This introduction paper is based on the paper "Mechanical Properties of Mixed Salt Core Made by Die Casting Machine" published by "鋳造工学 (Journal of the Japan Foundry Engineering Society, J. JFS)".

1. Overview:

- Title: Mechanical Properties of Mixed Salt Core Made by Die Casting Machine

- Author: Katsunari Oikawa, Kenichi Meguro, Jun Yaokawa, Koichi Anzai, Youji Yamada, Akihito Fujiwara and Hiroshi Yoshii

- Year of publication: 2009

- Journal/academic society of publication: 鋳造工学 (Journal of the Japan Foundry Engineering Society, J. JFS), Vol. 81 No. 5

- Keywords: salt core, carbonate, chloride, die casting, mechanical strength, microstructure

2. Abstract:

Effects of mold temperature and injection pressure on mechanical properties and surface defects of Na2CO3-20mol%NaCl-30mol%KCl salt-mixtures made by high pressure die-casting machine were investigated. The bending strength of the salt-mixture was increased with increasing mold temperature, while the injection pressure in the temperature range from 39MPa to 78MPa was not influenced by the bending strength. Results of the Weibull statistics analysis suggest that increasing the mold temperature is effective for increasing the reliability of the strength as well as the bending strength, because the surface crack decreases with increasing mold temperature. In addition, we succeeded in making a salt core for single closed deck type cylinder blocks. These results suggest that the Na2CO3-NaCl-KCl salt-mixtures made by die-casting machine are promising core material for aluminum alloy high pressure die-castings.

3. Introduction:

Aluminum alloy die castings are increasingly used in the automotive industry due to their light weight, high strength, high productivity, and high dimensional accuracy. Recently, there has been a demand for adapting these castings to more complex shapes, particularly those with undercut features, which poses a significant challenge. Collapsible cores are indispensable for forming undercut shapes. In the die casting process, high-strength cores are necessary to withstand the impact of molten metal injected at high speed and pressure. For instance, the NADCA PQ2 manual specifies that cores must withstand the impact of molten metal at gate speeds of 25.4-40.6 m/s and not deform or break under casting pressures exceeding 75 MPa, which is also needed to collapse blowholes that tend to form on the surface of insulating cores.

Conventional sand cores present a trade-off between strength and collapsibility. Consequently, efforts have focused on optimizing these properties by adjusting binder types and amounts.

Meanwhile, the application of salt cores is also being explored. Salts are generally water-soluble, allowing for easy removal even from high-strength materials, making them promising for die casting applications. Salts, like ceramics, are brittle materials, and their strengthening can be achieved through densification and grain refinement.

The research group has systematically investigated the mechanical properties and solidification structures of salt cores for aluminum alloy die casting. Previous studies showed that aluminum borate whiskers effectively reinforce alkali chlorides, and mixtures of alkali chlorides and alkali carbonates can achieve high strengths (20-30 MPa) without reinforcement. These high-strength mixed salts were produced by gravity casting, but suffered from significant external shrinkage (外引け) and dimensional accuracy issues. It is anticipated that forming salt cores using a die casting machine could dramatically improve dimensional accuracy and production efficiency.

4. Summary of the study:

Background of the research topic:

There is a growing need for high-strength, dimensionally accurate, and easily removable cores for producing complex aluminum alloy die castings, especially those with undercut features. Salt cores offer a potential solution due to their water solubility and potential for high strength. However, previous gravity-cast salt cores suffered from dimensional inaccuracies.

Status of previous research:

The authors' group had previously developed high-strength mixed salt cores (Na2CO3-NaCl-KCl systems) via gravity casting, achieving strengths of 20-30 MPa. However, these cores exhibited poor dimensional accuracy due to solidification shrinkage. The general understanding was that densification and grain refinement could enhance the strength of brittle salt materials.

Purpose of the study:

This study aimed to investigate the effects of mold temperature and injection pressure on the mechanical properties (specifically bending strength) and surface defects of Na2CO3-20mol%NaCl-30mol%KCl salt mixtures produced by a high-pressure die-casting machine. Additionally, the study aimed to demonstrate the applicability of these die-cast salt cores by attempting to produce a core for a single closed-deck type cylinder block.

Core study:

The core of the study involved die casting Na2CO3-20mol%NaCl-30mol%KCl salt mixtures under varying mold temperatures (175, 200, 225, 250°C) and injection pressures (39.2, 58.8, 78.4 MPa). The resulting specimens were evaluated for bending strength, Vickers hardness, surface defects (using dye penetrant testing and SEM), and microstructure (using SEM). Dimensional accuracy was compared to gravity-cast samples. Weibull statistics were used to analyze the reliability of bending strength.

5. Research Methodology

Research Design:

The research employed an experimental design where Na2CO3-20mol%NaCl-30mol%KCl salt mixtures were die-cast under systematically varied mold temperatures and injection pressures. The mechanical and microstructural properties of the resulting salt cores were then characterized.

Data Collection and Analysis Methods:

Specimen Preparation:

- Materials: 99.5% pure NaCl, KCl, and Na2CO3.

- Melting: In an alumina crucible in air at 688°C (approx. 50°C superheat).

- Composition: Na2CO3-20mol%NaCl-30mol%KCl.

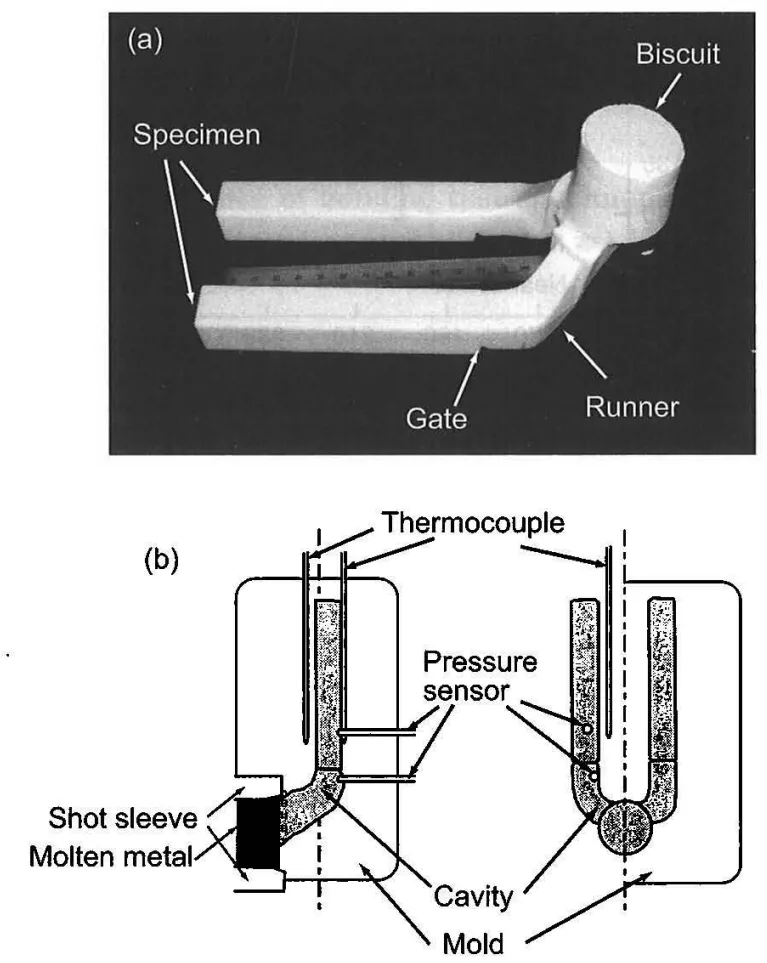

- Die Casting: Using a 110-ton cold chamber die casting machine to produce rectangular test specimens (Fig. 1 (a)).

- Process Parameters:

- Mold temperatures: 175, 200, 225, 250°C (controlled by thermocouples, Fig. 1 (b)). Sleeve temperature was maintained the same as mold temperature.

- Injection pressures: 39.2, 58.8, 78.4 MPa.

- Sleeve diameter: 50 mm.

- Injection speed: 34 mm/s.

- Fill rate: Approximately 60%.

- No two-stage injection was used. A core was inserted behind the sleeve to remove the chill layer.

- Pressure Monitoring: Pressure sensors were used in the runner and cavity sections (Fig. 1 (b), Fig. 2).

Testing and Characterization:

- Bending Test: 4-point bending tests were performed on specimens cut from the gate (Fig. 3). Crosshead speed was 1 mm/min. 10-20 specimens were tested for each condition.

- Hardness Test: Micro-Vickers hardness tests (4.9 N load, 30 s dwell time) were conducted on cross-sections, with 10 measurements near the surface and at the center.

- Surface Defect Observation: Dye penetrant inspection was used for visual examination of surface cracks.

- Microstructure Observation: Scanning Electron Microscopy (SEM) was used to observe polished and carbon-coated cross-sections and surfaces of the specimens.

- Dimensional Accuracy: Visual comparison of cross-sections of die-cast and gravity-molded samples.

- Statistical Analysis: Weibull statistics were applied to analyze bending strength data.

Research Topics and Scope:

The study focused on:

- The influence of mold temperature and injection pressure on the bending strength of die-cast salt cores.

- The effect of mold temperature on Vickers hardness.

- The relationship between processing conditions, surface defects (cracks, wrinkles), and microstructure (chill layer, dendrite size).

- The dimensional accuracy of die-cast salt cores compared to gravity-cast ones.

- The reliability of bending strength using Weibull analysis.

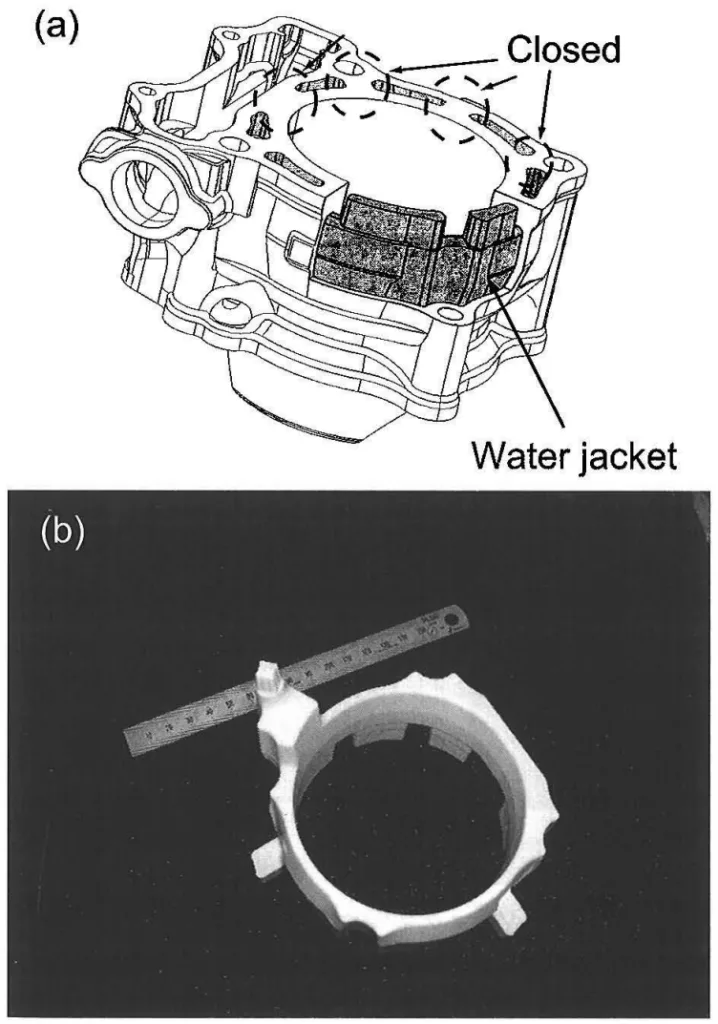

- A trial production of a complex salt core for an automotive application (cylinder block water jacket).

6. Key Results:

Key Results:

- Bending Strength:

- Bending strength increased with increasing mold temperature from 175°C up to 225°C. Above 225°C, the strength remained relatively constant, exceeding 25 MPa, comparable to gravity-cast material (Fig. 4).

- Injection pressure, within the range of 39.2 MPa to 78.4 MPa, did not significantly influence the bending strength (Fig. 5).

- Vickers Hardness:

- Near the surface, hardness was largely independent of mold temperature.

- In the center, the highest hardness was observed at the lowest mold temperature (175°C). At 175°C, surface and center hardness were similar. At higher mold temperatures, the surface was harder than the center (Fig. 6).

- Vickers hardness did not show a strong correlation with bending strength.

- Surface Defects and Microstructure:

- Dye penetrant tests revealed numerous large surface cracks on specimens made with low mold temperatures (175°C, 200°C). These cracks were significantly reduced or absent at higher mold temperatures (225°C, 250°C) (Fig. 7). These large cracks are thought to be caused by tensile stresses due to rapid solidification and volumetric shrinkage.

- SEM of specimen surfaces showed wrinkle-like patterns and associated micro-cracks at low mold temperatures (175°C), which diminished with increasing mold temperature (Fig. 8).

- SEM of cross-sections showed that at 175°C mold temperature, the microstructure was relatively uniform. At higher mold temperatures (200°C, 225°C, 250°C), coarser primary dendrites were observed in the center compared to the finer chill layer at the surface (Fig. 9). The surface microstructure was not significantly affected by mold temperature.

- Dimensional Accuracy:

- Die-cast salt cores exhibited significantly better dimensional accuracy with less external shrinkage (外引け) compared to gravity-molded salt cores (Fig. 10). Some internal shrinkage (内引け) was observed in the center of die-cast cores but was not greatly affected by injection conditions.

- Weibull Analysis:

- Specimens produced at a higher mold temperature (250°C, 78.4 MPa) showed a higher Weibull modulus (m=8.49), indicating greater reliability of strength.

- Specimens produced at a lower mold temperature (200°C, 78.4 MPa) exhibited a bi-modal Weibull distribution (m=1.04 for lower strength region, m=6.74 for higher strength region), suggesting multiple flaw populations (Fig. 11). Large surface cracks likely governed the low-strength failures, while micro-cracks were responsible for higher-strength failures.

- Application Trial:

- A salt core for the water jacket of a single closed-deck type cylinder block, featuring undercut shapes, was successfully produced using the die casting method. The core had a smooth surface and no visible defects (Fig. 12).

Figure Name List:

- Fig. 1 (a)Appearance of injection-molded salt mixture and (b) Schematic illustration of mold.

- Fig. 2 Molten salt pressure during injection process.

- Fig. 3 Size of bending test specimens.

- Fig. 4 Effect of mold temperature on bending strength at various injection pressures, (a) 39.2, (b) 58.8 and (c) 78.4 MPa.

- Fig. 5 Effect of injection pressure on bending strength at 175 and 250°C mold temperatures.

- Fig. 6 Effect of mold temperature on the Vickers hardness at 78.4 MPa injection pressure.

- Fig. 7 Appearance of bending test specimens by liquid penetrant test. Mold temperatures are (a) 175, (b) 200, (c) 225 and (d) 250°C.

- Fig. 8 SEM micro-photographs of bending test specimens on surface. Mold temperatures are (a) 175, (b) 200, (c) 225 and (d) 250°C.

- Fig. 9 SEM micro-photographs of cross sections near surface and center of bending test specimens.

- Fig. 10 Appearances of cross-section of (a) Gravity-molded and (b) Injection-molded salt mixtures. Brocken lines are the cavity size.

- Fig. 11 Weibull plots of bending strength.

- Fig. 12 (a) Design of trial single closed deck type cylinder block and (b) Appearance of salt core prepared for water jacket of single closed deck type cylinder block made by die casting machine.

7. Conclusion:

The study on die-cast Na2CO3-NaCl-KCl salt cores yielded the following conclusions:

- Die-cast salt core specimens exhibited superior dimensional accuracy with less external shrinkage compared to gravity-cast specimens.

- Bending strength increased with higher mold temperatures. However, injection pressure within the tested range (39.2 to 78.4 MPa) had no significant effect on bending strength.

- Dye penetrant inspection revealed large surface cracks on specimens made at low mold temperatures, which are considered a primary cause for reduced bending strength. SEM observations showed surface wrinkles and micro-cracks at low mold temperatures, which decreased as mold temperature increased; these are also considered potential fracture initiation sites.

- Weibull statistical analysis of bending strength data indicated that higher mold temperatures not only increased the bending strength but also improved its reliability (higher Weibull modulus).

- Based on these findings, a salt core for the water jacket of a single closed-deck type cylinder block was successfully produced by die casting, demonstrating the potential of this method for complex core geometries.

8. References:

- [1) J. Wronowicz, M. Cox and R. Fish: NADCA PQ2 EC700, 2006 July, 8.

- 2) 真鍋達也, 新田真, 矢口昌樹: 素形材, 44 (2003) 12, 26.

- 3) 駒崎徹, 宮本武雄, 新田真: 鋳造工学, 78 (2006), 533.

- 4) H.G. Muller: Z. Physik, 96 (1935), 321.

- 5) 佐多敏之: J. Ceram. Soc. Jpn, 107 (1999), 166.

- 6) 林千歳, 山崎太郎, 石黒智, 明浦上晃: アルトピア, 35 (2006) 6, 22.

- 7) 八百川盾, 安斎浩一, 山田養司, 吉井大, 福井博之: 鋳造工学, 76 (2004), 823.

- 8) 八百川盾, 澤田朋樹, 安斎浩一, 山田養司, 吉井大, 福井博之: 鋳造工学, 78 (2006), 59.

- 9) 八百川盾, 三浦大介, 安斎浩一, 山田養司, 吉井大: 鋳造工学, 78 (2006), 516.

- 10) 八百川盾, 三浦大介, 及川勝成, 安斎浩一, 山田養司, 吉井大: 鋳造工学, 79 (2007), 184.

- 11) Y. Yamada, J. Yaokawa, H. Yoshii, K. Anzai, Y. Noda, A. Fujiwara, T. Suzuki and H. Fukuda: 13th Small Engine Technology Conference, 2007 Oct Niigata, 20076584.

- 12) J. Yaokawa, K. Oikawa and K. Anzai: CALPHAD, 31 (2007), 155.

- 13) R. Danzer, T. Lube, P. Supancic and R. Damani: Adv. Eng. Mater., 10 (2008), 275.

- 14) A.G. Evans and T.G. Langdon: Progress in Mater. Sci., 21 (1976), 171.]

9. Copyright:

- This material is a paper by "Katsunari Oikawa, Kenichi Meguro, Jun Yaokawa, Koichi Anzai, Youji Yamada, Akihito Fujiwara and Hiroshi Yoshii". Based on "Mechanical Properties of Mixed Salt Core Made by Die Casting Machine".

- Source of the paper: https://doi.org/10.11279/jfes.81.232

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.