Solving the Cracking Puzzle in AlSi5Cu3 Alloy Castings: A Microstructural Investigation for HPDC Engineers

This technical summary is based on the academic paper "EVALUATION OF CRACKING CAUSES OF AlSi5Cu3 ALLOY CASTINGS" by Š. EPERJEŠI, M. MATVIJA, L. EPERJEŠI, M. VOJTKO, published in ARCHIVES OF METALLURGY AND MATERIALS (2014). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: AlSi5Cu3 Alloy Castings

- Secondary Keywords: Microstructure Analysis, Casting Defects, Crack Propagation, Low Pressure Die Casting, Automotive Components, Heat Treatment

Executive Summary

- The Challenge: Automotive AlSi5Cu3 alloy castings produced by low-pressure casting were failing due to cracking and low mechanical properties after heat treatment.

- The Method: A comparative microstructural analysis was conducted on suitable (non-defective) and non-suitable (defective) castings using light microscopy, scanning electron microscopy, EDX, and hardness testing.

- The Key Breakthrough: Cracks propagated along networks of sharp, needle-like intermetallic phases and eutectic Si-particles, with the defective casting showing evidence of insufficient heat treatment compared to the sound casting.

- The Bottom Line: Inconsistent heat treatment and stresses during solidification are the primary causes of cracking in AlSi5Cu3 alloy castings, highlighting the critical need for precise process control.

The Challenge: Why This Research Matters for HPDC Professionals

In the automotive industry, the demand for lightweight, high-performance components has driven the widespread adoption of aluminum-silicon alloys like AlSi5Cu3. These materials are crucial for parts like motor blocks, gearboxes, and turbo-blowers. However, producing these components with consistently high quality, long operating life, and guaranteed safety is a significant challenge.

This research was initiated after cracks and low mechanical properties were discovered on several AlSi5Cu3 alloy turbo-blower castings. These parts, produced via low-pressure casting into a metal mold and subsequently heat-treated, were failing prescribed tests. Understanding the root cause of these surface disruptions is essential for preventing recurrence, reducing scrap rates, and ensuring the reliability of critical automotive components.

The Approach: Unpacking the Methodology

To diagnose the cause of the failures, researchers conducted a direct comparison between defective ("non-suitable") and non-defective ("suitable") castings.

- Material: The study focused on a commercial hypoeutectic, heat-treatable AlSi5Cu3 alloy.

- Casting Process: Castings were produced using low-pressure casting into metal molds, a method chosen for its ability to produce high-quality, dense parts.

- Analysis Techniques: Samples were cut from both suitable and non-suitable castings for detailed examination.

- Microscopy: The microstructures were documented using a light microscope (LM) and a scanning electron microscope (SEM) to observe the morphology and distribution of different phases.

- Chemical Analysis: The chemical nature of intermetallic phase particles was determined using Energy-Dispersive X-ray Spectroscopy (EDX).

- Mechanical Testing: The effect of microstructural changes on mechanical properties was evaluated using Vickers hardness measurement (HV10).

- Quantitative Analysis: Statistical metallographic methods were used to evaluate the average size and number per unit area of eutectic Si-particles and intermetallic phases.

This comparative approach allowed for the precise identification of the microstructural differences responsible for the casting failures.

The Breakthrough: Key Findings & Data

The analysis revealed critical differences in the microstructure and mechanical properties between the suitable and non-suitable castings, pointing directly to deviations in the manufacturing process.

Finding 1: Crack Propagation Path and Detrimental Intermetallic Morphology

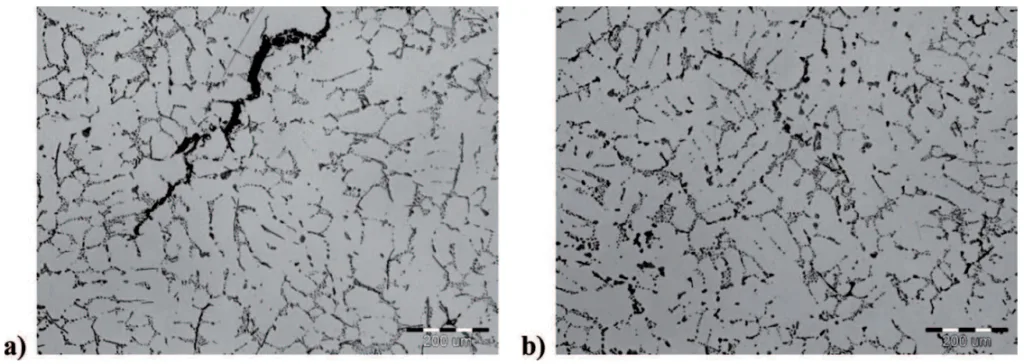

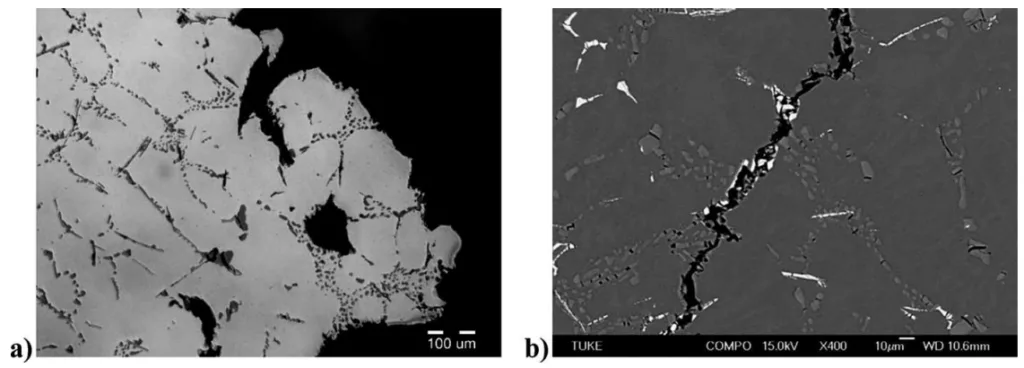

The investigation showed that in the non-suitable castings, cracks initiated on the surface and propagated along the interfaces between the α-solid solution dendrites and the surrounding eutectic Si-particle networks and intermetallic phases. This path represents the weakest point in the microstructure.

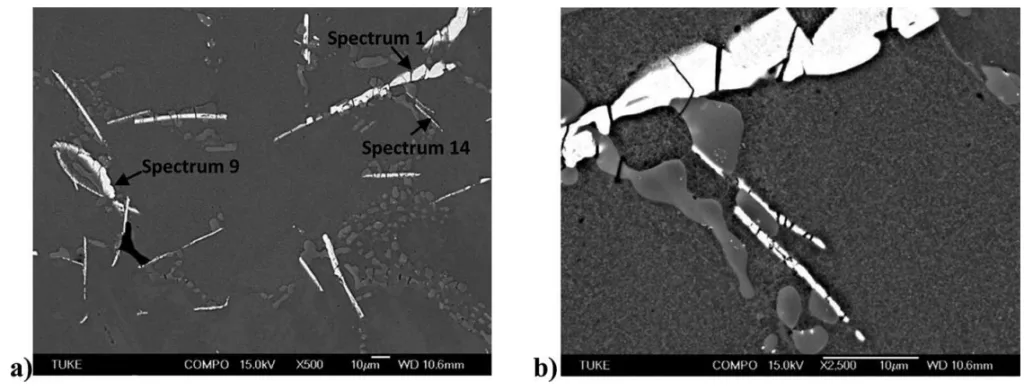

A key difference was the shape of the intermetallic phase particles:

- In the non-suitable casting, these particles were needle-like and blocky with sharp edges, creating a high notch effect that promotes crack formation (Figure 3). The average size was 3.6 µm with a density of 1.6×10³ mm⁻².

- In the suitable casting, the particles were rod-like with rounded edges, resulting in a lower notch effect and a more robust structure (Figure 4). The average size was similar at 3.5 µm, but the density was lower at 1.1×10³ mm⁻².

This demonstrates that the morphology of intermetallic phases is a critical factor in the structural integrity of AlSi5Cu3 alloy castings.

Finding 2: Evidence of Inconsistent Heat Treatment and Its Impact on Hardness

The study uncovered strong evidence that the heat treatment applied to the non-suitable castings was insufficient. This was observed in the state of the eutectic Si-particles, which were only partially spheroidized in both castings but to a lesser degree in the failed parts.

- In the non-suitable casting, the average size of Si-particles was 3.2 µm, and their number per unit area was 6.6×10³ mm⁻².

- In the suitable casting, the average size was slightly larger at 3.5 µm, but the number per unit area was almost two times lower at 3.5×10³ mm⁻².

The lower degree of particle coarsening and rounding of intermetallics in the non-suitable casting suggests it was subjected to a lower temperature or a shorter holding time during heat treatment. This was directly reflected in the mechanical properties: the non-suitable casting had a lower hardness of 105.7 HV10 compared to the suitable casting's 112.0 HV10.

Practical Implications for R&D and Operations

The findings of this paper offer actionable insights for improving the production of AlSi5Cu3 alloy castings.

- For Process Engineers: This study suggests that adjusting mold temperature and the cooling system to ensure even solidification may contribute to preventing the formation of initial microtears. The paper concludes that thermal or mechanical resistance during solidification (e.g., from the mold) can cause these initial defects, which later grow into full cracks.

- For Quality Control Teams: The data in Figure 3 and Figure 4 of the paper illustrates the effect of intermetallic morphology on casting integrity. The correlation between sharp, needle-like phases, lower hardness (105.7 HV10), and cracking could inform new microstructural inspection criteria for quality assurance.

- For Design Engineers: The findings indicate that stresses from uneven solidification influence defect formation. This suggests that part geometry, which dictates thermal gradients and potential resistance to shrinkage, is a valuable consideration in the early design phase to minimize the risk of microtears.

Paper Details

EVALUATION OF CRACKING CAUSES OF AlSi5Cu3 ALLOY CASTINGS

1. Overview:

- Title: EVALUATION OF CRACKING CAUSES OF AlSi5Cu3 ALLOY CASTINGS

- Author: Š. EPERJEŠI, M. MATVIJA, L. EPERJEŠI*, M. VOJTKO

- Year of publication: 2014

- Journal/academic society of publication: ARCHIVES OF METALLURGY AND MATERIALS, Volume 59, Issue 3

- Keywords: AlSi5Cu3 alloy, microstructure, cracks, hardness

2. Abstract:

Recently, the castings made from aluminum-silicon alloys by pressure die casting are increasingly used in the automotive industry. In practice, on these castings are high demands, mainly demands on quality of their structure, operating life and safety ensuring of their utilization. The AlSi5Cu3 alloy castings are widely used for production of car components. After the prescribed tests, the cracks and low mechanical properties have been identified for several castings of this alloy, which were produced by low pressure casting into a metal mould and subsequent they were heat treated. Therefore, analyses of the castings were realized to determine the causes of these defects. Evaluation of structure of the AlSi5Cu3 alloy and causes of failure were the subjects of investigation presented in this article.

3. Introduction:

Aluminum and its alloys are the most common materials for non-ferrous casting production due to their low density, good machinability, and castability. In the automotive industry, their use is critical for reducing vehicle weight, loudness, and vibrations. During the production of a turbo-blower from AlSi5Cu3 alloy using low-pressure casting, surface disruption was discovered on some castings after heat treatment and testing. To prevent recurrence, an analysis was conducted to evaluate the causes of these surface defects. The study notes that defects in low-pressure casting are influenced by multiple factors, including mold design, casting parameters, and alloy processing.

4. Summary of the study:

Background of the research topic:

The use of Al-Si alloy castings is growing in the automotive sector, where high standards for structural quality, service life, and safety are required. The AlSi5Cu3 alloy is widely used for car components, but defects like cracks can compromise performance.

Status of previous research:

The paper acknowledges that defects like cracks and tears in low-pressure casting are generally understood to be caused by temporary or residual shrinking or thermal stresses during solidification. These stresses can be exacerbated by mechanical or thermal hindrances to free shrinking.

Purpose of the study:

The primary purpose was to analyze the structure of failed AlSi5Cu3 castings and determine the root causes of the observed cracks and low mechanical properties to prevent their recurrence.

Core study:

The core of the study is a comparative microstructural and mechanical property analysis between suitable (non-defective) and non-suitable (defective) AlSi5Cu3 castings. The analysis focused on the morphology and distribution of eutectic Si-particles and intermetallic phases, as well as their role in crack initiation and propagation.

5. Research Methodology

Research Design:

The study employed a comparative research design, analyzing samples from both defective and non-defective castings of the same AlSi5Cu3 alloy produced under the same specified low-pressure casting process.

Data Collection and Analysis Methods:

Data was collected through metallographic sample preparation followed by analysis using a light microscope (LM), scanning electron microscope (SEM) with EDX for chemical analysis of phases, and Vickers hardness testing (HV10). Statistical methods were used to quantify particle size and density.

Research Topics and Scope:

The research was scoped to the AlSi5Cu3 alloy used for automotive turbo-blower components produced by low-pressure casting into a metal mold. The investigation focused on evaluating the microstructure, identifying the causes of cracking, and assessing hardness variations.

6. Key Results:

Key Results:

- Cracks in the non-suitable casting initiated on the surface and propagated along the interface of α-solid solution dendrites and networks of eutectic Si-particles and intermetallic phases.

- Intermetallic particles in the non-suitable casting were needle-like with sharp edges (high notch effect), whereas in the suitable casting, they were rod-like with rounded edges (low notch effect).

- The non-suitable casting showed evidence of insufficient heat treatment, indicated by a lower degree of Si-particle coarsening and intermetallic spheroidizing compared to the suitable casting.

- The non-suitable casting exhibited lower hardness (105.7 HV10) compared to the suitable casting (112.0 HV10), correlating with its defective microstructure.

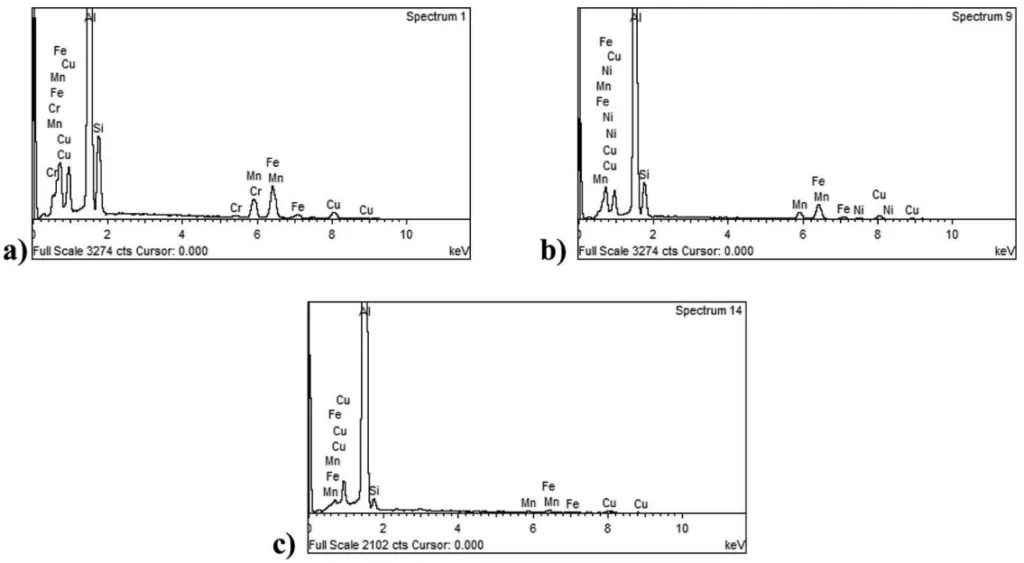

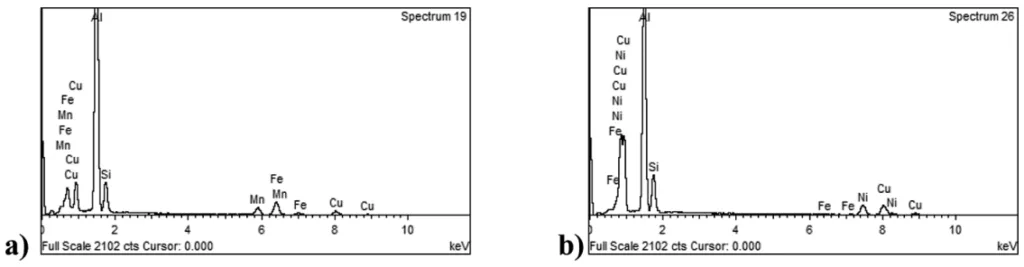

- EDX analysis identified the intermetallic phases in the non-suitable casting as being on the Al-Si-Fe-Mn-base and Al-Si-Fe-Mn-Ni(Cr)-base.

Figure Name List:

- Fig. 1. Microstructure of casting with not acceptable defect (a) and acceptable casting (b) of AlSi5Cu3 alloy

- Fig. 2. Character of crack propagation in structure of casting with not acceptable defect documented by LM (a) and SEM (b)

- Fig. 3. Morphology of intermetallic phase particles in structure of non-suitable casting (a) and detail of particles (b)

- Fig. 4. Morphology of intermetallic phase particles in structure of suitable casting (a) and detail of particles (b)

- Fig. 5. EDX spectra of intermetallic phase particles in non-suitable casting structure: Spectrum 1 (a), Spectrum 9 (b) and Spectrum 14(c)

- Fig. 6. EDX spectra of intermetallic phase particles in suitable casting structure: Spectrum 19 (a) and Spectrum 26 (b)

7. Conclusion:

- Surface disruption was initiated on the interface of α-solid solution and eutectic/intermetallic particles. This was likely caused by mechanical or thermal resistance during solidification (e.g., insufficient mold temperature, uneven solidification, or mold resistance to shrinkage), creating microtears that led to total failure after heat treatment.

- During the heat treatment of the non-suitable casting, sufficient spheroidizing of intermetallic particles did not occur, resulting in a higher notch effect and lower mechanical properties.

- From a metallurgical standpoint, it is recommended to pay increased attention to the preparation and composition of the charge and the refining of the melt.

8. References:

- [1] J. Malik, Technológia liatia zliatin hliníka, Košice, 2013.

- [2] R. Kantorík, D. Bolibruchová, International Foundry Reseach 63, 2, 18-23 (2011).

- [3] T. Grígerová, R. Kořený, I. Lukáč, Zlievarenstvo neželezných kovov, Bratislava, 1988.

- [4] W.K. Krajewski, J. Lelito, J.S. Suchy, P. Schumacher, Computed tomography a new tool in structural examinations of castings, Archives of Metallurgy and Materials 54, 2, 335-338 (2009).

- [5] K. Haberl, W.K. Krajewski, P. Schumacher, Microstructural features of the grain-refined sand cast AlZn20 alloy, Archives of Metallurgy and Materials 55, 3, 837-841 (2010).

- [6] W.K. Krajewski, A.L. Greer, P.K. Krajewski, Trends in developments of high-aluminium zinc alloys of stable structure and properties, Archives of Metallurgy and Materials 58, 3, 859-861 (2013).

- [7] E. Tillová, M. Chalupová, L. Hurtalová, M. Bonek, L.A. Dobrzański, Journal of Achievements in Materials and Manufacturing Engineering 47, 1, 19-25 (2011).

- [8] R. Colás, E. Velasco, S. Valtierra, Castings, In: G. E. Totten, D. C. MacKenzie (Ed.), Handbook of Aluminum, Physical Metallurgy and Processes, Boca Raton, 591-641 (2003).

- [9] M. Fujda, O. Milkovič, M. Vojtko, T. Kvačkaj, T. Donič, Metallurgical Journal 62, 1, 14-19 (2009).

- [10] M. Matvija, M. Fujda, M. Vojtko, R. Kočiško, Acta Metallurgica Slovaca - Conference 3, 75-81 (2013).

- [11] E. Sjölander, S. Seifeddine, Journal of Materials Processing Technology 210, 1249-1259 (2010).

Expert Q&A: Your Top Questions Answered

Q1: Why was a comparative analysis between "suitable" and "non-suitable" castings chosen for this study?

A1: A comparative analysis was the most direct method to isolate the specific microstructural variables responsible for the failure. By examining a "good" part alongside a "bad" part from the same production process, researchers could eliminate common variables and focus on the subtle differences—like intermetallic morphology and particle density—that ultimately determined the casting's performance.

Q2: The paper mentions cracks propagate along intermetallic phases. What was the specific morphology of these phases in the failed casting?

A2: As shown in Figure 3, the intermetallic particles in the non-suitable (failed) casting were characterized as having a needle-like and blocky morphology with sharp edges. This shape creates a high notch effect, acting as a stress concentrator within the microstructure and providing an easy path for cracks to initiate and propagate under load.

Q3: What evidence suggests that the heat treatment process was different between the two castings?

A3: The study presents two key pieces of evidence. First, the intermetallic particles in the non-suitable casting were sharp and needle-like, while they were rounded and rod-like in the suitable one, indicating insufficient time and/or temperature for spheroidization. Second, this was supported by the lower hardness value of 105.7 HV10 in the defective casting versus 112.0 HV10 in the sound one, which directly reflects the less-optimized microstructure.

Q4: What does the paper identify as the root cause of the initial microtears that form before heat treatment?

A4: The paper concludes that the initial defects are microtears that form during solidification. These are caused by thermal or mechanical resistance that prevents the casting from shrinking freely. This resistance can stem from several process factors, including an insufficient or non-uniform mold temperature, or physical resistance from the mold itself as the casting cools and contracts.

Q5: What was the chemical composition of the detrimental intermetallic particles found in the castings?

A5: According to the EDX analysis shown in Figure 5, the sharp, needle-like intermetallic particles in the non-suitable casting were identified as being on the Al-Si-Fe-Mn-base and Al-Si-Fe-Mn-Ni(Cr)-base. The presence of iron and manganese is typical in these alloys, but their precipitation into sharp morphologies is highly detrimental to mechanical properties.

Conclusion: Paving the Way for Higher Quality and Productivity

This investigation provides a clear and actionable diagnosis for a common and costly problem in the production of high-performance AlSi5Cu3 Alloy Castings. The root cause of failure was not a single issue, but a combination of stresses during solidification creating microtears, followed by an inconsistent heat treatment that failed to heal the microstructure. The presence of sharp, needle-like intermetallic phases served as the final pathway for catastrophic crack propagation.

The key takeaway for any manufacturer is that precise control over both the casting and heat treatment stages is non-negotiable. Ensuring uniform mold temperatures, managing solidification stresses, and verifying heat treatment cycles are critical steps to producing reliable, high-strength components and avoiding costly field failures.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

- This content is a summary and analysis based on the paper "EVALUATION OF CRACKING CAUSES OF AlSi5Cu3 ALLOY CASTINGS" by "Š. EPERJEŠI, M. MATVIJA, L. EPERJEŠI, M. VOJTKO".

- Source: https://doi.org/10.2478/amm-2014-0187

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.