This technical review is based on the academic paper "Modern High Pressure Die-casting Processes for Aluminium Castings" by M. Thirugnanam, published in Transactions of 61st Indian Foundry Congress 2013. CASTMAN's technical experts analyzed and summarized this with the help of AI.

1. Overview

- Title: Modern High Pressure Die-casting Processes for Aluminium Castings

- Author(s): M. Thirugnanam

- Year of Publication: 2013

- Journal/Academic Society: Transactions of 61st Indian Foundry Congress

- Keywords:

- Primary Keyword: High Pressure Die-casting

- Secondary Keywords: Aluminium, Air and gas blow holes, High integrity die-casting, Ultra high vacuum process, Semi-solid casting, Casting quality

2. Abstract

The paper reviews various modern High Pressure Die-casting (HPDC) processes developed to overcome the limitations of conventional HPDC, such as air entrapment and inability to weld or heat treat. It discusses high-integrity processes like squeeze casting, vacuum processes, and semi-solid casting, highlighting their ability to reduce defects and improve mechanical properties in aluminium castings.

3. Introduction

Conventional HPDC, while commercially successful, suffers from drawbacks like air and gas blow holes, shrinkage, and surface defects. These limitations prevent welding and heat treatment, hindering mechanical property enhancement. The paper addresses the need for advanced processes to overcome these defects, increase casting strength, and reduce minimum wall thickness, particularly for the automotive industry.

4. Executive Summary

- The Challenge: Overcoming the limitations of conventional HPDC, specifically air entrapment and the inability to weld or heat treat aluminium castings.

- The Method: Reviewing and summarizing various modern HPDC processes, including squeeze casting, vacuum processes, and semi-solid casting.

- The Key Breakthrough: Achieving higher casting quality, reduced defects, and improved mechanical properties through advanced HPDC techniques.

- The Bottom Line: Modern HPDC processes offer significant advantages over conventional methods, enabling the production of high-quality aluminium castings with enhanced properties.

5. Research Methodology

Research Design

The study addresses the limitations of conventional HPDC, where air and gas blow holes are inevitable, and castings cannot be heat-treated or welded. This necessitates the development of newer processes to meet current product design requirements.

The Approach: Methodology Explained

The paper reviews and summarizes various modern HPDC processes, including: 1. Squeeze casting 2. Local casting spot pressurizing 3. Ultrahigh vacuum process 4. Massive vent process 5. Vacural process 6. Minimum fill time process 7. Nissan Innovative process 8. Controlled filling process 9. Vacuum high vac –V process 10. Semi-solid casting processes

The Breakthrough: Key Findings and Data

Finding 1: Squeeze Casting

Molten metal is injected slowly (0.4 meters/sec max) into the die cavity, followed by a pressure of 500 to 1100 kg/cm² until solidification. This reduces air entrapment and gas inclusion, achieving gas content as low as 1cc/100 gm of aluminium.

Finding 2: Ultra High Vacuum Process

Vacuum pressure is below 10 kp, resulting in air and gas content below 5 cc per 100 grams of Al. This enables heat treatment and welding of the castings.

Practical Implications for R&D and Operations

This research suggests that by implementing squeeze casting or ultra-high vacuum processes, HPDC operators can produce castings with significantly reduced porosity and improved weldability.

Data Collection and Analysis Methods

The paper reviews existing literature and industrial practices related to modern HPDC processes.

Research Topics and Scope

The research covers various modern HPDC processes and their impact on casting quality and mechanical properties.

6. Key Results

- Summary of Results:

- Squeeze casting reduces air entrapment and gas inclusion.

- Ultra-high vacuum process enables heat treatment and welding.

- Minimum wall thickness can be reduced to 0.8 mm in vacuum die-castings.

- Figure and Table List:

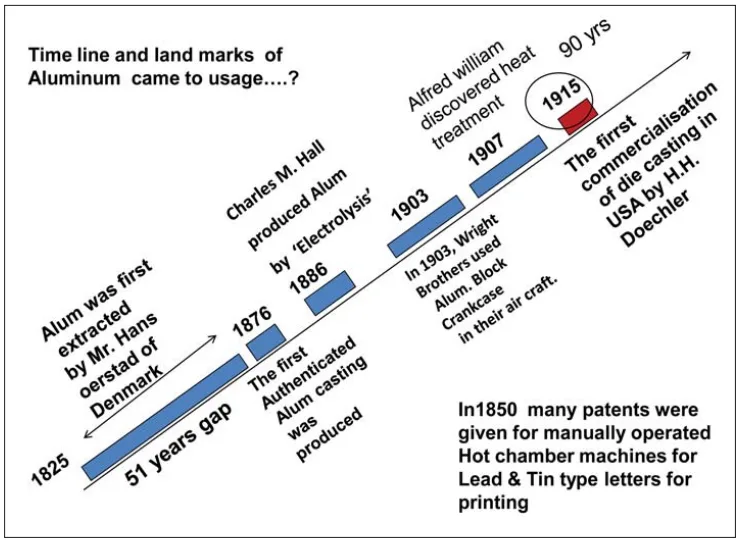

- Fig. 1: Traces 9 years of development of the processes.

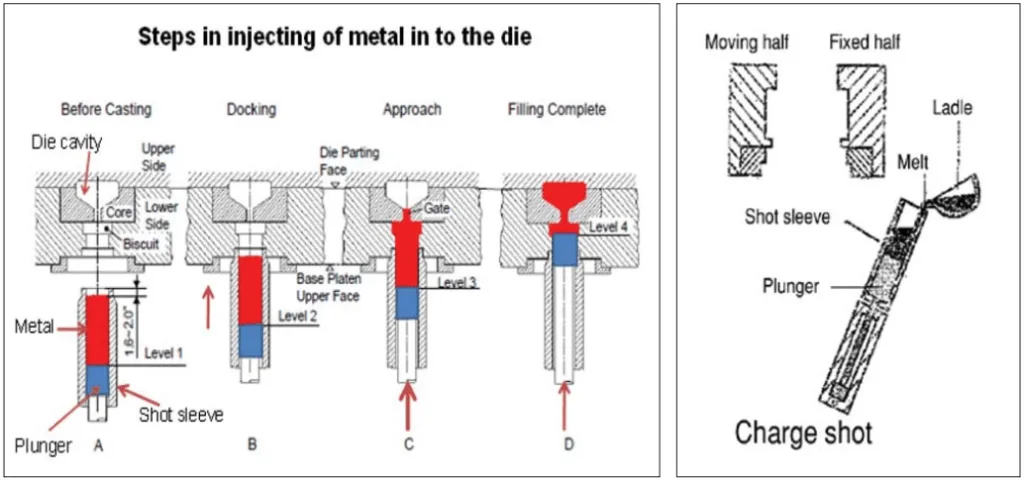

- Fig. 2: Steps in injecting of metal in to the die.

- Fig. 3: Charge shot.

- Fig. 4: The microstructure in the squeeze casting.

- Fig. 5: Acurad Process.

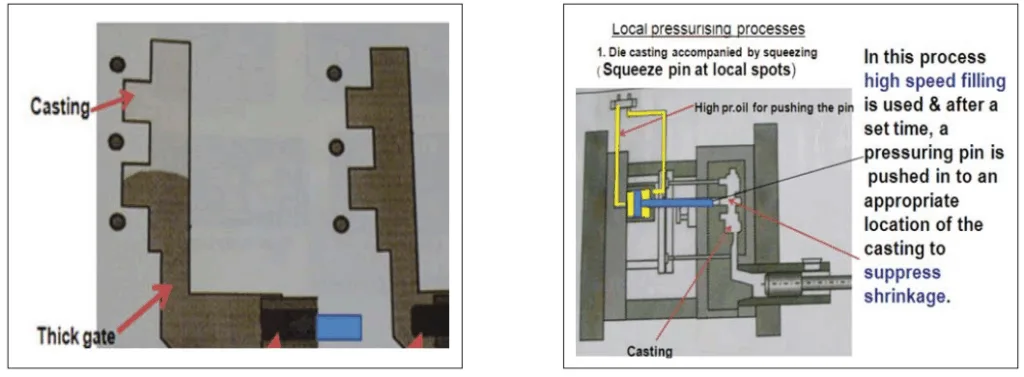

- Fig. 6: Local pressurising processes.

- Fig. 7: Vacuum.

- Fig. 8: Molten aluminium in holding furnace which is tightly sealed.

- Fig. 9: Oxygen is filled through this tube in to the shot sleeve.

- Fig. 10: Non planar filling, which is not desirable.

- Fig. 11: Planar filling.

- Fig. 12: Some typical Automotive components manufactured using semi- solid metal working processes.

- Fig. 13: The Trend and Direction in the Aluminium Component Production.

7. Why This Research Matters for HPDC Professionals

- For Process Engineers: Insight into advanced HPDC techniques for reducing defects and improving casting quality.

- For Quality Control Teams: Data on achievable porosity levels and mechanical properties with different HPDC processes.

- For Design Engineers: Information on reducing minimum wall thickness and designing for heat treatment and welding.

8. Conclusion

The paper highlights the advancements in High Pressure Die-casting processes, offering solutions to overcome the limitations of conventional methods. These modern techniques enable the production of high-quality aluminium castings with improved mechanical properties, reduced defects, and the ability to heat treat and weld, making them suitable for demanding applications in various industries.

9. References

TRANSACTIONS OF 61st INDIAN FOUNDRY CONGRESS 2013

Expert Q&A: Your Top Questions Answered

- Q1: Why was slow injection speed chosen in squeeze casting? A1: Slow injection speed in squeeze casting minimizes turbulence, reducing air entrapment and gas inclusion, leading to higher casting quality.

- Q2: What is the industrial implication of the ultra-high vacuum process? A2: The ultra-high vacuum process enables the production of aluminium castings that can be heat-treated and welded, expanding their application in structural components.

- Q3: How does this research compare to traditional approaches in HPDC? A3: This research showcases significant improvements in casting quality, defect reduction, and mechanical properties compared to traditional HPDC methods.

- Q4: What are the limitations of this study? A4: The paper primarily reviews existing processes and lacks detailed experimental data on specific alloy compositions and casting geometries.

- Q5: How can these findings be applied in real HPDC production lines? A5: These findings can guide the selection and implementation of advanced HPDC processes based on specific application requirements, such as high strength, weldability, or heat treatability.

Paving the Way for Higher Quality and Productivity

The paper reviews the challenges in conventional HPDC and the breakthrough achieved by modern HPDC processes. These processes offer practical benefits for R&D and operations, including reduced defects, improved mechanical properties, and the ability to heat treat and weld aluminium castings. At CASTMAN, we are committed to applying the latest academic and industrial research to help our customers achieve higher productivity, superior quality, and innovative design solutions. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be applied to your components.

Copyright Information

- This article is a analysis based on the paper "Modern High Pressure Die-casting Processes for Aluminium Castings" by "M. Thirugnanam".

- Source: [Provide DOI or direct link to the paper]

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited. Copyright © 2025 CASTMAN. All rights reserved.