This introduction paper is based on the paper "Parameter Optimization and Precision Control of Water-Soluble Support Cores for Hollow Composite Castings Fabricated by Slurry Microextrusion Direct Forming Method" published by "3D Printing and Additive Manufacturing".

1. Overview:

- Title: Parameter Optimization and Precision Control of Water-Soluble Support Cores for Hollow Composite Castings Fabricated by Slurry Microextrusion Direct Forming Method

- Author: Jiefei Huang, Fuchu Liu, Yingpeng Mu, Chi Zhang, Xin Liu, Guangchao Han, and Zitian Fan

- Year of publication: 2023

- Journal/academic society of publication: 3D Printing and Additive Manufacturing

- Keywords: hollow composite castings, slurry microextrusion direct forming method, magnesium sulfate support core, parameter optimization, precision control

2. Abstract:

The optimization of slurry content and forming process parameters has a significant effect in slurry micro-extrusion direct forming method. In this article, magnesium sulfate monohydrate (MgSO4) and polyvinylpyrrolidone (PVP) were used as raw materials to prepare the slurry, and the component ratios of the slurry and the optimization of its forming process were discussed. The optimum slurry content is 64 wt.% by mass of magnesium sulfate monohydrate and 36 wt.% by mass of binder consisting of PVP-EtOH. The process parameters that include printing speed, extrusion pressure, and the ratio of printing layer height to extrusion diameter were selected as influencing factors. The orthogonal experiment results show that a printing speed of 850 mm/min, an extrusion pressure of 250 kPa, and a layer height of 510 μm of the extrusion diameter are the optimized process parameters. Under the optimized printing parameters, the surface roughness of the prepared samples is 23.764 μm, with dimensional deviations of 0.71%, 0.77%, and 2.56% in the X, Y, and Z directions, respectively.

3. Introduction:

Hollow composite castings with complex internal cavities are increasingly used in aerospace, automotive, and telecommunication industries. These castings require soluble cores for support during forming, which are removed post-casting. Water-soluble salt cores are advantageous due to their good mechanical strength and water solubility. Traditional methods for preparing support cores, such as melt casting, have disadvantages like complex mould design, high energy costs, and long cycle times. Additive manufacturing, specifically slurry microextrusion direct forming, offers advantages like low cost, small equipment, fast forming speed, and short iteration period for fabricating soluble support cores. This method involves mixing powder material with a binder and solvent to form a slurry, which is then extruded. Previous research has explored various materials and methods for slurry-based 3D printing of support cores, but optimizing slurry composition and forming parameters for precision control remains crucial.

4. Summary of the study:

Background of the research topic:

The demand for hollow composite castings with complex internal structures is growing. Manufacturing these castings requires soluble support cores that can be easily removed. Water-soluble salt cores are a promising option, but their fabrication methods need improvement in terms of precision, cost, and efficiency. Slurry microextrusion direct forming is an additive manufacturing technique that can address these challenges.

Status of previous research:

Previous studies have focused on various water-soluble salt core materials (e.g., KNO3-based, potassium nitrate-potassium chloride based, alkali metal carbonates and chlorides) prepared by methods like melt casting. While these cores showed good properties, the preparation methods had limitations. Slurry microextrusion has been explored using materials like Al2O3, but optimization for specific salt core materials like magnesium sulfate, focusing on slurry content and process parameters for precision, is an area requiring further investigation. The paper notes that "the alcohol-based DIW technology with relatively low printing resolution was rarely reported, especially using magnesium sulfate monohydrate (MgSO4) and polyvinylpyrrolidone (PVP) as raw materials."

Purpose of the study:

The main objective of this article was to "obtain optimized slurry composition ratios and forming process parameters to process water-soluble salt support cores with good surface quality using the slurry microextrusion direct forming method." The study aimed to investigate the effects of solid content and binder content on the formability of water-soluble salt support core green body and to optimize process parameters using single-factor experiments and orthogonal experiments to obtain better fabricated cores with high precision.

Core study:

The study focused on optimizing the slurry content and forming process parameters for fabricating water-soluble support cores using magnesium sulfate monohydrate (MgSO4) and polyvinylpyrrolidone (PVP) via the slurry microextrusion direct forming method.

- Slurry Optimization: MgSO4·H2O was used as the base material, and PVP-K60 dissolved in anhydrous ethanol (PVP-EtOH) was used as the binder and plasticizer. The study investigated the effect of different solid contents (MgSO4·H2O) and binder (PVP-EtOH) concentrations on slurry viscosity and self-supporting properties. The optimal slurry composition was determined to be 64 wt.% MgSO4·H2O and 36 wt.% binder (25 wt.% PVP-K60 in ethanol).

- Process Parameter Optimization: Single-factor experiments were conducted to study the effects of printing speed, extrusion pressure, and layer height on the printing precision (dimensional deviation) and surface roughness of the samples.

- Orthogonal Experiments: Based on the single-factor experiment results, orthogonal experiments were designed and conducted to further optimize the printing parameters (printing speed, extrusion pressure, and layer height) by coupling them and refining their values to achieve higher printing quality and precision. Regression analysis was also performed.

5. Research Methodology

Research Design:

The research involved preparing a slurry using MgSO4·H2O as the solid powder and a PVP-EtOH solution as the binder.

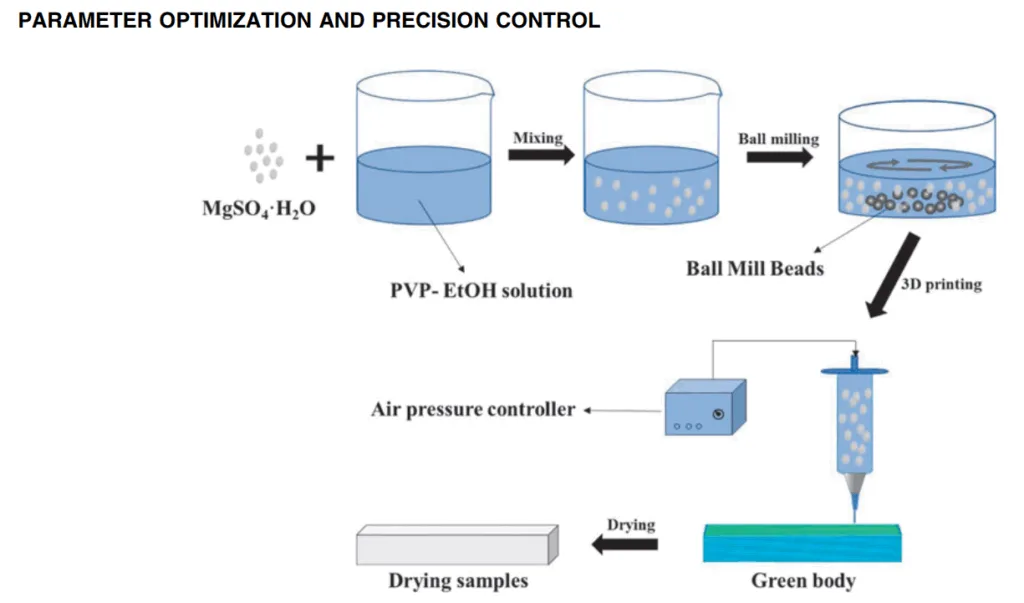

- Slurry Preparation: PVP-K60 was dissolved in anhydrous ethanol. MgSO4·H2O powder was added and manually stirred, followed by ball milling for 9 hours to obtain a stable magnesium sulfate slurry.

- Slurry Characterization: The effects of solid content (61 wt.% to 64 wt.% MgSO4·H2O) and binder content (PVP in ethanol) on slurry viscosity and self-supporting properties (relative settling height, printing characteristics) were investigated.

- Printing Process: A self-constructed printing device with a mechanical motion module, drive ink extrusion device, and software control system was used. A needle with an internal diameter of 600 μm was used. Printed samples were dried at 60°C for 12h.

- Parameter Optimization:

- Single-Factor Experiments: Investigated the individual effects of printing speed (600-1200 mm/min), extrusion pressure (200-500 kPa), and layer height (420-600 μm) on dimensional deviation and surface roughness.

- Orthogonal Experiments: An L9 orthogonal array was used with three factors (Printing speed: 750, 800, 850 mm/min; Extrusion pressure: 250, 300, 350 kPa; Layer height: 450, 480, 510 μm) at three levels each to find the optimal combination for minimizing dimensional deviations and surface roughness. Regression analysis was performed on the orthogonal experiment results.

Data Collection and Analysis Methods:

- Viscosity Measurement: A digital viscometer (NDJ-8S; Bonsey Instrument Shanghai Technology Co., Ltd., China) was used.

- Surface Roughness and Profile: A contact roughness profilometer (JB-6C roughness profiler) was used.

- Microstructure and Morphology: An ultra-depth-of-field microscope was used to observe the surface morphology of the samples.

- Dimensional Deviation: Calculated using the formula S = (L2 - L1) / L1, where S is the print size deviation rate, L2 is the actual printing size, and L1 is the surface roughness is checked by means of a roughness profiler (JB-6C roughness profiler). (Note: The paper states L1 is the design size, not surface roughness).

- Self-Supporting Properties: Assessed by observing the relative settling height of slurries and the printing characteristics of samples with different solid contents.

- Statistical Analysis: Extreme difference analysis and regression analysis were applied to the results of the orthogonal experiments.

Research Topics and Scope:

- Optimization of slurry composition: Determining the optimal ratio of MgSO4·H2O solid content and PVP-EtOH binder content for good rheological properties and formability.

- Optimization of forming process parameters:

- Effect of printing speed on sample quality (dimensional deviation, surface roughness, morphology).

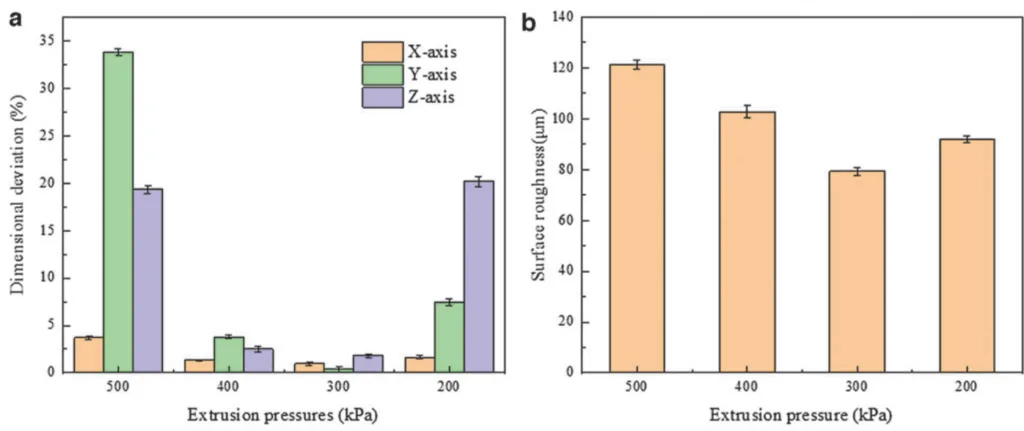

- Effect of extrusion pressure on sample quality.

- Effect of layer height on sample quality.

- Precision control: Achieving high dimensional accuracy and low surface roughness in the fabricated support cores through optimized slurry and process parameters.

- The scope was limited to MgSO4-based water-soluble support cores fabricated by slurry microextrusion direct forming method.

6. Key Results:

Key Results:

- Optimal Slurry Composition: The optimum slurry content was found to be 64 wt.% by mass of magnesium sulfate monohydrate and 36 wt.% by mass of binder consisting of PVP-EtOH (with PVP content of 25 wt.% in the binder solution). This composition provided sufficient strength for stable structure during extrusion and superior self-supporting properties.

- Single-Factor Experiment Insights:

- Printing Speed: 800 mm/min was found to be optimal, providing the lowest Z-axis dimensional deviation and surface roughness.

- Extrusion Pressure: 300 kPa was optimal, resulting in the lowest dimensional deviation in all three directions and the lowest surface roughness.

- Layer Height: 480 μm was optimal, yielding the lowest dimensional deviation and surface roughness.

- Orthogonal Experiment Optimization:

- The most significant factors affecting printing quality were identified. For X-axis, Y-axis, Z-axis dimensional deviations, and surface roughness, the order of significance was generally Extrusion Pressure (B) > Printing Speed (A) > Layer Height (C).

- The optimized printing process parameters were determined to be a printing speed of 850 mm/min, an extrusion pressure of 250 kPa, and a layer height of 510 μm (combination A1B3C1 from regression analysis for overall best performance, specifically for X-axis deviation and surface roughness, though other combinations were optimal for Y and Z deviations individually).

- Final Achieved Precision: Under the optimized printing parameters (850 mm/min speed, 250 kPa pressure, 510 μm layer height), the fabricated samples exhibited:

- Surface roughness: 23.764 μm.

- Dimensional deviations: 0.71% (X-axis), 0.77% (Y-axis), and 2.56% (Z-axis).

- Regression equations were developed to describe the relationship between process parameters and dimensional deviations/surface roughness:

- δχ = -6.79 – 0.001A + 0.012B + 0.009C (2)

- δy = 13.589 – 0.064A – 0.235B – 0.047C (3)

- δz = -9.267 – 0.032A + 0.213B – 0.027C (4)

- Ra = 56.267 – 0.102A + 0.373B – 0.042C (5)

Figure Name List:

- FIG. 1. Flow chart of slurry preparation.

- FIG. 2. Partial slurry printing characteristics with different solid contents: (a) 54 wt.%, (b) 56 wt.%, (c) 58 wt.%, (d) 60 wt.%.

- FIG. 3. Viscosity of slurries at different solid loading and binder contents.

- FIG. 4. Relative settling heights of slurries with different solid contents.

- FIG. 5. Effect of solid contents on the self-supporting properties of the slurry: (a) 61 wt.%, (b) 62 wt.%, (c) 63 wt.%, (d) 64 wt.%.

- FIG. 6. Schematic representation of the effect of solid content on stack forming.

- FIG. 7. Sample photos at different printing speeds: (a) 1200 mm/min, (b) 1000 mm/min, (c) 800 mm/min, (d) 600 mm/min.

- FIG. 8. Surface profile of the samples at different printing speeds: (a) 1200 mm/min, (b) 1000 mm/min, (c) 800 mm/min, (d) 600 mm/min.

- FIG. 9. Microscopic morphology of the samples at different printing speeds: (a) 1200 mm/min, (b) 1000 mm/min, (c) 800 mm/min, (d) 600 mm/min.

- FIG. 10. Effect of different printing speeds on the quality of the formed samples: (a) dimensional deviation rate, (b) surface roughness.

- FIG. 11. Sample photos at different extrusion pressures: (a) 500 kPa, (b) 400 kPa, (c) 300 kPa, (d) 200 kPa.

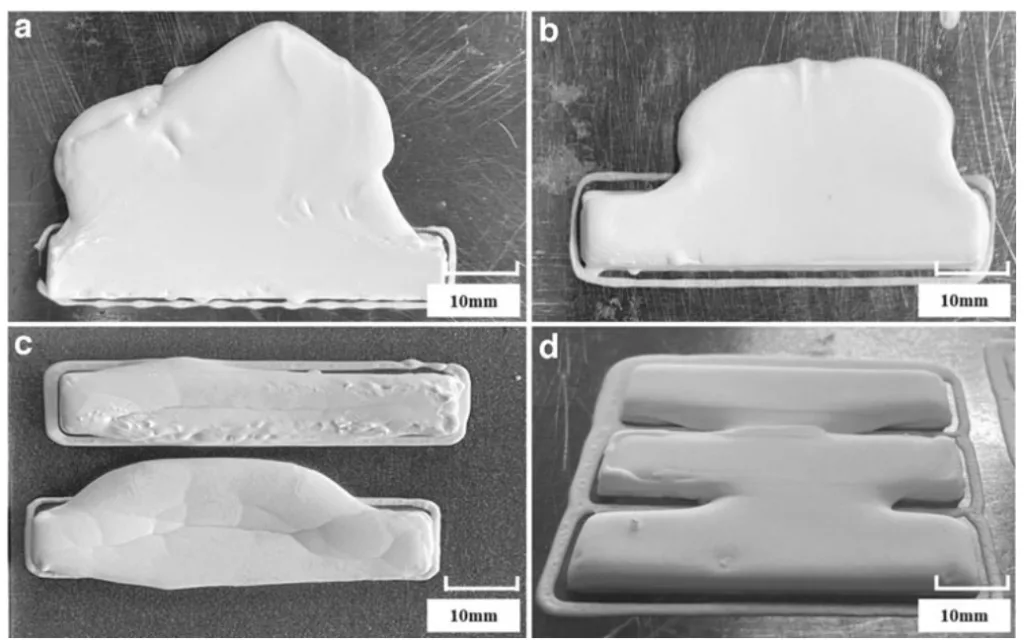

- FIG. 12. Surface profile of the samples at different extrusion pressures: (a) 500 kPa, (b) 400 kPa, (c) 300 kPa, (d) 200 kPa.

- FIG. 13. Microscopic morphology of the samples at different extrusion pressures: (a) 500 kPa, (b) 400 kPa, (c) 300 kPa, (d) 200 kPa.

- FIG. 14. Effect of different extrusion pressures on the forming quality of the samples: (a) dimensional deviation rate, (b) surface roughness.

- FIG. 15. Effect of different layer heights on printed samples.

- FIG. 16. Samples at different layer heights: (a) 600 μm, (b) 540 μm, (c) 480 μm, (d) 420 μm.

- FIG. 17. Surface profile of the samples at different layer heights: (a) 600 μm, (b) 540 μm, (c) 480 μm, (d) 420 μm.

- FIG. 18. Microscopic morphology of the samples at different layer height: (a) 600 μm, (b) 540 μm, (c) 480 μm, (d) 420 μm.

- FIG. 19. Effect of different layer heights on the forming quality of the samples: (a) dimensional deviation rate, (b) surface roughness.

- FIG. 20. Sample printing after process optimization: (a) sample view, (b) microscopic view of surface laminations, (c) 3D pseudo-color view of surface, (d) surface roughness view.

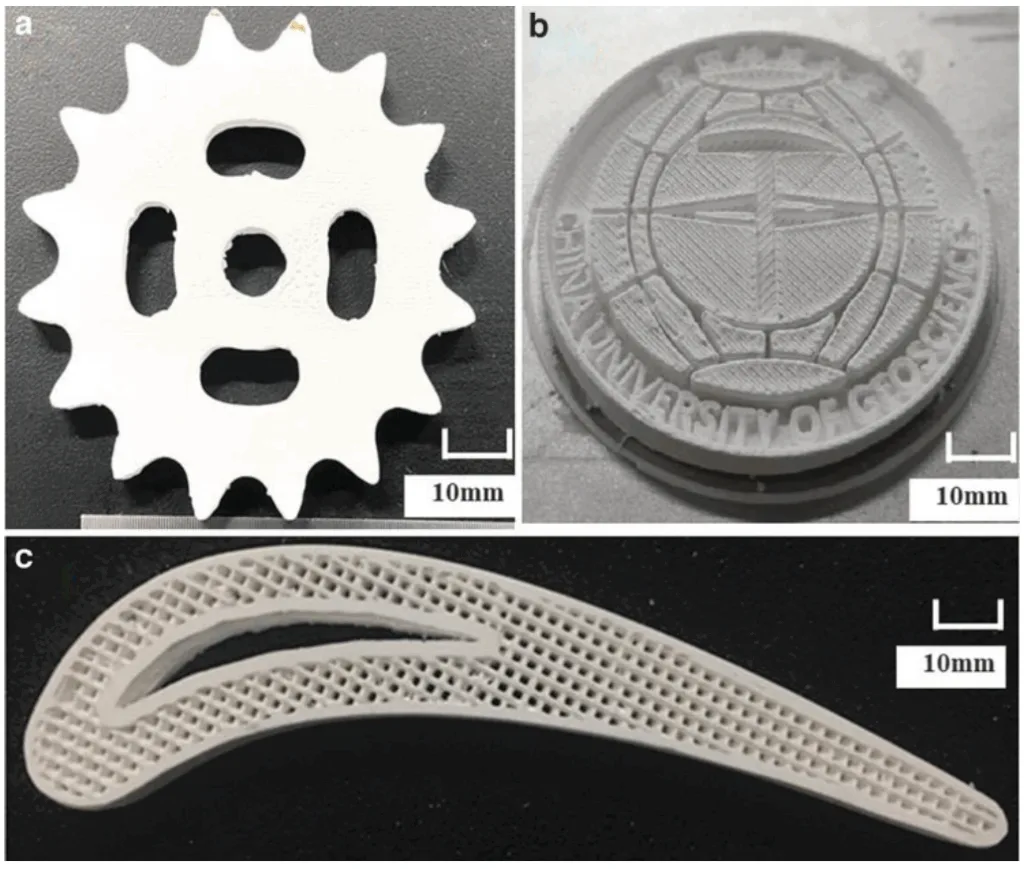

- FIG. 21. Different samples prepared by the optimized printing parameter obtained by the orthogonal experimental method: (a) Gear shape, (b) CUG badge, (c) Porous structure.

7. Conclusion:

A new method for fabricating samples suitable for forming hollow composite castings by alcohol-based DIW method using a water-soluble inorganic salt slurry is proposed. The slurry was prepared using MgSO4·H2O as aggregate and PVP in anhydrous ethanol as binder and solvent. The study optimized the slurry formulation and microextrusion direct forming process parameters.

Key findings include:

(1) A slurry solid content of 64 wt.% and PVP content of 25 wt.% in the binder (total binder solution 36 wt.%) possesses sufficient strength for stable extrusion and self-supporting properties.

(2) Single-factor experiments indicated that faster printing speed, lower extrusion pressure, and higher layer height tend to cause underload defects, while slower speed, higher pressure, and lower layer height tend to cause overload defects.

(3) Orthogonal experiments and analysis confirmed the main order of printing process parameter influence as extrusion pressure, printing speed, and layer height. Optimized parameters (printing speed of 850 mm/min, extrusion pressure of 250 kPa, layer height of 510 μm) resulted in samples with good forming precision and surface quality: dimensional deviations of 0.71% (X), 0.77% (Y), and 2.56% (Z), and a surface roughness of 23.764 μm.

The optimized process is effective for producing high-quality printed parts with magnesium sulfate-based water-soluble support salt cores.

8. References:

- [1. Dong X, Yang H, Zhu X, et al. High strength and ductility aluminium alloy processed by high pressure die casting. J Alloys Compounds 2019;773:86–96.]

- [2. Liu F, Jiang P, Huang Y, et al. A water-soluble magnesium sulfate bonded sand core material for manufacturing hollow composite castings. Comp Struct 2018;201:553–560.]

- [3. Liu F, Fan Z, Liu X, et al. Aqueous gel casting of water-soluble calcia-based ceramic core for investment casting using epoxy resin as a binder. Int J Adv Manufact Technol 2016;86(5–8):1235–1242.]

- [4. Xiao Z, Harper LT, Kennedy AR, et al. A water-soluble core material for manufacturing hollow composite sections. Comp Struct 2017;182:380–390.]

- [5. Liu F, Tu S, Gong X, et al. Comparative study on performance and microstructure of composite water-soluble salt core material for manufacturing hollow zinc alloy castings. Mater Chem Phys 2020;252:123257.]

- [6. Gong X, Jiang W, Liu F, et al. Effects of glass fiber size and content on microstructures and properties of KNO3-based water-soluble salt core for high pressure die casting. Int J Metalcast 2021;15(2):520–529.]

- [7. Tu S, Liu F, Li G, et al. Fabrication and characterization of high-strength water-soluble composite salt core for zinc alloy die castings. Int J Adv Manufact Technol 2018;95(1–4):505–512.]

- [8. Yaokawa J, Miura D, Anzai K, et al. Strength of salt core composed of alkali carbonate and alkali chloride mixtures made by casting technique. Mater Transact 2007;48(5):1034–1041.]

- [9. Qu P, Xiong D, Zhu Z, et al. Inkjet printing additively manufactured multilayer SOFCs using high quality ceramic inks for performance enhancement. Addit Manufact 2021;48:102394.]

- [10. Wei X, Pan Y, Chen Z. 3D printing of NiZn ferrite architectures with high magnetic performance for efficient magnetic separation. J Eur Ceram Soc 2022;42(4):1522–1529.]

- [11. Liu Z, Miao K, Lian W, et al. Effect of mould baffle technology on stray grain formation in single crystal blades by integral fabrication based on 3D printing. China Foundry 2021;18(5):433–441.]

- [12. Miao K, Zhou H, Gao Y, et al. Laser powder-bed-fusion of Si3N4 reinforced AlSi10Mg composites: Processing, mechanical properties and strengthening mechanisms. Mater Sci Eng A 2021;825:141874.]

- [13. Hirt L, Reiser A, Spolenak R, et al. Additive manufacturing of metal structures at the micrometer scale. Adv Mater 2017;29(17):1604211.]

- [14. Li Z, Li H, Yin J, et al. A review of spatter in laser powder bed fusion additive manufacturing: In situ detection, generation, effects, and countermeasures. Micromachines (Basel) 2022;13(8):1366.]

- [15. Chen Q, Jing Y, Yin J, et al. High reflectivity and thermal conductivity Ag-Cu multi-material structures fabricated via laser powder bed fusion: Formation mechanisms, interfacial characteristics, and molten pool behavior. Micromachines (Basel) 2023;14(2):362.]

- [16. Yin J, Zhang W, Ke L, et al. Vaporization of alloying elements and explosion behavior during laser powder bed fusion of Cu–10Zn alloy. Int J Machine Tools Manufact 2021;161:103686.]

- [17. Webbe Kerekes T, Lim H, Joe W Y, et al. Characterization of process-deformation/damage property relationship of fused deposition modeling (FDM) 3D-printed specimens. Addit Manufact 2019;25:532–544.]

- [18. Romero-Ocaña I, Molina SI. Cork photocurable resin composite for stereolithography (SLA): Influence of cork particle size on mechanical and thermal properties. Addit Manufact 2022;51:102586.]

- [19. Beloshenko V, Chishko V, Plavan V, et al. Production of filter material from polypropylene/copolyamide blend by material extrusion-based additive manufacturing: Role of production conditions and ZrO2 nanoparticles. 3D Print Addit Manufact 2021;8(4):253–262.]

- [20. Gao G, Du Z, Zhang W, et al. Investigation and improvement of pushing dislocation in ceramsite sand three-dimensional printing. 3D Print Addit Manufact 2023;10(2):289–297.]

- [21. Shi Y, Zhang J, Wen S, et al. Additive manufacturing and foundry innovation. China Foundry 2021;18(4):286–295.]

- [22. Tang S, Yang L, Fan Z, et al. A review of additive manufacturing technology and its application to foundry in China. China Foundry 2021;18(4):249–264.]

- [23. Tian X, Wu L, Gu D, et al. Roadmap for additive manufacturing: Toward intellectualization and industrialization. Chin J Mech Eng 2022;1(1):100014.]

- [24. Hao L, Tang D, Sun T, et al. Direct ink writing of mineral materials: A review. Int J Precis Eng Manufact Green Technol 2021;2:8.]

- [25. Fang Y, Guo Y, Liu T, et al. Advances in 3D bioprinting. Chin J Mech Eng 2022;1(1):100011.]

- [26. Chu X, Tang X, Chen W, et al. Direct-ink-write printing performance of zeolite catalysts with porous structures. Ceram Int 2023;49(9):13531–13541.]

- [27. Roth CC, Tancogne-Dejean T, Mohr D. Plasticity and fracture of cast and SLM AlSi10Mg: High-throughput testing and modeling. Addit Manufact 2021;43:101998.]

- [28. Jang S, Boddorff A, Jang DJ, et al. Effect of material extrusion process parameters on filament geometry and inter-filament voids in as-fabricated high solids loaded polymer composites. Additive Manufact 2021;47:102313.]

- [29. Plocher J, Panesar A. Review on design and structural optimisation in additive manufacturing: Towards next-generation lightweight structures. Mater Design 2019;183:108164.]

- [30. Truby RL, Lewis JA. Printing soft matter in three dimensions. Nature 2016;540(7633):371–378.]

- [31. Wang R, Zhu P, Yang W, et al. Direct-writing of 3D periodic TiO2 bio-ceramic scaffolds with a sol-gel ink for in vitro cell growth. Mater Design 2018;144:304–309.]

- [32. Peng E, Zhang D, Ding J. Ceramic robocasting: Recent achievements, potential, and future developments. Adv Mater 2018;30(47):e1802404.]

- [33. Tang S, Yang L, Li G, et al. 3D printing of highly-loaded slurries via layered extrusion forming: Parameters optimization and control. Addit Manufact 2019;28:546–553.]

- [34. Li G, Tang S, Yang L, et al. Fabrication of soluble salt-based support for suspended ceramic structure by layered extrusion forming method. Mater Design 2019;183:108173.]

- [35. Gong X, Liu X, Chen Z, et al. 3D printing of high-strength water-soluble salt cores via material extrusion. Int J Adv Manufact Technol 2022;118(9–10):2993–3003.]

- [36. Duoss EB, Twardowski M, Lewis JA. Sol-gel inks for direct-write assembly of functional oxides. Adv Mater (Weinheim) 2007;19(21):3485–3489.]

- [37. Lewis JA. Direct-write assembly of ceramics from colloidal inks. Curr Opin Solid State Mater Sci 2002;6(3):245–250.]

- [38. Smay JE, Cesarano J, Lewis JA. Colloidal inks for directed assembly of 3-D periodic structures. Langmuir 2002;18(14):5429–5437.]

- [39. Sun Y, Peng C, Wang X, et al. Rheological behavior of Al2O3 suspensions containing polyelectrolyte complexes for direct ink writing. Powder Technol 2017;320:223–229.]

- [40. Xia Y, Lu Z, Cao J, et al. Microstructure and mechanical property of Cf/SiC core/shell composite fabricated by direct ink writing. Script Mater 2019;165:84–88.]

9. Copyright:

- This material is a paper by "Jiefei Huang, Fuchu Liu, Yingpeng Mu, Chi Zhang, Xin Liu, Guangchao Han, and Zitian Fan". Based on "Parameter Optimization and Precision Control of Water-Soluble Support Cores for Hollow Composite Castings Fabricated by Slurry Microextrusion Direct Forming Method".

- Source of the paper: [https://doi.org/10.1089/3dp.2023.0136]

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.