HPDC and other liquid metal processes.

For Process Engineers: The research underscores the critical importance of precise process control. The optimal settings for melt and die temperature (740°C and 180°C, respectively) represent a "sweet spot" that ensures proper material flow and solidification without introducing defects like porosity or premature freezing [Ref. [34]]. This principle is directly applicable to HPDC, where thermal management is paramount for achieving sound castings.

For Quality Control: The strong link between process parameters and final mechanical properties is a key takeaway. The SEM images (Figure 8) provide a clear visual benchmark for what an ideal reinforcement dispersion looks like in a cast matrix. This can inform microstructural analysis standards for new composite alloys, helping QC teams identify potential issues related to particle agglomeration or porosity.

For R&D and Material Selection: This study serves as a powerful proof-of-concept for the next generation of high-performance castable alloys. It demonstrates that nano-reinforcements like graphene and MWCNTs can deliver dramatic improvements in hardness and wear resistance. For R&D managers and procurement specialists in the automotive, aerospace, or electronics industries, this research highlights a promising path toward developing new HPDC-compatible materials that can replace heavier steel components, leading to significant weight reduction and performance gains.

Paper Details

Stir Casting Process Analysis and Optimization for Better Properties in Al-MWCNT-GR-Based Hybrid Composites

1. Overview:

- Title: Stir Casting Process Analysis and Optimization for Better Properties in Al-MWCNT-GR-Based Hybrid Composites

- Author: Kanchiraya Shivalingaiah, Vinayaka Nagarajaiah, Chithirai Pon Selvan, Smitha Thothera Kariappa, Nandini Gowdru Chandrashekarappa, Avinash Lakshmikanthan, Manjunath Patel Gowdru Chandrashekarappa and Emanoil Linul

- Year of publication: 2022

- Journal/academic society of publication: Metals

- Keywords: Al-MWCNT-GR composite; hardness; wear rate; stir casting process; Taguchi-CRITIC-MOORA; Taguchi-CRITIC-GRA

2. Abstract:

Pure aluminium poses inferior properties that limit its use in load-bearing applications. Reinforcing multiwall carbon nano-tube (solid lubricant) and graphene to aluminium matrix offers better (antifriction, hardness, and wear resistance) properties in composites for such applications. A stir casting processing route is employed to prepare the hybrid composite (aluminium-multiwall carbon nanotube-graphene Al-MWCNT-GR). The Taguchi L16 experimental matrix representing four variables (percent reinforcement of graphene, die temperature, melt temperature, and stir speed) operating at four levels were studied to analyze and obtain higher hardness and low wear rate in hybrid composites. Percent reinforcement of graphene showed maximum impact, and die temperature resulted with the least contribution towards both the responses. Criteria importance through intercriteria correlation (CRITIC) method is applied to determine the weight fractions (importance) for hardness and wear rate equal to 0.4752 and 0.5482, respectively. Grey relational analysis (GRA) and multi-objective optimization by the ratio analysis (MOORA) method converts multiple objective functions into a single objective function with weight fractions assigned to each output. Taguchi-CRITIC-MOORA outperformed the Taguchi-CRITIC-GRA method, which could result in 31.77% increase in hardness and a 36.33% decrease in wear rate compared to initial conditions. The optimal conditions ensure a dense microstructure with minimal pores, result in enhanced properties compared to that obtained for initial and average stir casting conditions. The worn-out surface results in a few thin and slender grooves between tracks with less crack propagation, ensuring self-lubrication in composites fabricated with the optimized condition. The better properties resulted in the hybrid composites correspond to optimized stir casting conditions and can be implemented in industries for large-scale applications.

3. Introduction:

Modern industries aim to develop components with attractive properties like strength, stiffness, and wear resistance. Metal matrix composites (MMCs), particularly those with an aluminum matrix, are widely used in automotive, aerospace, and biomedical applications for their superior conductivity and mechanical properties compared to polymers [Ref. [5-8]]. Reinforcing aluminum with strong particles improves its strength, but traditional hard reinforcements (carbides, oxides) can cause issues like abrasiveness and reduced ductility [Ref. [19], [20]]. In recent years, carbon-based reinforcements like carbon nanotubes (CNTs) and graphene have gained attention for their exceptional strength and self-lubricating properties [Ref. [22], [23]]. While various methods exist to create these composites, stir casting is an economical and versatile route for large-scale production [Ref. [7], [31]]. However, the process is sensitive to parameters that can cause defects. Therefore, optimizing the stir casting process variables is essential to achieve the desired high-performance properties in the final composite.

4. Summary of the study:

Background of the research topic:

The fabrication of high-performance aluminum-based hybrid composites is critical for industrial applications requiring lightweight, strong, and wear-resistant materials. The properties of these composites are highly dependent on the manufacturing process parameters.

Status of previous research:

Previous research has established the benefits of reinforcing aluminum with either CNTs or graphene. Studies have also used methods like the Taguchi design to optimize stir casting for single properties. However, there is a lack of research on fabricating Al-MWCNT-GR hybrid composites via stir casting and, more importantly, a lack of using advanced hybrid multi-objective optimization methods to find a single set of process parameters that simultaneously improves both hardness and wear resistance.

Purpose of the study:

The primary goal was to analyze and optimize the stir casting process parameters to produce an Al-MWCNT-GR hybrid composite with maximum hardness and minimum wear rate. The study aimed to develop a systematic framework using hybrid optimization approaches (Taguchi-CRITIC-GRA and Taguchi-CRITIC-MOORA) to find the single best set of manufacturing conditions.

Core study:

The core of the study involved conducting a Taguchi L16 experimental matrix by varying four stir casting parameters: percent of graphene, die temperature, melt temperature, and stir speed. The resulting composites were tested for Vickers hardness and pin-on-disc wear rate. The data was then analyzed using Pareto ANOVA and the two hybrid multi-objective optimization models to determine factor contributions and identify the optimal process levels. The findings were validated through confirmation experiments and microstructural analysis.

5. Research Methodology

Research Design:

The study utilized a Taguchi L16 orthogonal array experimental design. This involved four process factors, each at four distinct levels. The response variables measured were hardness (larger-the-better) and wear rate (smaller-the-better). To resolve the conflict between these two objectives, multi-objective optimization was performed using Grey Relational Analysis (GRA) and Multi-Objective Optimization by Ratio Analysis (MOORA), with response weights determined by the Criteria Importance Through Intercriteria Correlation (CRITIC) method.

Data Collection and Analysis Methods:

- Hardness Measurement: Vickers hardness was measured on machined samples (Ø 10 mm × 10 mm) according to ASTM E384 standards.

- Wear Rate Measurement: A pin-on-disc wear test was conducted as per ASTM G99 standards on composite pins (Ø 6 mm × 30 mm). Wear rate was calculated from weight loss measurements.

- Microstructural Analysis: Scanning Electron Microscopy (SEM) and Energy-Dispersive X-ray Spectroscopy (EDS) were used to study the morphology of the raw reinforcement powders and the microstructure and worn surfaces of the cast composites.

- Statistical Analysis: Pareto Analysis of Variance (ANOVA) was used to determine the percent contribution of each process factor.

Research Topics and Scope:

The research was scoped to the fabrication of Al-2.5wt.%MWCNT-GR hybrid composites using a laboratory-scale stir casting setup. The study focused on the influence of four specific process parameters (graphene content, melt temperature, die temperature, stir speed) on two specific mechanical properties (hardness and wear rate).

6. Key Results:

Key Results:

- The percent reinforcement of graphene was the most influential parameter, contributing 76.77% to hardness and 80.31% to wear rate. Die temperature had the least effect (Table 3, Table 4).

- The CRITIC method determined the objective weights for optimization to be 0.4752 for hardness and 0.5428 for wear rate, indicating a slightly higher importance placed on minimizing wear (Table 8).

- The Taguchi-CRITIC-MOORA optimization model outperformed the Taguchi-CRITIC-GRA model.

- The optimal process parameters determined by the MOORA method were: 3% graphene, 180°C die temperature, 740°C melt temperature, and 520 rpm stir speed (Table 12).

- Under these optimal conditions, the composite achieved a hardness of 112 HV and a wear rate of 1.84 × 10⁻³ mm³/min, representing a 31.77% increase in hardness and a 36.33% decrease in wear rate over initial conditions (Table 13).

- SEM analysis confirmed that the optimized conditions produced a dense microstructure with minimal porosity and uniform reinforcement dispersion (Figure 8b), leading to enhanced properties.

- The worn surface of the optimized composite showed characteristics of mild abrasive wear with self-lubrication, evidenced by thin grooves and less crack propagation (Figure 10c).

Figure Name List:

- Figure 1. SEM morphologies of reinforcement materials: (a) MWCNT Nano-powder and (b) Graphene Nano-powder in pristine state.

- Figure 2. EDS analysis of reinforcement materials: (a) MWCNT Nano-powder and (b) Graphene Nano-powder in pristine state.

- Figure 3. Schematic representation and framework of stir cast process modeling and optimization.

- Figure 4. Details of dimensions of wear rate and hardness of stir cast composite samples.

- Figure 5. Framework of the hybrid approach to perform modeling and optimization.

- Figure 6. Main effect plots of hardness of stir casting composites.

- Figure 7. Main effect plots of wear rate of stir casting composites.

- Figure 8. SEM Morphology studies for different stir casting conditions: (a) PR₁DT₁MT₁SS₁ Condition (initial experiment: PR: 1%, DT: 140 °C, MT: 680 °C, and SS: 480 rpm), (b) PR₃DT₂MT₃SS₂ Condition (optimal condition: PR: 3%, DT: 180 °C, MT: 740 °C, and SS: 520 rpm), (c) PR₂DT₃MT₄SS₁ Condition (PR: 2%, DT: 220 °C, MT: 770 °C, and SS: 480 rpm).

- Figure 9. Microhardness indentation images of the present investigation.

- Figure 10. Wear Track and Wear Debris SEM images of the present investigation.

7. Conclusion:

The study successfully demonstrated a systematic framework for optimizing the stir casting process for Al-MWCNT-GR hybrid composites. The key conclusions are:

1. Percent reinforcement of graphene is the most dominant factor affecting hardness and wear rate.

2. The hybrid Taguchi-CRITIC-MOORA optimization method effectively identified a single set of optimal parameters (3 wt.% GR, 180°C die temp, 740°C melt temp, 520 rpm stir speed) that resulted in a 31.77% increase in hardness and a 36.33% decrease in wear rate.

3. The optimized process conditions yield a dense, uniform microstructure, which is the cause of the enhanced mechanical properties.

4. The optimized composite exhibits excellent self-lubricating characteristics, making it suitable for high-wear, load-bearing industrial applications.

8. References:

- [List of references 1-88 from the paper]

Expert Q&A: Your Top Questions Answered

Q1: Which single process parameter had the biggest impact on the composite's final properties?

A1: The percent reinforcement of graphene (PR) was by far the most dominant factor. The study's Pareto ANOVA showed it contributed over 76% to the final hardness and over 80% to the wear rate, dwarfing the effects of melt temperature, die temperature, and stir speed [Source: Paper Section 3, Tables 3 & 4].

Q2: What were the exact optimal settings found to achieve the best combination of hardness and wear resistance?

A2: The Taguchi-CRITIC-MOORA analysis identified the single best recipe for the process. The optimal parameters were: 3 wt.% graphene reinforcement, a die temperature of 180 °C, a melt temperature of 740 °C, and a stir speed of 520 rpm [Source: Paper Section 3.4, Table 12].

Q3: How much of an improvement did these optimal settings actually provide?

A3: The improvements were significant. When validated with a confirmation experiment, the composite made with the optimal parameters showed a 31.77% increase in hardness and a 36.33% decrease in wear rate when compared to the composite made under the initial, non-optimized conditions [Source: Paper Section 3.4, Table 13].

Q4: Why was the Taguchi-CRITIC-MOORA method the best approach for this problem?

A4: This hybrid method excelled because it could find a single, robust solution for multiple conflicting goals (maximizing hardness while minimizing wear). It scientifically assigned weights to each goal using the CRITIC method and ultimately outperformed the alternative GRA method in producing a composite with better overall properties [Source: Paper Abstract, Section 3.4, Table 13].

Q5: What does the microstructure of the optimized composite look like?

A5: The SEM analysis in Figure 8b shows that the composite produced under optimal conditions has a dense microstructure with minimal pores and excellent, uniform dispersion of the MWCNT and graphene reinforcements. This is in sharp contrast to the initial sample (Figure 8a), which showed more porosity and particle clustering.

Q6: How can these findings from stir casting be relevant to my HPDC process?

A6: While the manufacturing method is different, the core principles are highly relevant. This study provides a blueprint for how to approach the development of new, high-performance alloys. It proves the immense potential of nano-reinforcements like graphene and demonstrates that precise control over thermal parameters (melt/die temperature) and mixing energy (stir speed) is critical to achieving a good microstructure and superior properties—a fundamental truth in all liquid metal casting, including HPDC.

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing the mechanical properties of aluminum composites through systematic process optimization. The findings offer a clear, data-driven path toward improving quality by controlling key variables to achieve a superior microstructure, resulting in a material with significantly higher hardness and wear resistance.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers' most challenging die casting problems. If the issues of wear resistance and material strength discussed in this paper resonate with your operational goals, contact our engineering team to discuss how we can help you leverage advanced materials and processes in your components.

Copyright

- This material is a paper by "Kanchiraya Shivalingaiah, Vinayaka Nagarajaiah, et al.". Based on "Stir Casting Process Analysis and Optimization for Better Properties in Al-MWCNT-GR-Based Hybrid Composites".

- Source of the paper: https://doi.org/10.3390/met12081297

This material is for informational purposes only. Unauthorized commercial use is prohibited. Copyright © 2025 CASTMAN. All rights reserved.