Unlocking Peak Performance in AZ91 Magnesium Alloy HPDC: A Guide to Optimizing Process Parameters

This technical summary is based on the academic paper "Effects of process parameters on mechanical and metallurgical properties in high pressure die casting of AZ91 magnesium alloy" by Ali Serdar Vanli & Anil Akdogan*, published in Indian Journal of Engineering & Materials Sciences (2019).

Keywords

- Primary Keyword: AZ91 Magnesium Alloy HPDC

- Secondary Keywords: High Pressure Die Casting, Magnesium Alloys, Process Optimization, Mechanical Properties, Metallurgical Properties, Product Quality, Porosity Reduction

Executive Summary

- The Challenge: The widespread use of AZ91 magnesium alloy in High Pressure Die Casting (HPDC) is often hampered by defects and inconsistent mechanical performance in finished parts.

- The Method: The study employed a Taguchi L27 experimental design on an industrial-scale cold chamber HPDC line to systematically optimize five critical process parameters.

- The Key Breakthrough: A specific set of optimal process parameters was identified that consistently produces AZ91 castings with high mechanical strength, high density, and low porosity.

- The Bottom Line: By implementing these precise parameters, manufacturers can minimize defects, improve part quality, and unlock the full performance potential of AZ91 magnesium alloy in demanding applications.

The Challenge: Why This Research Matters for HPDC Professionals

Magnesium alloys like AZ91 are highly sought after in the automotive, aerospace, and electronics industries for their exceptional lightness and strength. High Pressure Die Casting (HPDC) is a leading method for manufacturing complex Mg alloy parts, but it's a precise process where slight variations can lead to significant problems. Many manufacturers experience low mechanical and metallurgical performance in their casting products due to defects that arise under heavy working conditions.

While the industry knows that process parameters are key, there is a wide and often conflicting range of suggested settings in existing literature. This ambiguity makes it difficult to reliably produce high-performance parts. This research addresses this critical knowledge gap by moving beyond theory to conduct experiments on an industrial-scale mass production line, aiming to define a clear, optimized process window for achieving superior product quality.

The Approach: Unpacking the Methodology

The researchers conducted a rigorous experimental study to isolate the most effective process parameters for HPDC of AZ91 magnesium alloy. The methodology was designed to reflect real-world industrial production, ensuring the findings are directly applicable.

Method 1: Industrial-Scale HPDC Setup

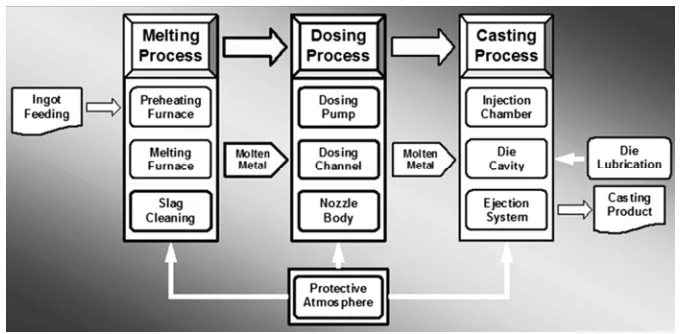

The experiment was performed on a complete production line featuring a METAL PRES MP100 cold chamber HPDC machine. The system included a MELTEC MDF-200C electrical resistance crucible furnace for melting, a dosing system, and a gas mixing unit for creating a protective atmosphere. The die, made from AISI H13 tool steel, was designed with four cavities to produce standardized cylindrical tensile test samples (per ASTM B557M-15).

Method 2: Taguchi Experimental Design

To efficiently test multiple variables, a Taguchi L27 orthogonal experimental design was used. This statistical method allowed for the systematic analysis of five key process parameters, each at three distinct levels:

- Bath Temperature: 640°C, 660°C, 680°C

- Die Temperature (Cover/Ejector): 150/200°C, 175/225°C, 200/250°C

- Protective Gas (N₂+SF₆) Concentration: 0.20 vol%, 0.25 vol%, 0.30 vol%

- Intensification Pressure: 80 MPa, 100 MPa, 120 MPa

- Gate Velocity: 30 m.s⁻¹, 45 m.s⁻¹, 60 m.s⁻¹

Method 3: Comprehensive Material Analysis

The resulting cast samples from 27 distinct experimental runs were subjected to extensive testing to evaluate their quality. This included tensile tests (for yield strength, tensile strength, elongation), Brinell hardness tests, density measurements (using Archimedes' principle to calculate porosity), and detailed metallurgical analysis using optical microscopy, Scanning Electron Microscopy (SEM), Energy-Dispersive X-ray Spectroscopy (EDS), and X-ray Diffraction (XRD).

The Breakthrough: Key Findings & Data

The experimental results provided a clear and actionable "recipe" for optimizing the HPDC process for AZ91 alloy. The analysis focused on identifying the parameter levels that maximized mechanical properties and density.

Finding 1: The Optimal "Recipe" for High-Performance AZ91 Castings

Through analysis of the Signal-to-Noise (S/N) ratios, the study identified a single combination of parameters that produced the best overall results. As detailed in the "Main effect plots for S/N ratios" (Figure 4), the optimal process parameters are:

- Bath Temperature: 660°C (Level 2)

- Die Temperature: 200/250°C (Level 3)

- Protective Gas Concentration: 0.30 vol% (Level 3)

- Intensification Pressure: 120 MPa (Level 3)

- Gate Velocity: 30 m.s⁻¹ (Level 1)

Confirmation tests run with these optimal settings, shown in Table 5, produced parts with an average tensile strength of 233.21 MPa, a yield strength of 145.79 MPa, an elongation of 6.52%, and a density of 1.78 g.cm⁻³.

Finding 2: Gate Velocity is the Most Influential Factor on Product Quality

The statistical analysis revealed a clear hierarchy of influence among the tested parameters. As shown in the "Effectiveness rank of the process parameters" in Table 4, gate velocity was determined to be the most effective parameter impacting the mechanical properties of the final product. The study found that the lowest tested gate velocity (30 m.s⁻¹) produced the best results. This is because lower velocities allow air to be evacuated from the die cavity more effectively, preventing air entrapment and the formation of macro gas porosity, which are common and detrimental defects in HPDC parts.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting gate velocity to the lower end of the operational window (specifically 30 m.s⁻¹) may contribute to a significant reduction in gas porosity. Furthermore, utilizing a high intensification pressure (120 MPa) is critical for preventing shrinkage porosity and achieving a stronger material structure.

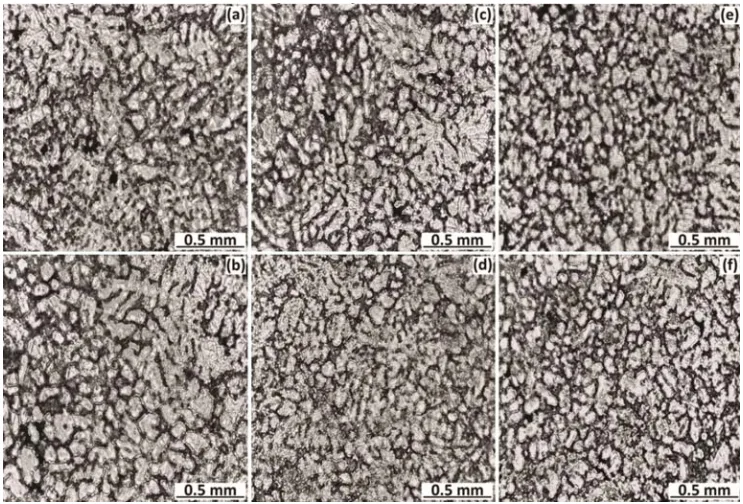

- For Quality Control Teams: The data in Table 5 provides a new quality benchmark for AZ91 components: average values of 66 HB hardness, 1.78 g.cm⁻³ density, and less than 2% porosity. The optical microscope images in Figure 5 clearly illustrate the correlation between finer grain structures and higher tensile strength, which could inform new microstructural inspection criteria.

- For Design Engineers: The findings underscore that process limitations must be considered during the design phase. The critical role of low gate velocity suggests that the design of the gating system is paramount to achieving defect-free parts. Aiming for designs that facilitate a gate velocity of around 30 m.s⁻¹ can prevent porosity issues from being engineered into the component.

Paper Details

Effects of process parameters on mechanical and metallurgical properties in high pressure die casting of AZ91 magnesium alloy

1. Overview:

- Title: Effects of process parameters on mechanical and metallurgical properties in high pressure die casting of AZ91 magnesium alloy

- Author: Ali Serdar Vanli & Anil Akdogan

- Year of publication: 2019

- Journal/academic society of publication: Indian Journal of Engineering & Materials Sciences

- Keywords: Magnesium alloys, High pressure die casting, Optimum process parameters, Mechanical and metallurgical properties, Product quality

2. Abstract:

High pressure die casting (HPDC) of magnesium (Mg) alloys has been the fastest grown up and the most globally developed section in magnesium industry. HPDC of complex shape Mg alloy products have increased considerably in recent years. But low mechanical and metallurgical performance of the casting products could be experienced due to defects in HPDC of Mg alloy parts under heavy working conditions. Process technologies should be modified and process parameters need to be optimized for the use of Mg based alloy products as high performance casting parts. The correct selection of the process parameters means the correct manufacturing of the casting parts. There is a wide range of suggested process parameters for HPDC of different Mg alloys in the literature. This paper specifies optimum process parameters for the required mechanical and metallurgical properties of the die casting parts, experimentally. Experimental tests are performed by using Taguchi experimental procedure to determine the optimum process parameters in cold chamber HPDC of Mg alloy parts. Confirmation and statistical analyzing tests have confirmed the results. The results minimize the available range of process parameters in the literature for high mechanical properties and low porosity content of casting products by conducting the designed experiments in an industrial scale mass production line considering the product quality.

3. Introduction:

Magnesium (Mg) alloys are widely used in sectors such as automotive, aerospace, and electronics due to their favorable characteristics like lightness and strength. High pressure die casting (HPDC) of Mg alloys has seen significant global development. However, factors including product design, die construction, and various process parameters can negatively affect product quality and mechanical properties. The high affinity of Mg for oxygen necessitates the use of gas protection systems during melting to prevent exothermic reactions. This paper aims to address the wide range of suggested process parameters in existing literature by experimentally specifying the optimum parameters for achieving high mechanical and metallurgical properties in die-cast parts. The goal is to minimize the process parameter range for an industrial-scale mass production system, thereby improving product quality.

4. Summary of the study:

Background of the research topic:

The research is set against the backdrop of the increasing industrial application of HPDC for complex-shaped magnesium alloy products. Despite its growth, the process is challenged by defects that lead to low mechanical and metallurgical performance, particularly in parts subjected to heavy working conditions. This necessitates the modification of process technologies and the optimization of process parameters.

Status of previous research:

The literature presents a wide range of suggested process parameters for the die casting of different Mg alloys. This study acknowledges the value of previous academic research correlating process parameters and mechanical properties but identifies a need to narrow down this broad range of parameters for practical application in an industrial mass production setting.

Purpose of the study:

The primary purpose of this study is to experimentally determine and specify the optimum process parameters for the cold chamber HPDC of AZ91 magnesium alloy. The objective is to achieve high mechanical and metallurgical properties, low porosity content, and high product quality, thereby minimizing the available range of process parameters suggested in the literature.

Core study:

The core of the study involved conducting a series of designed experiments on an industrial-scale HPDC production line. Using a Taguchi L27 orthogonal array, the effects of five key process parameters—bath temperature, die temperature, protective gas concentration, intensification pressure, and gate velocity—were investigated. The resulting AZ91 alloy cast samples were subjected to comprehensive testing to determine their physical, mechanical, metallurgical, and geometrical properties. The results were analyzed statistically to identify the optimal parameter settings and their relative influence on product quality.

5. Research Methodology

Research Design:

The study employed the Taguchi experimental design method, specifically an L27 orthogonal array, to investigate the effects of five process parameters at three levels each. This approach allows for an efficient and systematic analysis of parameter influence on the final product quality. The "larger is better" approach for the signal/noise (S/N) ratio was used to determine the optimum parameters that yield maximum density, elongation, and mechanical strength.

Data Collection and Analysis Methods:

Standardized cylindrical tensile test samples were manufactured using a cold chamber HPDC machine with AZ91 magnesium alloy. Data was collected through a series of tests:

- Mechanical Testing: Tensile tests (Shimadzu AG-X, 100 kN) to measure elongation, yield, and tensile strengths; Brinell hardness tests (Zwick Roell, ZHU/2.5).

- Physical Testing: Density measurements based on Archimedes' principle to calculate porosity percentage.

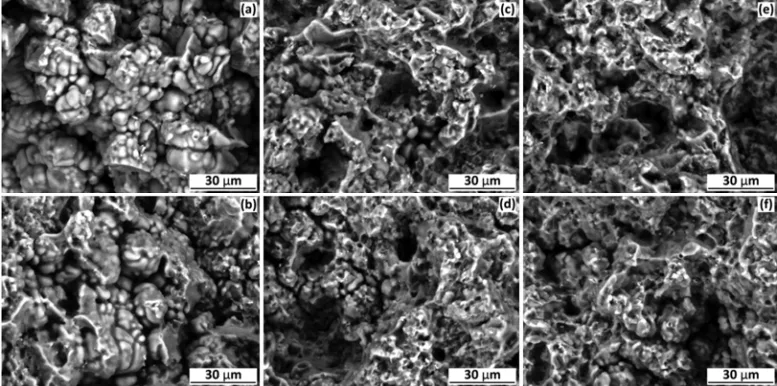

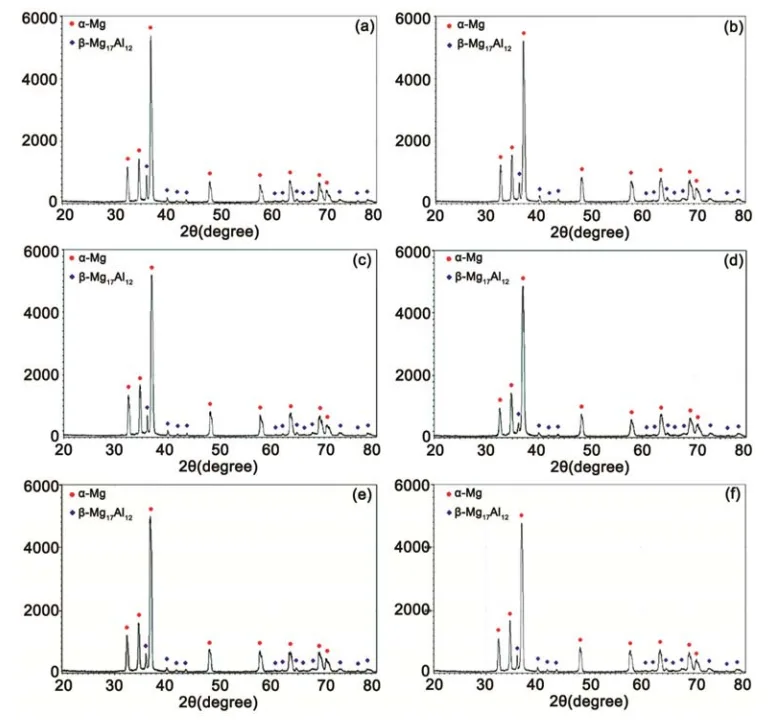

- Metallurgical Analysis: Optical microscopy (Leica, DM 750M) for microstructure and grain size analysis; Scanning Electron Microscopy (Hitachi, TM1000) for fractured surface examination; and EDS and XRD for chemical and phase composition analysis.

Statistical analysis, including S/N ratio analysis and ANOVA, was performed using Minitab 16.1.1 software.

Research Topics and Scope:

The research is focused on the high pressure die casting of AZ91 magnesium alloy. The scope is limited to the investigation of five specific process parameters:

1. Bath temperature: 640, 660, 680 °C

2. Die temperature (Cover/Ejector): 150/200, 175/225, 200/250 °C

3. Protective gas concentration (N₂+SF₆): 0.20, 0.25, 0.30 vol%

4. Intensification pressure: 80, 100, 120 MPa

5. Gate velocity: 30, 45, 60 m.s⁻¹

The response factors measured were density, diameter, elongation, yield strength, and tensile strength.

6. Key Results:

Key Results:

- The optimum process parameters for HPDC of AZ91 alloy were determined as: 660°C for bath temperature, 200/250°C for die temperature, 0.30 vol% for protective gas concentration, 120 MPa for intensification pressure, and 30 m.s⁻¹ for gate velocity.

- Samples manufactured with these optimum parameters exhibited an average density of 1.78 g.cm⁻³, 66 HB hardness, less than 2% porosity, ±0.04 mm dimensional tolerances, a maximum yield strength of 157 MPa, and a maximum ultimate tensile strength of 248 MPa with 7.67% elongation.

- The effectiveness rank of process parameters on mechanical properties, determined by S/N ratio analysis, was: (1) Gate Velocity, (2) Bath Temperature, (3) Intensification Pressure, (4) Gas Concentration, (5) Die Temperature.

- ANOVA results confirmed that gate velocity is the most statistically significant factor affecting the yield strength of the cast parts.

- Metallurgical analysis revealed that higher strength samples possessed finer grain structures. The fracture mechanism was identified as inter-crystalline semi-ductile fracture, occurring at the brittle β-Mg₁₇Al₁₂ intermetallic phase along the grain boundaries.

Figure Name List:

- Fig. 1 — The detailed flow chart of the HPDC production line

- Fig. 2 — Schematic drawing of the integrated system components (a) control panel, (b) HPDC machine, (c) melting furnace and (d) gas mixing unit

- Fig. 3 — Technical drawing of the die casting mold (a) front view and (b) side view

- Fig. 4 — Main effect plots for S/N ratios indicating the optimum process parameter levelsas the maximum points (a) bath temperature, (b) die temperature, (c) gas concentration, (d) intensification pressure and (e) gate velocity

- Fig. 5— Optical microscope images of the die cast parts (500X) (a) Run 5, (b) Run 9, (c) Run 18, (d) Run 20, (e) Run 11 and (f) Run 24

- Fig. 6 — SEM images of the fractured surface of the die casting parts (3000X) (a) Run 5, (b) Run 9, (c) Run 18, (d) Run 20, (e) Run 11 and (f) Run 24

- Fig. 7—XRD graphical analysis of the die casting parts Run 5, (b) Run 9, (c) Run 18, (d) Run 20, (e) Run 11 and (f) Run 24

7. Conclusion:

The study successfully identified the optimum process parameters for high-performance HPDC of AZ91 magnesium alloy parts by evaluating their effect on physical, geometrical, mechanical, and metallurgical properties. The determined optimal parameters are 660°C bath temperature, 200/250°C die temperature, 0.30 vol% protective gas concentration, 120 MPa intensification pressure, and 30 m.s⁻¹ gate velocity. These settings result in minimal porosity, high mechanical strength, and high density. Gate velocity was found to be the most effective process parameter on product quality. The study concludes that all process parameters that increase the interface strength between the α-Mg and β-Mg₁₇Al₁₂ phases by refining α-Mg grains improve the mechanical properties of the cast parts. The findings are valuable and comparable to literature data, offering a promising basis for manufacturing high-quality Mg alloy products in the HPDC industry.

8. References:

1 Vanli A S, Optimization of the Process Parameters Effective on the Product Quality in High Pressure Die Casting of Magnesium Alloys, Ph.D. Thesis, Yildiz Technical University, Istanbul, 2013.

2 Vanli A S, in Proc IJAS 11, 4(19) (2011) 269.

3 Butler W A, Die Cast Eng, 3 (2006) 29.

4 Vanli A S, Akdogan A, Sonmez H, in Proc IJAS'10, 3(9) (2010) 320.

5 Gutman E M, Unigovski Y, Levkovich M, Koren Z, Aghion E & Dangur M, Mater Sci Eng, A234-236 (1997) 880.

6 El-Mahallawy N A, Taha M A, Pokora E & Klein F, J Mater Process Technol, 73 (1998) 125.

7 Mayer H, Papakyriacou M, Zettl B & Stanzl-Tschegga S E, Int J Fatigue, 25 (2003) 245.

8 Lee S G, Gokhale A M, Patel G L & Evans M, Mater Sci Eng, A427 (2006) 99.

9 Aghion E, Moscovitch N & Arnon A, Mater Sci Eng, A447 (2007) 341.

10 Dobrzanski L A, Tanski T, Cizek L & Brytan Z, J Mater Process Technol, 192-193 (2007) 567.

11 Xinghao D & Erlin Z, Mater Lett, 61(2007) p.2333.

12 Braszczyńska-Malik K N, Zawadzki I, Walczak W & Braszczyński J, Arch Foundry Eng, 4 (2008) 15.

13 Dargusch M S, Easton M A, Zhu S M & Wang G, Mater Sci Eng, A523 (2009) 282.

14 Hu L, Chen S, Miao Y & Meng Q, Appl Surf Sci, 261 (2012) 851.

15 Vanli A S, Investigation of the Process Parameters in High Pressure Die Casting of Magnesium Alloys, M.Sc. Thesis, Yildiz Technical University, Istanbul, 2007.

16 Pettersen G, Qvrelid E, Tranell G, Fenstad J & Gjestland H, Mater Sci Eng, A332 (2002) 285.

17 Ha W & Kim Y J, J Alloys Compnds, 422 (2006) 208.

18 Chen, H.: Materials Characterization, 61, 2010, p.894.

19 Zhao L, Liu J R, Chen H K & Huang W D, J Alloys Compnds, 480 (2009) 711.

20 Kaufmann H, Uggowitzer P J, Metallurgy and Processing of High-Integrity Light Metal Pressure Castings, (Scihele & Schön, Berlin), 2007.

21 ASTM B94-13, Standard Specification for Magnesium-Alloy Die Castings, (ASTM International, Pennsylvania), 2013.

22 ASM Specialty Handbook: Magnesium and Magnesium Alloys, (ASM International Handbook Committee, Ohio), 1999.

23 Friedrich H E & Mordike B L, Magnesium Technology: Metallurgy, Design Data, Applications, (Springer, Berlin), 2006.

24 Kainer K U, Magnesium - Alloys and Technologies, (Wiley, Weinheim), 2003.

25 ASTM B557M-15: Standard Test Methods for Tension Testing Wrought and Cast Aluminium and Magnesium-Alloy Products, (ASTM Int, Pennsylvania), 2015.

26 Fowlkes Y & Creveling C M, Engineering Methods for Robust Product Design, Using Taguchi Methods in Technology and Product Development, (Addison-Wisley, New Jersey), 1995.

27 ASTM E10-15a: Standard Test Method for Brinell Hardness of Metallic Materials, (ASTM Int, Pennsylvania), 2016.

28 ASM Handbook: Metallography and Microstructures, (ASM Int Handbook Committee, Ohio), vol 9, 1990.

29 Brandes E A, Brook G B, Smithells Light Metals Handbook, (Cornwall, Butterworth-Heinemann), 1998.

30 Moreno I P, Nandy T K, Jones J W, Allison J E & Pollock T M, Scr Mater, 45 (2001) 1423.

31 Mayer H, Papakyriacou M, Zettl B, Stanzl-Tschegga S E, Int J Fatigue, 25 (2003) 245.

32 Prakash D G L & Regener D, J Alloys Compnds, 461 (2008) 139.

33 Bertram A, Tomas J, Micro-Macro Interactions: in Structured Media and Particle Systems, (Springer, Berlin), 2008.

34 Dargusch M S, Nave M, McDonald S D & John D H, J Alloys Compnds, 492 (2010) 64.

Expert Q&A: Your Top Questions Answered

Q1: Why was the Taguchi method chosen for this experiment over other experimental designs?

A1: The Taguchi method was selected because it is a highly efficient statistical tool for optimizing manufacturing processes. It allows for the study of the inherent variability of materials and processes by analyzing multiple parameters and their interactions with a relatively small number of experimental runs (27 in this case). This makes it ideal for an industrial setting where minimizing production downtime and material usage for experiments is critical.

Q2: What is the specific role of the N₂+SF₆ protective gas mixture, and why is it important?

A2: Molten magnesium has a very high affinity for oxygen and can react exothermally and uncontrollably with air. The N₂+SF₆ gas mixture is a "fluxless" protective atmosphere that creates a stable, thin film on the surface of the molten metal. This film prevents direct contact with oxygen, thereby suppressing oxidation and ensuring a safer, more controlled melting and dosing process, which is essential for producing high-quality castings.

Q3: The paper identifies gate velocity as the most critical parameter. Why does a lower gate velocity (30 m.s⁻¹) yield better results than a higher one?

A3: A lower gate velocity is crucial for minimizing defects related to gas entrapment. When the molten metal enters the die cavity at a very high speed, it can cause turbulence, trapping air inside the die which then forms gas porosity in the solidified part. The suggested lower velocity of 30 m.s⁻¹ allows for a more orderly fill, helping to evacuate the air from the die cavity through vents just before solidification begins, resulting in a denser, more solid casting.

Q4: How does increasing the die temperature to 200/250°C improve the final casting?

A4: A higher die temperature (200/250°C) delays the onset of solidification of the molten metal on the die cavity surfaces. This delay is beneficial because it extends the time window during which the third-phase intensification pressure can be effectively applied. This prolonged pressure application helps to feed molten metal into areas that are shrinking during cooling, significantly reducing shrinkage porosity and leading to a stronger, more sound part.

Q5: The study mentions that fracture occurs at the β-Mg₁₇Al₁₂ intermetallic phase. What does this imply about the material's failure mode?

A5: This finding indicates that the β-Mg₁₇Al₁₂ phase, which forms at the grain boundaries, is the weakest link in the microstructure. This phase is inherently more brittle than the primary α-Mg matrix. The fracture initiating and propagating along these boundaries is characteristic of an inter-crystalline failure. Therefore, any process parameter adjustments that refine the grain structure and strengthen the interface between these two phases will improve the overall mechanical properties of the alloy.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of producing defect-free, high-performance magnesium components is a constant in the HPDC industry. This research cuts through the ambiguity of process control by providing a clear, experimentally-validated roadmap for AZ91 Magnesium Alloy HPDC. The key breakthrough is the identification of an optimal set of five process parameters—most critically, a low gate velocity of 30 m.s⁻¹—that work in concert to reduce porosity and significantly enhance mechanical strength. These findings empower engineers to move from trial-and-error to a data-driven approach for process optimization.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Effects of process parameters on mechanical and metallurgical properties in high pressure die casting of AZ91 magnesium alloy" by "Ali Serdar Vanli & Anil Akdogan".

Source: Indian Journal of Engineering & Materials Sciences, Vol. 26, Feb 2019, pp. 27-35 (http://nopr.niscair.res.in/handle/123456789/46599)

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.