From Simulation to Perfection: Slashing Cycle Time and Defects in Automotive HPDC

This technical summary is based on the academic paper "SIMULATIONS OF THE SHRINKAGE POROSITY OF Al-Si-Cu AUTOMOTIVE COMPONENTS" by Lejla Lavtar¹, Mitja Petrič², Jožef Medved², Boštjan Taljat¹, Primož Mrvar², published in Materiali in tehnologije / Materials and technology (2012). It has been analyzed and summarized for technical experts by CASTMAN with the assistance of AI.

Keywords

- Primary Keyword: Shrinkage Porosity Simulation

- Secondary Keywords: High-Pressure Die Casting (HPDC), Al-Si-Cu Alloy, ProCast Software, Automotive Components, Cycle Time Reduction

Executive Summary

A 30-second overview for busy professionals.

- The Challenge: To efficiently produce high-integrity Al-Si-Cu automotive components by mitigating shrinkage porosity, a common and costly defect in HPDC.

- The Method: Researchers used ProCast, an FEM-based simulation software, to model the shot-sleeve and solidification stages of an HPDC process for an Al-Si9Cu3 alloy cast in an H13 steel die.

- The Key Breakthrough: The simulation accurately predicted the locations of shrinkage porosity ("red spots") and identified an optimized shot profile that reduced the process cycle time by 0.48 seconds.

- The Bottom Line: Advanced Shrinkage Porosity Simulation is a validated, effective tool for both improving component quality by predicting defect locations and increasing manufacturing efficiency by optimizing process parameters.

The Challenge: Why This Research Matters for HPDC Professionals

In the competitive automotive industry, the fast and economical production of components with high dimensional accuracy is paramount. High-pressure die casting (HPDC) of aluminum alloys is a key enabling technology, but it is not without its challenges. The integrity of cast components is directly affected by metallurgical operating conditions. If parameters like die temperature, metal velocity, and applied pressure are not precisely controlled, defects are inevitable.

Among the most critical defects is porosity, which can be caused by gas entrapment or shrinkage during solidification. Shrinkage porosity, in particular, is associated with "hot spots" in the casting and can compromise the mechanical properties of the final part. The traditional trial-and-error approach to optimizing casting-system design is time-consuming and costly. This research was undertaken to demonstrate how numerical simulation can serve as an effective tool for modeling the HPDC process, predicting defect formation, and improving the overall quality of castings before the first tool is cut.

The Approach: Unpacking the Methodology

The study focused on the HPDC of an automotive component using a standard industrial setup.

- Material: The casting alloy was Al-Si9Cu3, chosen for its good castability and lower proneness to shrinkage cavities. The chemical composition is detailed in Table 1 of the paper. The die was made from ALSI H13 chromium hot-work tool steel, selected for its high resistance to heat cracking and wear.

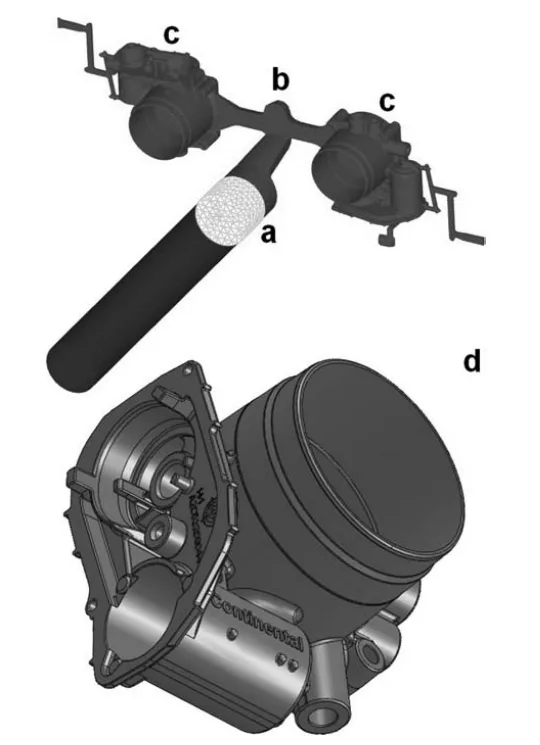

- Casting System: The system consisted of a shot sleeve with a plunger, a runner and gate system, and a die with two cavities for producing left and right components, as illustrated in Figure 1.

- Simulation Software: The researchers utilized ProCast, a finite element method (FEM)-based software, to conduct 3D simulations of the process.

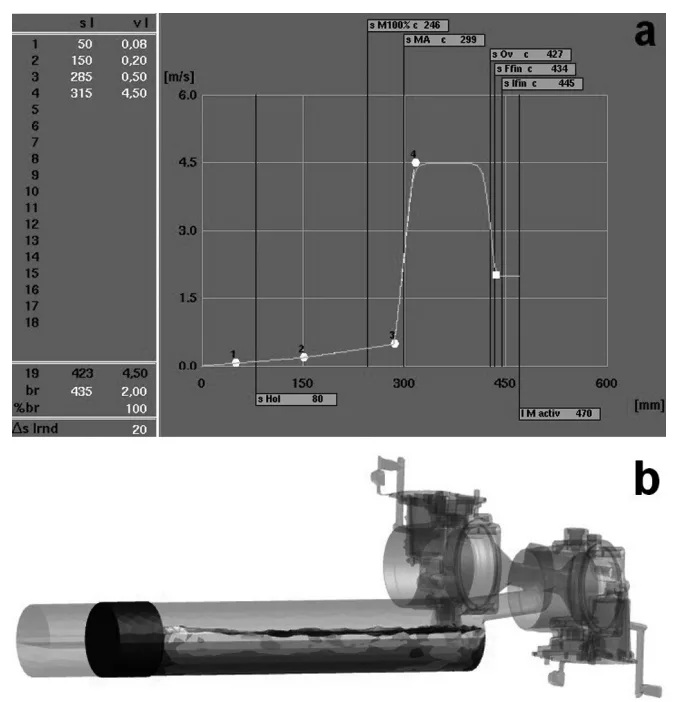

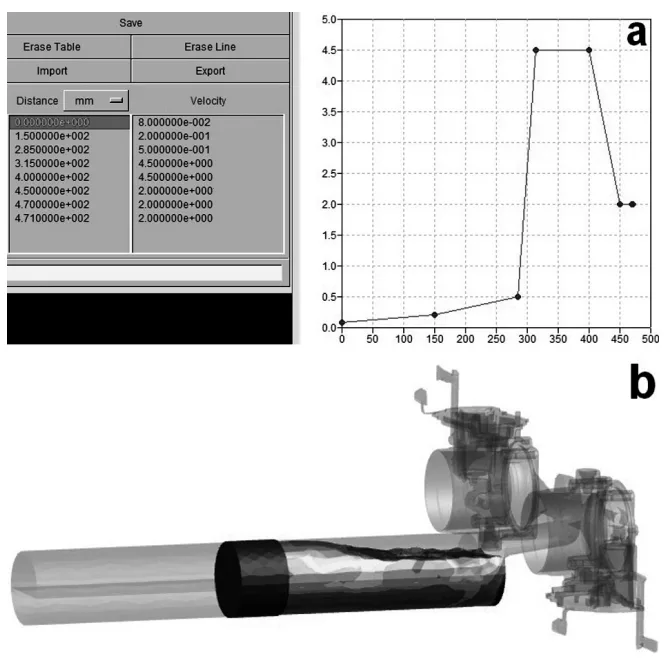

- Process Variables: The study simulated two different shot profiles. The first was an existing industrial process with four different plunger speeds (Figure 2a). The second was an optimized profile using only three plunger speeds (Figure 3a), designed to minimize the set-up time and shorten the cycle. The simulations were used as boundary conditions to then model cavity filling and predict shrinkage porosity formation. The simulated results were then compared to physical cut sections of actual castings.

The Breakthrough: Key Findings & Data

The simulations provided two significant, actionable breakthroughs for the HPDC process.

Finding 1: Shot Profile Optimization Reduces Cycle Time by 0.48 Seconds

By simulating a modified shot profile, the research team demonstrated a tangible process efficiency improvement. The initial industrial process used four distinct plunger speeds. The simulation showed that by moving to an optimized profile with three plunger speeds (Figure 3a), the set-up time for the shot stage of the HPDC process could be shortened by 0.48 seconds. Crucially, the simulation confirmed that this faster profile still resulted in no wave formation or air entrapment in the shot sleeve (Figure 3b), ensuring that the time savings did not come at the expense of introducing gas porosity.

Finding 2: Accurate Prediction of Shrinkage Porosity Locations

The study's primary goal was to validate the accuracy of Shrinkage Porosity Simulation. After running the simulation for ten casting cycles to achieve stable thermal conditions in the die, the software predicted specific locations of high porosity risk, identified as "red spots" (Figure 4). To verify this, researchers examined two of these high-risk spots in the actual left-side casting. As shown in Figures 5 and 6, there was a "good agreement" between the simulated porosity locations (Figures 5a and 6a) and the porosity observed in the physical cut sections of the components (Figures 5b and 6b). This confirms the simulation's power as a predictive quality tool.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting the plunger speed profile can directly contribute to reducing cycle time without negatively impacting melt flow in the shot sleeve. The 0.48s reduction per cycle represents a significant productivity gain in high-volume manufacturing.

- For Quality Control Teams: The data in Figure 4 of the paper illustrates the ability of simulation to pinpoint high-risk areas for shrinkage porosity. This information could inform new quality inspection criteria, allowing teams to focus their destructive or non-destructive testing on the most probable defect locations.

- For Design Engineers: The findings indicate that simulation can predict "hot spots" where shrinkage porosity is likely to form. Using this methodology in the early design phase allows for modifications to part geometry or gating systems to mitigate these issues before tooling is manufactured, saving significant time and cost.

Paper Details

SIMULATIONS OF THE SHRINKAGE POROSITY OF Al-Si-Cu AUTOMOTIVE COMPONENTS

1. Overview:

- Title: SIMULATIONS OF THE SHRINKAGE POROSITY OF Al-Si-Cu AUTOMOTIVE COMPONENTS

- Author: Lejla Lavtar, Mitja Petrič, Jožef Medved, Boštjan Taljat, Primož Mrvar

- Year of publication: 2012

- Journal/academic society of publication: Materiali in tehnologije / Materials and technology 46 (2)

- Keywords: high-pressure die casting, aluminium-silicon-copper alloy, shrinkage porosity, ProCast software

2. Abstract:

The 3D shoot-sleeve and shrinkage-porosity simulations of a high-pressure die-casting (HPDC) process are presented using the ProCast casting-simulation software. The porosity was studied during the casting and solidification of aluminium-silicon-copper alloy components in an H13 steel die. Excellent agreement between the simulated and experimental results was observed.

3. Introduction:

To manufacture a large variety of products with high dimensional accuracy using the process of high-pressure die casting (HPDC) the fast and economical production of aluminium automotive components has been developed. In the past two decades the rapid development of numerical simulation methodology and the solidification simulation of castings have been introduced as an effective tool for modeling the casting process and improving the quality of castings. The use of simulation software saves time and reduces the costs of the casting-system design and of the materials used. The physical, mechanical and esthetic properties directly depend on the metallurgical operating conditions during casting. If these parameters are not controlled properly, various defects in the finished component are to be expected. It is commonly accepted that the shrinkage and the gas are the two major causes of porosity.

4. Summary of the study:

Background of the research topic:

The production of high-quality automotive components via HPDC requires precise control over process parameters to avoid defects like porosity.

Status of previous research:

Numerical simulation has been established as an effective tool for modeling casting processes, saving time, and reducing costs. Research has shown that process variables like intensification pressure and casting velocity affect porosity.

Purpose of the study:

To describe the simulation of an HPDC process for an Al-Si9Cu3 casting in an H13 steel die and to compare the simulated shrinkage porosity with experimental results.

Core study:

The study involved two main simulation efforts using ProCast software:

1. A shot-sleeve simulation to analyze the melt flow under different plunger speed profiles and identify opportunities for cycle time reduction.

2. A shrinkage-porosity simulation using the shot-sleeve results as boundary conditions to predict the location of defects in the final casting, which was then validated against physical parts.

5. Research Methodology

Research Design:

The study used a comparative approach, contrasting simulation results with experimental observations. An initial industrial HPDC process was simulated and then compared to an optimized, simulated process. The shrinkage porosity predictions from the simulation were then compared with physical cut sections of the cast components.

Data Collection and Analysis Methods:

- Simulation: 3D simulations were performed using the FEM-based ProCast software.

- Experimental Validation: Visual observation of machined cut sections of the die-cast parts was used to confirm the presence and location of porosity predicted by the simulation.

Research Topics and Scope:

The research focused on the HPDC of an Al-Si-Cu automotive component. The scope included the simulation of the shot-sleeve filling process and the simulation of shrinkage porosity formation during solidification.

6. Key Results:

Key Results:

- The shot-sleeve simulation identified an optimized plunger speed profile that shortened the HPDC process set-up time by 0.48 s.

- The shrinkage-porosity simulation successfully predicted the locations of porosity ("red spots") in the castings.

- A good agreement was found between the simulated porosity locations and the porosity observed in the physical sections of the cast parts.

Figure Name List:

- Figure 1: Casting system: a) shot sleeve with plunger, b) gates and runner system, c) the two cavities left and right and d) the casting component

- Figure 2: a) Shot profile with four different plunger speeds and b) volume fraction picture of the alloy and the empty space in the shot sleeve

- Figure 3: a) Shot profile with three different plunger speeds and b) volume fraction picture of the alloy and the empty space in the shot sleeve

- Figure 4: Shrinkage porosity simulation of: a) left and b) right castings

- Figure 5: Shrinkage porosity in left casting at spot 1: a) simulation, b) cut section

- Figure 6: Shrinkage porosity in left casting at spot 3: a) simulation, b) cut section

7. Conclusion:

The shot-sleeve simulation provides valuable information for improving the final quality of components by minimizing air entrapment and offers savings in cycle time. The simulation also gives accurate information about the location of shrinkage porosity in castings, with the simulated results showing good agreement with experimental findings.

8. References:

- ¹M. S. Dargusch, G. Dour, N. Schauer, C. M. Dinnis, G. Savage, J. Mater. Process. Technol., 180 (2006), 37-43

- ²T. R. Vijayaram, S. Sulaiman, A. M. S. Hamuda, J. Mater. Process. Technol., 178 (2006), 29-33

- ³L. A. Dobrzanski, M. Krupinski, J. H. Sokolowski, J. Mater. Process. Technol., 167 (2005), 456-462

- ⁴K. J. Laws, B. Gun, M. Ferry, Mater. Sci. Eng., A425 (2006), 114-120

- ⁵P. W. Cleary, J. Ha, M. Prakash, T. Nguyen, Appl. Math. Model., 30 (2006), 1406-1427

- ⁶M. Petrič, J. Medved, P. Mrvar, Metalurgija, 50 (2011) 2, 127-131

- ⁷http://www.cintool.com/catalog/mold_quality/H13. pdf

- ⁸W. Thorpe, V. Ahuja, M. Jahedi, P. Cleary, N. Stokes, Trans. 20th int. die casting cong. & expo NADCA, Cleveland, 1999, T99-014

Expert Q&A: Your Top Questions Answered

Q1: Why was the Al-Si9Cu3 alloy chosen for this study?

A1: The paper states that the Al-Si9Cu3 alloy (composition in Table 1) was selected because it is less prone to shrinkage and internal shrinkage cavities and possesses very good castability. These characteristics make it a suitable material for complex automotive components where internal integrity is critical.

Q2: What was the key difference between the initial industrial process and the simulated, optimized process?

A2: The primary difference was the plunger speed profile. The initial process, shown in Figure 2a, utilized four different speeds. The optimized process, shown in Figure 3a, was simplified to use only three speeds. This change allowed the shot stage of the HPDC process to be shortened by 0.48 s without introducing defects like air entrapment.

Q3: How was the accuracy of the shrinkage porosity simulation validated?

A3: The accuracy was validated through direct comparison with physical parts. The simulation identified high-risk porosity areas, or "red spots" (Figure 4). Researchers then physically cut open the cast components at these specific locations. The paper reports "a good agreement" between the simulated porosity shown in Figures 5a and 6a and the actual porosity found in the cut sections shown in Figures 5b and 6b.

Q4: The paper mentions both gas and shrinkage porosity. Did this simulation address gas porosity?

A4: While the introduction mentions gas porosity as a major cause of defects, the primary focus of this paper's results is on Shrinkage Porosity Simulation. However, the shot-sleeve simulation is directly related to preventing gas porosity. The results in Figures 2b and 3b confirmed that the melt flow profile created "no wave and no air entrapment," which is essential for minimizing the amount of gas trapped in the sleeve before injection.

Q5: What is the significance of establishing stable die conditions over nine cycles before analysis?

A5: In HPDC, the temperature of the die changes with each cycle until it reaches a stable, cyclical thermal state. Simulating nine cycles before analyzing the tenth ensures that the thermal conditions used for the porosity prediction—such as die temperature and cooling rates—are representative of a continuous, real-world production environment, making the simulation results much more accurate and reliable.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides clear, validated evidence that modern simulation tools are indispensable for today's HPDC operations. By accurately modeling melt flow and solidification, manufacturers can address the core challenge of porosity before production begins. The key breakthrough is twofold: not only can Shrinkage Porosity Simulation reliably predict the location of critical defects, but it can also be used to optimize process parameters for significant gains in productivity, such as the 0.48-second cycle time reduction demonstrated here. This dual benefit of improved quality and increased efficiency is crucial for success in the demanding automotive sector.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

- This content is a summary and analysis based on the paper "SIMULATIONS OF THE SHRINKAGE POROSITY OF Al-Si-Cu AUTOMOTIVE COMPONENTS" by "Lejla Lavtar, et al.".

- Source: Materiali in tehnologije / Materials and technology 46 (2012) 2, 177-180

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.