Optimizing AlCu4MgSi Ingots: How Continuous Casting Parameters Impact Mechanical Properties for Downstream Processing

This technical summary is based on the academic paper "MECHANICAL PROPERTIES AND FRACTURE ANALYSIS OF AlCu4MgSi ALLOY INGOTS OBTAINED BY HORIZONTAL CONTINUOUS CASTING" by P.M. Nuckowski and T. Wróbel, published in Arch. Metall. Mater. (2019).

Keywords

- Primary Keyword: AlCu4MgSi Alloy Properties

- Secondary Keywords: horizontal continuous casting, mechanical properties of aluminum, fracture analysis, solidification, casting process optimization, EN AW-2017A

Executive Summary

- The Challenge: Achieving the optimal structure and mechanical properties in semi-finished AlCu4MgSi alloy products is difficult, as it requires precise control at the initial casting stage.

- The Method: The study produced AlCu4MgSi alloy ingots using a horizontal continuous casting process, systematically varying the casting speed and the flow rate of the cooling liquid.

- The Key Breakthrough: Increasing the casting speed and cooling rate directly impacts the final ingot properties, causing a decrease in hardness but a significant increase in elongation, which is linked to changes in grain size and the morphology of intermetallic phases.

- The Bottom Line: Precise control over continuous casting parameters is a powerful tool for tailoring the mechanical properties of AlCu4MgSi ingots, ensuring they meet the specific performance requirements for subsequent manufacturing processes.

The Challenge: Why This Research Matters for HPDC Professionals

Aluminum alloys, particularly high-strength series like AlCu4MgSi (EN AW-2017A), are foundational materials in the aerospace, automotive, and construction industries. The challenge lies in the fact that the final performance of a component is heavily influenced by the quality of the initial semi-finished product, such as a cast ingot. It is difficult to achieve the optimum structure and properties using only one manufacturing method.

This research addresses a critical need: the ability to shape the material's microstructure at the very first stage of production. By understanding how to control the horizontal continuous casting process, manufacturers can improve the quality and consistency of their feedstock, leading to significant cost savings and better performance in downstream operations like extrusion, forging, or die casting.

The Approach: Unpacking the Methodology

The research team conducted a systematic investigation using a dedicated horizontal continuous casting test stand to determine how process parameters influence the final properties of AlCu4MgSi alloy ingots.

Method 1: Controlled Continuous Casting

- Material: AlCu4MgSi alloy (EN AW-2017A) with a chemical composition as detailed in Table 1 of the paper.

- Equipment: An aluminum alloys horizontal continuous casting test stand.

- Process: 30 mm diameter ingots were produced using sequential extraction, consisting of a pulling phase (duration tp) and a rest phase (duration ts).

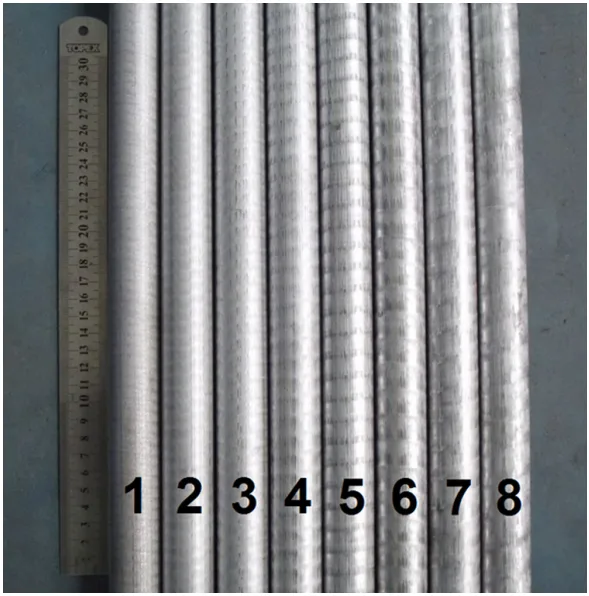

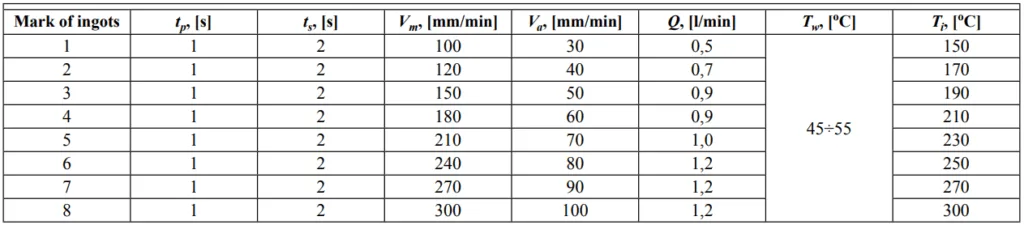

- Key Variables: The average casting speed (Va) was varied from 30 to 100 mm/min, and the cooling water flow rate (Q) was adjusted from 0.5 to 1.2 l/min. The specific parameters for each of the 8 tested ingots are detailed in Table 2.

Method 2: Comprehensive Material Analysis

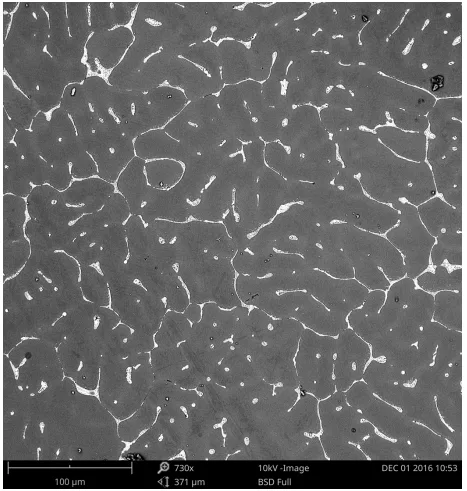

- Microstructural Examination: The structure of the ingots was analyzed using a Zeiss Axio Observer light microscope and a Phenom ProX scanning electron microscope (SEM) with an EDS detector for chemical analysis in microareas.

- Mechanical Testing: Static tensile tests were performed on a Zwick Roell Z100 machine to determine tensile strength and elongation. Hardness was measured using a Rockwell hardness tester (Zwick/ZHR 4150 TK) and converted to the Brinell scale (HB).

- Phase Analysis: Qualitative phase analysis was conducted using X-ray diffraction (XRD) to identify the intermetallic phases present in the alloy.

The Breakthrough: Key Findings & Data

The study revealed a direct and predictable relationship between continuous casting parameters and the resulting microstructure and mechanical properties of the AlCu4MgSi ingots.

Finding 1: Casting Speed Governs Microstructure and Grain Size

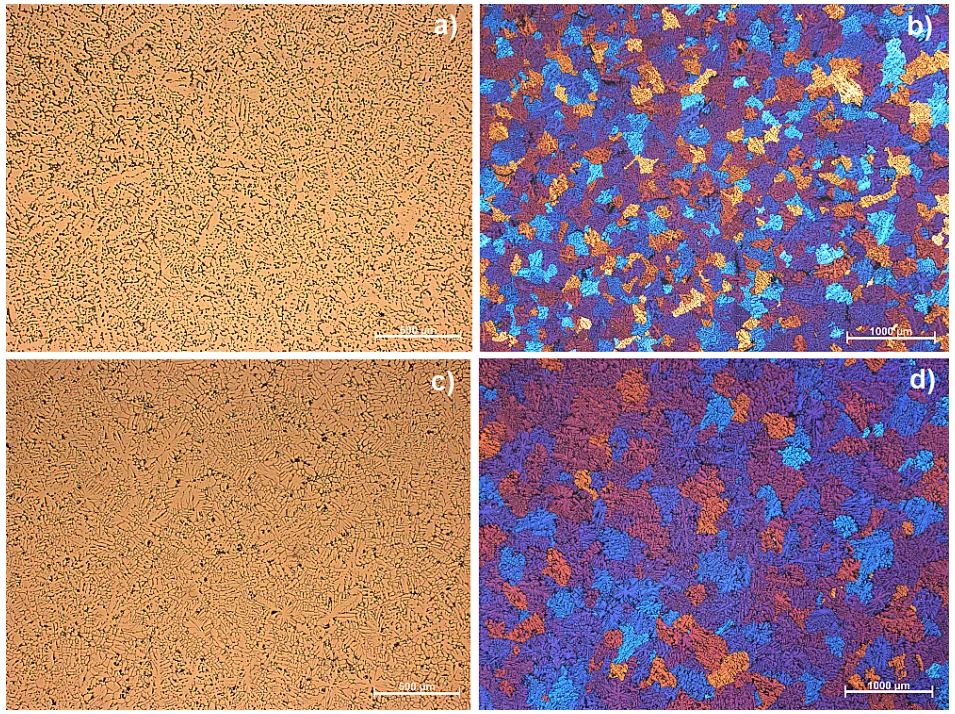

The research demonstrated that as the casting speed increases, the average grain size of the alloy also increases. This is because higher casting speeds correspond to a lower effective cooling rate, which in turn affects the temperature gradient during solidification. All ingots showed a dendritic structure with non-equilibrium phases located in the interdendritic regions.

As shown in Figure 2 of the paper, the ingot cast at a slower speed of 30 mm/min (Fig. 2a, 2b) exhibits a finer structure compared to the ingot cast at a higher speed of 100 mm/min (Fig. 2c, 2d), which has a visibly coarser dendritic structure.

Finding 2: A Trade-off Between Strength, Hardness, and Ductility

The mechanical properties of the ingots were highly sensitive to the casting parameters.

- Hardness vs. Elongation: A clear inverse relationship was observed. As casting speed increased from 30 to 100 mm/min, the hardness decreased from 100 HB to 93 HB. Concurrently, elongation increased significantly from 0.70% to 2.28% (Table 4). This is primarily attributed to the increase in average grain size at higher speeds.

- Tensile Strength: The ultimate tensile strength (Rm) showed a more complex trend. It increased from 247 MPa at 30 mm/min to a peak of 284 MPa at 60 mm/min, after which it slightly decreased to 274 MPa at 100 mm/min. The authors suggest this is due to a combination of factors, including centerline porosity at lower speeds and large dendrite expansion at higher speeds.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting the casting speed and cooling water flow rate provides a powerful method to tailor the properties of AlCu4MgSi feedstock. For applications requiring higher ductility and formability, higher casting speeds are preferable, while lower speeds can be used to achieve higher hardness.

- For Quality Control Teams: The data in Table 4 of the paper illustrates the direct effect of casting speed on key mechanical properties like tensile strength, elongation, and hardness. This data can be used to establish new process windows and inform more precise quality inspection criteria for incoming raw materials.

- For Design Engineers: The findings indicate that the solidification conditions during continuous casting influence defect formation, such as centerline porosity and the morphology of brittle intermetallic phases (θ-Al2Cu and β-Mg2Si). This knowledge is valuable when specifying material for components where fracture resistance is a critical design consideration.

Paper Details

MECHANICAL PROPERTIES AND FRACTURE ANALYSIS OF AlCu4MgSi ALLOY INGOTS OBTAINED BY HORIZONTAL CONTINUOUS CASTING

1. Overview:

- Title: MECHANICAL PROPERTIES AND FRACTURE ANALYSIS OF AlCu4MgSi ALLOY INGOTS OBTAINED BY HORIZONTAL CONTINUOUS CASTING

- Author: P.M. NUCKOWSKI, T. WRÓBEL*

- Year of publication: 2019

- Journal/academic society of publication: Arch. Metall. Mater. 64 (1), 113-118

- Keywords: AlCu4MgSi alloy, horizontal continuous casting, fracture analysis, mechanical properties of ingots, aluminum.

2. Abstract:

The article presents the results of research concerning AlCu4MgSi alloy ingots produced using horizontal continuous casting process under variable conditions of casting speed and cooling liquid flow through the crystallizer. The mechanical properties and structure of the obtained ingots were correlated with the process parameters. On the basis of the obtained results, it has been shown that depending on the cooling rate and the intensity of convection during solidification, significant differences in the mechanical properties and structure and of the ingots can occur. The research has shown that, as the casting speed and the flow rate of the cooling liquid increase, the hardness of the test samples decreases, while their elongation increases, which is related to the increase of the average grain size. Also, the morphology of the intermetallic phases precipitations lattice, as well as the centerline porosity and dendrite expansion, significantly affect the tensile strength and fracture mechanism of the tested ingots.

3. Introduction:

Aluminum alloys are widely used in engineering due to their low density and high strength-to-weight ratio. A significant portion of aluminum production utilizes foundry technologies to obtain semi-finished and final products. Continuous casting is an advantageous technology for producing semi-finished products due to its high efficiency, flexibility, and ability to control the material structure during solidification. This process allows for improving quality and achieving cost savings. This paper aims to determine the influence of horizontal continuous casting parameters on the mechanical properties and structure of AlCu4MgSi alloy ingots.

4. Summary of the study:

Background of the research topic:

The study focuses on AlCu4MgSi (EN AW-2017A), an aluminum alloy widely used in industries like aerospace and automotive. The properties of final products made from this alloy are heavily dependent on the quality of the initial semi-finished ingots. Continuous casting is a key technology for producing these ingots, offering advantages over conventional foundry methods.

Status of previous research:

The paper extends previous research by the authors [9-10] and builds upon existing knowledge regarding continuous casting [6-8] and the behavior of aluminum alloys during solidification [11-15]. The authors note that it is difficult to obtain optimum structure and properties using only one manufacturing method, highlighting the importance of controlling the initial casting process.

Purpose of the study:

The aim of the research was to determine the influence of the parameters of the horizontal continuous casting process (specifically casting speed and cooling liquid flow rate) on the mechanical properties and structure of the obtained AlCu4MgSi alloy ingots. The results are intended to be used to optimize production processes for aluminum alloy profiles.

Core study:

The core of the study involved producing 30 mm diameter AlCu4MgSi alloy ingots under eight different sets of process conditions, with average casting speeds ranging from 30 to 100 mm/min and cooling water flow rates from 0.5 to 1.2 l/min. The resulting ingots were then subjected to extensive analysis, including metallography, scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS), X-ray diffraction (XRD), static tensile tests, and hardness measurements. The mechanical properties were then correlated with the process parameters and the observed microstructures.

5. Research Methodology

Research Design:

The study employed an experimental research design where key process parameters of horizontal continuous casting were systematically varied to observe their effect on the final product. Eight distinct ingots were produced, each representing a unique combination of average casting speed and cooling water flow rate.

Data Collection and Analysis Methods:

- Ingot Production: AlCu4MgSi alloy ingots were produced on a horizontal continuous casting test stand.

- Metallographic Examination: Samples were examined using a Zeiss Axio Observer light microscope and a Phenom ProX SEM with an EDS detector.

- Mechanical Testing: Static tensile tests were conducted using a Zwick Roell Z100 universal testing machine. Hardness was measured with a Zwick/ZHR 4150 TK Rockwell tester.

- Phase Analysis: X-ray diffraction was performed using a Panalytical X’Pert Pro MPD diffractometer to identify crystalline phases.

Research Topics and Scope:

The research focused on AlCu4MgSi (EN AW-2017A) alloy. The scope was limited to ingots of 30 mm diameter produced by horizontal continuous casting. The investigated parameters were average casting speed (30-100 mm/min) and cooling water flow rate (0.5-1.2 l/min). The analysis covered microstructure, phase composition, mechanical properties (tensile strength, elongation, hardness), and fracture morphology.

6. Key Results:

Key Results:

- Microstructure: All ingots exhibited a dendritic structure. An increase in casting speed led to an increase in the average grain size due to a decreased cooling rate. The morphology of the intermetallic precipitate lattice (mainly θ-Al2Cu and β-Mg2Si) was also affected by casting speed.

- Mechanical Properties: As casting speed and cooling flow rate increased, hardness decreased (from 100 to 93 HB), while elongation increased (from 0.70% to 2.28%).

- Tensile Strength: Ultimate tensile strength peaked at 281-284 MPa for casting speeds of 60-70 mm/min and slightly decreased at higher speeds. This behavior is attributed to the interplay between centerline porosity and dendrite expansion.

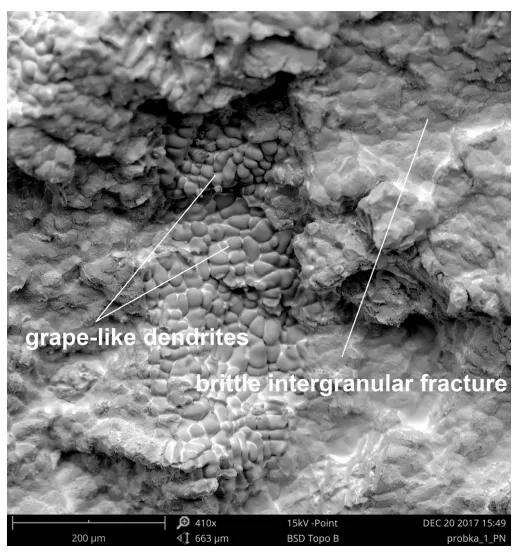

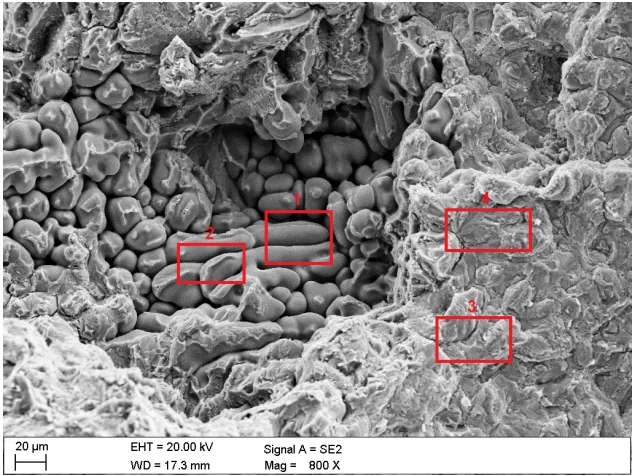

- Fracture Analysis: The fracture mechanism was predominantly brittle intergranular fracture. The cracking was facilitated by the lattice of intermetallic phase precipitates, which block dislocation slip. SEM images revealed exposed "grape-like dendrites" and evidence of shrinkage micro-porosity.

Figure Name List:

- Fig. 1. Fragments of AlCu4MgSi alloy ingots obtained in horizontal continuous casting process

- Fig. 2. Structure of the ingots cast with an average speed of; a, b) 30 mm/min; c, d) 100 mm/min (centre area of cross-section, light microscope; bright field and polarized light)

- Fig. 3. Structure of the ingots cast with an average speed of 30 mm/min; cross-section (SEM)

- Fig. 4. Structure of the ingots cast with an average speed of 100 mm/min; cross-section (SEM)

- Fig. 5. XRD analysis of AlCu4MgSi alloy ingots cast with an average speed of: a) 30 mm/min, b) 100 mm/min

- Fig. 6. Structure of the ingot cast with an average speed of 100 mm/min; cross-section (SEM)

- Fig. 7. Fracture of the ingot cast with an average speed of 30 mm/min

- Fig. 8. Fracture of the ingot cast with an average speed of 100 mm/min

- Fig 9. Fracture of the ingot cast with an average speed of 30 mm/min (marked EDS analysis area)

- Fig. 10. Samples after a tensile test

7. Conclusion:

The research demonstrated that increasing the ingot casting speed and the cooling liquid flow rate in the horizontal continuous casting of AlCu4MgSi alloy influences the shape of the precipitate lattice. As casting speed and cooling flow increase, hardness decreases and elongation increases, which is related to an increase in average grain size. The tensile strength and cracking mechanism were found to be mostly influenced by the shape and morphology of the intermetallic phase precipitates. Wider bands of precipitates at lower speeds contribute to brittle intergranular fracture. Centerline porosity and dendrite expansion also affected the tensile strength.

8. References:

- [1] K. Poznański, J. Sozański, M. Suchowolec, J. Szafraniak, Intelligent innovation in aluminum industry – conference report (in Polish), Warsaw (2017).

- [2] A. Zaki (ed.), Aluminium Alloys – New Trends in Fabrication and Applications, InTech, Rijeka (2012).

- [3] T. Kvačkaj, R. Bidulskỳ (ed.), Aluminium Alloys, Theory and Applications, InTech, Rijeka (2011).

- [4] A. Śliwa, W. Kwaśny, M. Sroka, R. Dziwis, Metalurgija 56 (3-4), 422-424 (2017).

- [5] B. Tomiczek, M. Kujawa, G. Matula, M. Kremzer, T. Tański, L.A. Dobrzański, Materialwiss. Werkst. 46 (4-5), 368-376 (2015). (DOI: 10.1002/mawe.201500411).

- [6] T. Wróbel, J. Szajnar, 22nd International Conference on Metallurgy and Materials (METAL) 15-17 May 2013, Brno, Czech Republic, 1177-1182.

- [7] H.F. Schrewe, Continous Casting of Steel, Fundamental Principles and Practice, Stahl und Eisen, Dusseldorf (1991).

- [8] W. Sebzda, J. Szajnar, 22nd International Conference on Metallurgy and Materials (METAL) 15-17 May 2013, Brno, Czech Republic, 178-184.

- [9] P.M. Nuckowski, T. Wróbel, Arch. Foundry Eng. 18 (1), 196-202 (2018). (DOI: 10.24425/118837).

- [10] T. Wróbel, P.M. Nuckowski, P. Jurczyk, Arch. Foundry Eng. 18 (2), 181-186 (2018). (DOI: 10.24425/122525).

- [11] J. Huang, L. Xia, Y. Znang, S. Li, Case Studies in Engineering Failure Analysis, 2 (1), 15-24 (2014).

- [12] J. Campbell, Complete Casting Handbook: Metal Casting Processes, Metallurgy, Techniques and Design: Second Edition, Elsevier, Oxford (2015).

- [13] ASM International: Casting Desing and Performance, ASM International, Ohio (2009).

- [14] M. Stawarz, Arch. Foundry Eng. 18 (2), 100-104 (2018). (DOI: 10.24425/122509).

- [15] A. Dulska, C. Baron, J. Szajnar, 25th Anniversary International Conference on Metallurgy and Materials (METAL) 25-27 May 2016, Brno, Czech Republic, 110-115.

Expert Q&A: Your Top Questions Answered

Q1: The study found that a higher casting speed led to a larger average grain size. This seems counterintuitive, as faster processing often leads to finer grains. Why did this occur?

A1: The paper explains this relationship is due to the effective cooling rate. The authors state, "This relationship is related to the cooling rate, which decreases with the increase of the casting speed, which in turn affects the temperature gradient and convection intensity of the molten metal." In this horizontal continuous casting setup, a higher ingot withdrawal speed reduces the residence time within the primary cooling zone of the crystallizer, leading to slower overall heat dissipation and thus promoting the growth of larger grains.

Q2: What is the primary cause of the brittle intergranular fracture observed in the samples?

A2: The analysis concludes that the main factor causing brittle fracture is the presence of a lattice of intermetallic phase precipitates, identified by XRD as mainly θ-Al2Cu and β-Mg2Si. These hard, brittle phases form in the interdendritic regions during solidification and act as barriers, "blocking the dislocation slip." This forces the crack to propagate along the grain boundaries, leading to an intergranular fracture mode.

Q3: Why did the ultimate tensile strength peak at a casting speed of 60-70 mm/min and then slightly decrease?

A3: The paper suggests a dual mechanism is responsible for this trend. At lower casting speeds, a larger temperature gradient can lead to an increased "share of centerline porosity," which acts as a defect and reduces tensile strength. At speeds higher than 70 mm/min, the authors note that "a large dendrite expansion will affect Rmmax value slightly decreased." This suggests that the coarser dendritic structure formed at higher speeds is less effective at bearing load compared to the structure formed at the optimal 60-70 mm/min speed.

Q4: The paper mentions "grape-like dendrites." What does this term refer to and what is its significance in the fracture analysis?

A4: "Grape-like dendrites" is a descriptive term for the morphology of the exposed dendrite structures observed on the fracture surface with SEM (as seen in Figure 7). This morphology is characteristic of materials that have solidified with a dendritic microstructure. Its significance is that it visually confirms the dendritic solidification pattern and shows that the fracture path has moved through the weaker interdendritic regions, exposing the primary α-Al dendrite arms.

Q5: Were other phases besides θ-Al2Cu and β-Mg2Si identified, and did they play a role in the material's properties?

A5: Yes, the EDS analysis (Table 3) indicated the presence of complex multi-component phases, presumed to be AlxSixMnxFexCux and AlxCuxMgxSix. However, the XRD analysis and the main discussion focused on θ-Al2Cu and β-Mg2Si as the primary intermetallic precipitates influencing the mechanical properties. While the complex phases are part of the overall microstructure, the paper attributes the dominant fracture mechanism to the network formed by the more prevalent Al2Cu and Mg2Si phases.

Conclusion: Paving the Way for Higher Quality and Productivity

This research effectively demonstrates that the mechanical performance of continuously cast AlCu4MgSi alloy is not a fixed characteristic but a tunable outcome of the manufacturing process. The core problem—achieving consistent and optimized feedstock—can be solved by precisely controlling casting speed and cooling parameters. The key breakthrough is the clear correlation established between these parameters and the final AlCu4MgSi Alloy Properties, particularly the trade-off between hardness and ductility.

These insights are invaluable for R&D and operations teams looking to enhance material performance and reduce variability in their supply chain. By understanding the science of solidification, we can produce superior semi-finished products tailored for demanding applications.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "MECHANICAL PROPERTIES AND FRACTURE ANALYSIS OF AlCu4MgSi ALLOY INGOTS OBTAINED BY HORIZONTAL CONTINUOUS CASTING" by "P.M. Nuckowski and T. Wróbel".

Source: https://doi.org/10.24425/amm.2019.126225

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.