Optimizing A356.2 Alloy: A Data-Driven Guide to Heat Treatment in Super-Slow-Speed Die Casting (SSS HPDC)

This technical summary is based on the academic paper "Investigation on Heat Treatment Process Optimization of Super-Slow-Speed Die Casting A356.2 Alloy" by Lu Zhang¹,², Hengcheng Liao¹, Jiang Li², Liangchao Tang ², published in The 75th World Foundry Congress (2024).

Keywords

- Primary Keyword: Super-Slow-Speed Die Casting (SSS HPDC)

- Secondary Keywords: A356.2 Alloy, Heat Treatment Optimization, CALPHAD, Mechanical Properties, Electrical Conductivity, Solution Treatment

Executive Summary

- The Challenge: Standard High Pressure Die Casting (HPDC) often produces defects that prevent effective heat treatment, while the newer Super-Slow-Speed HPDC process requires a precisely optimized heat treatment to balance strength and elongation in A356.2 alloy.

- The Method: The study combined CALPHAD-based thermodynamic modeling with extensive experimental analysis—including DSC, mechanical testing, and microscopy—to evaluate a range of solution heat treatment parameters.

- The Key Breakthrough: A solution treatment at 520°C for 1 hour, followed by aging, was identified as the optimal process, achieving the highest Quality Index (QI) of 418.5 MPa and an excellent balance of mechanical properties.

- The Bottom Line: For SSS HPDC A356.2 alloy, the ideal solution treatment temperature range is 480°C-520°C; temperatures of 540°C must be avoided as they cause dimensional instability due to local material remelting.

The Challenge: Why This Research Matters for HPDC Professionals

High Pressure Die Casting (HPDC) is a cornerstone of modern manufacturing, but it's not without its challenges. Defects inherent to the process can compromise strength and plasticity, making subsequent heat treatments difficult or ineffective. Super-Slow-Speed HPDC (SSS HPDC) has emerged as a powerful alternative, reducing these defects and opening the door for property enhancement through heat treatment.

However, for tough alloys like A356.2, finding the right heat treatment recipe is critical. While aging treatments can increase strength, they often do so at the expense of elongation. This study addresses a crucial industry need: developing a heat treatment process for SSS HPDC A356.2 that achieves a superior balance of tensile strength, yield strength, and elongation, ensuring components are both strong and ductile.

The Approach: Unpacking the Methodology

This research was built on a rigorous and comprehensive experimental framework to ensure the findings are directly applicable to industrial settings.

- Material & Process: The study used A356.2 alloy cast via the SSS HPDC process on an 840-ton Büler Ecoline S machine. The test casting was a component for a vehicle's toolkit with a 4mm wall thickness.

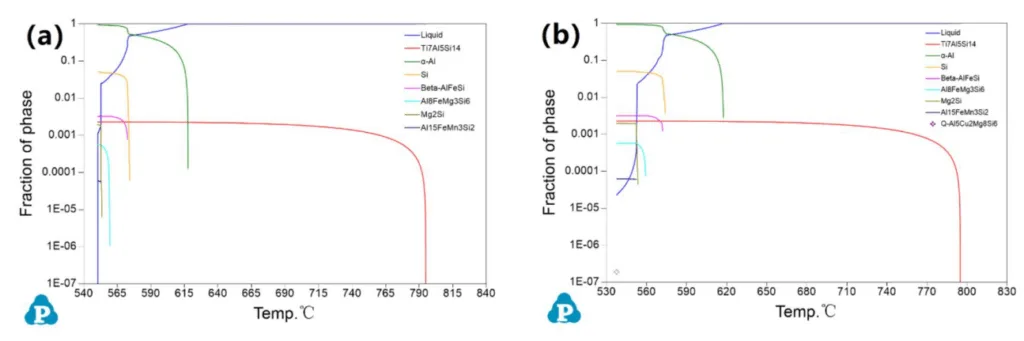

- Modeling & Simulation: The CALPHAD (Calculation of Phase Diagrams) method was used to analyze the alloy's phase composition during solidification, comparing the standard Scheil model with a modified DB model to predict phase formation and solidification temperatures.

- Physical Analysis: A suite of advanced analytical tools was employed:

- DSC and Thermomechanical Analyzer: To determine thermal properties and measure dimensional changes at various temperatures.

- Optical Microscopy: To observe the evolution of the microstructure, particularly the eutectic silicon, under different heat treatment conditions.

- Conductivity Meter: To measure electrical conductivity, which is sensitive to changes in the alloy's matrix.

- Universal Testing Machine: To conduct tensile tests and gather precise data on mechanical properties, with each result being an average of three samples.

The Breakthrough: Key Findings & Data

The study delivered clear, data-driven conclusions for optimizing the heat treatment of A356.2 alloy in SSS HPDC.

Finding 1: Identifying the Optimal Heat Treatment Window for Mechanical Performance

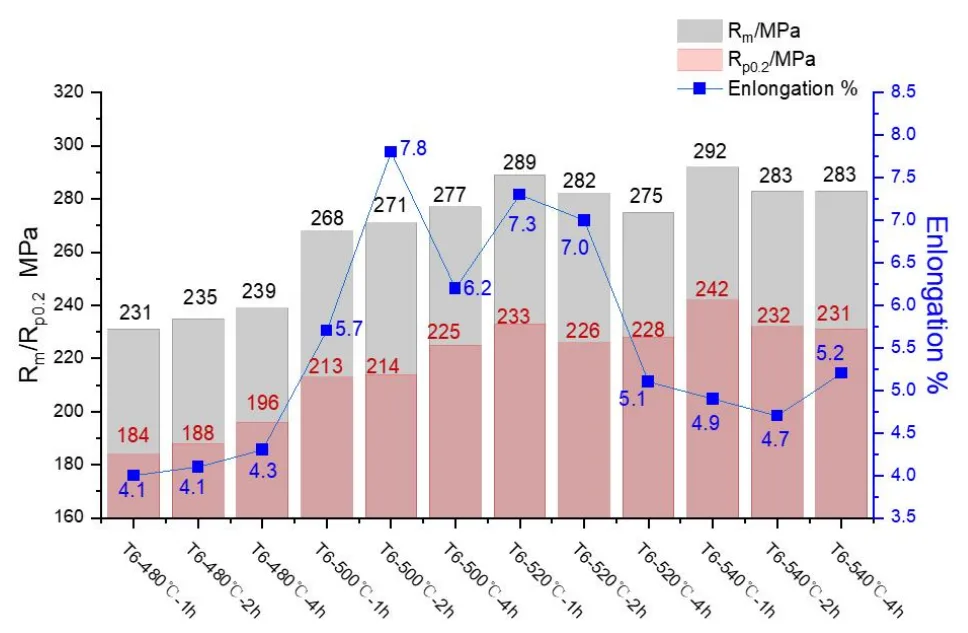

The research pinpointed a specific set of parameters that deliver the best combination of strength and ductility. As shown in Figure 4, after solution treatment followed by aging at 180°C for 6 hours, the highest Quality Index (QI) of 418.5 MPa was achieved with a solution treatment at 520°C for 1 hour. At these parameters, the alloy exhibited a tensile strength (Rm) of 292 MPa, a yield strength (Rp0.2) of 275 MPa, and an elongation of 7.8%. While other parameters at 500°C and 540°C also yielded necessary mechanical properties, the 520°C/1h condition represented the peak performance balance.

Finding 2: Pinpointing the Upper Temperature Limit to Prevent Deformation

A critical finding for production stability was identifying the absolute upper limit for solution treatment temperature. The thermal expansion analysis, summarized in Figure 5, showed no significant dimensional changes in samples heated in the 480°C-520°C range. However, when the temperature was raised to 540°C, local remelting of the material occurred, causing size deformation. This indicates that despite achieving good mechanical properties, operating at 540°C introduces a significant risk of dimensional instability, making it unsuitable for reliable, high-volume production.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting the solution treatment temperature to 520°C for 1 hour may contribute to achieving the highest quality index. Exceeding this temperature to 540°C, even for short durations, should be avoided to prevent part deformation and ensure dimensional accuracy.

- For Quality Control Teams: The data in Figure 4 provides a clear performance benchmark for tensile strength, yield strength, and elongation. Furthermore, the electrical conductivity data in Figure 3 shows a distinct correlation with solution treatment parameters, suggesting it could be explored as a rapid, non-destructive method for verifying the effectiveness of the heat treatment process.

- For Design Engineers: The findings indicate that SSS HPDC A356.2 components with a 4mm wall thickness can be reliably heat-treated to achieve superior mechanical properties. This is a valuable consideration in the early design phase for components requiring a combination of high strength, ductility, and light weight.

Paper Details

Investigation on Heat Treatment Process Optimization of Super-Slow-Speed Die Casting A356.2 Alloy

1. Overview:

- Title: Investigation on Heat Treatment Process Optimization of Super-Slow-Speed Die Casting A356.2 Alloy

- Author: Lu Zhang, Hengcheng Liao, Jiang Li, Liangchao Tang

- Year of publication: 2024

- Journal/academic society of publication: The 75th World Foundry Congress

- Keywords: A356.2 alloy, Electrical conductivity, Solution temperature, CALPHAD, Mechanical properties

2. Abstract:

A356.2 alloy die casting is produced by the Super-Slow-Speed die casting process. The phase composition of the alloy under the Scheil model and DB model (modified Scheil model) was analyzed by the CALPHAD-based method. Combined with DSC, conductivity meter, universal testing machine, and thermomechanical analyzer, the heat treatment process, microstructure, and mechanical properties of the material were studied, and the range of heat treatment process parameters required for actual production was determined.

3. Introduction:

High pressure die casting (HPDC) is widely used but can have defects that affect strength and plasticity. Super-Slow-Speed HPDC (SSS HPDC) reduces these issues, enabling heat treatment for property enhancement. A356.2 alloy, known for toughness, is now used in HPDC. Aging treatments can strengthen but may decrease elongation. This study seeks to develop a heat treatment process for A356.2 in SSS HPDC that balances tensile strength, yield strength, and elongation, utilizing CALPHAD, electrical conductivity, and thermal expansion tests.

4. Summary of the study:

Background of the research topic:

Standard HPDC processes can lead to defects that limit the effectiveness of heat treatment. SSS HPDC mitigates these issues, allowing for property enhancement in alloys like A356.2.

Status of previous research:

While aging treatments are known to strengthen A356.2, they can also reduce elongation. There is a need to find an optimized heat treatment process that balances these competing properties specifically for the SSS HPDC method.

Purpose of the study:

To develop a heat treatment process for SSS HPDC A356.2 that balances tensile strength, yield strength, and elongation by determining the optimal range of process parameters for actual production.

Core study:

The study investigated the effect of different solution heat treatment temperatures (480°C, 500°C, 520°C, 540°C) and times (1, 2, 4 hours) on the microstructure, electrical conductivity, and mechanical properties of SSS HPDC A356.2 alloy.

5. Research Methodology

Research Design:

The research combined computational modeling (CALPHAD) with physical experimentation. A range of solution heat treatment parameters were tested, and the resulting material properties were systematically analyzed.

Data Collection and Analysis Methods:

- CALPHAD: Scheil and DB models were used to analyze phase composition during solidification.

- Experimental Analysis: The study utilized a Bruker spectrometer for chemical composition, DSC for thermal properties, an electrical conductivity meter, optical microscopy for microstructure, a universal testing machine for tensile tests (average of three samples), and a thermomechanical analyzer for dimensional changes.

Research Topics and Scope:

The research focused on A356.2 alloy produced by SSS HPDC on an 840Ton Büler Ecoline S machine. The casting had a 4mm wall thickness. The scope included solidification analysis, solution heat treatment process optimization, and characterization of microstructure and mechanical properties.

6. Key Results:

Key Results:

- The DB model in CALPHAD analysis was found to be suitable for the SSS HPDC process, predicting a final solidification temperature of 536°C.

- Thermal expansion tests confirmed that solution treatment at 540°C causes local remelting and size deformation, making the 480°C-520°C range suitable for production.

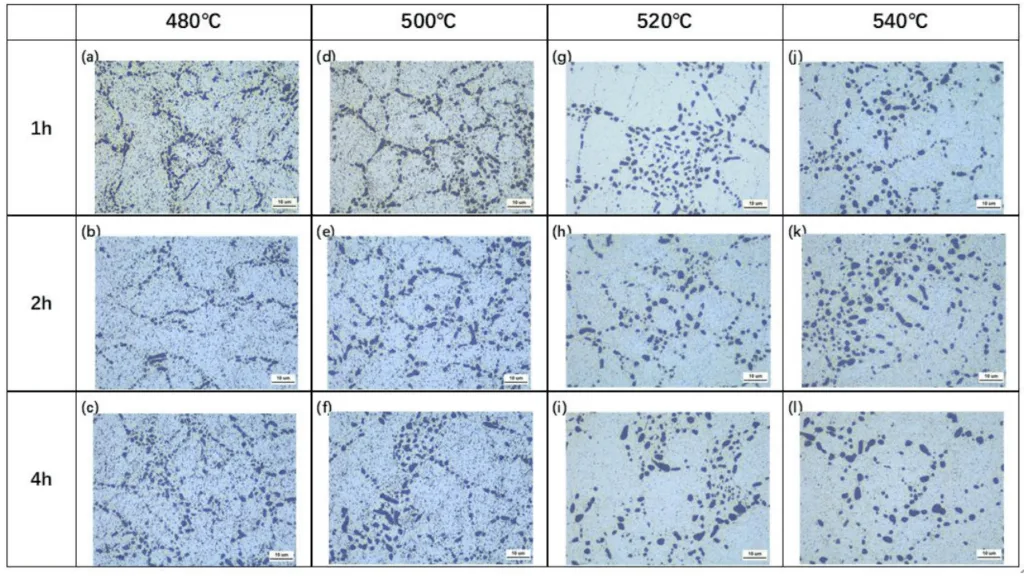

- Microstructure analysis showed that at 520°C and 540°C, Si particles spheroidize significantly after 1-2 hours but coarsen after 4 hours.

- The highest Quality Index (QI) of 418.5MPa was achieved with a solution heat treatment at 520°C for 1 hour, followed by aging at 180°C for 6 hours.

Figure Name List:

- Figure1 Fraction of phase in the Scheil model (a); Fraction of phase in the DB model (b).

- Figure 2 Microstructure after solution heat treatment on 480°C for 1, 2, 4 h (a, b, c); 500°C for 1, 2, 4 h (d, e, f); 520°C for 1, 2, 4 h (g, h, i); and 540°C for1, 2, 4 h (j, k, l).

- Figure 3 displays the electrical conductivity of an Al-Si alloy that underwent solution treatment at varying temperatures and holding times.

- Figure 4 Mechanical properties of different solution treatments followed by aging at 180°Cfor 6 h, the highest QI should be 418.5MPa when heating at 520°C and holding for 1 h.

- Figure 5 displays the effect of heating as-cast samples to different temperatures ranging from 480°C to 540°C for 6 hours.

7. Conclusion:

The study concludes that the DB model is well-suited for analyzing solidification in the SSS HPDC process for A356.2 alloy. The optimal solution treatment temperature range is 480°C-520°C. A temperature of 540°C is not recommended due to negative size changes from local remelting. The highest QI value of 418.5MPa is achieved at 520°C for 1 hour. In practice, the specific heat treatment process should be chosen based on the production situation.

8. References:

- [The provided document does not contain a list of references.]

Expert Q&A: Your Top Questions Answered

Q1: Why were both the Scheil and the modified DB models used for the CALPHAD analysis, and which was more accurate?

A1: The paper used both models to predict the alloy's phase composition during solidification. The modified DB model was found to be more suitable for the super-slow-speed die casting process. It predicted a final solidification temperature of 536°C, which aligns closely with the experimental results from the thermomechanical analyzer (Figure 5) that showed local remelting and deformation occurring at 540°C.

Q2: The mechanical properties at 540°C for 1h are very similar to those at 520°C for 1h. Why is 520°C recommended as the optimum?

A2: While the mechanical properties shown in Figure 4 are indeed comparable, the critical difference lies in dimensional stability. The thermal expansion test data summarized in Figure 5 revealed that at 540°C, the material undergoes "local remelting," which caused a "negative size change" or deformation. This makes 540°C a high-risk temperature for industrial production, where dimensional accuracy is paramount. The 520°C temperature provides top-tier mechanical properties without this risk.

Q3: What does the microstructure analysis in Figure 2 tell us about the effect of holding time at higher temperatures?

A3: Figure 2 clearly shows that time is as critical as temperature. While 1-2 hours at 520°C and 540°C leads to significant and beneficial spheroidization of Si particles, extending the holding time to 4 hours causes these particles to coarsen. Coarsened Si particles can be detrimental to mechanical properties, particularly ductility and fatigue life. This highlights the need to precisely control both temperature and duration during solution treatment.

Q4: How can the electrical conductivity data from Figure 3 be used in a practical production environment?

A4: Figure 3 shows that electrical conductivity is sensitive to the solution treatment parameters. This is because conductivity is affected by the amount of silicon and other elements dissolved in the aluminum matrix and the morphology of the Si phase. A fully optimized solution treatment will result in a predictable conductivity value. Therefore, electrical conductivity testing could potentially be used as a fast, non-destructive quality control method to verify that a batch of castings has been heat-treated correctly.

Q5: The study focuses on a 4mm wall thickness. Would these results apply to castings with different thicknesses?

A5: The paper explicitly states its findings are based on a casting with a 4mm wall thickness. Solidification rates and thermal profiles can vary significantly with part geometry and thickness, which would in turn affect the as-cast microstructure and its response to heat treatment. While the principles and the identified temperature limits (like the 540°C deformation risk) are broadly informative, direct application of the optimal 520°C/1h parameter to parts with substantially different thicknesses would require further process validation.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a clear and actionable roadmap for unlocking the full potential of A356.2 alloy in Super-Slow-Speed Die Casting (SSS HPDC). By systematically investigating the interplay between temperature, time, microstructure, and performance, the study demonstrates that an optimal balance of high strength and ductility is achievable. The key breakthrough—identifying 520°C for 1 hour as the ideal solution treatment to maximize mechanical properties while avoiding the production risks of deformation at 540°C—is a critical insight for any manufacturer aiming for top-tier quality and process reliability.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Investigation on Heat Treatment Process Optimization of Super-Slow-Speed Die Casting A356.2 Alloy" by "Lu Zhang, Hengcheng Liao, Jiang Li, Liangchao Tang".

- Source: The 75th World Foundry Congress, October 25-30, 2024, Deyang, Sichuan, China.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.