This technical summary is based on the academic paper "Surface Engineering and its Role in Preventing Early Failures" by J. N. Balaraju, published in the SFA Newsletter (May 2013). It was analyzed and summarized for HPDC experts by CASTMAN experts with the help of LLM AI such as Gemini, ChatGPT, and Grok.

Keywords

- Primary Keyword: Electroless Nickel Plating

- Secondary Keywords: Surface Engineering, Corrosion Prevention, Wear Resistance, Component Failure, Aerospace Coatings, Automotive Coatings, Surface Modification

Executive Summary

- The Challenge: A vast majority of engineering component failures are due to surface-level phenomena like wear, corrosion, and fatigue. Fabricating the entire component from highly resistant (and expensive) material is often not economically viable.

- The Method: The paper explores surface engineering, a discipline focused on modifying only the surface of a component to achieve superior performance. It highlights electroless nickel plating as a particularly versatile, scalable, and economical technique.

- The Key Breakthrough: Through several real-world case studies, the research demonstrates that electroless nickel plating effectively solves critical failure issues across diverse industries—from preventing corrosion in automotive carburetors to providing wear resistance in aerospace components and enabling specific optical properties in satellites.

- The Bottom Line: Surface engineering, specifically with electroless nickel plating, allows for the use of cost-effective substrate materials while achieving performance enhancements that neither the substrate nor the coating could accomplish on its own, thereby extending component life and improving overall efficiency.

The Challenge: Why This Research Matters for HPDC Professionals

In any manufacturing operation, from automotive to aerospace, component degradation and failure are major drivers of cost and downtime. As this research points out, the root cause is often not the bulk material but the surface, which is constantly exposed to wear, corrosion, and fatigue. The traditional approach of using expensive, strategically important materials for the entire component is a brute-force solution that is often cost-prohibitive.

This has led to the development of surface engineering, defined by Bell [1] as “the design of surface and substrate together as a system, to give a cost-effective performance enhancement of which neither is capable on its own.” The core idea is elegant and efficient: use a lean, cheaper material for the bulk of the component (the substrate) and apply a specialized, high-performance coating to the surface. This creates a synergistic system that delivers the required performance without the exorbitant cost of a full-body alloy.

The Approach: Unpacking the Methodology

While numerous coating methods exist, such as physical vapour deposition (PVD) and chemical vapour deposition (CVD), this paper focuses on electroless plating. This process has gained considerable attention because it is versatile, economical, and scalable.

Unlike traditional electrochemical methods, electroless plating offers several key advantages that make it ideal for complex engineering components:

- More uniform coating thickness, even on intricate shapes and in deep recesses.

- No need for a power supply or electrical contacts, simplifying the process.

- Ability to deposit on non-conductive materials.

- Produces coatings with less porosity.

These characteristics allow process methodologies to be easily tailored to meet specific property requirements, making it a powerful tool for modifying surfaces to prevent failures.

The Breakthrough: Key Findings & Data

The paper presents several compelling case studies demonstrating the practical success of electroless nickel plating in preventing surface-related failures.

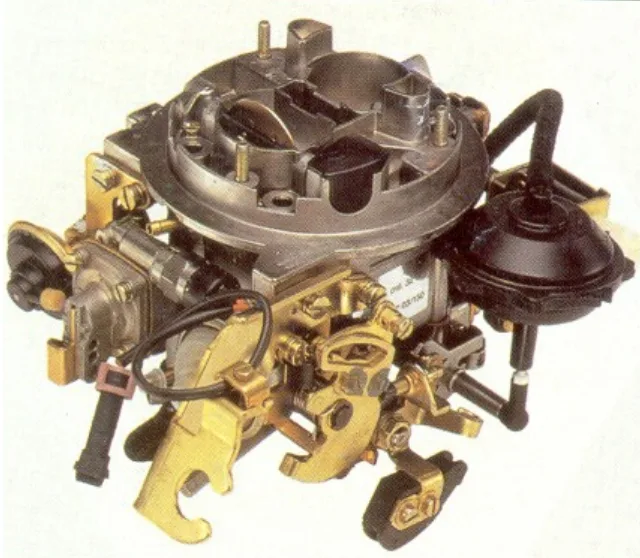

- Finding 1: Solving Automotive Corrosion: In Brazil, the switch from gasoline to ethanol fuel created highly corrosive conditions that severely damaged zinc diecast carburetor components. The application of an electroless nickel deposit successfully resolved these corrosion problems, preventing the blockage of narrow channels and orifices (Figure 1).

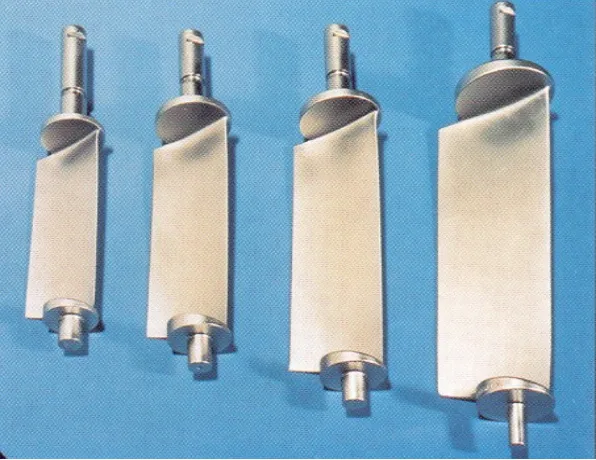

- Finding 2: Enhancing Aerospace Durability: In military and commercial aircraft, compressor components require protection from corrosive and erosive particles at temperatures up to 425°C. Traditional Ni/Cd and aluminide coatings suffered from non-uniform thickness. High phosphorus electroless nickel provided a superior alternative with uniform thickness, excellent corrosion/erosion resistance on airfoil surfaces, and wear resistance on trunnions (Figure 2).

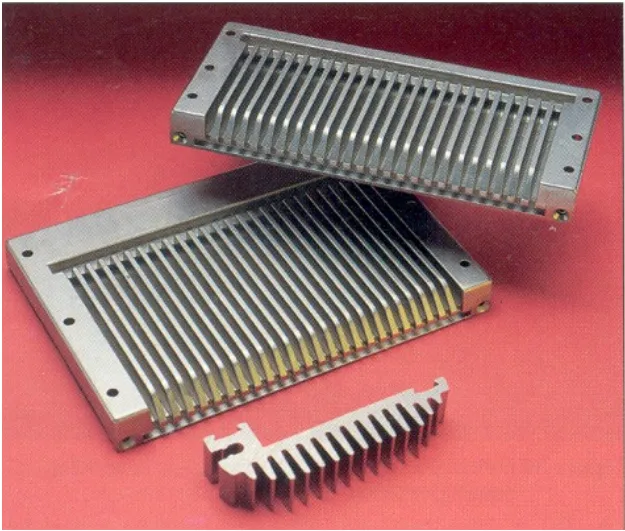

- Finding 3: Improving Electronics Performance: Heat sinks, often made of aluminum, require a hard, durable coating that also allows for soldering or brazing. The complex design with deep fins makes uniform coating difficult. Electroless nickel provides a hard, durable coating with good solderability, protecting the component from corrosion while meeting assembly requirements (Figure 3).

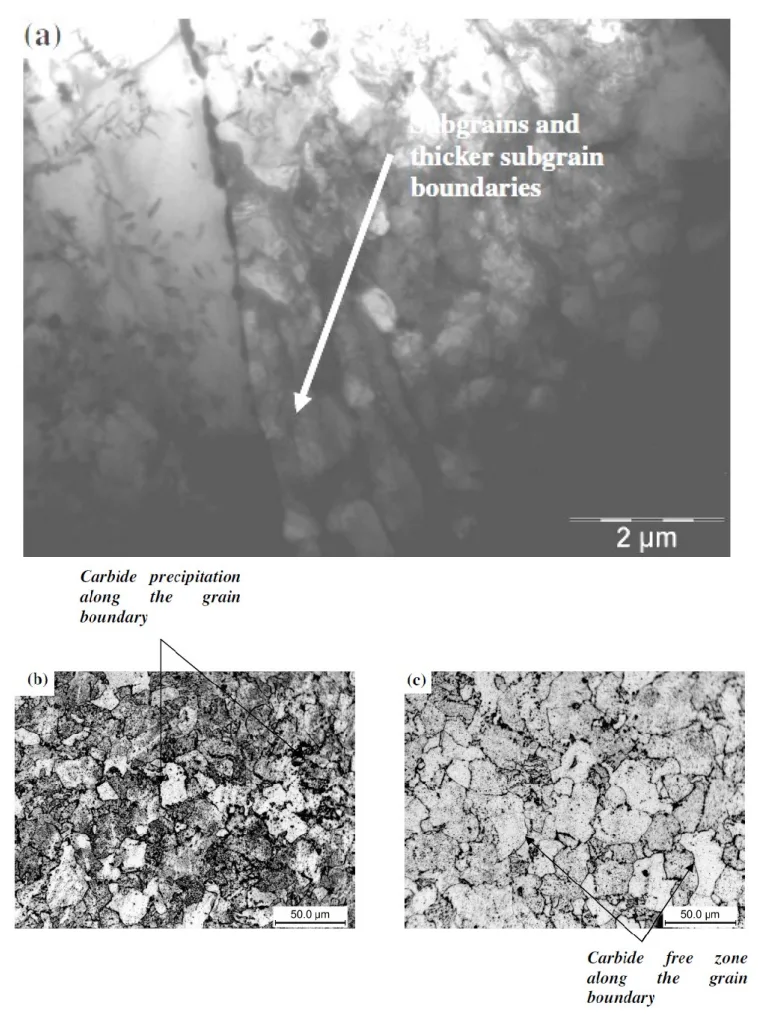

- Finding 4: Enabling Advanced Optical Properties: For passive radiative coolers on INSAT satellites, aluminum mirrors needed to be highly polishable to achieve specific reflectivity values. Due to aluminum's poor scratch resistance, it could not be polished directly. The solution was a multilayer system featuring a nanocrystalline electroless nickel coating, which provided a highly polishable surface that, when overlaid with PVD aluminum, met the stringent optical requirements (Figure 4).

Practical Implications for HPDC Products

The findings presented in this research have direct and valuable implications for modern manufacturing and die casting operations.

- For Process Engineers: The success of electroless nickel on complex geometries like heat sinks (Figure 3) and airfoils (Figure 2) suggests it is a robust solution for providing uniform protective coatings on intricate die-cast parts where line-of-sight methods like PVD or spray coatings may fail.

- For Quality Control: The inherent uniformity of electroless plating can simplify quality assurance processes. Unlike electroplating, which can lead to thickness variations at edges and in recesses, electroless plating provides a consistent layer, reducing the need for extensive point-by-point thickness verification.

- For Die Design & Material Selection: This research validates the strategy of designing with lower-cost substrate alloys and relying on advanced surface engineering to meet demanding performance criteria. This allows for significant cost savings without compromising on the corrosion, wear, or functional properties of the final component.

Paper Details

Surface Engineering and its Role in Preventing Early Failures

1. Overview:

- Title: Surface Engineering and its Role in Preventing Early Failures

- Author: J. N. Balaraju

- Year of publication: 2013

- Journal/academic society of publication: SFA Newsletter, Issue 8

- Keywords: Surface engineering, surface modification, electroless plating, corrosion, wear, component failure

2. Abstract:

A vast majority of engineering components fail in service due to surface-related phenomena like wear, corrosion, and fatigue. This has led to the development of surface engineering, an interdisciplinary field that aims to create innovative techniques for superior material performance. The basic idea is to use lean, cheaper materials as substrates and apply rare or expensive materials as coatings to achieve a cost-effective performance enhancement. This report discusses the role of surface engineering, with a focus on the electroless plating method, in preventing early failures. Several case studies from the automotive, aerospace, electronics, and satellite sectors are presented to illustrate the versatility and effectiveness of this technique in improving corrosion resistance, wear resistance, and achieving specific optical properties.

3. Introduction:

Surface modification has a long history, maturing from an art form into an established scientific discipline. It addresses the common problem of engineering components degrading due to surface-related phenomena. Surface engineering begins with defining the functional requirements of a surface to prevent failure, choosing the right material, and selecting a modification process that is economical and extends the component's life. The core principle is to use cost-effective substrates with high-performance coatings, creating a synergistic system. According to Bell [1], surface engineering is "the design of surface and substrate together as a system, to give a cost-effective performance enhancement of which neither is capable on its own.”

4. Summary of the study:

Background of the research topic:

Engineering components frequently fail due to surface issues. This necessitates surface modification techniques to ensure functionality under aggressive conditions.

Status of previous research:

Many coating methods like PVD, CVD, and electroplating are available. However, electroless plating has received considerable attention for its versatility, economy, and unique process advantages.

Purpose of the study:

To demonstrate the significant role of surface engineering, particularly electroless nickel plating, in preventing premature component failure and enhancing performance across various industrial applications.

Core study:

The paper reviews several real-world applications where electroless nickel plating was successfully used to solve critical engineering problems. These include preventing corrosion in automotive carburetors, protecting aerospace compressor parts from corrosion and erosion, providing durable and solderable coatings for electronic heat sinks, and engineering highly polishable surfaces for satellite mirrors.

5. Research Methodology

Research Design:

The study is a review of practical applications and case studies where electroless plating was implemented as a surface engineering solution.

Data Collection and Analysis Methods:

The paper analyzes the outcomes of applying electroless nickel coatings in four distinct industrial sectors: automotive, aerospace, electronics, and satellite technology. The effectiveness of the solution is evaluated based on its ability to resolve specific failure modes (e.g., corrosion, wear) or achieve desired functional properties (e.g., solderability, polishability).

Research Topics and Scope:

The research covers the application of electroless nickel plating for:

- Corrosion resistance in zinc diecast carburetors using ethanol fuel.

- Corrosion and erosion resistance at high temperatures for aircraft compressor components.

- Providing a hard, durable, and solderable coating for aluminum heat sinks.

- Achieving high polishability and specific optical properties on aluminum mirrors for satellites.

6. Key Results:

Key Results:

- Electroless nickel plating resolved severe corrosion issues in zinc diecast carburetors caused by hydrated alcohol fuel.

- High phosphorus electroless nickel deposits outperformed traditional Ni/Cd and thermally sprayed aluminide coatings for protecting aircraft compressor vanes and trunnions, offering superior uniformity and resistance to corrosion and erosion.

- For electronic heat sinks with complex fin designs, electroless nickel provided a hard, durable coating with good solderability, which is difficult to achieve with other methods.

- A multilayer coating system incorporating a nanocrystalline electroless nickel layer was key to producing highly polishable aluminum mirrors for passive radiative coolers on INSAT satellites, meeting stringent optical property requirements.

Figure Name List:

- Fig. 1 Electroless nickel resolved corrosion problems on carburetors using ethanol fuel

- Fig. 2 High phosphorus deposits on variable vanes and trunions have provided performance and cost advantages

- Fig. 3 Electroless nickel provides a hard, durable coating with good solderability on heat sinks

- Fig. 4 Highly polishable coatings for passive radiative coolers of satellites

7. Conclusion:

Surface engineering plays a vital role in modifying surfaces to enhance performance and improve the total efficiency of a product. Among the various methods, electroless nickel plating is a widely used and powerful technique. The examples discussed in the report clearly demonstrate that this surface modification method has tremendous potential in preventing the early failure and degradation of engineering components. Beyond improving abrasion, wear, and corrosion resistance, the method is also suitable for achieving required optical properties.

8. References:

- [1] T. Bell, “Surface Engineering: Past, present and future, Surface Engineering", 6.1 (1991) 31.

- [2] A. Zanini, “Nickel”, Nickel Development Institute (NiDI) March 1987 Publication.

- [3] F. Brindisi, “The use of electroless nickel in the aerospace industry – An Overview", S.W. Ontario Branch AESF Springfest Symposium, Kitchener, Ontario, April 1997.

- [4] G.O. Mallory and J.B. Hajdu, 'Electroless plating: Fundamentals and Applications', (AESF, Orlando, FL, 1990).

- [5] W.F. Riedel, Electroless Nickel Plating, ASM Int. Metals Park, Ohio, USA, 1991.

Expert Q&A: Your Top Questions Answered

Q1: Why should I consider electroless nickel plating over more traditional methods like electroplating?

A1: The paper highlights that electroless plating offers superior coating uniformity, especially on parts with complex geometries, deep recesses, or sharp edges. Unlike electroplating, it does not require an electric current, which eliminates the problem of uneven current distribution that causes thickness variations. It can also be used to coat non-conductive materials.

Q2: What specific, demanding problems has this method been proven to solve?

A2: The research provides several powerful examples. It solved severe corrosion in automotive carburetors running on aggressive ethanol fuel (Figure 1) and provided high-temperature corrosion and erosion protection for critical aerospace compressor components, outperforming previous coating systems (Figure 2).

Q3: Is this process only useful for preventing wear and corrosion?

A3: No. While it excels at improving wear and corrosion resistance, the study shows its versatility extends to other functional properties. A key example is its use on satellite mirrors, where a nanocrystalline electroless nickel layer was essential for creating a highly polishable surface to meet demanding optical requirements (Figure 4).

Q4: What is the core cost-saving principle of surface engineering discussed in this study?

A4: The fundamental idea, as stated by Bell [1], is to design the surface and the substrate as a complete system. This allows you to use lean, cost-effective materials for the main body of the component and apply a specialized coating to achieve high performance only where it's needed—at the surface. This provides a cost-effective enhancement that neither part could achieve alone.

Q5: How well does electroless nickel plating handle parts with intricate designs, like die-cast heat sinks?

A5: It handles them exceptionally well. The paper points to heat sinks with deep fins as a prime example (Figure 3). The electroless process ensures a uniform coating throughout the complex surface, providing consistent corrosion protection and a durable, solderable finish, which is a significant advantage over line-of-sight coating methods.

Conclusion & Next Steps

This research provides a valuable and practical overview of how a targeted surface engineering strategy can solve critical component failures and unlock new levels of performance. The findings demonstrate that electroless nickel plating is not just a protective layer but a versatile engineering tool that can be tailored to meet a wide range of industrial challenges, from corrosion and wear to advanced optical applications.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers' most challenging die casting problems. If the issues of corrosion, wear, or achieving specific functional properties on complex components resonate with your operational goals, contact our engineering team to discuss how we can help you implement these advanced principles in your components.

Copyright

- This material is a paper by "J. N. Balaraju". Based on "Surface Engineering and its Role in Preventing Early Failures".

- Source of the paper: SFA Newsletter, Issue 8, May 2013.

This material is for informational purposes only. Unauthorized commercial use is prohibited. Copyright © 2025 CASTMAN. All rights reserved.