- Marcin BrzezińskiAGH University of Krakow, Al. A. Mickiewicza 30, 30-059, Krakow https://orcid.org/0000-0002-3989-3657

- Jakub WiśniowskiAGH University of Krakow, Al. A. Mickiewicza 30, 30-059 Krakow, Poland / Limatherm S.A., ul. Tarnowska 1, 34-600 Limanowa, Poland https://orcid.org/0009-0004-6107-0923

DOI:

https://doi.org/10.7494/jcme.2023.7.3.27

ABSTRACT

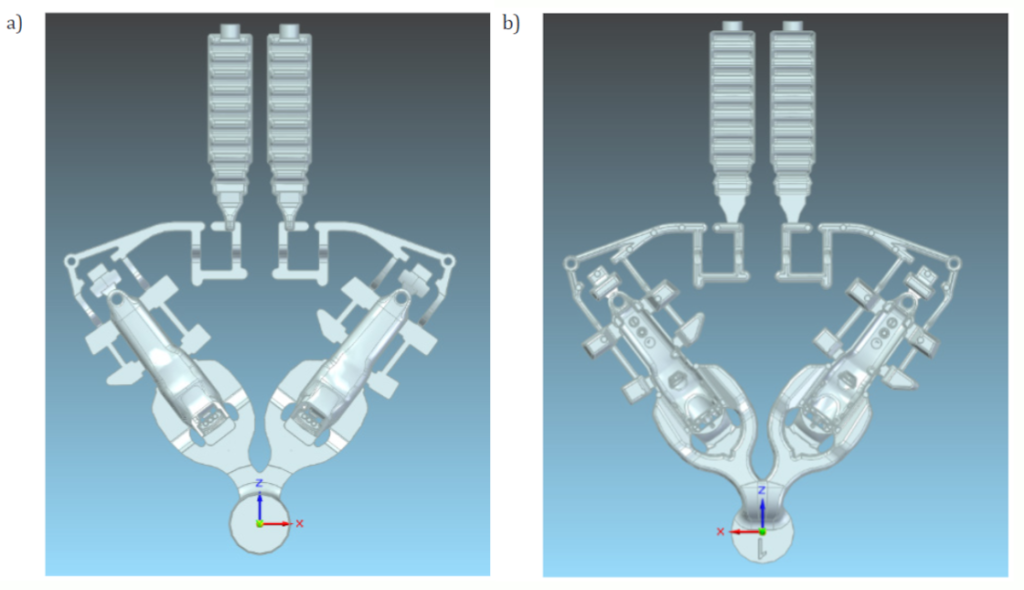

This article presents an analysis of the effect of cavitation on the erosion of pressure moulds intended for the HPDC casting mould manufacturing process. Changes in the surface area of the eroded areas were investigated via photographs of castings at the beginning of the mould life as well as at 30%. The individual process variables were described and their influence verified via the cavitation potential module of the Flow3D simulation programme. The results are presented graphically with a description of the relationships and observations. The summary provides an explanation of the results and the dependencies that occurred.

DOWNLOADS

REFERENCES

Sobczak J., Balcer E. & Kryczek A. (2018). Odlewnictwo w kraju i na świecie – status quo i tendencje rozwojowe. Przegląd Odlewnictwa, 68(1–2), 8–14.

Census of World Casting Production. Global Casting Production Growth Stalls (2017). Modern Casting, 24–28.

Sawicki J., Górecki M., Kaczmarek Ł. & Świniarski J. (2013). Numerical analysis of stresses in mould in the process of pressure casting, Biuletyn WAT, 42(2), 33–41.

Zinc Die Casting Manufacturer & Supplier. Retrieved from: https://www.dycastspec.com/blog/common-defects-in-high-pressure-die-casting/ [accessed: 29.05.2023].

Aluminum Die Casting Defects: Causes & Solutions (2023). Retrieved from: https://castingod.com/aluminum-die-casting-defects-causes-solutions-2023/ [accessed: 29.05.2023].

Fiorese E., Bonollo F., Timelli G., Arnberg L. & Gariboldi E. (2015). New Classification of Defects and Imperfections for Aluminum Alloy Castings. International Journal of Metalcasting, 9(1), 55–66. Doi: https://doi.org/10.1007/BF03355602.

Dańko J. (2000). Maszyny i urządzenia do odlewania pod ciśnieniem. Uczelniane Wydawnictwa Naukowo-Dydaktyczne AGH, Kraków.

Kowalczyk W. & Dańko R. (2013). Nowe kierunki i rozwiązania w konstrukcji zimnokomorowych maszyn ciśnieniowych nowej generacji. Archives of Foundry Engineering, 13(spec. iss. 3), 83–88.

Dańko R., Dańko J. & Stojek J. (2015). Experiments on the model testing of the 2nd phase of die casting process compared with the results of numerical simulation. Archives of Foundry Engineering, 15(4), 21–24. Doi: https://doi.org/10.1515/afe-2015-0072.

Koya E. & Nakagawa M. (2018). Influence of defects on HPDC strength and effectiveness of gas porosity by atomize flow. Congress Proceedings 73rd World Foundry Congress, Kraków.

Dong X., Zhu X. & Ji S. (2019). Effect of super vacuum assisted high pressure die casting on the repeatability of mechanical properties of Al-Si-Mg-Mn die-cast alloys. Journal of Materials Processing Technology, 266, 105–113. Doi: https://doi.org/10.1016/j.jmatprotec.2018.10.030.

Kowalczyk W. & Dańko R. (2017). Rola dokładności i powtarzalności ilościowej dozowania ciekłego stopu w zimnokomorowym procesie odlewania pod wysokim ciśnieniem. Przegląd Odlewnictwa, 67(1–2), 22–25.

Zyska A., Konopka Z., Łągiewka M. & Nadolski M. (2015). Porosity of castings produced by the vacuum assisted pressure die casting method, Archives of Foundry Engineering, 15(1), 125–130. Doi: https://doi.org/10.1515/afe-2015-0023.

Krella A.K. & Zakrzewska D.E. (2018). Cavitation erosion – phenomenon and test rigs. Advances in Materials Science, 18(2), 15–26. Doi: https://doi.org/10.1515/adms-2017-0028.

Grassivaro D. (2016). Application of cavitation models to study a real case of die erosion. Retrieved from: http://www.formstampi.it/media/EUC-2016_FORM-SRL.pdf [accessed: 29.05.2023].