Unlocking Superior Strength: A Deep Dive into Aluminium-Titania Metal Matrix Composites for High-Performance Casting

This technical summary is based on the academic paper "Mechanical Characterization of Aluminium -Titania Metal Matrix Composites" by Padmavathi K R, RamakrishnanR, KarthikeyanL, and ChezhianBabuS, published in Intelligent Systems and Computer Technology (2020).

Keywords

- Primary Keyword: Aluminium Metal Matrix Composites

- Secondary Keywords: nanotitania reinforcement, stir casting, mechanical properties, Aluminium 6061, composite materials, advanced materials

Executive Summary

- The Challenge: Industries like aerospace and automotive require materials with higher strength-to-weight ratios and greater reliability than conventional alloys can provide.

- The Method: Researchers fabricated Aluminium 6061 metal matrix composites using the cost-effective stir casting method, reinforcing the alloy with varying percentages (0.5% to 2.0%) of nano-sized titania particles.

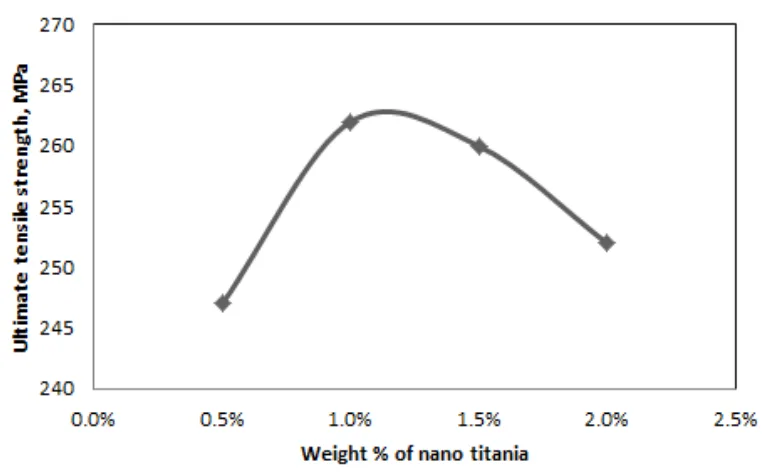

- The Key Breakthrough: The addition of 1.0 weight percentage of nanotitania reinforcement resulted in the highest ultimate tensile strength, significantly enhancing the material's mechanical characteristics.

- The Bottom Line: Nanotitania is a viable reinforcement material for Aluminium 6061, and a 1.0 wt% concentration offers an optimal balance for improving tensile strength, with continuous gains in hardness, compressive, and impact strength at higher percentages.

The Challenge: Why This Research Matters for HPDC Professionals

In the pursuit of lighter, stronger, and more durable components, engineers are constantly pushing the limits of traditional materials. For applications in automotive engines, aircraft fuselages, and high-performance industrial parts, standard aluminium alloys often fall short. The industry needs advanced materials that offer high fatigue and corrosion resistance, a superior strength-to-weight ratio, and exceptional reliability. This is where Aluminium Metal Matrix Composites (AMMCs) come in. However, fabricating these composites effectively and economically remains a challenge. Issues like poor particle distribution, porosity, and low wettability can compromise the final product's integrity, making reliable manufacturing methods essential. This research addresses the critical need to understand how nano-sized reinforcements, specifically nanotitania, can be used to overcome these hurdles and enhance the performance of widely used alloys like Aluminium 6061.

The Approach: Unpacking the Methodology

To explore the potential of nanotitania-reinforced aluminium, the researchers employed a systematic and commercially viable fabrication process. This approach ensures the findings are not just academically interesting but also relevant for industrial-scale production.

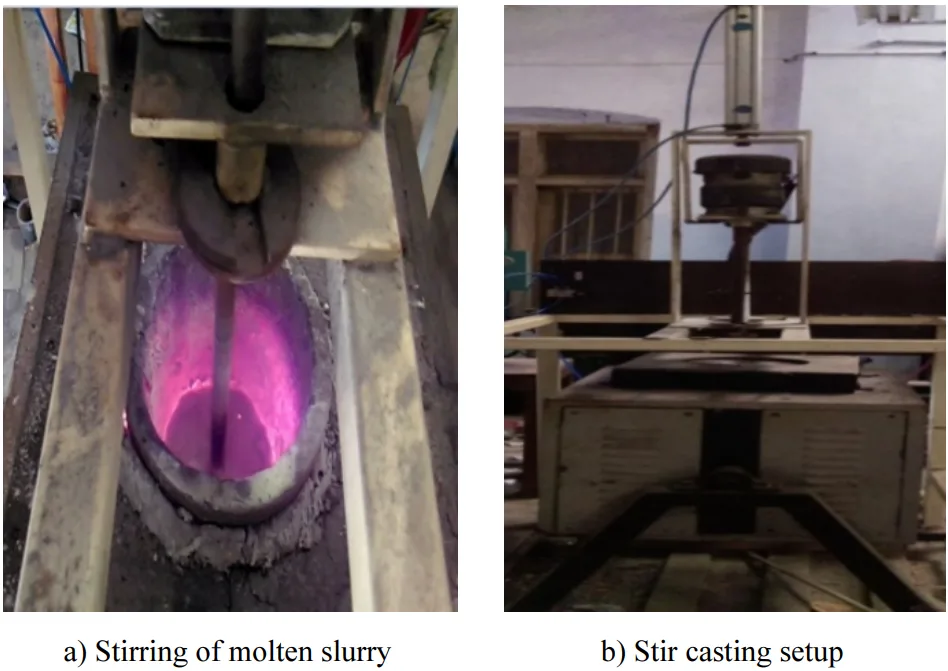

Method 1: Material Formulation and Stir Casting

The matrix material was Aluminium alloy 6061, a workhorse in the industry. The reinforcement chosen was nanotitania (titanium dioxide) with a particle size of 50 nanometers. Composites were fabricated with four different weight percentages of nanotitania: 0.5%, 1.0%, 1.5%, and 2.0%. The fabrication was performed using the stir casting method, a cost-effective technique for producing AMMCs. The process involved melting the Al6061, cooling it to a semi-solid state, and then introducing the preheated nanotitania particles.

Method 2: Process Optimization for Uniform Dispersion

A key challenge in creating AMMCs is ensuring the reinforcement particles are spread evenly throughout the matrix. To achieve this, the researchers optimized several process parameters. A three-blade mild steel impeller, coated with alumina to prevent iron contamination, was tilted at 45° and placed 20 mm from the crucible bottom. The molten slurry was stirred for 5 minutes at an optimized speed of 310 rpm, creating a vortex that effectively distributed the nanoparticles. An inert environment was created using wetting agents like TiK₂F₆ to prevent oxidation. The final composite material was then die-cast into rods and heat-treated.

The Breakthrough: Key Findings & Data

The mechanical properties of the fabricated composites were rigorously tested, revealing a clear relationship between the amount of nanotitania reinforcement and the material's performance.

Finding 1: Tensile Strength Peaks at 1.0% Nanotitania

The ultimate tensile strength of the composite material showed a significant improvement with the addition of nanotitania, but only up to a certain point. As shown in Figure 3, the tensile strength increased from the baseline, reaching a peak value of approximately 263 MPa at a 1.0 weight percentage of nanotitania. Beyond this concentration, the tensile strength began to decrease. This suggests that while the nanoparticles initially provide higher resistance to tensile stress, higher concentrations lead to poor wettability and particle agglomeration, which compromises strength.

Finding 2: Hardness, Compressive, and Impact Strength Continuously Improve

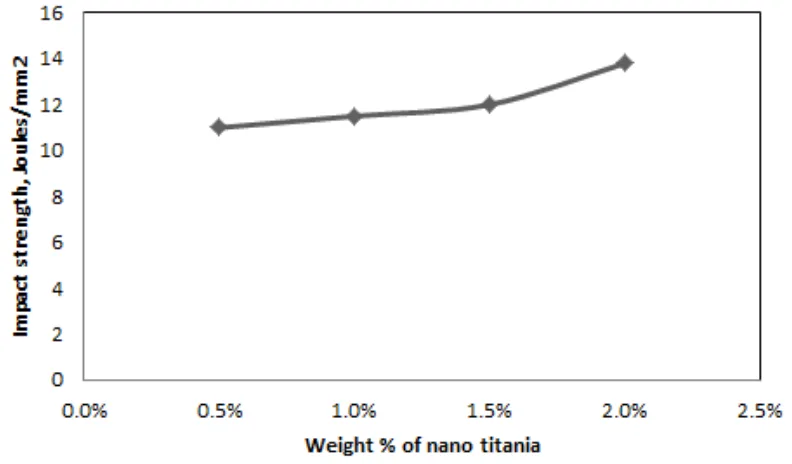

Unlike tensile strength, other key mechanical properties showed a consistent positive correlation with the amount of nanotitania reinforcement.

- Microhardness: The Vickers microhardness increased steadily as the weight percentage of nanotitania increased from 0.5% to 2.0%. As seen in Figure 6, the hardness rose from approximately 90 VHN to over 102 VHN, an improvement attributed to the presence of the extremely hard ceramic nanoparticles within the softer aluminium matrix.

- Compressive & Impact Strength: Both ultimate compressive strength (Figure 4) and impact strength (Figure 5) demonstrated a clear upward trend with increasing nanotitania content. The hard ceramic particles act as obstacles to dislocation motion, contributing to a tougher and more compression-resistant material.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that for applications requiring maximum tensile strength, a reinforcement level of 1.0 wt% nanotitania is optimal. For applications where hardness and compressive strength are the primary concerns, increasing the reinforcement percentage up to 2.0% is beneficial. The stirring parameters (310 rpm, 5 minutes, 45° blade angle) provide a valuable baseline for process optimization.

- For Quality Control Teams: The data in Figure 6 and Figure 7 of the paper illustrates the direct relationship between nanotitania content and microhardness, and the resulting uniform microstructure. Hardness testing can serve as a quick and effective proxy for verifying the successful incorporation and distribution of the nano-reinforcement.

- For Design Engineers: The findings indicate that AMMCs reinforced with nanotitania offer a tunable set of mechanical properties. This allows for the design of components with tailored characteristics—for example, a part requiring high surface hardness but also optimized tensile performance can be engineered by selecting the appropriate reinforcement percentage.

Paper Details

Mechanical Characterization of Aluminium -Titania Metal Matrix Composites

1. Overview:

- Title: Mechanical Characterization of Aluminium -Titania Metal Matrix Composites

- Author: Padmavathi K R, RamakrishnanR, KarthikeyanL, and ChezhianBabuS

- Year of publication: 2020

- Journal/academic society of publication: Intelligent Systems and Computer Technology (IOS Press)

- Keywords: Aluminium Metal Matrix Composites, nanotitania, stir casting, heat treatment.

2. Abstract:

Researchers investigated the mechanical properties of Aluminium Metal Matrix Composites (AMMC) with several reinforcements and negligible work has been administered on analysing the mechanical characteristics of AMMC with rutile nanotitania reinforcement material. Metal matrix composite with Aluminium 6061 metallic element as matrix material and nanotitania as reinforcement with 0.5, 1.0, 1.5 and 2.0 weight percentages was fabricated through stir casting method followed by die casting and heat treatment. Consequent exploration on mechanical characteristics viz. micro hardness, tensile, compressive and impact strength were carried out. The fabricated samples were examined using scanning electron microscopy and analysed. The outcomes exhibited enhanced mechanical characteristics for 1.0 weight percentage nanotitania reinforced aluminium6061 metal matrix composite material.

3. Introduction:

Composites are combinations of two or more materials that result in a new material with characteristics different from the individual components. Metal matrix composites (MMCs), which consist of a particle or fibre reinforcement within a metal matrix, are used in demanding applications like aerospace and automotive industries due to their high fatigue and corrosion resistance and high strength-to-weight ratio. Aluminium alloys are common matrix materials, often reinforced with particles like silicon carbide or aluminium oxide. This study focuses on a further improvement: the addition of nano-sized reinforcements to the matrix. Specifically, it investigates Aluminium Metal Matrix Composites (AMMCs) using Aluminium 6061 as the matrix and nanotitania as the reinforcement, an area where limited research has been conducted.

4. Summary of the study:

Background of the research topic:

Aluminium metal matrix composites (AMMCs) are advanced materials offering superior mechanical and thermal properties compared to monolithic alloys. They find applications in automotive, aerospace, and industrial fields. The addition of nano-sized reinforcements can further enhance these properties. Stir casting is a commercially accepted, low-cost technique for producing AMMCs, but it presents challenges such as achieving uniform reinforcement distribution and good wettability.

Status of previous research:

While AMMCs have been studied extensively with various reinforcements, the paper notes that negligible work has been done on analyzing the mechanical characteristics of AMMCs using rutile nanotitania as the reinforcement material. Previous work has established the benefits and challenges of stir casting, including methods to improve wettability and prevent particle segregation.

Purpose of the study:

The purpose of this research was to fabricate and mechanically characterize Aluminium 6061 metal matrix composites reinforced with varying weight percentages (0.5, 1.0, 1.5, and 2.0 wt%) of nanotitania. The study aimed to determine the effect of the nanotitania concentration on the micro hardness, tensile strength, compressive strength, and impact strength of the composite.

Core study:

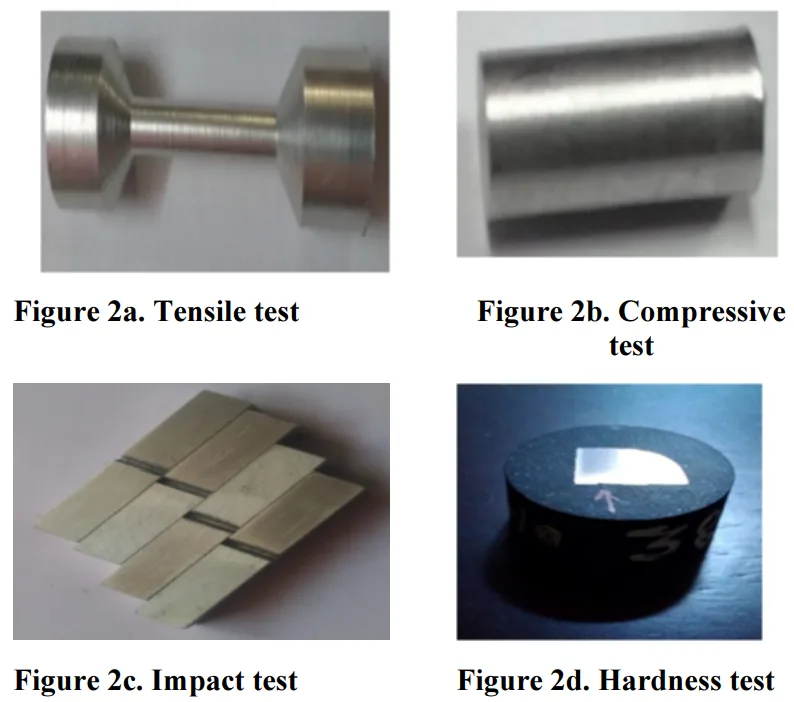

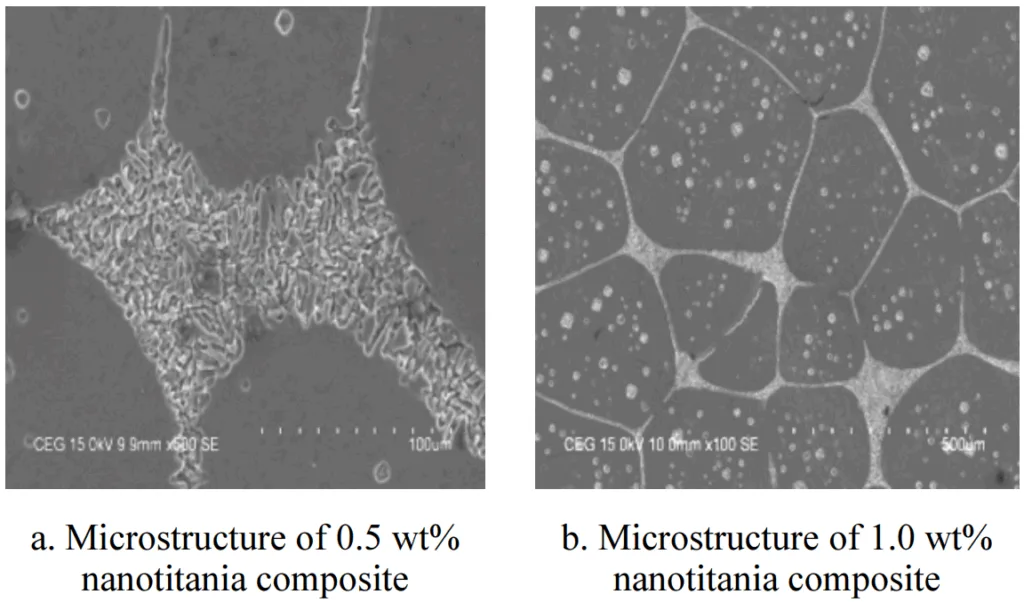

The core of the study involved the fabrication of Al6061-nanotitania composites via a stir casting method, followed by die casting and heat treatment. The fabricated samples were then subjected to a series of mechanical tests according to ASTM specifications to evaluate their properties. A Vickers microhardness tester, Charpy impact tester, and universal testing machine were used. Additionally, the microstructure of the composites was examined using scanning electron microscopy (SEM) to analyze the distribution of the reinforcement particles.

5. Research Methodology

Research Design:

The study employed an experimental research design. The independent variable was the weight percentage of nanotitania reinforcement (0.5%, 1.0%, 1.5%, 2.0%). The dependent variables were the mechanical properties of the resulting composite: ultimate tensile strength, ultimate compressive strength, impact strength, and microhardness.

Data Collection and Analysis Methods:

- Fabrication: Composites were fabricated using a stir casting process. Aluminium 6061 was melted in a graphite crucible furnace. Preheated nanotitania particles (50 nm size) were added to the semi-solid slurry. Stirring was performed at 310 rpm for 5 minutes with a 45° tilted three-blade impeller to ensure homogeneous distribution. The composite was then die-cast and heat-treated (solutionizing, quenching, artificial ageing).

- Mechanical Testing: Specimens were prepared as per ASTM standards.

- Microhardness was measured with a Vickers microhardness tester under a 5 N load with a 15-second dwell time.

- Impact strength was measured using a Charpy impact tester.

- Tensile and compressive tests were conducted to obtain stress-strain diagrams and determine ultimate strengths.

- Microstructural Analysis: The distribution of reinforcement particles was examined using a scanning electron microscope (SEM).

Research Topics and Scope:

The research was focused on Aluminium 6061 as the matrix material and nanotitania as the reinforcement. The scope was limited to four weight percentages of reinforcement. The investigation covered the fabrication via stir casting and the subsequent characterization of four key mechanical properties and the microstructure.

6. Key Results:

Key Results:

- The ultimate tensile strength of the composites increased with nanotitania content up to 1.0 weight percentage, after which it decreased. The peak strength was observed at 1.0 wt%.

- The ultimate compressive strength and impact strength of the composites increased continuously with the increasing weight fraction of nanotitania reinforcement up to 2.0 wt%.

- The Vickers microhardness of the composites also increased progressively with the addition of nanotitania, which is attributed to the presence of the hard ceramic particles in the aluminium matrix.

- SEM analysis of the 0.5 wt% and 1.0 wt% composites showed that the nanotitania reinforcement particulates were distributed uniformly throughout the Aluminium 6061 matrix.

Figure Name List:

- Figure 1. (a-b) Stir casting

- Figure 2. Specimen for mechanical characterization

- Figure 3. Ultimate tensile strength of nanotitania composites

- Figure 4. Ultimate compressive strength of nanotitania composites

- Figure 5. Impact strength of nanotitania composites

- Figure 6. Vickers micro hardness of nanotitania composites

- Figure 7 (a-b). Microstructure of nanotitania – aluminum6061 composite

7. Conclusion:

Based on the studies of the fabricated aluminium 6061-nano titania reinforced metal matrix composites the following conclusions can be obtained.

- Nano titania particles can be used as reinforcement material to improve the mechanical properties of the aluminium 6061 matrix material.

- Addition of nanotitania enhances the ultimate tensile strength of composites up to 1.0 weight percent of reinforcement particles.

- Addition of nanotitania augments the compressive and impact strength of the fabricated composites.

- Addition of nanotitania enriches the micro hardness of composites.

- The microstructure of the nanotitania reinforced aluminium 6061 metal matrix composites depicts the unvarying distribution of reinforcement particles in the matrix material.

8. References:

- [1] Rajan T.P.D., Pillai R.M. and Pai B.C, Reinforcement coatings and interfaces in aluminium metal matrix composites. Journal of Materials Science, Vol. 33, Issue 14, pp. 3491-3503, 1998.

- [2] Prasad S.V., and Asthana R., Aluminum Metal-Matrix Composites for Automotive Applications: Tribological Considerations.Tribology Letters, Vol. 17, Issue 3, pp. 445-453, 2004

- [3] Mavhungu S.T., Alinlabi E.T., Onitiri M.A. and Varachia F.M., Aluminium Matrix composites for industrial use: Advances and Trends .Procedia Manufacturing, Vol. 7, pp. 178-182, 2017

- [4] Padmavathi K.R. and Ramakrishnan R., Tribological and Mechanical characterization of Aluminium Metal Matrix Composites. Indian Journal of Science and Technology, Vol. 9(S1), pp. 1-6, 2016

- [5] Surappa M.K., Aluminium matrix composites: Challenges and opportunities.Sadhana, Vol. 28, Issue 1-2, pp. 319-334, 2003

- [6] Mavhungu S.T., Alinlabi E.T., Onitiri M.A. and Varachia F.M., Aluminium Matrix composites for industrial use: Advances and Trends.Procedia Manufacturing, Vol. 7, pp. 178-182, 2017

- [7] Soltani S., Azari Khosroshahi R., Mousavian Taherzadeh. R., Jiang Z., Fadavi Boostani A. and Brabazon D., Stir castingprocess for manufacture of Al-SiC composites.Rare Metals, Vol. 36, No. 7, pp. 581-590, 2017

- [8] Hashim, J., Looney, L. and Hashmi, M.S.J., Metal matrix composites: production by the stir casting method.Journal of Materials Processing Technology, Vol. 1-7, pp. 92-93, 1999

- [9] Pardeep Sharma, GulshanCauhan and Neeraj Sharma, Production of AMC by stir casting - An Overview. International Journal of Contemporary Practices, Vol. 2, Issue 1, pp. 23-46, 2008.

- [10] Ramesh C.S., Anwar Khan A.R., Ravikumar N. and Savanprabhu, P, Prediction of wear coefficient of Al6061-TiO2 composites. Wear, Vol. 259, pp. 602-608, 2005

- [11] Padmavathi K.R., Ramakrishnan R. and Palanikumar.K, Wear properties of SiCp and TiO2p reinforced aluminium metal matrix composites.Indian Journal of Engineering & Materials Sciences, Vol. 26, pp. 51-58, 2019

- [12] Shubham Mathur and Alok Barnawal, Effect of Process Parameter of Stir Casting on Metal Matrix Composites. International Journal of Science and Research (IJSR), Vol. 2, Issue 12, pp. 2319-7064, 2013

- [13] Riccardo Casati and Maurizio Vedani, Metal Matrix Composites Reinforced by Nano-Particles-A Review. Metals, Vol. 4, pp. 65-83, 2014

- [14] Veeresh Kumar G.B., Rao C.S.P. and Selvaraj N., Mechanical and Tribological behavior of Particulate Reinforced Aluminum Metal Matrix Composites a review. Journal of Minerals & Materials Characterization & Engineering, Vol. 10, pp. 55-91, 2011.

- [15] Antony Vasantha Kumar, C. and Selwin Rajadurai J., Influence of rutile (TiO2) content on wear and microhardness characteristics of aluminium-based hybrid composites synthesized by powder metallurgy.Transactions of Nonferrous Metals Society of China, Vol. 26, pp. 63-73, 2016

- [16] Rajmohan T and Palanikumar K, Artificial neural network model to predict thrust force in drilling of hybrid metal matrix composites.National Journal on Advances in Building Sciences and Mechanics, Vol. 1, No.2, 2010

- [17] X. M. Du, K. F. Zheng, F. G. Liu, "Effect of clustering on the mechanical properties of sic p reinforced aluminum metal matrix composites", Digest Journal of Nanomaterials and Biostructures, Vol. 13, No. 1, pp. 253 - 261, 2018.

- [18] S. Sivasankaran and Abdulaziz S. Alaboodi, " Structural Characterization and Mechanical Behavior of Al 6061 Nanostructured Matrix Reinforced with TiO2 Nanoparticles for Automotive Applications.Functionalized Nanomaterials, http://dx.doi.org / 10.5772/ 65947, pp.3-35, 2016

- [19] Karthikeyan L. and Senthil Kumar V.S., Relationship between process parameters and mechanical properties of friction stir processed AA6063-T6 aluminum alloy. Materials & Design 32 (5), 3085-3091, 2010.

- [20] Karthikeyan L., Senthilkumar V.S., Balasubramanian V, and Natarajan S., “Mechanical property and microstructural changes during friction stir processing of cast aluminum 2285 alloy” Materials & Design 30 (6), 2237-2242, 2009.

- [21] Ramesh S., Govindaraju N. and Suryanarayan C.P., Investigation on Mechanical and Fatigue behaviour of Aluminium Based SiC/ZrO2 Particle Reinforced MMC. IOP Conference Series: Materials Science and Engineering, Vol. 346, pp. 1-8, 2018.

- [22] Chezhian Babu S. and V.S.Senthil Kumar, Investigations on incremental forming of low carbon steel sheets.Applied mechanics and materials, Vol. 26-28, pp. 340-346.

Expert Q&A: Your Top Questions Answered

Q1: Why was the stir casting method chosen for this research over other fabrication techniques?

A1: The paper states that stir casting is "commercially accepted as a low-cost technique" for producing Aluminium Metal Matrix Composites. Its benefits include "uncomplicatedness, suppleness, and its capability in large volume production." This makes it the "utmost cost-effective of several existing ways for AMMCs fabrication," ensuring that the research findings are applicable to industrial-scale manufacturing.

Q2: What caused the ultimate tensile strength to decrease after the 1.0 wt% nanotitania addition?

A2: The paper attributes the decrease in tensile properties at higher volume fractions to the "poor wettability" of the reinforcement particles with the matrix. While the initial addition of reinforcements provides higher resistance to tensile stresses, too many particles can lead to clumping and weak interfaces between the particles and the aluminium matrix, which in turn reduces the overall tensile strength.

Q3: How was the uniform distribution of the nano-sized titania particles achieved during casting?

A3: Several specific parameters were optimized to achieve a homogeneous distribution. The impeller blades were tilted at 45° to prevent the heavier nanotitania from settling. Stirring was conducted at an optimized speed of 310 rpm for 5 minutes, which created a vortex in the melt that effectively improved particle distribution. Furthermore, adding the reinforcement while the matrix was in a semi-solid state helped prevent segregation.

Q4: Why do compressive strength and hardness continue to increase with more nanotitania, while tensile strength does not?

A4: The paper explains that the increase in compressive strength, impact strength, and hardness is due to the "addition of the hard ceramic particles, which act as the hindrances to the motion of dislocation." In compression and indentation (hardness testing), the hard particles effectively bear the load and prevent the softer matrix from deforming. In tension, the quality of the bond (wettability) between the particle and the matrix is more critical, and this bond weakens at higher concentrations, leading to failure.

Q5: What was the purpose of heat treating the composite specimens after casting?

A5: The paper mentions that the stir-casted composite specimens were "later heat treated by solutionizing, quenching and artificial ageing." While it doesn't detail the effects, this is a standard T6 heat treatment process for 6061 aluminium alloys. This process is used to precipitate strengthening phases within the aluminium matrix, significantly increasing its strength and hardness, thereby ensuring the baseline properties of the matrix material are optimized.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a clear and valuable roadmap for enhancing the performance of a widely used industrial alloy. It demonstrates that Aluminium Metal Matrix Composites, specifically Al6061 reinforced with nanotitania, can offer significantly improved mechanical properties. The key breakthrough is identifying the 1.0 wt% concentration as the sweet spot for maximizing ultimate tensile strength, while also confirming that hardness and compressive strength can be progressively increased. These findings are directly applicable to industries seeking lighter, stronger, and more durable materials for high-performance components.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

This content is a summary and analysis based on the paper "Mechanical Characterization of Aluminium -Titania Metal Matrix Composites" by "Padmavathi K R, RamakrishnanR, KarthikeyanL, and ChezhianBabuS".

Source: https://doi.org/10.3233/APC200214

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.