This article introduces the paper "Magnesium Diecasting Alloys for High Temperature Applications".

1. Overview:

- Title: Magnesium Diecasting Alloys for High Temperature Applications

- Authors: Mihriban O. Pekguleryuz, A. Arslan Kaya

- Year of Publication: 2004

- Journal/Conference: Magnesium Technology

- Keywords: Magnesium alloys, Die casting, High temperature applications, Creep resistance, Automotive, Powertrain

2. Research Background:

A new growth area for automotive use of magnesium is in powertrain applications such as transmission cases and engine blocks. These components operate in temperature ranges of 150-200°C under tensile and compressive loads of 50-70 MPa. Furthermore, they must meet requirements for metallurgical stability, fatigue resistance, corrosion resistance, and castability. Existing commercial magnesium-aluminum alloys (AM series, AZ91 alloy), while offering good room-temperature strength and ductility, corrosion resistance, and die castability, do not satisfy the performance demands at these elevated temperatures. Therefore, the development of creep-resistant magnesium alloys suitable for high-temperature automotive applications is essential. Over the past decade, concentrated efforts have been made to develop magnesium alloys with good creep resistance, resulting in several alloys based on rare-earth and alkaline earth element additions.

3. Research Objective and Research Questions:

The objective of this study is to provide an overview of various magnesium alloy systems for use in elevated-temperature applications. The focus is specifically on creep resistance, discussing alloy systems, microstructure, creep behavior, and comparative properties. The core research questions are:

- What are the creep deformation mechanisms in magnesium alloys at high temperatures?

- Which magnesium alloy systems exhibit suitable creep resistance for high-temperature automotive applications?

While the paper does not explicitly state a research hypothesis, it explores the potential for enhancing the creep resistance of magnesium alloys through various alloying element additions and microstructure control.

4. Research Methodology:

This study is a literature review paper that comprehensively analyzes existing research and knowledge related to the creep resistance of magnesium alloys. It gathers information on creep mechanisms, alloy systems, and properties of magnesium alloys by reviewing various research papers and materials. This information is then qualitatively analyzed and synthesized. In particular, the Arrhenius relationship is used to analyze creep activation energy and stress exponents, inferring creep mechanisms. The scope of the research focuses on high-temperature applications, particularly magnesium die-casting alloys used in automotive powertrain components. It delves into the creep behavior and mechanisms of specific alloy systems such as AZ91D and AM50.

5. Main Research Findings:

- Key Findings: Creep in magnesium alloys is a time-dependent, slow, and continuous deformation, being a function of stress, time, and temperature. Creep deformation is caused by the thermally activated short-range component of stress. The creep mechanism in magnesium varies depending on temperature and stress levels. Stress-activated recovery is dominant at low to moderate temperatures, while thermally activated recovery is dominant at high temperatures. Microstructural changes such as creep-induced precipitation and grain boundary migration influence creep behavior in specific alloys (AZ91D, AM50).

- Statistical/Qualitative Analysis Results:

- AZ91D alloy: At 125-175°C and 50 MPa, the activation energy Q was found to be 30-45 kJ/mol, and the stress exponent n = 2. This is similar to the activation energy for discontinuous precipitation of Mg17Al12, suggesting that creep-induced Mg17Al12 precipitation contributes to the creep mechanism. At higher stresses above 50 MPa, Q changes to 95 kJ/mol and n to 5, indicating a possible shift to mechanisms related to activated cross-slip or grain boundary diffusion.

- AM50 alloy: At 150-225°C and 100 MPa, the activation energy Q was measured to be 126 kJ/mol, which is consistent with the dislocation climb mechanism.

- Data Interpretation: The activation energy values are significant indicators for identifying the dominant creep mechanisms in magnesium alloys under specific conditions. In the case of AZ91D alloy, under low stress conditions, Mg17Al12 precipitation appears to facilitate grain boundary sliding and migration, leading to creep deformation. Under high stress conditions, other mechanisms become dominant. The high activation energy of AM50 alloy suggests that dislocation climb is the primary creep deformation mechanism.

- Figure Name List:

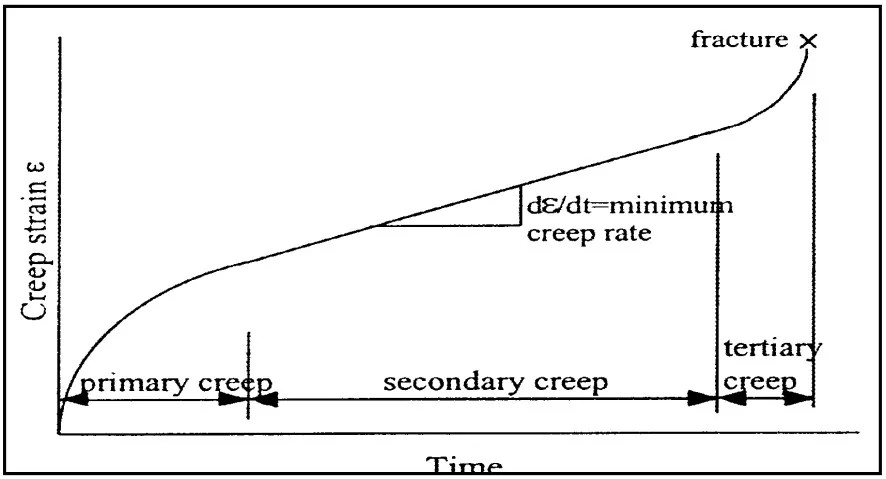

- Fig. 1. Typical creep strain vs. time curve showing the three stages of creep.

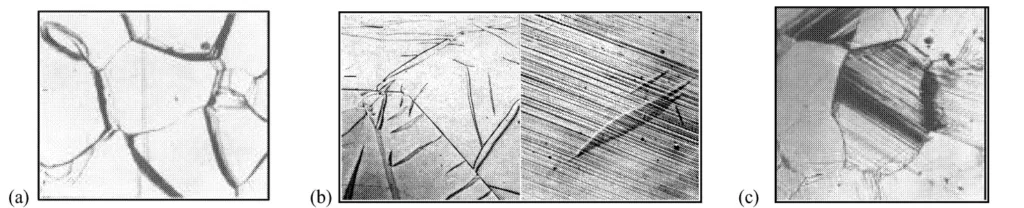

- Fig. 2 (a) Sub-grain formation in Mg (b) twinning and basal slip in Mg. (c) non-basal slip concentrated at grain boundaries rather than grain interiors at high temperatures (Ref. 3).

- Fig. 3. (a) creep induced precipitates of Mg17Al12 and (b) grain boundary migration in AZ91D (ref.5).

6. Conclusion and Discussion:

This study provides a comprehensive overview of the creep behavior and mechanisms of magnesium die-casting alloys for high-temperature applications, particularly in automotive powertrain components. It explains various creep mechanisms and their temperature and stress dependence, and discusses the influence of alloy systems and microstructure on creep resistance based on research findings for AZ91D and AM50 alloys.

- Academic Significance: Enhances the understanding of high-temperature deformation behavior in magnesium alloys and expands the academic knowledge base by providing information on various creep mechanisms and activation energies. Summarizes research findings on creep mechanisms in specific die-casting alloys, contributing to related research fields.

- Practical Implications: Provides insights into alloy design and microstructure control strategies for developing creep-resistant magnesium alloys for high-temperature applications. Suggests directions for expanding the applicability of magnesium alloys in high-temperature applications such as automotive powertrain components. Emphasizes the need to consider practical factors such as castability, corrosion resistance, and cost in alloy development.

- Limitations of the Study: This study is a literature review paper and does not present new experimental data. It focuses on comprehensively analyzing existing research findings, and the depth of discussion on specific alloy systems may be limited by the available literature at the time.

7. Future Follow-up Research:

Future research should focus on developing high-temperature creep-resistant magnesium alloys more suitable for automotive powertrain applications. Exploring new alloying element additions and processing methods to improve creep resistance while ensuring castability, corrosion resistance, and cost-effectiveness is necessary. In-depth investigation of creep mechanisms in various Mg alloy systems and research on long-term creep behavior and fatigue-creep interaction should also be conducted.

8. References:

(While a reference list is not provided in this paper extract, references are cited within the text.)

9. Copyright:

This material is based on the paper by Mihriban O. Pekguleryuz and A. Arslan Kaya: Magnesium Diecasting Alloys for High Temperature Applications.

Paper Source: (DOI URL is not specified in the paper extract)

This material is a summary based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.