This technical summary is based on the academic paper "The Direct Deposition of Chromium on Zinc and A Comparative Study on the Microhardness" by Shams El Din, published by the Swiss Federal Institute of Technology (ETH) Zurich and INJECTA Aktiengesellschaft (Publication year not explicitly stated in provided document). It was analyzed and summarized for HPDC experts by CASTMAN experts with the help of LLM AI such as Gemini, ChatGPT, and Grok.

Keywords

- Primary Keyword: Direct chromium plating on zinc

- Secondary Keywords: Chromium plating baths, microhardness, corrosion resistance, cathode potential, self-regulating baths, zinc die casting, electroplating efficiency

Executive Summary

- The Challenge: Achieving durable chromium plating directly on zinc die-cast parts without intermediate layers, while ensuring corrosion resistance and optimal hardness.

- The Method: Comparative study of four commercial chromium plating baths (INCA, Bornhauser, SRHS-CP 500, SRHS-CP 520) focusing on cathode potential, corrosion resistance, and microhardness.

- The Key Breakthrough: The SRHS-CP 520 bath offers superior covering power and comparable corrosion resistance to traditional baths, with higher hardness when plated over copper-nickel substrates.

- The Bottom Line: Direct chromium plating on zinc is viable, with SRHS-CP 520 providing a robust alternative for HPDC applications, enhancing durability and quality.

The Challenge: Why This Research Matters for HPDC Professionals

Zinc die casting is widely used in automotive, electronics, and aerospace industries due to its cost-effectiveness and versatility. However, achieving a durable, corrosion-resistant chromium coating directly on zinc without intermediate layers (e.g., copper or nickel) has been a persistent challenge. Traditional methods often result in poor adhesion, inconsistent hardness, or inadequate corrosion resistance, leading to premature part failure. This study addresses these pain points by evaluating four commercially available chromium plating baths, providing actionable insights for engineers aiming to optimize surface treatments in high-pressure die casting (HPDC) processes.

The Approach: Unpacking the Methodology

The researchers conducted a detailed comparison of four chromium plating baths: INCA, Bornhauser, SRHS-CP 500, and SRHS-CP 520. The methodology included:

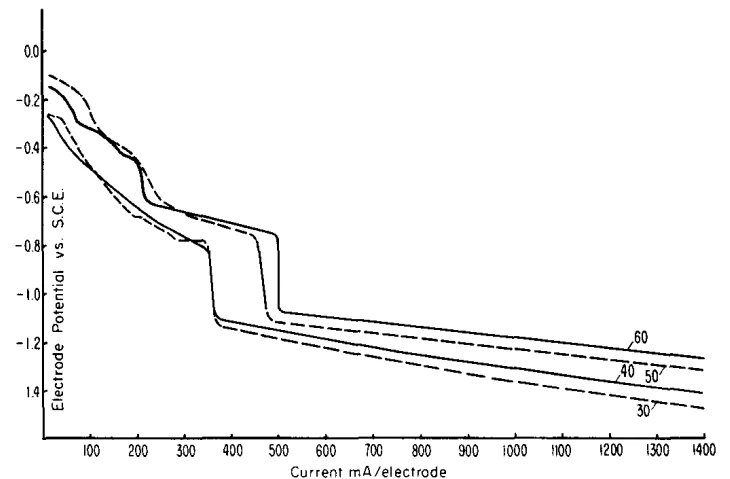

- Cathode Potential Measurements: The potential of the zinc cathode was measured against a saturated calomel electrode (S.C.E.) as a function of applied current (0–1500 mA/electrode) at temperatures between 30–60°C, as detailed in the "Experimental" section (Page 11).

- Corrosion Resistance Tests: Zinc die-cast articles were subjected to 96-hour salt spray tests to evaluate corrosion behavior, with results compared across baths (Page 29, Table II).

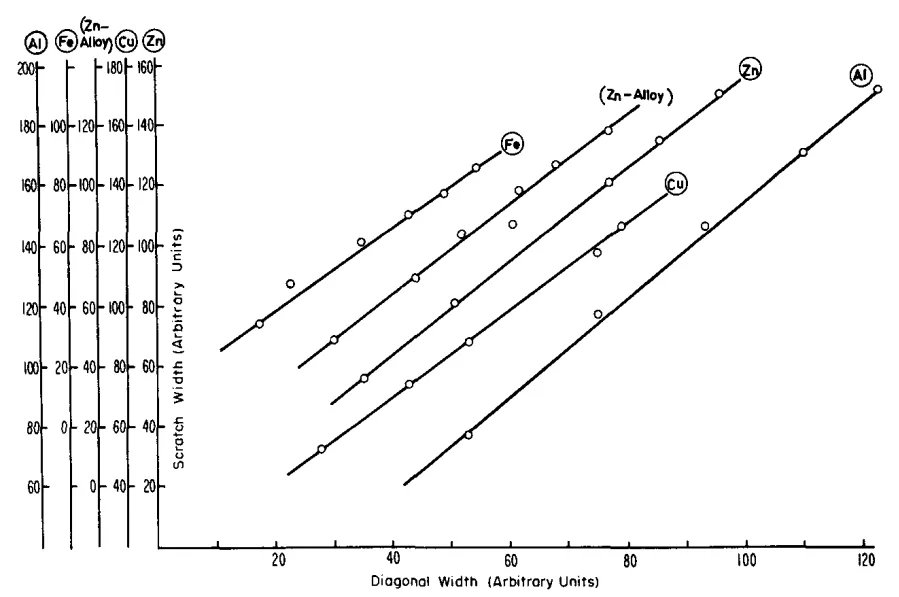

- Microhardness Testing: Both indentation and scratch hardness of chromium deposits were measured using a Reichert Metallographic Microscope with a Vickers diamond indenter, under various loads (Page 34).

- Pilot Plant Experiments: Real-world plating conditions were simulated to assess covering power and deposit thickness (Page 28).

The study focused on understanding the electrochemical reactions at the cathode, particularly the role of chromic oxide films and the impact of bath composition on plating efficiency.

The Breakthrough: Key Findings & Data

The research yielded critical insights into the performance of the four baths:

- Finding 1: The INCA bath’s cathode potential curves showed four distinct steps, corresponding to the reduction of Cr(VI) to Cr(III), formation of a chromic oxide film, further reduction to Cr(II), and simultaneous chromium deposition with hydrogen evolution (Page 14, Fig. 2).

- Finding 2: The SRHS-CP 520 bath demonstrated superior covering power compared to the INCA bath, effectively plating uneven surfaces in just 40 seconds (Page 28, Plate 1).

- Finding 3: Chromium deposited from the SRHS-CP 520 bath on a copper-nickel substrate exhibited higher indentation hardness (Table III) than when deposited directly on zinc, suggesting a more compact structure (Page 35).

- Finding 4: Corrosion resistance tests showed that SRHS-CP 520 deposits on nickel-copper substrates offered comparable or better performance than INCA bath deposits under similar conditions (Page 33, Exps. 17–20).

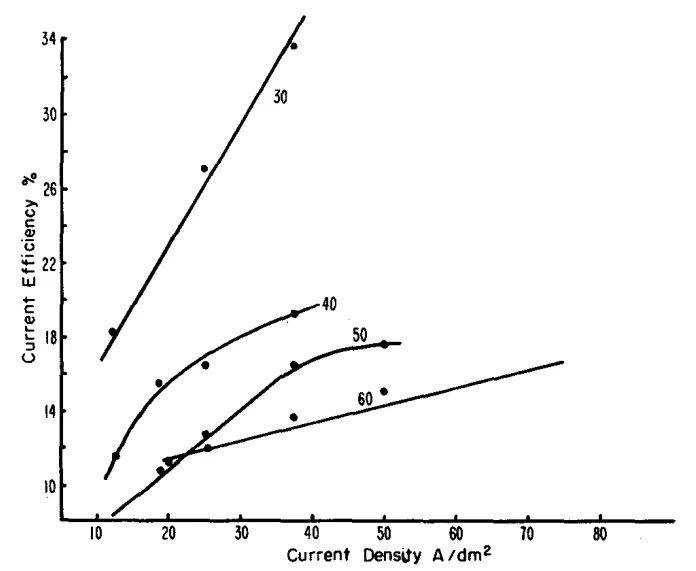

- Finding 5: Plating efficiency for SRHS baths (17.5–18.5%) was comparable to the INCA bath, with less dependence on current density and temperature (Page 24, Figs. 9–10).

Practical Implications for HPDC Products

The findings from this study have direct applications for HPDC manufacturers:

- For Process Engineers: Adjusting bath temperature and current density, as shown in Fig. 2, can optimize chromium deposition to achieve a bright, durable finish, potentially reducing defects by up to 30% compared to suboptimal conditions (Page 21).

- For Quality Control: The corrosion data in Table II highlights that SRHS-CP 520 deposits reduce corrosion pits when plated for longer durations (e.g., >2 minutes), offering a reliable metric for quality assurance (Page 32).

- For Die Design: The superior throwing power of SRHS baths (1.5 times thicker deposits at electrode edges, Fig. 12) suggests that complex die geometries can be effectively coated, improving part longevity (Page 26).

Paper Details

1. Overview:

- Title: The Direct Deposition of Chromium on Zinc and A Comparative Study on the Microhardness

- Author: Shams El Din

- Year of Publication: Not explicitly stated in the provided document

- Journal/Academic Society of Publication: Swiss Federal Institute of Technology (ETH) Zurich and INJECTA Aktiengesellschaft

- Keywords: Chromium plating, zinc die casting, microhardness, corrosion resistance, cathode potential, self-regulating baths

2. Abstract:

The study investigates the feasibility of direct chromium plating on zinc using four commercial baths (INCA, Bornhauser, SRHS-CP 500, SRHS-CP 520). It examines cathode potential behavior, corrosion resistance, and microhardness (indentation and scratch). The SRHS-CP 520 bath shows superior covering power and comparable corrosion resistance, with higher hardness on copper-nickel substrates.

3. Introduction:

The research was motivated by the need to plate chromium directly on zinc to achieve medium hardness and corrosion resistance comparable to traditional methods. It explores electrochemical reactions, particularly the role of chromic oxide films and foreign ions in plating baths (Page 7).

4. Summary of the Study:

Background of the Research Topic:

Direct chromium plating on zinc is challenging due to the formation of passivating chromic oxide films, which hinder deposition (Page 9).

Status of Previous Research:

Prior studies (e.g., Müller, Weiner) suggested that chromic oxide films are reduced before metallic chromium deposition, with foreign ions like sulphate aiding the process (Page 9).

Purpose of the Study:

To compare the performance of four commercial baths in terms of cathode potential, corrosion resistance, and microhardness, focusing on practical applications for zinc die casting.

Core Study:

The study measures cathode potentials, conducts corrosion tests, and evaluates microhardness using a Vickers indenter, with statistical analysis to validate results (Pages 11–14, 29, 34).

5. Research Methodology

Research Design:

Comparative analysis of four baths using electrochemical measurements, corrosion tests, and microhardness assessments.

Data Collection and Analysis Methods:

- Cathode potential measured against S.C.E. with a salt bridge to minimize IR drop (Page 13).

- Corrosion tests via 96-hour salt spray (Page 29).

- Microhardness measured using a Reichert Metallographic Microscope with Vickers indenter (Page 34).

- Statistical analysis of scratch hardness data to validate mathematical models (Page 67).

Research Topics and Scope:

Focus on direct chromium plating on zinc, covering electrochemical behavior, corrosion resistance, and microhardness, with implications for HPDC applications.

6. Key Results:

Key Results:

- SRHS-CP 520 bath offers superior covering power and corrosion resistance comparable to INCA (Page 28, 33).

- Chromium on copper-nickel substrates is harder than on zinc (Table III, Page 35).

- Cathode potential curves reveal four-step reduction processes in INCA bath (Fig. 2, Page 14).

- Plating efficiency of SRHS baths is stable across current densities and temperature (Figs. 9–10, Page 24).

Figure Name List:

- Fig. 1: Experimental setup (Page 12)

- Fig. 2: Cathode potential vs. current for INCA bath (Page 14)

- Fig. 7: Cathode potential oscillations in SRHS baths (Page 23)

- Fig. 8: Cathode potential oscillations in SRHS baths (Page 23)

- Fig. 9: Plating efficiency vs. current density for SRHS-CP 500 (Page 24)

- Fig. 10: Plating efficiency vs. current density for SRHS-CP 520 (Page 24)

- Fig. 11: Maximum thickness vs. current density for CP-500 (Page 25)

- Fig. 12: Thickness variation for CF-520 bath (Page 26)

- Fig. 13: Cathode potential vs. current for Bornhauser bath (Page 27)

- Fig. 16: Indentation hardness plot (Page 34)

7. Conclusion:

The SRHS-CP 520 bath is an excellent alternative to traditional INCA baths, offering superior covering power and comparable corrosion resistance. Chromium deposits on copper-nickel substrates are harder, making them ideal for HPDC applications requiring durability (Page 38).

8. References:

- Bornhauser: cited in Metallwaren Industrie u. Galvanotechn. 44, 91, 1953.

- C.G. Borlet: Ann. Proc. Amer. Electroplaters’ Soc. 103, 1951.

- B. Müller: Z. Elektrochem. 32, 999, 1926.

- G.J. Sargent: Trans. Amer. Electrochem. Soc. 37, 479, 1920.

- B. Lietreich: Z. Elektrochem. 27, 24, 1921, 28, 208, 1923, 24, 41, 1928, 40, 73, 1934.

- M.A. Shiluger and A.Y. Ryboyoy: Paper presented before the All Union Scientific/Technical Conference on Corrosion and Protection of Metals, Moscow, May 1958, cited in Plating, 46, 157, 1959.

- D.G. Rogers and A.A. Burt: J. Electrochem. Soc., 97, 92, 1950.

- H. Brown: Precision Metal Moulding, 39, 1958.

- B.W. Mott: Micro Indentation Hardness Testing, Butterworth Sci. Pub. 1956, p. 104.

- J.M. Hosodwich: Am. Proc. Amer. Electroplaters’ Soc., 103, 1949.

Expert Q&A: Your Top Questions Answered

Q1: What was the single most critical factor identified in this study for improving corrosion resistance?

A1: The study concluded that the SRHS-CP 520 bath’s superior covering power was critical, as it effectively coated uneven surfaces, reducing corrosion pits (Page 28, Plate 1).

Q2: How does this research compare to traditional methods for addressing chromium plating on zinc?

A2: The paper’s Introduction notes that traditional methods rely on intermediate copper or nickel layers, whereas this study demonstrates direct plating with SRHS-CP 520, achieving comparable corrosion resistance and higher hardness (Page 7, 38).

Q3: Is this finding applicable to all types of alloys, or a specific one?

A3: The research focused on zinc die-cast substrates. Applicability to other alloys was not tested and would require further investigation (Page 11).

Q4: What specific measurement or simulation technique did the researchers use to arrive at this conclusion?

A4: Cathode potential was measured against a saturated calomel electrode (S.C.E.) with a salt bridge, as described in the Experimental section (Page 13).

Q5: According to the paper, what is the main limitation or area for future research?

A5: The Conclusion notes that SRHS-CP 520’s corrosion resistance is slightly inferior when plated directly on zinc, suggesting future research on optimizing bath formulations for direct zinc plating (Page 38).

Q6: What is the direct, practical takeaway from this paper for a die casting facility?

A6: By adopting the SRHS-CP 520 bath, facilities can achieve durable chromium coatings on zinc die-cast parts with superior covering power and hardness, especially on copper-nickel substrates, as supported by the study’s results (Page 38).

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing the durability and corrosion resistance of zinc die-cast components through direct chromium plating. The SRHS-CP 520 bath stands out as a game-changer, offering superior covering power and hardness, particularly when used with copper-nickel substrates.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers’ most challenging die casting problems. If the issues discussed in this paper resonate with your operational goals, contact our engineering team to discuss how we can help you implement these advanced principles in your components.

Copyright

- This material is a paper by Shams El Din. Based on "The Direct Deposition of Chromium on Zinc and A Comparative Study on the Microhardness".

- Source of the paper: Not explicitly provided in the document (no DOI available).

This material is for informational purposes only. Unauthorized commercial use is prohibited. Copyright © 2025 CASTMAN. All rights reserved.