This introduction paper is based on the paper "OPTIMIZATION AND EFFECT OF SQUEEZE CASTING PROCESS PARAMETERS ON TENSILE STRENGTH OF HYBRID METAL MATRIX COMPOSITE" published by "Journal of Manufacturing Technology Research".

1. Overview:

- Title: OPTIMIZATION AND EFFECT OF SQUEEZE CASTING PROCESS PARAMETERS ON TENSILE STRENGTH OF HYBRID METAL MATRIX COMPOSITE

- Author: M. Arulraj, P. K. Palani, M. Sowrirajan, S. Vijayan, and J. P. Davim

- Year of publication: 2019

- Journal/academic society of publication: Journal of Manufacturing Technology Research

- Keywords: squeeze casting, metal matrix composite, LM24 aluminium alloy, silicon carbide, coconut shell ash, Taguchi method, genetic algorithm

2. Abstract:

The squeeze casting process is leading liquid state method for casting metal matrix composite. This is accomplished economically through the conversion of mechanical energy into interface energy at the reinforcement-matrix interface zone. This experimental study focuses on processing of hybrid metal matrix (LM24-SiCp-coconut shell ash) composite to optimize and to analyze the effect of squeeze casting process parameters viz. reinforcement percentage, pouring temperature, squeeze pressure and mould temperature on the tensile strength of the composites. Experiments were conducted based on L27 (34) orthogonal array. Results revealed that squeeze pressure and reinforcement percentage were the most influencing process parameters on tensile strength. A mathematical model was developed for the prediction of tensile strength using nonlinear regression analysis and validated through confirmation experiments. Optimum parametric condition was obtained using Taguchi method and Genetic Algorithm tool, which could exhibit 25% improvement on tensile strength of the composite comparing conventional alloys.

3. Introduction:

Metal Matrix Composites (MMCs) are engineered to achieve high strength properties, with particulate-reinforced aluminum MMCs being of particular interest in industries like Aerospace and Automotive. The addition of ceramic particles, such as silicon carbide (SiC), to aluminum alloys typically enhances yield and tensile strength but can reduce ductility and fracture toughness. The properties of these composites are influenced by microstructural variables including the matrix alloy, ageing conditions, and the volume fraction and size of particulate reinforcement.

Squeeze casting is an advanced manufacturing method that combines aspects of gravity and pressurized casting, effectively eliminating many defects associated with high-pressure die casting. This process involves applying high pressure during solidification, which promotes complete die filling, reduces shrinkage and porosity, and refines the grain structure of the cast material. Previous research has demonstrated the benefits of squeeze casting for various aluminum alloys, showing improvements in mechanical properties.

Recently, there has been a growing trend towards using agro-industrial wastes, such as Coconut Shell Ash (CSA), as secondary reinforcement in aluminum MMCs. These materials offer advantages like low cost, wide availability, and lower density compared to traditional ceramic reinforcements. Agro waste ashes are often rich in silicon dioxide (SiO2), which can contribute to the composite's properties. While SiC is a common reinforcement known for enhancing strength, CSA is also a promising, economical alternative. This study investigates the processing of a hybrid LM24 aluminum alloy composite reinforced with both SiC particles (SiCp) and CSA using the squeeze casting technique. The aim is to optimize the process parameters to enhance the tensile strength of these hybrid composites.

4. Summary of the study:

Background of the research topic:

The demand for high-strength, lightweight materials has driven research into Metal Matrix Composites (MMCs). Squeeze casting is a promising manufacturing route for MMCs, offering improved material properties by applying high pressure during solidification. The use of hybrid reinforcements, combining traditional ceramics like SiCp with economical agro-waste materials like coconut shell ash (CSA), is an emerging area aimed at developing cost-effective composites with tailored properties.

Status of previous research:

Numerous studies have explored the effects of squeeze casting parameters on various aluminum alloys, generally reporting enhanced mechanical properties. Research on MMCs has also investigated different reinforcement types, including SiCp, which is known to increase strength but potentially reduce ductility. Studies on agro-waste ashes as reinforcements have highlighted their potential due to cost and availability, with some investigations into their effect on mechanical properties. However, the optimization of squeeze casting parameters for hybrid composites containing both SiCp and CSA, specifically focusing on tensile strength, requires further detailed investigation.

Purpose of the study:

The primary purpose of this study was to optimize the squeeze casting process parameters—specifically reinforcement percentage (ratio of CSA to SiCp), pouring temperature, squeeze pressure, and mould temperature—to maximize the tensile strength of a hybrid LM24-SiCp-coconut shell ash composite. A secondary aim was to develop a mathematical model for predicting tensile strength based on these parameters.

Core study:

The core of the study involved experimentally investigating the squeeze casting of LM24 aluminum alloy reinforced with varying proportions of SiCp and coconut shell ash. An L27 (34) orthogonal array was used to design the experiments, varying four key process parameters at three levels each. The tensile strength of the produced composites was measured. Statistical tools, including the Taguchi method and Analysis of Variance (ANOVA), were used to identify the optimal parameter settings and determine the significance of each parameter. A mathematical regression model was developed, and Genetic Algorithm (GA) was employed for further optimization. Confirmation experiments were conducted to validate the findings.

5. Research Methodology

Research Design:

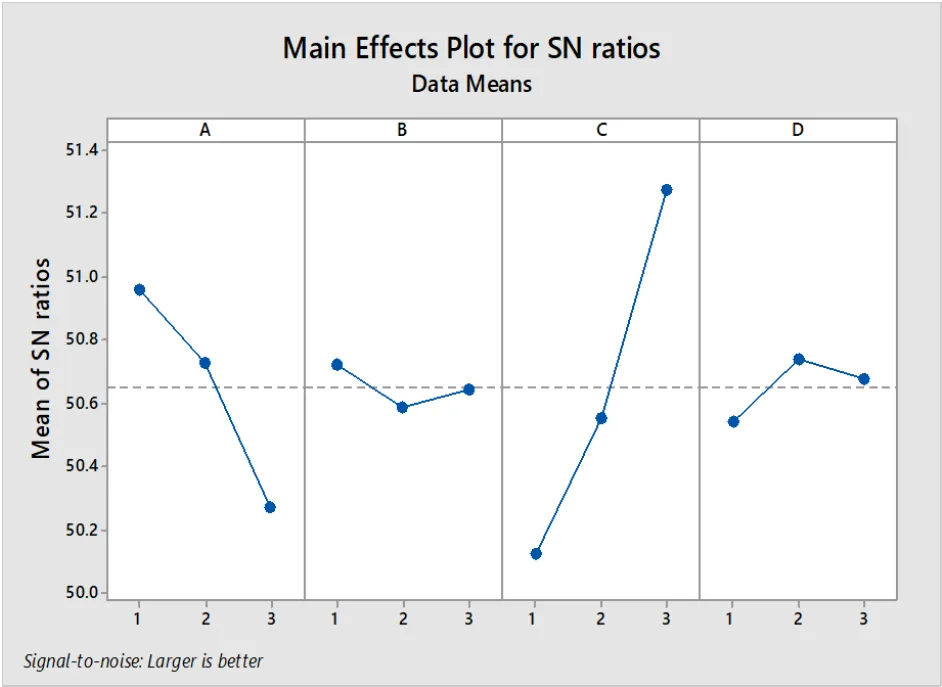

The research employed an experimental design based on Taguchi’s L27 (34) orthogonal array to investigate the effect of four squeeze casting process parameters, each at three levels, on the tensile strength of LM24-SiCp-CSA hybrid composites. The parameters studied were: Reinforcement (A: varying ratios of 2.5-7.5% CSA and 7.5-2.5% SiCp, maintaining a total of 10% reinforcement), Pouring temperature (B: 675°C, 700°C, 725°C), Squeeze pressure (C: 50 MPa, 100 MPa, 150 MPa), and Mould temperature (D: 200°C, 250°C, 300°C). Optimization was performed using Signal-to-Noise (S/N) ratio analysis (larger-the-better criterion for tensile strength) and Genetic Algorithm (GA).

Data Collection and Analysis Methods:

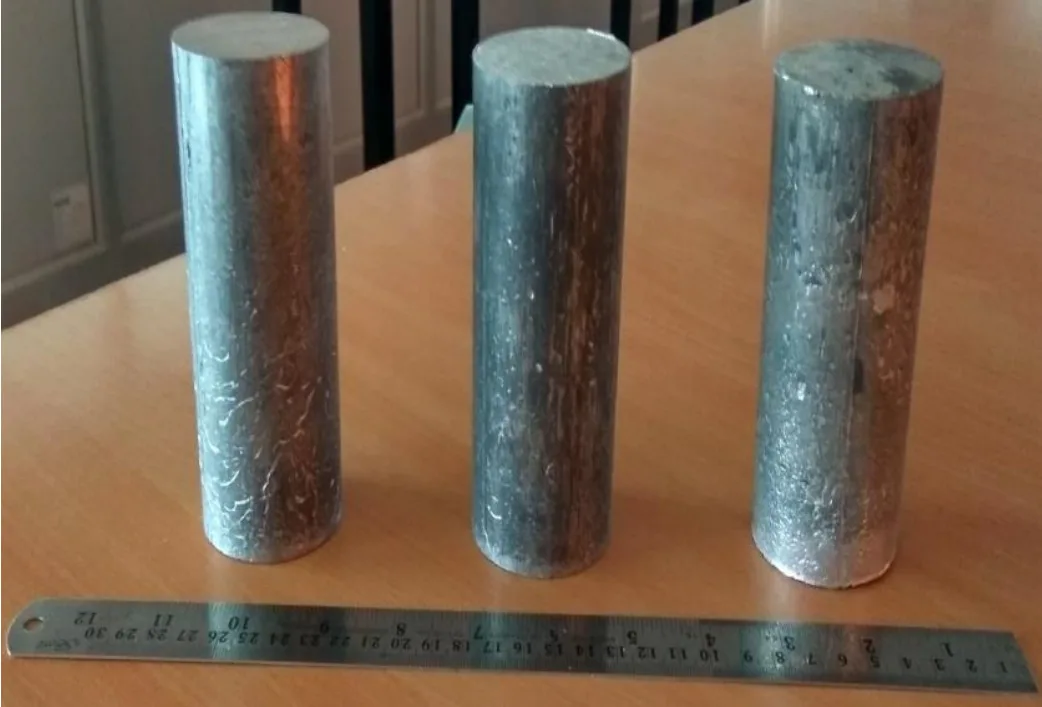

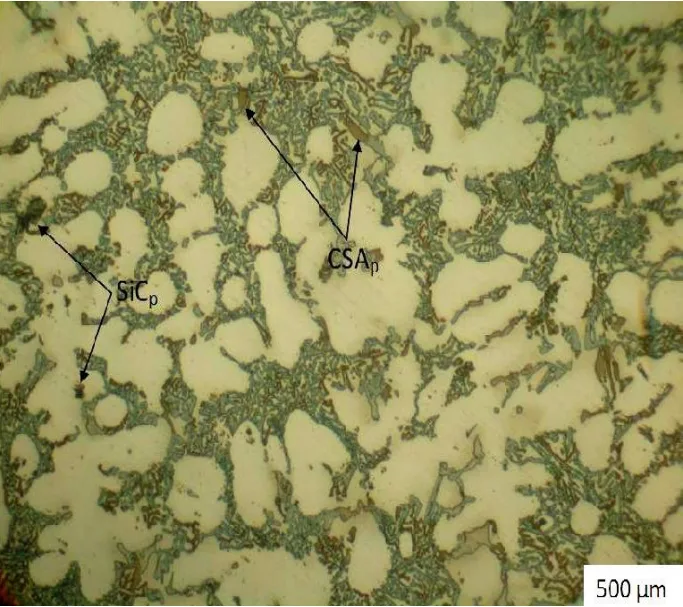

LM24 aluminum ingots were melted and reinforced with pre-determined combinations of SiCp and CSA. These were then processed using a squeeze casting setup (detailed in Figure 1) according to the L27 experimental plan. Cast samples (Figure 2) were machined into tensile test specimens (Figure 3) as per ASTM-E8M-04 standards. Tensile tests were conducted using a Universal Testing Machine. The experimental tensile strength values (Table 3) were analyzed using Minitab 17 software. A mathematical regression model (Equation 1) was developed to predict tensile strength. ANOVA was performed to determine the percentage contribution of each parameter. GA optimization was carried out using MATLAB R2013a with the regression model as the objective function (Equation 2). Microstructural characterization of an optimally produced sample was done using optical microscopy (Figure 4) and XRD analysis (Figure 5).

Research Topics and Scope:

The research focused on the optimization of squeeze casting process parameters for a hybrid metal matrix composite consisting of LM24 aluminum alloy as the matrix, and silicon carbide particles (SiCp) and coconut shell ash (CSA) as reinforcements. The scope included:

- Investigating the effect of reinforcement percentage (specifically the ratio of CSA to SiCp), pouring temperature, squeeze pressure, and mould temperature on the tensile strength of the composite.

- Determining the optimal combination of these parameters to achieve maximum tensile strength.

- Developing a predictive mathematical model for tensile strength.

- Comparing the optimization results from the Taguchi method and Genetic Algorithm.

- Characterizing the microstructure of the optimized composite.

6. Key Results:

Key Results:

The study successfully optimized squeeze casting parameters for LM24-SiCp-CSA hybrid composites. Microstructural analysis of the optimally cast sample showed homogeneous dispersion of reinforcement particles, good wettability, and negligible porosity (Figure 4). XRD analysis confirmed the presence of SiC and coconut shell particles (Figure 5).

Analysis of Variance (ANOVA) revealed that squeeze pressure was the most significant parameter affecting tensile strength (66.56% contribution), followed by reinforcement percentage (26.23% contribution) (Table 6, Figure 6). Pouring temperature and mould temperature had insignificant effects within the tested ranges and were pooled as error.

The Taguchi method suggested an optimum parametric setting of A1 (2.5% CSA + 7.5% SiCp), B1 (675°C pouring temperature), C3 (150 MPa squeeze pressure), and D3 (300°C mould temperature).

Genetic Algorithm (GA) provided a tuned optimum setting: Reinforcement at level 1 (2.5%CSA + 7.5%SiCp), pouring temperature at 690°C, squeeze pressure at 200 MPa, and mould temperature at 211°C (Table 7).

Confirmation experiments (Table 8) showed good agreement between predicted and observed tensile strengths (error < 1%), with the GA-optimized parameters yielding a tensile strength of 387 MPa. This represented a ~25% improvement compared to conventional alloys.

The main effects plot (Figure 8) indicated that:

- Increasing the proportion of CSA (and decreasing SiCp) within the reinforcement (Parameter A, from level 1 to 3) decreased tensile strength.

- Squeeze pressure had a strong positive effect on tensile strength.

- Pouring temperature and mould temperature showed more complex, less pronounced effects.

Figure Name List:

- Figure 1. Squeeze casting experimental set-up.

- Figure 2. Few casting samples.

- Figure 3. Few samples for tensile test.

- Figure 4. Optical microstructure of LM24 /SiCp /coconut shell ash composite.

- Figure 5. XRD pattern of the squeeze cast composite specimen.

- Figure 6. Percentage contributions of significant parameters.

- Figure 7. Fitness function values via generations.

- Figure 8. Main effects of process variables on tensile strength.

7. Conclusion:

The study demonstrated that the squeeze casting process can be successfully used for fabricating quality aluminum hybrid metal matrix composites (LM24 - SiCp- coconut shell ash). Squeeze pressure was identified as the most influential process parameter affecting the tensile strength of the composite castings. A mathematical regression model was developed that accurately predicts tensile strength, which can be a useful tool for operators. Both Taguchi and Genetic Algorithm (GA) methods proved effective for optimizing process parameters, with GA offering finer tuning capabilities. The optimum parametric conditions suggested by the Taguchi method were A1 (2.5% CSA + 7.5% SiCp), B1 (675°C), C3 (150 MPa), D3 (300°C), while GA suggested a tuned set of 1 (coded, for 2.5%CSA + 7.5%SiCp); 1.601 (coded, for 690°C); 3 (coded, for 200MPa); 2.215 (coded, for 211°C) respectively for reinforcement, pouring temperature, squeeze pressure and mould temperature. Confirmation experiments validated the prediction model and the optimized settings. Castings produced under optimal conditions exhibited improved grain refinement in their microstructure and achieved approximately a 25% improvement in tensile strength compared to conventional alloys.

8. References:

- Shetty R., Pai R. B., Rao S. S., Nayak R. (2009) Taguchi's technique in machining of metal matrix composites. Journal of the Brazilian Society of Mechanical Sciences and Engineering 31(1):12-20.

- Surappa M. K. (2003) Aluminium matrix composites: Challenges and Opportunities 28(1):319-334.

- Ibrahim I. A., Mohamed F. A., Lavernia E. J. (1991) Particulate reinforced metal matrix composites-a review. Journal of materials science 26(5):1137-1156.

- Adalarasan R, Sundaram AS (2015) Parameter design in friction welding of Al/SiC/Al2O3composite using grey theory based principal component analysis (GT-PCA). Journal of the Brazilian Society of Mechanical Sciences and Engineering 37(5):1515-1528.

- Yue, T. M. Squeeze casting of high strength aluminum wrought alloy AA7010. J. Mater. Process. Technol., 1997, 66,179–185.

- Abou El-khair, M. T. Microstructure characterization and tensile properties of squeeze cast AlSiMg alloys. Mater. Lett, 2005, 59, 894-900.

- Tone Rolland, Robert Flatval and Lars Arnberg. Strain induced macrosegregation in squeeze cast Al-Mg and Al-Si alloys. Mater. Sci. Eng. A, 1993,173, 267-270.

- Lee, J. H. Won, C. W. Cho, S. S. Chun, B. S. and Kim, S. W. Effects of melt flow and temperature on the macro and microstructure of scroll compressor in direct squeeze casting. Mater. Sci. and Eng. A, 2000,281, 8-16.

- Vijian, P. and Arunachalam, V. P. Optimization of squeeze cast parameters of LM6 aluminium alloy for surface roughness using Taguchi method. J. Mater. Process. Technol., 2006, 180, 161–166.

- Maleki, A. Niroumand, B. and Shafyei, A. Effects of squeeze casting parameters on density, macrostructure and hardness of LM13 alloy. Mater. Sci. Eng. A, 2006, 428, 135-140.

- Kim, S. W. Durrant, G. Lee, J. H. and Cantor, B. The microstructure of squeeze cast and gravity die cast 7050 wrought Al alloy. J. Mater. Synth. Process. 1998;6(2):75-87.

- Gokhale, A.M and Patel, G.R. Quantitative fractographic analysis of variability in tensile ductility of a squeeze cast Al-Si-Mg base alloy. Mater. Character. 2005, 54, 13-20.

- Yue, T. M. Squeeze casting of high strength aluminum wrought alloy AA7010. J. Mater. Process. Technol., 1997, 66,179–185.

- Zhang Ming, Zhang Wei-wen, Zhao Hai-dong, Zhang Da-tong and Li Yuan-yuan. Effect of pressure on microstructures and mechanical properties of Al-Cu-based alloy prepared by squeeze casting. Trans. Nonferrous Met. Soc. China, 2007, 17, 496-501.

- Fan, C. H. Chen, Z. H. He, W. Q. Chen, J. H. and Chen, D. Effects of the casting temperature on microstructure and mechanical properties of the squeeze cast Al-Zn-Mg-Cu alloy. J. Alloys and Compounds, 2010, 504, L42-L45.

- Senthil P, Amirthagadeswaran KS (2012) Optimization of squeeze casting parameters for non-symmetrical AC2A aluminium alloy castings through Taguchi method. Journal of Mechanical Science and Technology 26(4):1141-1147.

- Senthil P, Amirthagadeswaran KS (2014) Experimental study and squeeze casting process optimization for high quality AC2A aluminium alloy castings. Arabian Journal for Science and Engineering 39:2215-2225.

- Manjunath Patel G. C., Krishna P., Parappagoudar M. B. (2016) Modelling and multi-objective optimisation of squeeze casting process using regression analysis and genetic algorithm. Australian Journal of Mechanical Engineering 14(3):182-198.

- Rajagopal S. (1981) Squeeze casting: a review and update. Journal of Applied Metalworking 1(4):3-14.

- Ghomashchi M. R., Vikhrov A. (2000) Squeeze casting: An overview. Journal of Materials Processing Technology 101(1):1-9.

- Ravikumar A. R., Amirthagadeswaran KS, Senthil P (2014) Parametric optimization of squeeze cast AC2A-Ni coated composite using Taguchi technique. Advances in Materials Science and Engineering 1-10.

- Alaneme K. K., Akintunde I. B., Olubambi P. A., Adewale T. M. (2013) Fabrication characteristics and mechanical behaviour of rice husk ash-Alumina reinforced Al-Mg-Si alloy matrix hybrid composites. Journal of Materials Research and Technology 2(1):60-67.

- Mazahery A., Shaban M. O. Characterization of cast A356 alloy reinforced with nano SiC composites. Journal of Transactions of Nonferrous Metals Society of China, 2012, 22(2): 275-280.

- Kumar, K. Ravi, T. Pridhar, and V. S. Sree Balaji. “Mechanical properties and characterization of zirconium oxide (ZrO2) and coconut shell ash (CSA) reinforced aluminium (Al 6082) matrix hybrid composite." Journal of Alloys and Compounds 765 (2018): 171-179.

- Venkatesh, L., T. V. Arjunan, and K. Ravikumar. “Microstructural characteristics and mechanical behaviour of aluminium hybrid composites reinforced with groundnut shell ash and B4C." Journal of the Brazilian Society of Mechanical Sciences and Engineering 41.7 (2019): 295.

- Manjunath Patel GC, Krishna P, Parappagoudar MB, Vundavilli PR (2016) Multi-objective optimization of squeeze casting process using evolutionary algorithms. International Journal of Swarm Intelligence Research 7(1):55-74.

- Arulraj, M., & Palani, P. K. (2018). Parametric optimization for improving impact strength of squeeze cast of hybrid metal matrix (LM24-SiCp-coconut shell ash) composite. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 40(1), 2.

- Arulraj, M., Palani, P. K. and Venkatesh, L., 2019. Multi-Objective Optimization of High Speed Turning Parameters of Hybrid Aluminium Matrix Composite Reinforced with Silicon Carbide and Coconut Shell Ash. Journal of the Chinese Society of Mechanical Engineers, 40(2), pp.191-200.

- Arulraj, M., Palani, P. K. and Venkatesh, L., 2019, Optimization of machining parameters in turning of hybrid aluminium-matrix (LM24–SiCp-coconut shell ash) composite. Materiali in Tehnologije (Materials and Technologies), 53(2), pp.263-268.

- Arulraj, M., Palani, P. K. and Venkatesh, L., 2017. Optimization of Process Parameters in Stir Casting of Hybrid Metal Matrix (LM25/SiC/B4C) Composite Using Taguchi Method. Journal of Advances in Chemistry, 13(9), pp.6475-6479.

- Sowrirajan, M., P. Koshy Mathews, and S. Vijayan. “Simultaneous multi-objective optimization of stainless steel clad layer on pressure vessels using genetic algorithm." Journal of Mechanical Science and Technology 32.6 (2018): 2559-2568.

- Sowrirajan, Maruthasalam, P. Koshy Mathews, and S. Vijayan. “Investigation and optimization of process variables on clad angle in 316L stainless steel cladding using genetic algorithm.” High Temperature Material Processes: An International Quarterly of High-Technology Plasma Processes 21.2 (2017).

9. Copyright:

- This material is a paper by "M. Arulraj, P. K. Palani, M. Sowrirajan, S. Vijayan, and J. P. Davim". Based on "OPTIMIZATION AND EFFECT OF SQUEEZE CASTING PROCESS PARAMETERS ON TENSILE STRENGTH OF HYBRID METAL MATRIX COMPOSITE".

- Source of the paper: https://www.researchgate.net/publication/338886709

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.

Summarize:

This research paper focuses on optimizing the squeeze casting process parameters for manufacturing LM24 aluminum alloy composites reinforced with a hybrid of silicon carbide (SiCp) and coconut shell ash (CSA). The objective was to maximize the tensile strength of these composites. Using an L27 orthogonal array for experimental design, the study investigated the effects of reinforcement composition, pouring temperature, squeeze pressure, and mould temperature. The Taguchi method and Genetic Algorithm (GA) were employed for optimization. Key findings indicate that squeeze pressure is the most dominant factor influencing tensile strength, followed by the reinforcement composition. The optimized parameters, particularly those derived from GA, led to a significant improvement in tensile strength (approximately 25% higher than conventional alloys), attributed to better microstructural characteristics like homogeneous particle dispersion and grain refinement. A predictive mathematical model for tensile strength was also developed and validated.

Key questions and answers about the research:

This study aimed to optimize squeeze casting parameters (reinforcement percentage, pouring temperature, squeeze pressure, mould temperature) for LM24-SiCp-coconut shell ash hybrid composites to maximize tensile strength. Using Taguchi design and Genetic Algorithms, the research identified squeeze pressure and reinforcement percentage as the most significant factors. The optimized parameters resulted in castings with improved microstructure and a 25% increase in tensile strength compared to conventional alloys.

Q1. What was the primary objective of this research?

A1. To optimize the squeeze casting process parameters (reinforcement percentage, pouring temperature, squeeze pressure, and mould temperature) to maximize the tensile strength of a hybrid LM24-SiCp-coconut shell ash metal matrix composite. (Source: Abstract; OPTIMIZATION AND EFFECT OF SQUEEZE CASTING PROCESS PARAMETERS ON TENSILE STRENGTH OF HYBRID METAL MATRIX COMPOSITE)

Q2. Which process parameters were found to be most influential on the tensile strength of the composite?

A2. Squeeze pressure and reinforcement percentage were the most influential process parameters affecting tensile strength. (Source: Abstract, Section 3.2.2 Analysis of Variance; OPTIMIZATION AND EFFECT OF SQUEEZE CASTING PROCESS PARAMETERS ON TENSILE STRENGTH OF HYBRID METAL MATRIX COMPOSITE)

Q3. What was the composition of the hybrid metal matrix composite studied?

A3. The study focused on a hybrid metal matrix composite made of LM24 aluminium alloy reinforced with Silicon Carbide particles (SiCp) and coconut shell ash (CSA). (Source: Abstract, Section 2.1 Materials Used; OPTIMIZATION AND EFFECT OF SQUEEZE CASTING PROCESS PARAMETERS ON TENSILE STRENGTH OF HYBRID METAL MATRIX COMPOSITE)

Q4. What methodologies were used to optimize the process parameters?

A4. The Taguchi method (L27 orthogonal array and S/N ratio analysis) and Genetic Algorithm (GA) were employed for optimization, along with the development of a mathematical regression model. (Source: Abstract, Section 2.2.3 Optimization using Taguchi Method and Genetic Algorithm; OPTIMIZATION AND EFFECT OF SQUEEZE CASTING PROCESS PARAMETERS ON TENSILE STRENGTH OF HYBRID METAL MATRIX COMPOSITE)

Q5. What was the observed improvement in tensile strength with the optimized parameters?

A5. The optimized parametric condition, identified using Taguchi and Genetic Algorithm tools, could exhibit a 25% improvement in the tensile strength of the composite compared to conventional alloys. (Source: Abstract, Conclusion; OPTIMIZATION AND EFFECT OF SQUEEZE CASTING PROCESS PARAMETERS ON TENSILE STRENGTH OF HYBRID METAL MATRIX COMPOSITE)

Q6. How did increasing the squeeze pressure affect the tensile strength of the composite?

A6. Increasing the applied squeeze pressure significantly improved the tensile strength of the casting by developing a better particle-matrix interface, inducing strong internal stress, ensuring effective load transfer, and promoting grain refinement due to enhanced solidification rate. (Source: Section 3.4 Effect of Squeeze Casting Process Parameters on Tensile Strength; OPTIMIZATION AND EFFECT OF SQUEEZE CASTING PROCESS PARAMETERS ON TENSILE STRENGTH OF HYBRID METAL MATRIX COMPOSITE)