Balancing Cost vs. Wear: The Impact of AZ91 Scrap on HPDC Equipment Life

This technical summary is based on the academic paper "Influence of the Home Scrap Content on the Service Life of Equipment Used in High Pressure Die Casting of AZ91 Alloy" by Z. Konopka, M. Łągiewka, A. Zyska, published in ARCHIVES of FOUNDRY ENGINEERING (2018)

Keywords

- Primary Keyword: HPDC Equipment Life

- Secondary Keywords: AZ91 Alloy, Home Scrap Recycling, Die Casting Wear, Magnesium Alloy Casting, Casting Set Durability

Executive Summary

- The Challenge: Recycling in-house magnesium alloy scrap is economically attractive, but its impact on the durability of expensive hot chamber machine components is not well quantified.

- The Method: The study systematically varied the percentage of AZ91 home scrap (from 0% to 100%) in the melt and measured the number of injections until failure for key "casting set" components like the syphon, plunger, and nozzles.

- The Key Breakthrough: A direct correlation was found: as the percentage of home scrap increases, the service life of all monitored casting instrumentation decreases significantly, with some components seeing their life reduced by more than half.

- The Bottom Line: While recycling scrap up to 50% has a manageable impact on tool life and can even improve certain mechanical properties, exceeding this threshold leads to accelerated, "expressive" wear that can negate the cost savings from recycling.

The Challenge: Why This Research Matters for HPDC Professionals

In the high-volume world of pressure die casting, every decision is a balance between cost, quality, and efficiency. The use of "home scrap"—runners, imperfect castings, and other internally generated metal—is a standard practice to reduce material costs and improve sustainability. For magnesium alloys like AZ91, which are widely used in automotive and electronics, this "closed turnover" recycling is particularly appealing.

However, this cost-saving measure comes with a hidden risk. Home scrap, even when carefully handled, can introduce contaminants like oxides and other non-metallic inclusions into the melt. The critical question for any foundry manager or process engineer is: What is the real cost of this recycling? Does the money saved on virgin material get spent on replacing worn-out syphons, plungers, and nozzles? This research directly addresses that pain point by providing concrete data on the trade-off between scrap content and the service life of critical, expensive machine components.

The Approach: Unpacking the Methodology

To build confidence in the findings, the researchers conducted a systematic, long-term study under real-world production conditions. Their methodology was robust and designed to isolate the effect of scrap content.

Method 1: Controlled Melt Compositions

The core of the experiment involved creating five distinct melts of AZ91 alloy with varying levels of home scrap. This allowed for a direct comparison of equipment wear under different conditions:

- Melt A1: 100% virgin AZ91 alloy pig

- Melt A2: 70% virgin pig, 30% home scrap

- Melt A3: 50% virgin pig, 50% home scrap

- Melt A4: 30% virgin pig, 70% home scrap

- Melt A5: 100% home scrap

Method 2: Real-World Production & Monitoring

The study was not a lab simulation. Castings were produced on a hot chamber pressure die casting machine with a 6300 kN squeezing force. Key process parameters, such as melt temperature (903 K) and plunger velocity, were kept constant across all melts to ensure a fair comparison. The researchers meticulously monitored the "casting set"—the syphon, plunger, sliding rings, nozzle, and injection moulding nozzle—registering the total number of injections each component could withstand before damage required its replacement or regeneration.

The Breakthrough: Key Findings & Data

The results provide a clear, data-driven picture of the abrasive effect of recycled scrap on machine components.

Finding 1: Increased Scrap Content Directly Reduces Equipment Service Life

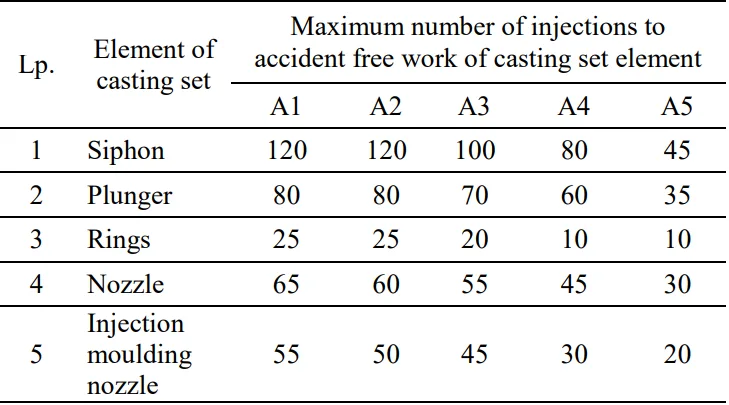

The most significant finding is the inverse relationship between the percentage of home scrap and the durability of the casting set. As the scrap content increased, the maximum number of accident-free injections plummeted for every component.

As shown in Table 1, the impact was dramatic. The syphon, one of the most expensive components, saw its life drop from 120,000 injections with 100% virgin material (A1) to just 45,000 injections with 100% scrap (A5)—a 62.5% reduction. The injection moulding nozzle experienced a similar decline, from 55,000 injections down to 20,000. The primary cause identified was abrasive wear from hard non-metal inclusions (magnesium and aluminum oxides) present in the scrap, which increases friction and erosion.

Table 1. Wear of the casting instrumentation

| Lp. | Element of casting set | Maximum number of injections to accident free work of casting set element | | | | |

|---|---|---|---|---|---|---|

| | | A1 (0% Scrap) | A2 (30% Scrap) | A3 (50% Scrap) | A4 (70% Scrap) | A5 (100% Scrap) |

| 1 | Siphon | 120 | 120 | 100 | 80 | 45 |

| 2 | Plunger | 80 | 80 | 70 | 60 | 35 |

| 3 | Rings | 25 | 25 | 20 | 10 | 10 |

| 4 | Nozzle | 65 | 60 | 55 | 45 | 30 |

| 5 | Injection moulding nozzle | 55 | 50 | 45 | 30 | 20 |

Finding 2: Scrap Content Alters Microstructure and Mechanical Properties

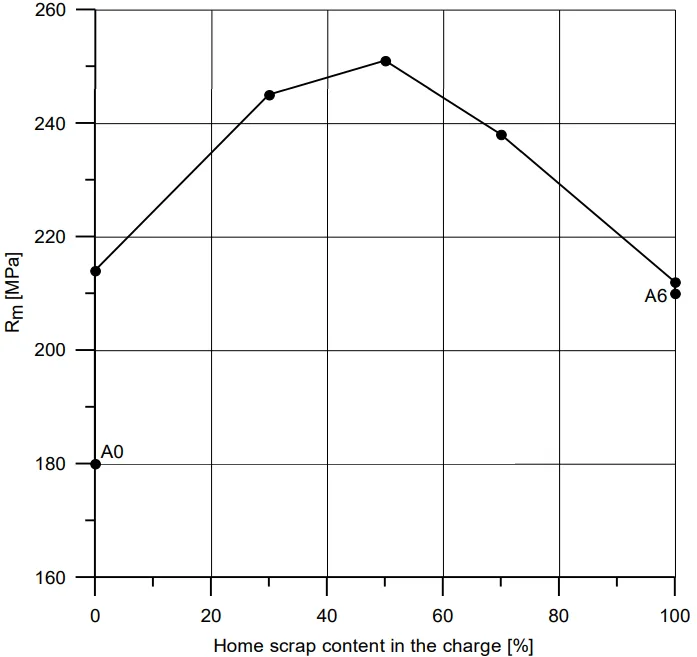

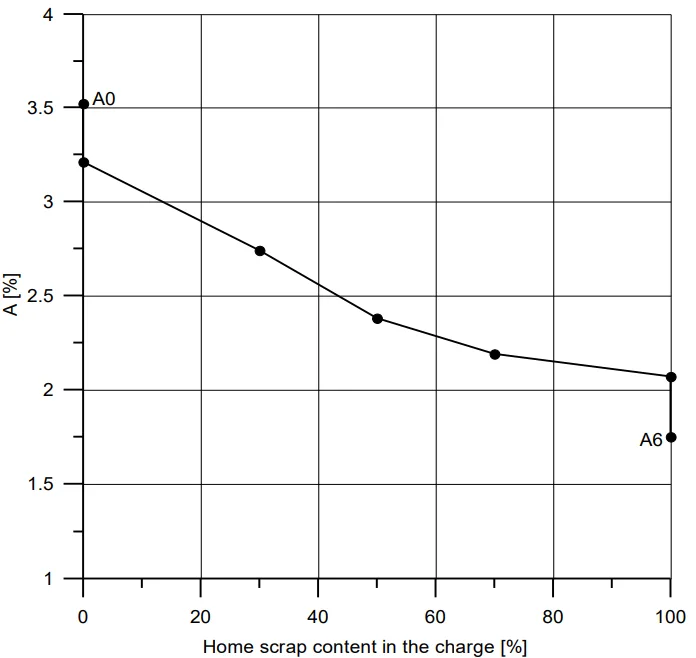

The study also confirmed that using home scrap changes the final casting's properties. The increased presence of oxides and a higher participation of the hard Mg17Al12 phase were observed in the microstructure (Figures 1 and 2). Interestingly, this had a mixed effect on mechanical properties.

As shown in Figure 3, the tensile strength of the AZ91 castings actually increased as scrap content rose to 50%, before declining at higher concentrations. Conversely, Figure 4 shows that elongation steadily decreased as scrap content increased, indicating a reduction in ductility. This highlights a complex trade-off: while moderate scrap levels can enhance strength, they do so at the cost of ductility and, as shown above, significant tool wear.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that a scrap content of around 50% may be the optimal ceiling to balance material cost savings with manageable tool wear. Exceeding this level leads to a rapid acceleration in component failure, increasing downtime and replacement costs.

- For Quality Control Teams: The data in Figure 3 and Figure 4 of the paper illustrates that scrap content directly affects tensile strength and elongation. This could inform new quality inspection criteria, especially for components where ductility is a critical design requirement.

- For Design Engineers: The findings indicate that the presence of hard inclusions from scrap could influence material flow and wear patterns within the die itself, not just the machine components. This is a valuable consideration when designing gating and runner systems for parts made with recycled magnesium.

Paper Details

Influence of the Home Scrap Content on the Service Life of Equipment Used in High Pressure Die Casting of AZ91 Alloy

1. Overview:

- Title: Influence of the Home Scrap Content on the Service Life of Equipment Used in High Pressure Die Casting of AZ91 Alloy

- Author: Z. Konopka, M. Łągiewka, A. Zyska

- Year of publication: 2018

- Journal/academic society of publication: ARCHIVES of FOUNDRY ENGINEERING, Volume 18, Issue 2/2018

- Keywords: Innovative materials and casting technologies, Mechanization and automation of casting processes, Guard of environment, Casthouse Rigging, Magnesium alloys

2. Abstract:

The results of estimation of home scrap addition in charge influence on durability and wear of casting instrumentation life in the high-pressure casting technology using the hot chamber machine of alloy of AZ91 are presented. The wear of the following elements of the casting instrumentation so-called "casting set" as: syphon, plunger, sliding-rings, nozzle and injection moulding nozzle was estimated. A wear was estimated quantitative by registering the number of mould injections for different charges to the moment of element damage supervision. A damage had to be at such level that liquidated an element from further exploitation and necessary was an exchange on new or regeneration. In a final result allowed it the detailed determination of durability of the applied rigging elements in dependence on the type of the applied type of melt. It is noticed, that together with the increase of home-scrap participation in the charge wear of pressure machine instrumentation elements increases.

3. Introduction:

The mass production of pressure castings from magnesium alloys necessitates the recirculation of materials, primarily home scrap such as runners and imperfect castings. While recycling home scrap in a closed-loop system within the foundry offers economic benefits (reduced investment, transport savings, better alloy quality), it also introduces challenges. Home scrap can be contaminated with oxides, oils, and cooling liquids, which can affect the final casting and the production equipment. This study was undertaken to estimate the influence of home scrap content in the charge on the wear and service life of the casting instrumentation (sleeve, plungers, sliding-rings, etc.) used in hot chamber die casting of AZ91 alloy.

4. Summary of the study:

Background of the research topic:

Magnesium alloys like AZ91 are increasingly used for pressure castings due to their low density and good mechanical properties. Mass production involves significant material recirculation, primarily of home scrap.

Status of previous research:

Previous research has established the benefits of closed-loop recycling systems for magnesium alloys. Studies have also examined the effect of scrap on the mechanical properties and porosity of the final castings. However, a quantitative analysis of the direct impact of varying scrap percentages on the service life of hot chamber machine components was needed.

Purpose of the study:

The aim of the work was to present the influence of home scrap participation in the charge on the wear of the "casting set" (syphon, plunger, sliding-rings, nozzle, and injection moulding nozzle) during high-pressure die casting of AZ91 alloy.

Core study:

The study involved producing castings from five different melts of AZ91 alloy, with home scrap content varying from 0% to 100%. The service life of each component of the casting set was quantified by recording the number of injections completed before failure. The wear mechanisms were analyzed, and the effect of scrap on the casting's microstructure and mechanical properties (tensile strength, elongation) was also evaluated.

5. Research Methodology

Research Design:

The research was an experimental study conducted over a three-year period under industrial production conditions. Five types of melts with different shares of home scrap in the charge were prepared and used to produce pen castings. The durability of the casting instrumentation was the primary dependent variable, measured against the independent variable of home scrap percentage.

Data Collection and Analysis Methods:

Quantitative data was collected by registering the number of injections for each casting set element until failure. Qualitative estimation of wear was performed by visual supervision of dismantled elements to identify the type, degree, and reasons for wear (e.g., abrasive wear, erosion, cracks). Mechanical properties were tested to determine tensile strength and elongation. Microstructure was analyzed visually.

Research Topics and Scope:

The research focused on the AZ91 magnesium alloy cast using a hot chamber pressure die casting machine (6300 kN). The scope was limited to the wear of five specific components: syphon, plunger, sliding-rings, nozzle, and injection moulding nozzle. The study also examined the resulting microstructure and mechanical properties of the castings.

6. Key Results:

Key Results:

- Increasing the participation of home scrap in the charge leads to a progressive increase in the wear of all casting instrumentation elements.

- The service life of components like the syphon and injection moulding nozzle was reduced by over 60% when using 100% home scrap compared to 100% virgin alloy.

- The primary reason for increased wear is the presence of hard non-metal inclusions, such as aluminum and magnesium oxides, in the remelted scrap, which causes greater abrasive wear.

- The use of home scrap alters the casting's microstructure, increasing the participation of the hard Mg17Al12 phase.

- Tensile strength of the AZ91 alloy initially increased with scrap content up to 50% and then decreased. Elongation consistently decreased with increasing scrap content.

Figure Name List:

- Fig. 1 Microstructure of casting obtained from a pig, but after previous melted (A1)

- Fig. 2 Microstructure of casting obtained from 100% home scrap in charge (A5)

- Fig. 3. The tensile strength of AZ91 alloy castings with the home scrap in the charge

- Fig. 4. The elongation of AZ91 alloy castings with the home scrap in the charge.

7. Conclusion:

Increasing the participation of home scrap in the charge has a negative effect on the wear of casting instrumentation. The life of all elements is comparable to using virgin metal for scrap content up to about 50%, but higher contents cause expressive wear. The wear is primarily caused by contaminants like oxides. The obtained results help determine the optimal level of home scrap participation for high-pressure casting of AZ91 alloy, balancing economic benefits with equipment durability.

8. References:

- [1] PN-EN 1753. (2001). Magnesium and magnesium alloys. PKN. (in Polish).

- [2] Avedesian, M.M., Baker, H. (1999). Magnesium and Magnesium Alloys. ASM Internatonal.

- [3] Eliezer, D., Aghion, E. & Froes, F.H. (1997). Magnesium science, technology and applications. Magnesium 97. Dead Sea, Israel. 169-177.

- [4] Fitze, R. (2003). 11th Magnesium Automotive and End User Seminar. Improve the competitiveness of magnesium die casting by inline recycling of ten runner system. Aalen.

- [5] Street, A.C. (1986). The die casting book. Portenllis press, second edition.

- [6] Kainer, K.U. (2000). Magnesium Alloys and their Application. Sb. Int. Congress Magnesium Alloys and their Aplication. Mnichov (3-8, 534-608).

- [7] Moscovitch, N., Gertsberg, G., Nagar, N., Gur, D., Bronfin, B., Aghion, E. (2000). The use of die casting technology in the process of developing new magnesium alloys. 9th Magnesium and User Seminar. Aallen. Germany.

- [8] Sannes, S., Gjestland, H., Westengen, H., Laukli. H.I. (2003). Magnesium alloys and applic. Germany: DGM, Wolfsburg. 725-731.

- [9] Konopka, Z. & Chojnacki, A. (2011). Structure of the AZ91 alloy pressure castings fabricated of home-scrap containing charge. Archives of Foundry Engineering. 11(2), 61-64.

- [10] Konopka, Z., Chojnacki, A., Lagiewka, M. & Zyska, A. (2017). The Influence of Home Scrap on Mechanical Properties of MgAl9Zn1 Alloy Castings. Archives of Foundry Engineering. 17(2), 39-42.

- [11] Konopka, Z., Chojnacki, A., Lagiewka, M. & Zyska, A. (2017). The Influence of Home Scrap on Porosity of MgAl9Zn1 Alloy Pressure Castings. Archives of Foundry Engineering. 17(1), 99-102.

Expert Q&A: Your Top Questions Answered

Q1: What was the primary mechanism identified for the increased equipment wear when using home scrap?

A1: The paper states the main reason for the megascopic wear is an increase in the content of hard non-metal inclusions in the metal, specifically aluminum and magnesium oxides. These oxides have a higher melting temperature than the alloy and exist as hard, constant particles. Their high hardness substantially increases the friction coefficient between moving parts (like the plunger and rings) and causes greater abrasive wear on all components exposed to the flowing metal.

Q2: Did the use of home scrap offer any benefits to the final casting's properties?

A2: Yes, the study revealed a complex trade-off. While increasing scrap content led to greater tool wear, it also had some positive or neutral effects on the casting's mechanical properties up to a certain point. As shown in Figure 3, the tensile strength of the AZ91 alloy increased as scrap content rose from 0% to 50%. The paper also references earlier research [11] that found a positive influence of home scrap on reducing the porosity of castings.

Q3: Based on the data, what would be considered the "optimal" or maximum recommended percentage of home scrap?

A3: The paper concludes that the service life of the instrumentation when using up to 50% home scrap is "comparable" to that of using 100% virgin metal. However, beyond this 50% threshold, the wear becomes "expressive" (i.e., accelerates rapidly). This suggests that for this specific process and alloy, an operational ceiling of around 50% home scrap is the optimal point to balance material cost savings against increased maintenance and component replacement costs.

Q4: Which components of the "casting set" were most sensitive to the increase in scrap content?

A4: While all components showed reduced life, Table 1 indicates that the rings, injection moulding nozzle, and siphon were particularly sensitive. The life of the rings dropped by 60% (from 25k to 10k injections) when moving from 50% to 70% scrap. The injection moulding nozzle's life was more than halved (55k to 20k) across the full range, and the siphon's life dropped by 62.5% (120k to 45k).

Q5: Were the process parameters, like melt temperature and injection speed, kept constant during the experiment?

A5: Yes, the methodology section confirms that key process parameters were standardized for all investigated melts to ensure a valid comparison. The pouring temperature was identical at 903 K for all melts. The plunger velocity was set at V₁ = 0.15 m/s (first phase) and V₂ = 2.5 m/s (second phase), and the pressure intensification time was 1.5 s. This control ensures that the observed differences in wear were due to the scrap content, not variations in the casting process.

Conclusion: Paving the Way for Higher Quality and Productivity

The decision to use recycled home scrap is a constant balancing act in modern foundries. This research provides invaluable quantitative data that transforms the decision from guesswork into an informed, strategic choice. The key breakthrough is clear: while recycling AZ91 scrap is beneficial, exceeding a 50% threshold can severely shorten HPDC Equipment Life, leading to increased downtime and operational costs that may outweigh the material savings.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Influence of the Home Scrap Content on the Service Life of Equipment Used in High Pressure Die Casting of AZ91 Alloy" by "Z. Konopka, M. Łągiewka, A. Zyska".

Source: https://doi.org/10.24425/122523

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.