This introduction paper is based on the paper "Impact strength of squeeze casting AlSi13Cu2-CF composite" published by "ARCHIVES of FOUNDRY ENGINEERING".

1. Overview:

- Title: Impact strength of squeeze casting AlSi13Cu2-CF composite

- Author: A. Zyska, Z. Konopka, M. Łągiewka

- Year of publication: 2020

- Journal/academic society of publication: ARCHIVES of FOUNDRY ENGINEERING

- Keywords: Squeeze casting composites, Carbon fibers, Impact strength, Microstructure

2. Abstract:

The paper presents the results of research on microstructure and impact strength of AlSi13Cu2 matrix composite reinforced by Ni-coating carbon fibers (CF) with a volume fraction of 5%, 10% and 15%. The composite suspensions were prepared using by stirring method and subsequently squeeze casted under different pressures of 25, 50, 75 and 100 MPa. As part of the study, fiber distribution in aluminum matrix was evaluated and variation in impact strength of composite as a function of the carbon fibers volume fraction and pressure applied were determined. It has been found that the presence of Ni coating on carbon fibers clearly improves their wettability by liquid aluminum alloy and in combination with the stirring parameters applied, composite material with relatively homogeneous structure can be produced. Charpy's test showed that the impact strength of composite reaches the highest value by carrying out the squeeze casting process at 75 MPa. In the next stage of research, it was found that the impact strength of composites increases with the increase of carbon fibers volume fraction and for 15% of fibers is close to 8 J/cm². Observations of fracture surfaces have revealed that crack growth in the composites propagates with a quasi-cleavage mechanism. During the creation of the fracture, all fibers arranged perpendicular to its surface were sheared. At the same time, the metal matrix around the fibers deformed plastically creating characteristic ductile breaks. The fracture surface formation through the fibers indicates a cohesive and strong connection of the reinforcement with the matrix. In addition to the phenomena mentioned, debonding the fiber-matrix interfaces and the formation of voids between components were observed on the fracture surface.

3. Introduction:

Composites based on silumins reinforced with carbon fibers are recognized as attractive construction materials due to their high specific strength, high modulus of elasticity, high crack resistance, creep resistance at elevated temperatures, low coefficient of thermal expansion, and corrosion resistance. However, achieving good quality castings with homogeneous structure and high operational properties presents a significant technological challenge. Carbon fibers, typically used in bundles, are poorly wetted by aluminum below 1100°C and can react to form brittle Al4C3 carbide, leading to composite weakening. These factors can cause fiber segregation and structural heterogeneity. To address this, various surface preparations for reinforcements, such as technological coatings (Ni, Cu), barrier coatings (SiC, B4C, TiC, SiO2), and special coatings, are employed. Another challenge is the high viscosity and low fluidity of composite suspensions, which increases with fiber content. Correct mold filling often requires high external pressures, making high pressure die casting and squeeze casting effective techniques. Aluminum composites with carbon fibers find applications in aerospace, marine, automotive, chemical, sports, and mineral industries.

4. Summary of the study:

Background of the research topic:

The development of AlSi13Cu2 matrix composites reinforced with carbon fibers (CF) is driven by the need for materials with enhanced mechanical properties. Key challenges include ensuring good wettability of carbon fibers by the aluminum alloy, achieving homogeneous fiber distribution, and minimizing defects. Squeeze casting is a promising manufacturing route due to its ability to apply high pressure during solidification.

Status of previous research:

Previous research highlighted the benefits of carbon fiber reinforcement in aluminum alloys, such as improved strength and wear resistance. Issues like poor wettability of carbon fibers and the formation of detrimental aluminum carbide (Al4C3) were identified. Surface coatings on fibers (e.g., Ni) were explored to improve wettability and protect fibers. Squeeze casting has been recognized as an effective method for producing metal matrix composites, capable of overcoming issues related to high viscosity of composite suspensions and ensuring good interfacial bonding.

Purpose of the study:

The aim of the study is to assess the influence of squeeze casting pressure and carbon fibers volume fraction on the impact strength of AlSi13Cu2-CF composite.

Core study:

The core study involved preparing AlSi13Cu2 matrix composites reinforced with Ni-coated carbon fibers (CF) at volume fractions of 5%, 10%, and 15%. Composite suspensions were made using a stirring method. These were then squeeze cast under varying pressures (25, 50, 75, and 100 MPa) to determine the optimal pressure. Subsequently, composites with different fiber volume fractions were produced at this optimal pressure. The study focused on evaluating the fiber distribution in the aluminum matrix and determining the variation in impact strength as a function of carbon fiber volume fraction and applied pressure. Microstructure and fracture surfaces were also analyzed.

5. Research Methodology

Research Design:

The research was conducted in two stages.

- In the first stage, composite suspensions with a fibers volume fraction of 10% were prepared and squeeze casted under different pressures: 25, 50, 75, and 100 MPa to determine the optimum pressure.

- In the second stage, composite squeeze castings with fibers volume fraction of 5, 10, and 15% were produced by applying the optimum pressure value identified in the first stage.

Data Collection and Analysis Methods:

- Material Preparation: The matrix was AlSi13Cu2 alloy, and reinforcement was Nickel-coated carbon fibers (diameter 7.5 µm, length 5 mm). Composite suspensions were prepared by melting the matrix alloy (650-700°C), gradually introducing fibers, and mixing with a paddle mixer (600-800 rpm for 3-5 minutes).

- Squeeze Casting: Performed on a hydraulic press. The die was preheated to ~200°C and lubricated. Composite suspensions (1300 g) were dosed into the die and squeeze casted. Pressure duration was 50s.

- Metallographic Observations: Conducted using a NIKON EPIPHOT light microscope.

- Impact Strength Testing: Charpy impact tests were performed according to PN-EN ISO 179-1:2010 on 10 × 10 × 50 mm un-notched specimens.

- Fractographic Studies: Carried out on fracture surfaces of composite samples (10% fiber volume fraction) using an SEM JSM-5400 Joel scanning electron microscope.

Research Topics and Scope:

The research investigated:

- The effect of squeeze casting pressure (25, 50, 75, 100 MPa) on the impact strength of AlSi13Cu2-CF (10% CF) composite.

- The effect of carbon fiber volume fraction (5%, 10%, 15%) on the impact strength of AlSi13Cu2-CF composite produced at the determined optimum pressure.

- Microstructure of the composites, including fiber distribution.

- Fracture mechanisms of the composites.

6. Key Results:

Key Results:

- The presence of a Ni coating on carbon fibers significantly improves their wettability by liquid aluminum alloy, enabling the production of composite material with a relatively homogeneous structure when combined with appropriate stirring parameters.

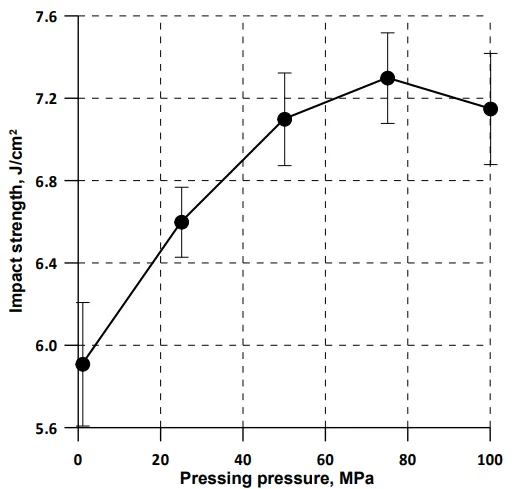

- The impact strength of the AlSi13Cu2-CF composite (10% CF) reaches its highest value when the squeeze casting process is carried out at a pressure of 75 MPa. Higher pressures (e.g., 100 MPa) slightly reduce impact strength.

- The impact strength of the composites increases with an increasing volume fraction of carbon fibers. For a 15% fiber volume fraction, the impact strength is close to 8 J/cm², which is approximately 35% higher than that of the unreinforced AlSi13Cu2 alloy (5.85 J/cm²).

- Microstructural observations indicated a uniform distribution of reinforcement in the matrix, without significant internal defects like fiber clusters or gas porosity.

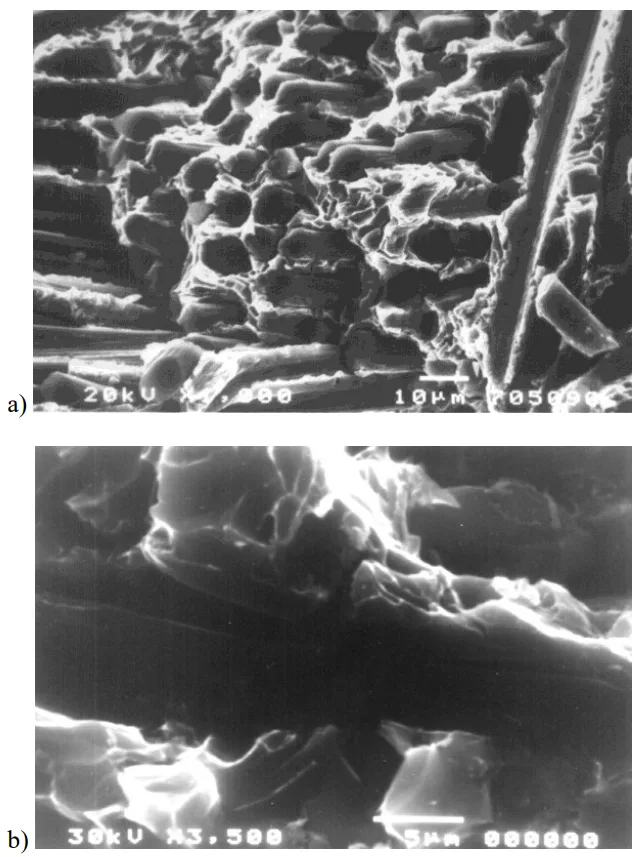

- Fractographic analysis revealed that crack growth in the composites propagates via a quasi-cleavage mechanism. Fibers oriented perpendicular to the fracture surface were sheared, while the surrounding metal matrix deformed plastically. This indicates a cohesive and strong bond between the reinforcement and the matrix.

- Debonding at fiber-matrix interfaces and the formation of voids between components were also observed on the fracture surfaces.

Figure Name List:

- Fig. 1. The microstructure of squeeze casting AlSi13Cu2 alloy a) and the composite reinforced by Ni-coating carbon fibers (CF) with a volume fraction of 5% b), 10% c) 15% d)

- Fig. 2. The effect of squeeze casting pressure on the impact strength of a composite with a fiber volume fraction of 10%

- Fig. 3. The influence of the volume fraction of CF on impact strength of the composite- squeeze casting pressure of 75 MPa

- Fig. 4. The fracture surfaces of squeeze casting AlSi13Cu2 - 10% CF composite: a) ×1000 mag., b) ×3500 mag.

7. Conclusion:

- The presence of a Ni layer on carbon fibers clearly improves their wettability by a liquid aluminum alloy and in combination with the stirring parameters used, a composite material with a relatively homogeneous structure can be produced.

- The impact strength of the composite achieves the highest value by carrying out the squeeze casting process at 75 MPa. Higher squeeze casting pressures slightly reduce composite impact strength.

- The impact strength of the composite increases with the carbon fibers volume fraction and for 15% of fibers is close to 8 J/cm², which is an increase of about 35% compared to the metal matrix of composite.

- Cracking of the composites occurs through a quasi-fissile mechanism. During the destruction, the fibers located perpendicular to the fracture surface break, while the fibers arranged in parallel are detached from the metal matrix along the bonding interface. The propagation of cracking through fibers indicates a cohesive and strong connection between the components of the composite.

8. References:

- [1] Kumar N, Chittappa H.C., Vannan S.E. (2018). Development of Aluminium-Nickel Coated Short Carbon Fiber Metal Matrix Composites. Materials Today: Proceedings. 5, 11336-11345.

- [2] Kaczmar, J.W., Naplocha, K., Morgiel, J. (2012). High temperature mechanical properties of en AC 44200 aluminium alloy based composite materials strengthened with ceramic fibers. 70th World Foundry Congress 2012, WFC 2012. 528-535.

- [3] Miracle D.B. (2005) Metal matrix composites – From science to technological significance. Composites Science and Technology. 65, 2526-2540.

- [4] Shalu T., Abhilash E. & Joseph M.A. (2009). Development and characterization of liquid carbon fibred reinforced aluminum matrix composite. Journal of Materials Processing Technology. 209, 4809-4813.

- [5] Konopka, Z., Łągiewka, M., Nadolski, M. & Zyska, A. (2013). Determination of the strengthening coefficient of pressure cast AlSi13Cu2/chopped carbon fiber composite. Archives of Metallurgy and Materials. 58, 957-960.

- [6] Ramanathan A., Pradeep Kumar K. & Rajaraman M. (2019). A review on the production of metal matrix composites through stir casting – Furnace design, properties, challenges, and research opportunities. Journal of Manufacturing Processes. 42, 213-245.

- [7] Rams J., Ureña A., Escalera M.D. & Sánchez M. (2007). Electroless nickel coated short carbon fibres in aluminium matrix composites. Composites A. 38, 566-575.

- [8] Baghi M., Niroumand B. & Emadi R. (2017). Fabrication and characterization of squeeze cast A413-CSF composites. Journal of Alloys and Compounds. 710, 29-36.

- [9] Gawdzińska K., Chybowski L., Przetakiewicz W. & Laskowski R. (2017). Application of FMEA in the quality estimation of metal matrix composite castings produced by squeeze infiltration. Archives of Metallurgy and Materials. 62, 2171-2182.

- [10] Alten A, Erzi E., Gürsoy O, Agaoglu G.H., Dispinar D. & Orhan G. (2019). Production and mechanical characterization of Ni-coated carbon fibers reinforced Al-6063 alloy matrix composites. Journal of Alloys and Compounds. 787, 543-550.

- [11] Bhav Singh B. & Balasubramanian M. (2009). Processing and properties of copper-coated carbon fibre reinforced aluminium alloy composites. Journal of Materials Processing Technology. 209, 2104-2110.

- [12] Hajjari E., Divandari M. & Mirhabibi A.R. (2010). The effect of applied pressure on fracture surface and tensile properties of nickel coated continuous carbon fiber reinforced aluminum composites fabricated by squeeze casting. Materials and Design. 31, 2381-2386.

- [13] Dyzia, M., Dolata, A.J. & Śleziona, J. (2012) Preliminary analysis of aluminum matrix compositions for composites reinforcement with carbon fibers. Steel Research International. 83, 981-987.

- [14] Ghomashchi M.R. & Vikhrov A. (2000). Squeeze casting: an overview. Journal of Materials Processing Technology. 101, 1-9.

- [15] Bielecka, A., Konopka, Z., Zyska, A. & Łągiewka, M. (2007) Investigation of pressure die casting of the aluminium alloy matrix composites with SiC particles. Archives of Metallurgy and Materials. 52, 497-502.

- [16] Macke A.J, Schultz B. & Rohatgi P.K. (2012). Metal Matrix Composites Offer the Automotive Industry an Opportunity to Reduce Vehicle Weight. Improve Performance Advanced Materials and Processes. 170, 19-23.

- [17] Cai J., Chen Y., Nesterenko V.F. & Meyers M.A. (2008). Effect of strain rate on the compressive mechanical properties of aluminum alloy matrix composite filled with discontinuous carbon fibers. Materials Science Engineering A. 485, 681-689.

9. Copyright:

- This material is a paper by "A. Zyska, Z. Konopka, M. Łągiewka". Based on "Impact strength of squeeze casting AlSi13Cu2-CF composite".

- Source of the paper: https://doi.org/10.24425/afe.2020.131301

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.