This introduction paper is based on the paper "Innovative Die Lubricant Trends for Evolving Productivity and Process Requirements" published by "NADCA North American Die Casting Association (at the 2013 Die Casting Congress & Tabletop)".

1. Overview:

- Title: Innovative Die Lubricant Trends for Evolving Productivity and Process Requirements

- Author: Dr. Sid Asthana

- Year of publication: 2013

- Journal/academic society of publication: NADCA North American Die Casting Association

- Keywords: Not specified in the paper.

2. Abstract:

The continued push for improved productivity in the high pressure die cast (HPDC) industry places ever increasing performance and productivity demands on die lubricants. The majority of new technology developments in die lubricants have been spurred by developments in automotive castings. The relentless push for vehicle weight reduction and improved productivity requirements, coupled with the casting of larger and more complex parts, has brought forward the necessity of significant innovations in die lubricants. This paper discusses the impacts of these trends on die lubricants while examining how new die lubricant technologies address the changing industry needs.

3. Introduction:

The high pressure die cast (HPDC) process is an attractive casting method due to high productivity and the ability to produce high-quality complex castings with various alloys. The HPDC market's global growth mirrors that of the automotive industry. This growth is contingent on addressing automotive industry challenges, primarily: 1. Increased fuel economy, 2. Cost reductions via improved productivity, and 3. Improved occupant safety.

Rising fuel costs and environmental regulations drive improvements in automotive fuel efficiency, with weight reduction being key. Lower density alloys like aluminum and magnesium are gaining market share. An average North American vehicle uses ~340 lbs. of aluminum (~8.3% of gross weight), expected to rise to ~16% by 2025. These alloys are used in engine, transmission, chassis components, and increasingly in steering knuckles, suspension arms, and cross-members.

The push for productivity leads to more complex die cast parts, reducing assembly steps but increasing shot weights and die complexity. This makes uniform die cooling challenging, placing higher demands on die lubricant (DL) for thermal management.

Higher occupant safety standards have led to new alloys and processes for low porosity, high ductility parts. Newer alloys can be more abrasive and have low iron content. High vacuum techniques are used in HPDC for low porosity, heat-treatable parts.

These trends mean die casters face challenges in equipment efficiency, machine downtime, and stricter environmental regulations. Complex/large parts are cast with newer alloys in dies running at higher temperatures (often exceeding 400°C in some regions, while colder regions can be 200°C). This necessitates a new generation of die lubricants.

4. Summary of the study:

Background of the research topic:

The HPDC industry faces continuous pressure for improved productivity and efficiency. This is largely driven by the automotive sector's demands for vehicle weight reduction (through lightweight alloys like aluminum and magnesium), cost efficiency, and the production of larger, more complex parts. These factors lead to more demanding casting conditions, such as higher die operating temperatures and wider temperature variations across the die surface. Consequently, die lubricants (DL) are critical and must meet significantly enhanced performance requirements.

Status of previous research:

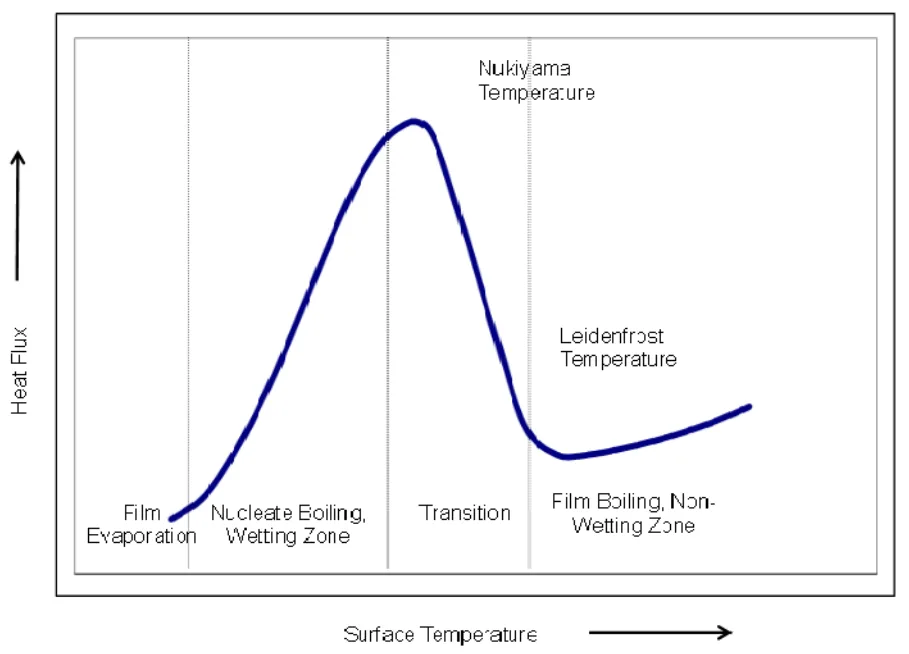

The paper builds upon established understanding of heat transfer phenomena during die spraying, such as the cooling curve (film boiling, transition, nucleate boiling regimes, Leidenfrost point, Nukiyama point, Critical Heat Flux) as described in referenced literature (Bernadin J.D., et al., 1997; Incropera, F.P., DeWitt, D.P., 1981). Previous work has also highlighted the effect of die lubricant spray on die thermal balance (Graff J. L., et. al., 1993). The challenges addressed, such as solder prevention, lubrication of moving parts, carbon buildup, and ex-cavity buildup, are known issues in the die casting industry that new lubricant technologies aim to mitigate.

Purpose of the study:

This paper aims to discuss the impacts of current automotive and HPDC industry trends on die lubricants. It examines how new die lubricant technologies are being developed and applied to address the changing and increasingly demanding needs for productivity and process requirements in the HPDC industry.

Core study:

The core of the study involves:

- Identifying key performance challenges for die lubricants arising from industry trends. These include wetting die surfaces over a wide temperature range, forming effective and uniform films, providing balanced film performance (protecting hot spots without causing buildup in cold areas), minimizing downtime from ex-cavity buildup, and meeting safety/environmental regulations.

- Analyzing the cooling phenomenon exhibited by DLs and how lubricant technology can impact cycle time through factors like overcoming the Leidenfrost barrier, shortening the transition regime, and achieving high Critical Heat Flux (CHF).

- Presenting and evaluating new generations of die lubricant technologies based on laboratory tests and field experience. This includes assessing:

- Wetting temperatures of different DLs.

- The effect of die temperature on wetting time and film formation.

- The Die Adhesion Index to measure film formation uniformity.

- The spreading ability of DLs on die surfaces.

- The reduction of ex-cavity buildup with new DL chemistries.

- Illustrating the practical benefits of these new technologies, such as improved productivity, reduced cycle times, better part quality, and decreased machine downtime.

5. Research Methodology

Research Design:

The paper presents a review of current industry trends and their impact on die lubricant requirements, combined with the presentation of performance data for newly developed die lubricant technologies. The research involves:

- Theoretical discussion of die lubricant performance characteristics (e.g., cooling, wetting, film formation).

- Laboratory-based comparative testing of different die lubricant formulations (standard vs. new generations).

- A field trial to validate laboratory findings in a production environment.

Data Collection and Analysis Methods:

Data was collected through:

- Cooling Curve Analysis: (Conceptual, Figure 1) Describing heat flux changes with temperature during DL spray.

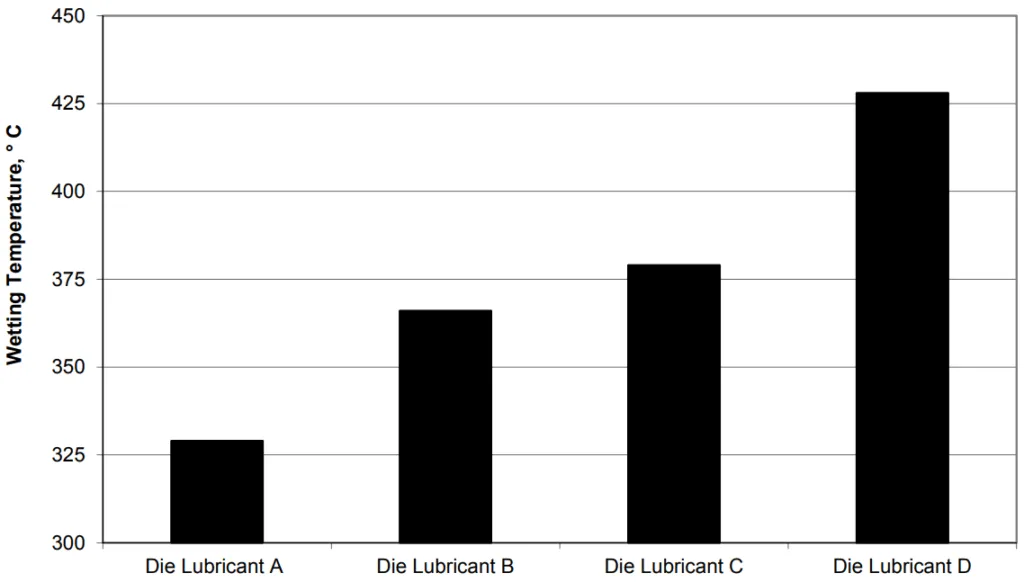

- Wetting Temperature Tests: Determining the maximum temperature at which DL film formation starts for different lubricants (Figure 2).

- Wetting Time vs. Die Temperature Tests: Measuring the time taken to breach the Leidenfrost barrier at various die temperatures for different lubricants (Figure 3).

- Film Formation (Adhesion) Tests: Quantifying the amount of DL film deposited on a surface at different temperatures (Figure 4).

- Die Adhesion Index Tests: Calculating the ratio of film formed at 350°C to that formed at 250°C to assess film uniformity across varying temperatures (Figure 5).

- Spreading Ability Tests: Measuring the diameter of spread for different DLs on a heated surface (Figure 6).

- Ex-Cavity Buildup Tests: Comparing the amount of overspray accumulation for standard and new technology DLs under laboratory conditions (Figure 7) and in a field trial (Figure 8, and associated collected buildup data).

- Field Trial: A 200-part trial run on a truck oil pan casting, collecting DL buildup from a specific die area using a metal template and assessing performance parameters like release, solder protection, and in-cavity buildup.

Research Topics and Scope:

The research focuses on innovative trends in die lubricants tailored for evolving productivity and process requirements in the HPDC industry. The scope includes:

- The influence of automotive industry demands (lightweighting, complex parts, higher safety standards) on HPDC processes and die lubricant performance.

- Key performance characteristics of die lubricants: thermal management (cooling, wetting), film formation uniformity, spreading ability, and minimization of buildup (in-cavity and ex-cavity).

- Development and comparative performance of new generation die lubricant technologies designed to operate effectively at high die temperatures, across wide temperature ranges, and to reduce common production issues like solder and buildup.

- The impact of these advanced lubricants on cycle time reduction, productivity improvement, and machine downtime.

6. Key Results:

Key Results:

The study highlights several key advancements and performance characteristics of new die lubricant technologies:

- Improved Thermal Management: New DLs are designed to overcome the Leidenfrost barrier at higher die temperatures, possess short transition regimes to reach CHF quickly, and have high CHF points for maximum heat extraction, contributing to reduced cycle times (discussed in relation to Figure 1).

- Higher Wetting Temperatures: Different DL technologies exhibit varying wetting temperatures, with newer formulations capable of wetting at higher die surface temperatures (Figure 2 shows a range from ~325°C to over 425°C for Die Lubricants A-D).

- Faster Wetting Times: While wetting time generally increases with die temperature, advanced DLs can achieve faster wetting, crucial for reducing cycle times. Understanding the die temperature profile is essential for optimizing spray application (Figure 3).

- Temperature-Dependent Film Formation: Less DL film is deposited at high die temperatures compared to cooler areas. This necessitates careful die temperature mapping for effective solder prevention and buildup control (Figure 4 shows decreasing adhesion with increasing temperature).

- Enhanced Film Uniformity (Die Adhesion Index): Newer generations of DLs demonstrate a higher Die Adhesion Index, indicating more uniform lubricant film formation across both hot (e.g., 350°C) and cold (e.g., 250°C) regions of the die. Generation 4 shows a significantly higher index compared to standard products (Figure 5).

- Improved Spreading Ability: The spreading ability of DLs is critical for complex dies with unsprayed regions. Newer DL chemistries show improved spreading at high temperatures (Figure 6 shows Product D having the best spreading).

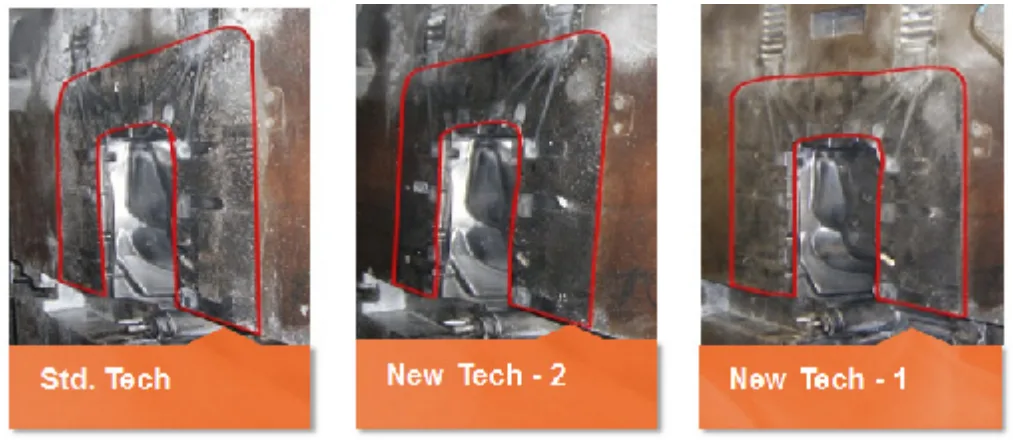

- Reduced Ex-Cavity Buildup: New DL technologies significantly reduce ex-cavity buildup compared to standard technology. Laboratory tests showed substantial reductions (Figure 7), and a field trial confirmed these findings.

- Field Trial Success: In a trial producing a truck oil pan, a new technology DL reduced ex-cavity buildup by almost 50% compared to a conventional DL. Additionally, the customer reported improvements in release, solder protection, and in-cavity buildup, moving from "acceptable" to "excellent." This new technology also enabled a reduction in ex-cavity cleaning frequency from 2-3 times per shift to once in eight shifts.

Figure Name List:

- Figure 1: Change of heat flux with temperature in forced convection cooling due to spray impingement.

- Figure 2: Wetting temperatures of a select few die lubricants.

- Figure 3. Effect of die temperature on wetting time for two commercially available die lubricant technologies

- Figure 4. Effect of die temperature on film formation.

- Figure 5: Die Adhesion Index of key die lubricant generations.

- Figure 6: Spreading ability of some commercially important die lubricants.

- Figure 7: Comparison of ex-cavity buildup properties of standard technology with those of new generation die lubricant technologies.

- Figure 8: Pictures of dies from trials for low ex-cavity technology. Picture on left is for die sprayed with conventional technology die lubricant, picture in middle and right is for die sprayed with new technology die lubricants.

7. Conclusion:

HPDC technology is rapidly evolving to meet new market trends, which in turn drives the introduction of new die lubricant technologies into the die casting market. These new technologies enable higher productivity in die casting plants by helping casters produce high-quality and complex castings at high die temperatures while simultaneously reducing machine downtime. Chem-Trend, as a leading global supplier to the HPDC industry, is committed to partnering with the industry to continually develop advanced die lubricant chemistries that will improve die casters' quality, productivity, and profitability.

8. References:

- [1] Bernadin J.D., et al., “Mapping of Impact and Heat Transfer regimes of water drops Impinging on a Polished Surface”, International Journal of Heat Mass Transfer, 40, pages 247-267, (1997).

- [2] Incropera, F.P., DeWitt, D.P., Fundamentals of Heat and Mass Transfer, 2nd edition, John Wiley & Sons, New York, NY, (1981).

- [3] Graff J. L., et. al.; "The Effect of Die Lubricant Spray on the Thermal Balance of Dies", Paper T93-083, NADCA Meeting, Cleveland, Oct 18-21, (1993).

- [4] Leidenfrost, J.G., “A Tract About Some Qualities of Common Water”, (1756).

- [5] Asthana S., Belyk J.J., “Die Lubricant Technology Trends to Address Changing Industry Needs", Alucast 2012, India, 18-26, (2012).

9. Copyright:

- This material is a paper by "Dr. Sid Asthana". Based on "Innovative Die Lubricant Trends for Evolving Productivity and Process Requirements".

- Source of the paper: Not specified in the paper.

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.