Unlocking Microstructural Control in Al-Si Alloys with Advanced Friction Stir Processing Simulation

This technical brief is based on the academic paper "Quantification of Microstructural Homogeneity and the Mechanisms of Particle Refinement During FSP of Al-Si Alloys" by Chun Y. Chan and Philip B. Prangnell. It is summarized and analyzed for industry professionals by the experts at STI C&D.

Keywords

- Primary Keyword: Friction Stir Processing (FSP) of Al-Si Alloys

- Secondary Keywords: Particle refinement, microstructural homogeneity, Al-Si A380 alloy, Dirichlet tessellation, stop-action experiment, FSP simulation, automotive alloys

Executive Summary

- The Challenge: To improve the performance of cast Al-Si alloys for demanding automotive applications, it's critical to refine the coarse, brittle silicon particles and create a uniform microstructure. However, the exact mechanisms and controlling factors during Friction Stir Processing (FSP) were not fully understood.

- The Method: Researchers subjected a gravity die-cast Al-Si A380 alloy to a range of FSP conditions. The study combined detailed image analysis, Dirichlet tessellation for homogeneity quantification, innovative 'stop-action' experiments to visualize particle breakup, and a finite element (FE) thermal model to predict temperature profiles.

- The Key Breakthrough: The study revealed that while FSP is highly effective at refining particles to a 2-3 µm size, this final size is surprisingly insensitive to process parameters like tool rotation speed. The refinement occurs almost instantly as material enters the tool's shear zone. The homogeneity of the particle distribution, however, is significantly affected by processing conditions, improving with higher rotation speeds.

- The Bottom Line: For engineers using FSP, controlling the final particle size is less about process intensity and more about the initial cast material's quality. Control over process parameters, particularly rotation speed, is the key to achieving a uniform and homogeneous microstructure, which is critical for predictable mechanical performance.

The Challenge: Why This Research Matters for HPDC Professionals

Al-Si alloys are the workhorses of the automotive industry due to their low cost, light weight, and excellent castability. However, to meet the demands of higher efficiency engines and more severe operating conditions, their mechanical performance, especially fatigue properties, must be improved. The as-cast microstructure, characterized by coarse, irregular silicon (Si) flakes, is often the limiting factor.

Friction Stir Processing (FSP) has emerged as a powerful technique for locally refining these microstructures. By subjecting a component to the intense deformation from a rotating tool, FSP can dramatically reduce grain size and break up second-phase particles. Previous studies confirmed that FSP improves the tensile and fatigue properties of Al-Si alloys (Refs. [6-9]). Yet, a deep, quantitative understanding of how these particles break up and how to control their final distribution has been lacking. This research tackles that knowledge gap, providing a data-driven guide to optimizing the FSP process for superior material properties.

The Approach: Unpacking the Methodology

To dissect the FSP process, the researchers employed a multi-faceted approach on a commercial LM24/A380 Al-Si alloy:

- Systematic Processing: Cast plates were processed using a CS Powerstir FSW machine across a matrix of tool rotation speeds (300-900 RPM) and travel speeds (100-400 mm/min) to study the effect of process parameters (Table 1).

- Quantitative Image Analysis: The processed zones (PZ) were meticulously analyzed using optical microscopy and ImagePro software to quantify particle size distributions and average particle sizes (Equivalent Circular Diameter, ECD).

- Homogeneity Quantification: To move beyond simple size averages, the team used the Dirichlet tessellation method (Ref. [12]). This advanced statistical technique measures the spatial distribution of particles, providing a clear metric for clustering and homogeneity.

- 'Stop-Action' Experiments: In a crucial step, the FSW machine was stopped instantly, leaving the tool embedded in the workpiece. By sectioning these samples, the researchers could trace the evolution of particles along flow lines around the tool, effectively capturing the breakup process "in the act."

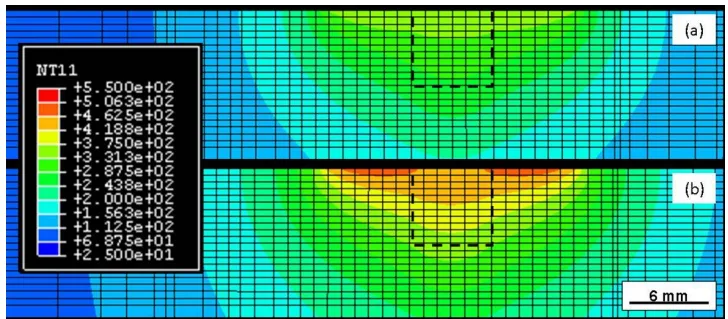

- Thermal Modeling: A finite element (FE) heat transfer model was developed in ABAQUS to predict the temperature profile within the process zone for each condition. This allowed the team to correlate thermal conditions with the observed microstructural changes.

The Breakthrough: Key Findings & Data

This comprehensive methodology yielded several critical insights into the FSP of Al-Si alloys.

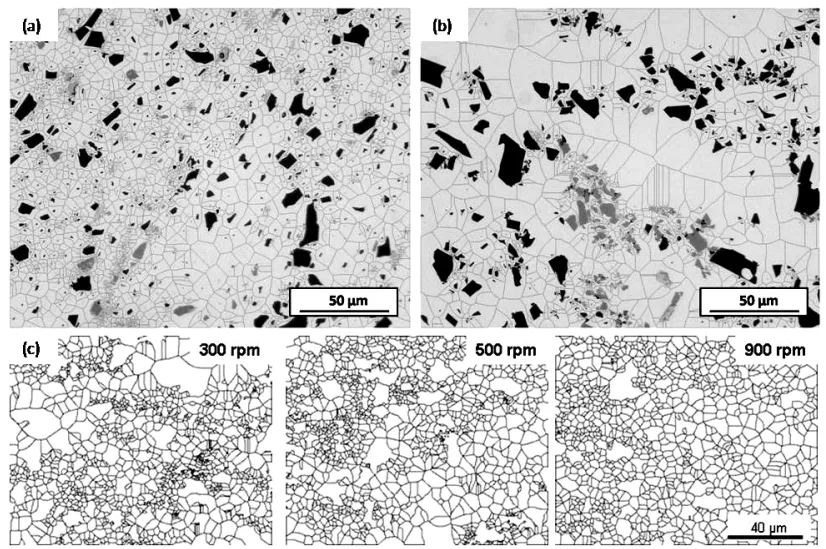

- Finding 1: Dramatic and Consistent Particle Refinement: FSP successfully broke down the coarse, flake-like eutectic Si and other intermetallics into fine, angular particles. The average particle size was consistently reduced from an initial 8-10 µm to a refined size of approximately 2-3 µm across a wide range of conditions (Figure 1, Figure 2).

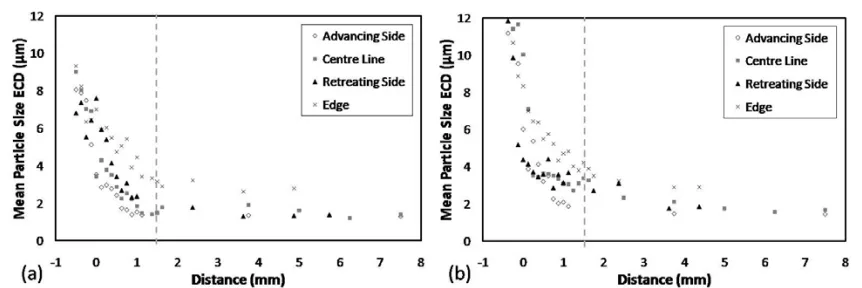

- Finding 2: Particle Size is Largely Insensitive to Rotation Speed: Interestingly, changing the tool rotation speed from 300 to 900 RPM had an "insignificant effect on the average size of the refined particles" (Figure 2b). However, increasing the travel speed from 100 to 400 mm/min resulted in a slight increase in average particle size from ~2.2 µm to ~2.7 µm (Figure 2d).

- Finding 3: Homogeneity is Highly Dependent on Process Parameters: While particle size remained stable, the uniformity of the particle distribution was highly sensitive to the process. As shown by the tessellation analysis in Figure 4 and quantified in Figure 5a, higher rotation speeds produced a more homogeneous particle distribution (lower variance ratio), reducing the "particle rich and particle free bands" that were more prominent at lower RPMs.

- Finding 4: Refinement is Rapid and Mechanically Driven: The 'stop-action' experiments revealed that particle fracture begins even before the material enters the main shear zone and "bottoms out at quite an early stage" (Figure 7, Figure 9). Refinement is completed within a very short distance (~1.5 mm) along the flow path. This suggests the total strain required for fracture is much lower than the total strain imparted by FSP, explaining why further processing (e.g., more rotations) does not lead to smaller particles. The minimum size is likely dictated by defects in the original cast particles.

Practical Implications for Your HPDC Operations

The findings from this paper have direct, actionable implications for engineers and managers looking to leverage FSP or similar severe plastic deformation processes.

- For Process Engineers: The research suggests that to achieve a target particle size, the focus should be less on maximizing process intensity (e.g., high RPM) and more on selecting an appropriate travel speed. To control microstructural uniformity and eliminate particle clustering, increasing the tool rotation speed is the most effective lever. This decouples the control of size from the control of homogeneity.

- For Quality Control: The use of Dirichlet tessellation (Figure 4c) offers a powerful quantitative tool for quality assurance. Instead of relying solely on average particle size, which this study shows can be misleading, tessellation analysis can certify the microstructural homogeneity of a processed zone, providing a more reliable predictor of consistent mechanical performance.

- For Simulation and R&D: The combination of a calibrated thermal model (Figure 3) with 'stop-action' experimental data provides a robust framework for process simulation. This approach allows for the prediction of thermal fields and their direct correlation with refinement mechanisms, enabling virtual process optimization and reducing the need for costly and time-consuming physical trials. The study confirms that particle fracture is a high-strain-rate phenomenon that occurs early, a critical insight for developing more accurate material models.

Paper Details

Quantification of Microstructural Homogeneity and the Mechanisms of Particle Refinement During FSP of Al-Si Alloys

1. Overview:

- Title: Quantification of Microstructural Homogeneity and the Mechanisms of Particle Refinement During FSP of Al-Si Alloys

- Author: Chun Y. Chan and Philip B. Prangnell

- Year of publication: Circa 2008-2009 (based on latest references)

- Journal/academic society of publication: Not specified in the provided text.

- Keywords: Friction stir processing; FSP; Al-Si, particle refinement.

2. Abstract:

In the present study, the mechanisms of particle refinement during FSP were investigated in a gravity die cast Al-Si LM24/A380 alloy. The homogeneity of distribution of the refined particles was also evaluated in relationship to the processing parameters. Detailed image analysis and Dirichlet tessellation were carried out to quantify particle refinement and clustering. 'Stop-action' experiments were used to study the mechanisms of particle break up, by following the behaviour along flow lines through the deformation zone surrounding the tool. A computer model was also used to predict the temperature profile during FSP, within the process zone, which was related to the refinement process.

3. Introduction:

Al-Si alloys are widely used in automotive applications due to their favorable properties, but increasing performance demands require microstructural improvements. Friction Stir Processing (FSP), a variant of Friction Stir Welding (FSW), uses the intense deformation from a rotating tool to refine microstructures. Previous work has shown FSP can dramatically reduce grain size and refine second-phase particles in Al-Si alloys, improving mechanical properties like fatigue life. This study aims to build on that work by investigating the specific mechanisms of particle refinement and quantifying the homogeneity of the resulting microstructure as a function of FSP parameters.

4. Summary of the study:

Background of the research topic:

Cast Al-Si alloys are essential in the automotive sector, but their performance is limited by their as-cast microstructure, particularly the coarse Si particles. Improving this microstructure is key to meeting demands for higher engine efficiency and durability.

Status of previous research:

Prior investigations have established that FSP can achieve significant microstructural refinement in Al-Si alloys, reducing Si particle size to below 3 µm and grain size to below 5 µm, leading to improved tensile and fatigue properties. Researchers have reported on the effects of processing parameters, but the fundamental mechanisms of particle refinement and a quantitative measure of homogeneity have not been thoroughly investigated.

Purpose of the study:

This study aimed to:

- Investigate the mechanisms of particle refinement in a gravity die-cast Al-Si A380 alloy during FSP.

- Quantify the homogeneity of the refined particle distribution.

- Evaluate the relationship between processing parameters (rotation and travel speed) and the resulting particle size and distribution.

- Use 'stop-action' experiments and computer modeling to understand the particle breakup behavior and thermal conditions within the process zone.

Core study:

The core of the study involved subjecting an Al-Si LM24/A380 alloy to FSP under a matrix of different tool rotation and travel speeds. The resulting microstructures were analyzed for particle size and spatial distribution using image analysis and Dirichlet tessellation. 'Stop-action' samples, where the tool was left embedded in the material, were examined to trace particle evolution along flow lines. A finite element heat transfer model was used to correlate temperature profiles with the observed refinement.

5. Research Methodology

Research Design:

The experiment was designed to systematically vary FSP parameters and observe the effects on the microstructure. A commercial hypo-eutectic LM24/A380 Al-Si alloy was used. A matrix of FSP conditions was defined, varying tool rotation speed (300, 500, 700, 900 RPM) and travel speed (100, 200, 400 mm/min). 'Stop-action' experiments were conducted at a fixed travel speed to freeze the deformation process for analysis.

Data Collection and Analysis Methods:

- Material Processing: FSP was performed using a CS Powerstir FSW machine with a H13 steel tool.

- Microstructural Analysis: Samples were sectioned, and optical microscopy was used to capture images. ImagePro analysis software quantified particle size distributions and average Equivalent Circular Diameter (ECD).

- Homogeneity Analysis: The spatial distribution of particles was characterized using the Dirichlet tessellation method, which involves expanding each particle until impingement to create a cellular map, the variance of which indicates clustering.

- Thermal Modeling: An FE heat transfer model was implemented in ABAQUS using a translated heat source to simulate the tool and predict the thermal field for each FSP condition. The model was calibrated against thermocouple measurements.

Research Topics and Scope:

The research focused on a single gravity die-cast Al-Si alloy (LM24/A380). The scope included the effect of tool rotation speed and travel speed on particle refinement and distribution. The investigation was limited to the processed zone (PZ) created by a tool with a 5.8 mm pin length. The 'stop-action' analysis was conducted at a depth of 4 mm below the plate surface.

6. Key Results:

Key Results:

- The initial microstructure of coarse, irregular eutectic Si (8-10 µm ECD) was transformed into fine, angular particles (2-3 µm ECD) after FSP (Fig. 1).

- The average particle size across the processed zone (PZ) was largely uniform, with some tendency to be finer at the bottom of the PZ due to lower temperatures (Fig. 2c, Fig. 3).

- Tool rotation speed had an "insignificant effect" on the final average particle size (Fig. 2b).

- Travel speed had a more noticeable effect, with faster speeds leading to slightly larger particles (Fig. 2d).

- The homogeneity of particle distribution was significantly affected by rotation speed. Higher RPMs resulted in a more uniform distribution (less clustering), especially on the retreating side of the PZ (Fig. 4, Fig. 5a).

- 'Stop-action' experiments showed that particle fracture occurs very rapidly as material enters the shear zone around the tool pin, with the minimum particle size being reached within a short distance of ~1.5 mm along the flow path (Fig. 7, Fig. 9).

- The deformation zone was found to be very narrow and confined to the tool surface, with its width changing with rotation speed (Fig. 6).

Figure Name List:

- Fig. 1: The cast starting material (a) showing coarse flake eutectic Si (dark), a-AlFeMnSi (medium grey), and Al2Cu (light grey) phases and the typical refined particles present in the centre of the PZ after FSP with a travel speed of 200 mm min⁻¹ for (b) 300 RPM and (c) 900 RPM.

- Fig. 2: In (a) a typical particle size distribution is shown from the 300 RPM sample. Average particle sizes (ECD) measured (b) across and (c) down the centre of the PZ, after FSP at 200 mm min⁻¹ with a range of rotation speeds, and (d) across the PZ for a range of travel speeds, with the rotation speed kept constant at 500 RPM.

- Fig. 3: Images from the FE thermal model, predicting the temperature field during FSP at (a) 300 RPM and (b) 700 RPM with a travel speed of 200 mm min⁻¹. The dotted line illustrates the position of the tool pin.

- Fig. 4: Micrographs from the sample processed at 200 mm min⁻¹ and 500 RPM on (a) the advancing side, and (b) the retreating side, with the tessellated cells overlaid. (c) Examples of the effect of tool rotation speed on cells constructed from images taken at 1 mm from the centre line on the retreating side of the PZ, where the particles were less homogeneously distributed, all with a travel speed of 200 mm min⁻¹.

- Fig. 5: The normalised cell size variance ratio measured across the centre of the PZ after FSP with a range of ration speeds, at 200 mm min⁻¹, and (b) a range of travel speeds, with the rotation speed kept constant at 500 RPM; in (c) the variance is shown down the centre of the PZ with a travel speed of 200 RPM for increasing rotation speeds.

- Fig. 6: Micrographs taken from the 'stop-action' samples processed at (a) 300 RPM and (b) 500 RPM, and both with a travel speed of 200 mm min⁻¹. The extent of the deformation zone around the pin was measured from the surface of the pin.

- Fig. 7: Micrographs showing the particle refinement and distribution along a typical flow path around the pin from a 'stop-action' sample processed at 200 mm min⁻¹ and 300 RPM.

- Fig. 8: Micrograph of the 'stop-action' sample processed at 200 mm min⁻¹ and 500 RPM. The flow lines in which particle break up had been extensively studied are shown, and these are from the advancing side (-1.5 mm), the centre line (0 mm), the retreating side (1.5 mm), and the edge (2.5 mm).

- Fig. 9: Average particle sizes (ECD) measured along the different flow paths around the tool pin within the stop action samples processed at (a) 300 RPM and (b) 500 RPM.

7. Conclusion:

FSP achieves a high level of particle refinement in A380 Al-Si alloy, resulting in an average particle size of 2-3 µm. The final refined particle size is remarkably insensitive to processing conditions and position within the PZ. This is because particle refinement occurs very rapidly upon entering the shear zone, "bottoming out" at a strain level much lower than the total strain generated during FSP. The minimum achievable particle size is likely dictated by the defect density and dimensions of the original cast particles. In contrast, the spatial distribution (homogeneity) of the particles is sensitive to processing parameters, becoming significantly more random and uniform with a reduction in tool pitch (i.e., higher rotation speed for a given travel speed). The fracture of particles is associated with void formation, which is progressively healed as the particles are dispersed by the continued strain along the flow line around the tool.

8. References:

- [1] R.Mishra, in: Friction Stir Welding and Processing, edited by R.S. Mishra, M.W. Mahoney: ASM (2007), p. 309.

- [2] C.G. Rhodes, M.W. Mahoney, W.H. Bingel, M. Calabrese: Scripta Mater. 48 (2003), p. 1451.

- [3] R.S. Mishra, Z.Y. Ma, I. Charit: Mater. Sci. Eng. 341A (2003), p. 307.

- [4] Z.Y. Ma, A.L. Pilchak, M.C. Juhas, J.C. Williams: Scripta Mater. 58 (2008), p. 361.

- [5] L.B. Johannes, I. Charit, R.S. Mishra, R. Verma: Mater. Sci. Eng. 464A (2007), p. 351.

- [6] W.B. Lee, Y.M. Yeon, S.B. Jung: Mater. Sci. Eng. 355A (2003), p. 154.

- [7] S.R. Sharma, Z.Y. Ma, R.S. Mishra: Scripta Mater. 51 (2004), p. 237.

- [8] M.L. Santella, T. Engstrom, D. Storjohann: Scripta Mater. 53 (2005), p. 201.

- [9] Z.Y. Ma, S.R. Sharma, R.S. Mishra : Scripta Mater. 54 (2006), p. 1623.

- [10] Z.Y. Ma, S.R. Sharma, R.S. Mishra: Mater. Sci. Eng. 433A (2006), p. 269.

- [11] Z.Y. Ma, S.R. Sharma, R.S. Mishra: Metall. Mater. Trans. 37A (2006), p. 3323.

- [12] P.B. Prangnell, S.J Barnes, S.M. Roberts, P.J. Withers: Mat. Sci. Eng. A220 (1996), p. 41.

- [13] Q. Shi, T. Dickerson, H.R. Shercliff: Proceedings of the 4th International Symposium on FSW (CD ROM), TWI, Utah, USA, 2003.

- [14] D.G. Richards, P.B. Prangnell, S.W. Williams, P.J. Withers: Mat. Sci. Eng A489 (2008) p. 351

- [15] A.M. Murphy, S.J. Howard, T.W. Clyne: Key Eng. Mater. 127-131 (1997), p. 919.

- [16] A.P.Reynolds: Sci. Technol. Weld. Joining 5 (200), p. 120.

- [17] P.A. Colegrove, H.R. Shercliff: Sci. Technol. Weld. Joining 9 (2004), p. 483.

- [18] P.A. Colegrove, H.R. Shercliff, R. Zettler: Sci. Technol. Weld. Joining 12 (2007), p. 284.

- [19] S.M. Roberts, P.J. Withers, S.J. Barnes and P.B. Prangnell, in: the Numerical Predictions of Deformation Processes and the Behaviour of Real Materials, 15th Risø Int. Symp, edited by. S.I. Andersen, et al., Roskilde, DK, (1994), p. 505.

- [20] P.B. Prangnell, C.P. Heason: Acta Mater. 53 (2005), p. 3179.

- [21] A.F. Norman, I. Brough, P.B. Prangnell: Mat. Sci. Forum Vol. 331-337 (2000), p. 1713.

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing microstructural control in FSP of Al-Si alloys. The findings offer a clear, data-driven path toward improving material quality not just by refining particles, but by ensuring they are homogeneously distributed, a key factor for reliable performance.

STI C&D is committed to applying cutting-edge industry research to solve our customers’ most challenging technical problems. If the problem discussed in this white paper aligns with your research goals, please contact our engineering team to discuss how we can help you apply these advanced principles to your research.

Expert Q&A:

- Q1: What is the main benefit of using FSP on cast Al-Si alloys according to this study?

- A: The primary benefit is significant microstructural refinement. FSP breaks down coarse, brittle silicon particles into fine (2-3 µm), angular particles and removes casting porosity. This refined and homogenized microstructure is expected to improve mechanical performance, particularly fatigue properties, as supported by the introduction (Refs. [1,4,5]).

- Q2: To get the smallest possible particles, should I use the highest rotation speed?

- A: No, not necessarily. The study found that tool rotation speed had an "insignificant effect on the average size of the refined particles." The final particle size is reached very quickly and is likely limited by the properties of the original cast material, not the intensity of the FSP process. This is clearly shown in the data from Figure 2b.

- Q3: If rotation speed doesn't affect particle size, what does it control?

- A: Rotation speed is the primary control for the homogeneity of the particle distribution. The study shows that higher rotation speeds lead to a more uniform, less clustered distribution of refined particles, as quantified by the Dirichlet tessellation analysis in Figure 5a. This is critical for achieving consistent properties across the processed zone.

- Q4: How quickly does the particle refinement actually happen during the FSP process?

- A: The refinement is extremely rapid. The 'stop-action' experiments revealed that particle fracture "bottoms out at quite an early stage," occurring within a short distance of approximately 1.5 mm into the shear path around the tool. This is detailed in the analysis of the flow paths shown in Figure 7 and quantified in Figure 9.

- Q5: What is the mechanism for particle breakup during FSP?

- A: Particle breakup occurs largely by load transfer from the soft, deforming aluminum matrix to the hard silicon particles. The 'stop-action' samples show that this fracture is associated with the formation of small voids in the matrix within cracked silicon flakes. These voids are then progressively healed as the refined fragments are redistributed by the material flow around the tool.

Copyright

- This material is an analysis of the paper "Quantification of Microstructural Homogeneity and the Mechanisms of Particle Refinement During FSP of Al-Si Alloys" by Chun Y. Chan and Philip B. Prangnell.

- Source of the paper: The provided document is a direct copy of the research paper.

- This material is for informational purposes only. Unauthorized commercial use is prohibited.

- Copyright © 2025 STI C&D. All rights reserved.