Driving Down Costs and CO2: A Deep Dive into Energy-Saving Innovations for Automotive HPDC

This technical summary is based on the academic paper "Green Innovations in Foundry Production Processes of Automobile Castings" by Josef Bradáč, Martin Folta, Jiří Machuta, Jiří Slabý, and Michal Beneš, published in Rocznik Ochrona Środowiska (2024). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: Energy Savings in HPDC

- Secondary Keywords: Foundry Innovations, Automotive Die Casting, Sustainable Manufacturing, CO2 Reduction in Foundries, Process Optimization

Executive Summary

- The Challenge: High energy and resource consumption are persistent financial and environmental pressures in high-volume automotive aluminum foundries.

- The Method: The study documents the implementation and quantification of a series of targeted technological innovations in a large-scale foundry, addressing everything from melting and casting to facility lighting.

- The Key Breakthrough: The research demonstrates that substantial, measurable reductions in natural gas, electricity, water, and chemical usage are achievable through specific, targeted upgrades to existing equipment and processes.

- The Bottom Line: A systematic, data-driven approach to process innovation can yield significant financial savings and environmental benefits, proving that sustainability and operational efficiency in HPDC are not mutually exclusive.

The Challenge: Why This Research Matters for HPDC Professionals

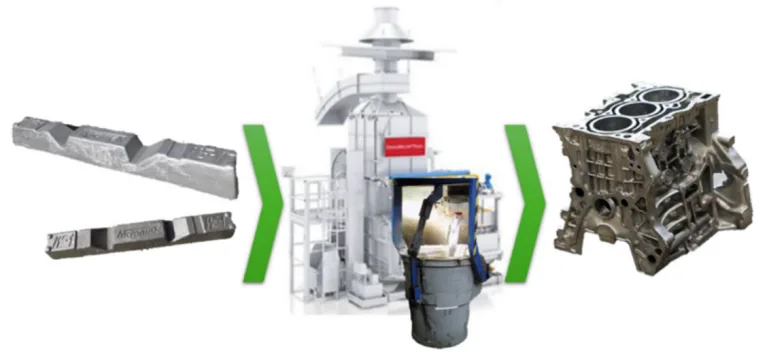

In today's industrial landscape, the pressure is on to reduce environmental impact and operational costs simultaneously. For the automotive HPDC sector, which produces complex components like engine blocks and gearboxes, this challenge is particularly acute. Foundry operations are inherently energy-intensive, characterized by high natural gas consumption for melting, significant electricity usage for casting machines, and large volumes of water for cooling.

The complexity of car manufacturing demands constant innovation and optimization to deliver high-quality products at minimum cost and lead time. This paper addresses the critical need for practical, proven solutions that enhance efficiency. It moves beyond theoretical models to present real-world innovations implemented in a high-volume foundry, providing a valuable roadmap for any professional looking to reduce energy consumption, lower CO2 production, and improve the bottom line.

The Approach: Unpacking the Methodology

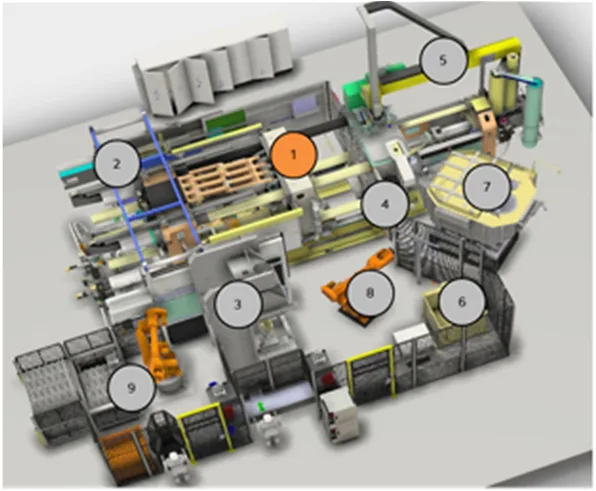

The research was conducted at the Škoda Auto aluminum foundry, a major production facility producing approximately 2 million parts annually, including engine blocks and gearbox housings. The facility operates 4 aluminum melting furnaces, 20 high-pressure die-casting machines (clamping force 1800-3500 t), and associated heat treatment and finishing equipment.

The methodology involved implementing and evaluating a series of distinct "green innovations" across the entire production flow. The effectiveness of each innovation was measured by quantifying the reduction in consumption of a specific resource (natural gas, electricity, water, or chemicals). The study leverages digital data monitoring, using tools like Power BI, to track consumption before and after implementation, allowing for a precise assessment of the financial and environmental benefits of each solution.

The Breakthrough: Key Findings & Data

The paper presents compelling, data-backed evidence of significant resource savings across multiple operational areas.

Finding 1: Drastic Reductions in Electricity Consumption Through Targeted Upgrades

The study identified several key areas where electricity consumption could be dramatically reduced.

- Casting Machine Hydraulics: By installing frequency converters to control the hydraulic pumps, hourly power consumption was reduced by 54 kW in working mode and 10 kW in waiting mode. For a single machine, this resulted in an annual saving of 257,852 kWh (Table 2).

- Extraction Systems: Optimizing the extraction system to reduce power when the mould is closed and eliminate consumption in standby mode yielded an annual saving of 35,224 kWh (Table 3).

- Cutting Press Controls: A new control system reduced the press's annual electricity consumption from 60,480 kWh to just 11,742 kWh (Table 4).

- Facility Lighting: A comprehensive upgrade from conventional 400 W lamps to modern LED lighting resulted in a massive annual saving of 2,680 MWh.

Finding 2: Optimizing Thermal Energy and Process Fluids

Beyond electricity, the research demonstrated significant savings in natural gas, water, and chemicals.

- Furnace Efficiency: Renovating the internal refractory lining of a melting furnace led to annual natural gas savings of 584 m³, which also reduced the time needed to reach melting temperature, improving efficiency.

- Waste Heat Recovery: An innovative system was installed to capture waste heat from the annealing furnaces. As shown in Figure 8, this provided 120 kW of heating benefit, allowing for a reduction in electric heating power from 230 kW to 110 kW and achieving winter electricity savings of 691,000 kWh/year.

- Waterless Mould Treatment: The implementation of micro-lubrication technology completely eliminated the need for industrial water in the mould release agent application. Consumption went from 6 liters of water per cycle to zero, drastically reducing water usage and wastewater production.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that retrofitting hydraulic circuits with frequency converters offers a high-impact opportunity for immediate energy savings. Furthermore, the data strongly supports a transition to micro-spraying for mould treatment, which not only saves water but can also reduce cycle time and increase productivity by 20-30%.

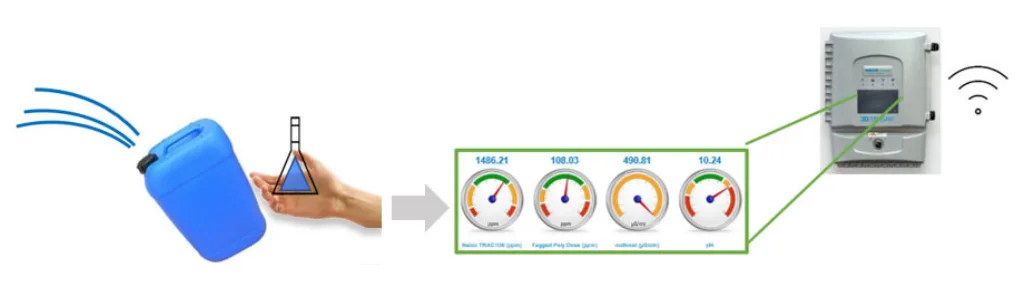

- For Quality Control Teams: The data in the paper highlights that innovations can improve quality. The shift to micro-lubrication is noted to reduce internal porosity and improve the surface quality of castings. The use of digital monitoring tools like the Power BI report (Figure 2) and the 3D Trasar online device for cooling water (Figure 10) enables faster identification of process deviations that could impact quality.

- For Maintenance & Facility Managers: The study makes a powerful case for two key actions: scheduling regular renovation of furnace linings to prevent heat loss and prioritizing a facility-wide transition to LED lighting, which delivered the single largest electricity saving.

Paper Details

Green Innovations in Foundry Production Processes of Automobile Castings

1. Overview:

- Title: Green Innovations in Foundry Production Processes of Automobile Castings

- Author: Josef Bradáč, Martin Folta, Jiří Machuta, Jiří Slabý, Michal Beneš

- Year of publication: 2024

- Journal/academic society of publication: Rocznik Ochrona Środowiska

- Keywords: foundry, innovations, energy savings, environmental impact

2. Abstract:

The paper deals with individual possibilities for energy savings and the use of chemicals in the production of automotive components. Specifically, it focuses on operating an aluminium foundry where shape-complex castings such as engine blocks and gear and clutch housings are produced using high-pressure die-casting technology. Regarding the production process, foundry operations are characterized by high energy consumption and high wastewater production. On the other hand, there is also a great potential for introducing various innovations and seeking savings. This paper aims to present selected innovative solutions throughout the foundry operation and assess their benefits in energy consumption savings, reduced wastewater production, and chemicals usage. The impact of the presented savings is financial in terms of the production of components and environmental in terms of CO2 production.

3. Introduction:

Nowadays, there is an increasing interest in environmental protection and a general effort to reduce the production of harmful substances related to all areas of human activities. This is valid for the industrial sector and industrial production in general. The automotive industry is complex and specific, with high demands on innovation, quality, and cost efficiency. This applies particularly to energy-intensive production areas like foundries. In the automotive industry, foundry plants mainly produce parts of combustion engines and gearboxes from aluminium alloys using high-pressure die casting. This paper focuses on green innovations in the foundry production process at Škoda Auto, aimed at reducing the consumption of energy and operating substances.

4. Summary of the study:

Background of the research topic:

Foundry operations in the automotive industry are characterized by high consumption of energy (natural gas, electricity), water, and chemicals, leading to high operational costs and significant environmental impact. There is increasing pressure to adopt "green production" trends and improve efficiency.

Status of previous research:

Previous research and industry trends point towards digitization (Industry 4.0), waste heat recovery, and process optimization as key avenues for improving efficiency and reducing environmental impact in industrial production.

Purpose of the study:

This paper aims to present and quantify the benefits of selected innovative solutions implemented throughout a real-world foundry operation. The goal is to assess their impact on energy savings, reduced wastewater production, and chemical usage, translating these into financial and environmental (CO2 reduction) terms.

Core study:

The study details a series of specific innovations implemented in an aluminum HPDC foundry producing automotive components. These innovations include: renovating furnace linings, installing frequency converters on casting machine hydraulics, optimizing extraction and cutting press controls, implementing waste heat recovery from annealing furnaces, upgrading to LED lighting, and adopting new technologies for mould treatment (micro-lubrication) and cooling water management. The paper provides specific data on the savings achieved by each measure.

5. Research Methodology

Research Design:

The study uses a case-study approach, documenting and analyzing a series of technological interventions at a single, large-scale industrial facility (Škoda Auto foundry). It is an applied research paper focused on practical implementation and results.

Data Collection and Analysis Methods:

Data on the consumption of energy (natural gas, electricity), water, and chemicals were collected before and after the implementation of each innovation. Digital monitoring systems and Power BI reports were used to track and visualize consumption data. The analysis consists of quantifying the reduction in consumption and calculating the annual savings.

Research Topics and Scope:

The scope is limited to the production processes within an aluminum foundry for automotive castings. The research topics cover energy and resource consumption in melting, casting, heat treatment, facility operations (lighting), and process fluid management (cooling and mould treatment).

6. Key Results:

Key Results:

- Renovation of a furnace lining saves 584 m³/year of natural gas.

- Installing a frequency converter on a casting machine's hydraulic circuit saves 257,852 kWh/year.

- An innovative extraction system solution saves 35,224 kWh/year.

- A new control for the cutting press reduces its annual energy consumption by over 80%, from 60,480 kWh to 11,742 kWh.

- A waste heat recovery system from annealing furnaces provides 691,000 kWh/year in electricity savings for hall heating.

- Replacing conventional lighting with LED lamps saves 2,680 MWh annually (for 2022).

- Micro-lubrication technology for mould treatment eliminates the use of industrial water (from 6 L/cycle to 0) and reduces separator consumption.

- Automated chemical dosing for cooling water (3D Trasar system) optimizes chemical consumption.

Figure Name List:

- Fig. 1. The procedure of cylinder block production, from molten metal to final product

- Fig. 2. Power BI report of gas consumption in individual melting devices for a selected period

- Fig. 3. Melting furnace with an example of an inner lining of the melting space

- Fig. 4. Schematic view of individual devices in the casting workplace: (1 – high pressure casting machine, 2 – machine extraction, 3 – cutting press, 4 – data matrix code punch, 5 – foundry mould treatment manipulator, 6 – cooling bath, 7 – holding furnace, 8 – handling robot, 9 – robotic, automatic palletizing)

- Fig. 5. Control status of the casting machine hydraulic circuit before and after applying the frequency converter

- Fig. 6. Comparison of energy consumption of an extraction system, before (top) and after (bottom)

- Fig. 7. Graphical representation of the innovation concerning savings of the cutting press, before (red), after application of the innovation (green)

- Fig. 8. Situation before and after the implementation of waste heat recovery system from annealing furnaces

- Fig. 9. Transition from the old type of lighting on the left to the modern type of LED lamps on the right

- Fig. 10. Transition from manual water sampling and manual laboratory analysis to the use of the 3D Trasar online equipment for precise analysis and dosing of chemical products to be used in the cooling water

7. Conclusion:

The paper demonstrates that individual, targeted solutions can bring a foundry closer to desired targets for energy savings and CO2 reduction. Digitization of data is an important driver, enabling frequent and accurate monitoring of the entire production process to minimize losses. The study recommends the use of 100% micro-spraying of moulds to increase product quality and daily monitoring to reduce leakages of all process substances. These actions have a substantial environmental benefit and do not necessarily require a large initial investment.

8. References:

- Bajdur, W., Zielińska, A., Gronba-Chyła, A. (2023). Product Life Cycle Assessment (LCA) as a Tool for Environmental Management. Rocznik Ochrona Środowiska, 25(1), 389-398.

- Chamier-Gliszczynski, N., Krzyzynski, T. (2005). On modelling three-stage system of receipt and automotive recycling. REWAS'04, Global Symposium on Recycling, Waste Treatment and Clean Technology 2005, 2813-2814, Madrid, Spain, 26-29 September 2004, Conference Paper, ISBN: 8495520060.

- Chamier-Gliszczyński, N. (2012). Modeling system mobility in urban areas. Congress Proceedings, CLC 2012: Carpathian Logistics Congress, 501-508, 111467.

- Espuny, M., Costa, A.C.F., Reis, J.S.M., Barbosa, L.C.F.M, Snatos, R.C.G., Oliveira, O.J. (2022). Identification of the Elements and Systematisation of the Pillars of Solid Waste Management. Quality Innovation Prosperity, 26(2), 147-169.

- Gabrylewicz, I., Lenort, R., Wędrychowski, M., Krupa, P., Woźniak, W. (2021). Environmental Loads Resulting from Manufacturing Technology. Rocznik Ochrona Srodowiska, 23, 613-628. https://doi.org/0.54740/ros.2021.043

- Ghadge, A., Mogale, D.G., Bourlakis, M., Maiyar, L.M., Moradlou, H. (2022). Link between Industry 4.0 and green supply chain management: Evidence from the automotive industry. Computers & Industrial Engineering, 169(1), 1-14.

- Ignatowicz, K., Piekarski, J., Kogut, P. (2021). Influence of selected substrate dosage on the process of biogas installation start-up in real conditions. Energies, 14(18), 5948. https://doi.org/10.3390/en14185948

- Jenek, M., Ociepa, M., Woźniak, W., Vilmová, Š., Švecová, E. (2022). Rocznik Ochrona Srodowiska, 24, 360-370. https://doi.org/10.54740/ros.2022.025

- Kostrzewski, M., Chamier-Gliszczynski, N., Królikowski, T. (2020). Selected reflections on formal modeling in Industry 4.0. Procedia Computer Science, 176, 3293-3300. https://doi.org/10.1016/j.procs.2020.09.118

- Kuczynski, W., Kaminski, K., Znaczko, P., Chamier-Gliszczynski, N., Piatkowski, P. (2021). Features and Thermal Efficiency of Flat-Plate Solar Collectors. Energies, 14(2), 261. https://doi.org/10.3390/en14020261

- Lenort, R., Baran, J., Wysokinski, M., Golasa, P., Bienkowska-Golasa, W., Golonko, M., Chamier-Gliszczynski, N. (2019). Economic and Environmental Efficiency of the Chemical Industry in Europe in 2010-2016. Rocznik Ochrona Srodowiska, 21(2), 1393-1404.

- Menti, F., Romero, D., Jacobsen, P. (2023). A technology assessment and implementation model for evaluating socio-cultural and technical factors for the successful deployment of Logistics 4.0 technologies. Technological Forecasting and Social Change, 190(1), 1-17.

- Mir, M., Llach, J., Casadesus, M. (2022). Degree of Standardization and Innovation Capability Dimensions as Driving Forces for Innovation Performance. Quality Innovation Prosperity, 26(2), 1-20.

- Nawrocki, W., Stryjski, R., Woźniak, W., Jakubowski, J. (2018). Improving the quality of manufacturing processes in Toyota motor manufacturing, Poland. Proceedings of the 31st International Business Information Management Association Conference, IBIMA 2018: Innovation Management and Education Excellence through Vision 2020, 143853, 5931-5945.

- Obzina T., Merta V., Folta M., Bradáč J., Beňo J., Novohradsaká N., Gawronová M., Kroupová I., Lichý P., Radkovský F., Janovská K., Vasková I., Drobíková K., Nguyenová I. Technological and Quality Aspects of the Use of Innovative Inorganic Binders in the Production of Castings. Metals, 11(11), 1-13.

- Orłowska, M. (2022). Saving Energy – a Smart, Ecological and Necessary Trend. Rocznik Ochrona Środowiska, 24(1), 472-480.

- Saetta, S., Caldarelli, V. (2020). Lean production as a tool for green production: the green foundry case study. Procedia Manufacturing, 42(1), 498-502.

- Samtleben, S., Schleich, CH., Chenk, M. (2021). Identifying energy flexible manufacturing layouts in a light metal foundry. Procedia CIRP, 104(1), 1589-1594.

- Sąsiadek, M., Niedziela, M., Woźniak, W., Jachowicz, T., Mikušová, N. (2023). A New Effective Algorithm for Mechanical Assembly Sequence Planning. Advances in Science and Technology Research Journal, 17(5), 56-67. https://doi.org/10.12913/22998624/171271

- Sharma, M., Luthra, S., Joshi, S., Kumar, A., Akshat, J. (2023). Green logistics driven circular practices adoption in industry 4.0 Era: A moderating effect of institution pressure and supply chain flexibility. Journal of Cleaner Production, 383(1), 1-12.

- Scharf, S., Sander, B., Kujath, M., Richter, H., Riedel, E, Stein, N., Felde, J.T. (2022). Sustainability potentials of an innovative technology and plant system in non-ferrous foundries. Procedia CIRP, 105(1), 758-763.

- Scharf, S., Sander, B., Kujath, M., Richter, H., Riedel, E., Stein, N., Felde, J.T. (2021). Foundry 4.0: An innovative technology for sustainable and flexible process design in foundries. Procedia CIRP, 98(1), 73-78.

- Staniuk, W., Staniuk, M., Chamier-Gliszczynski, N., Jacyna, M., Klodawski, M. (2022). Decision-Making under the Risk, Uncertainty and COVID-19 Pandemic Conditions Applying the PL9A Method of Logistics Planning-Case Study. Energies, 15(2), 639. https://doi.org/10.3390/en15020639

- Sumasto, M., Arliananda, Almansuri, F., Aisyah, S., Purwojatmiko, B.H., (2023). Enhancing Automotive Part Quality in SMEs through DMAIC Implementation: A Case Study in Indonesian Automotive Manufacturing. Quality Innovation Prosperity, 27(3), 57-74.

- Szajna, A., Kostrzewski, M., Ciebiera, K., Stryjski, R., Woźniak W. (2021). Application of the deep CNN-based method in industrial system for wire marking identification. Energies, 14(12), 3659. https://doi.org/10.3390/en14123659

- Ťavodová, M., Vargová, M., Stančeková, D., Hajdúch, A., Mrázik, J. (2022). Evaluation of the Influence of Process Parameters on the Mechanical Properties of Castings during High Pressure Die Casting. Manufacturing Technology, 22(6), 764-770.

Expert Q&A: Your Top Questions Answered

Q1: What was the single most significant source of electricity savings identified in the study?

A1: The transition from conventional large 400 W lamps to modern fluorescent and LED lighting was the most impactful measure. The paper specifies that for the year 2022, this single change resulted in electricity savings of 2,680 MWh. This highlights the importance of addressing facility-wide systems in addition to core production equipment.

Q2: The paper mentions renovating the furnace lining. What was the specific benefit of this action beyond just saving gas?

A2: Renovating the furnace lining to restore its integrity and prevent heat loss had a primary benefit of saving 584 m³ of natural gas per year. However, the paper also notes a crucial secondary benefit: a shorter time needed to achieve the melting temperature. This directly contributes to increasing production efficiency and capacity.

Q3: How exactly did installing a frequency converter on the casting machine's hydraulic circuit achieve such a large energy saving?

A3: As illustrated in Figure 5, the original system ran the 52 kW hydraulic pump continuously to maintain pressure. The innovation involved installing a frequency converter that allows for precise control of the pump's operation. This means the pump only generates the necessary pressure when required, reducing its power consumption to 12 kW and saving 54 kW during the working mode, leading to the annual savings of 257,852 kWh.

Q4: What are the key advantages of micro-lubrication technology over conventional water-based mould treatment?

A4: The paper lists several key advantages. Environmentally, it enables zero industrial water consumption for this step and reduces separator consumption. Operationally, it positively reduces the casting cycle time, can increase foundry productivity by 20-30%, reduces air consumption by 50-80%, and improves the quality of castings by reducing internal porosity and improving surface finish.

Q5: The paper emphasizes data monitoring. What specific tool was mentioned for visualizing energy consumption, and why is it important?

A5: The paper explicitly shows a Power BI report for gas consumption in Figure 2. This tool is important because it allows for the digital monitoring and visualization of consumption trends for individual devices. This enables managers and engineers to accurately assess the benefits of implemented innovations and to quickly identify and correct faults or losses in the system.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a clear and actionable blueprint for achieving significant Energy Savings in HPDC operations. By systematically addressing inefficiencies in everything from melting furnaces and hydraulic systems to facility lighting and water management, foundries can unlock substantial financial benefits and drastically reduce their environmental footprint. The key takeaway is that a data-driven approach, powered by modern digital monitoring, is essential for identifying opportunities and verifying the impact of innovations.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Green Innovations in Foundry Production Processes of Automobile Castings" by J. Bradáč, M. Folta, J. Machuta, J. Slabý, and M. Beneš.

- Source: https://doi.org/10.54740/ros.2024.050

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.