From Simulation to Reality: A Validated Model for Predicting Mechanical Properties in A356 Aluminum Castings

This technical summary is based on the academic paper "Development of a model for the prediction of mechanical properties for Al-Si-Mg castings" by C. Ransenigo, M. Tocci, C. Viscardi, M. Serafini, A. Pola, published in La Metallurgia Italiana (2022).

Keywords

- Primary Keyword: Predictive Modeling for Aluminum Castings

- Secondary Keywords: A356 Alloy, T6 Heat Treatment, Mechanical Properties, Casting Simulation, SDAS, Shrinkage Porosity, Low Pressure Die Casting (LPDC)

Executive Summary

- The Challenge: While casting simulation software can predict microstructure and defects, it typically does not provide reliable local mechanical strength values, making it difficult to optimize component design before production.

- The Method: Researchers investigated the microstructural and mechanical properties of an A356 alloy wheel, used casting simulation to predict parameters like Secondary Dendrite Arm Spacing (SDAS), and developed mathematical models to correlate these parameters with experimental tensile properties.

- The Key Breakthrough: The study produced and validated two distinct mathematical models: one for predicting Yield Strength (YS) based on SDAS, and a more innovative model for Ultimate Tensile Strength (UTS) that incorporates both SDAS and shrinkage porosity.

- The Bottom Line: These validated models allow engineers to accurately predict local mechanical properties throughout a casting directly from simulation data, enabling more effective design optimization and material exploitation before a single part is cast.

The Challenge: Why This Research Matters for HPDC Professionals

In the competitive world of automotive and structural components, using A356 aluminum alloy with a T6 heat treatment is standard practice to achieve a high strength-to-weight ratio. Casting simulation software like ProCAST® is an indispensable tool for predicting solidification, identifying potential defects like shrinkage porosity, and refining the casting process.

However, a critical gap remains. These powerful simulation tools often fall short of providing accurate, localized mechanical property values (like yield strength and tensile strength). This forces engineers to rely on assumptions or extensive, costly prototyping and testing. The ability to accurately predict the final mechanical behavior of a component before it's produced would be a game-changer, allowing for more aggressive design optimization, weight reduction, and faster development cycles. This research directly addresses that challenge by bridging the gap between simulation outputs and real-world mechanical performance.

The Approach: Unpacking the Methodology

The research team employed a robust, multi-stage methodology that combined physical experimentation with advanced simulation to ensure the developed models were grounded in real-world data.

Method 1: Experimental Characterization

- Material & Component: Two 22-inch wheels were produced from A356 aluminum alloy using the Low Pressure Die Casting (LPDC) process. One wheel was kept in the as-cast condition, while the other underwent a full T6 heat treatment (solution at 530°C, quenching, and aging at 146°C for 3 hours).

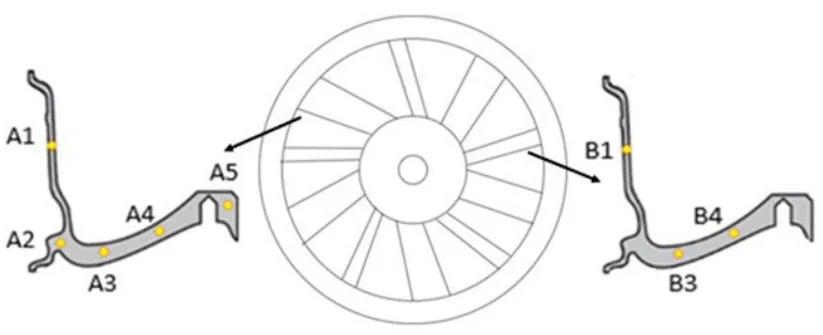

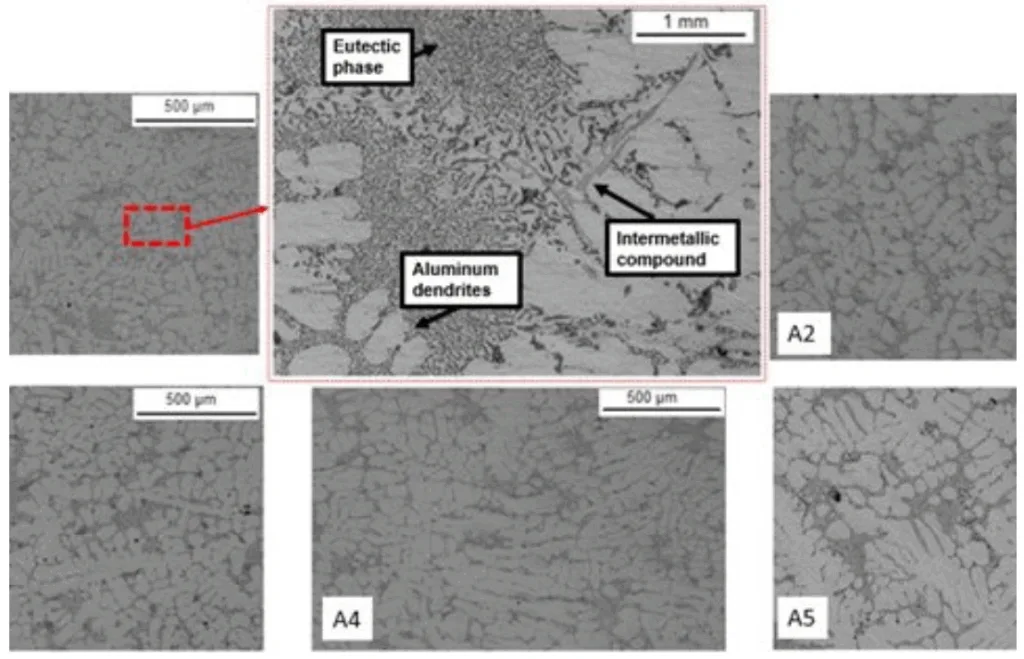

- Sampling & Analysis: Samples were taken from various locations on the wheels (rim, main spoke, minor spoke) to capture different thicknesses and cooling rates. These samples were analyzed for microstructure (specifically, Secondary Dendrite Arm Spacing - SDAS) using optical microscopy.

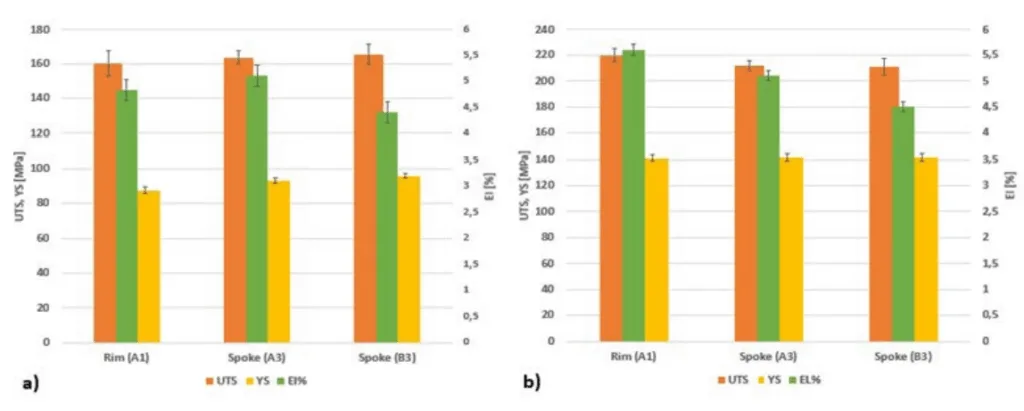

- Mechanical Testing: Tensile tests were performed on cylindrical specimens machined from the rim and spokes of both the as-cast and T6 wheels to determine experimental Yield Strength (YS), Ultimate Tensile Strength (UTS), and elongation.

Method 2: Casting Simulation & Model Development

- Simulation Setup: Using the commercial software ProCAST®, a complete casting simulation of the 22-inch wheel was created based on foundry parameters. The simulation provided outputs for SDAS, solidification time, and shrinkage porosity levels throughout the component.

- Model Formulation: The researchers started with established theoretical equations linking microstructure to mechanical properties. They then used the simulation-generated data (SDAS, porosity) and experimental tensile test results to define the specific coefficients for their predictive models, first for the as-cast condition and then extending it to the T6 condition.

The Breakthrough: Key Findings & Data

The study successfully developed and validated mathematical models for predicting both Yield Strength (YS) and Ultimate Tensile Strength (UTS) with remarkable accuracy.

Finding 1: A Reliable Model for Predicting Yield Strength (YS) from SDAS

The research confirmed that Yield Strength is primarily influenced by the microstructure, specifically the SDAS. By correlating simulation data with experimental results, they developed a precise equation for the as-cast condition.

YS = 31.6 + 16.4 * ln(ln(SDAS))

The model's predictions were validated against experimental tensile tests, showing a mean error of only about 2%. As shown in Table 2, the predicted YS for the rim (A1) was 86.9 MPa, closely matching the experimental value of 87.7 ± 2.1 MPa. A similar model was also proposed for the T6 condition.

Finding 2: An Innovative UTS Model Incorporating Shrinkage Porosity

The team recognized that Ultimate Tensile Strength is affected not only by microstructure (SDAS) but also by casting defects. Their most innovative contribution was developing a model that explicitly includes the level of shrinkage porosity, a value provided by the simulation software.

UTS = YS * (1 – 0.5 * %SHR. POROSITY) + (280 * 3 * e^(3.5/SDAS)) * (ln(ln(1 + El%/100)))^0.5

This more complex model provides a more accurate prediction of UTS by accounting for the strength reduction caused by defects. As detailed in Table 3, the validation was highly successful. For the main spoke (A3), the model predicted a UTS of 168.1 MPa, which is well within the experimental range of 163.6 ± 6.1 MPa. The maximum error between predicted and experimental values was less than the experimental standard deviation, confirming the model's validity.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that simulation results for SDAS and shrinkage porosity can be used to directly predict mechanical properties. This allows for process adjustments to be evaluated for their impact on final strength without running physical trials.

- For Quality Control Teams: The data in Table 1 and Table 2 of the paper illustrates the direct link between SDAS (a result of cooling conditions) and Yield Strength. This knowledge can inform where to focus quality inspections on complex parts, as areas with higher simulated SDAS are predicted to have lower YS.

- For Design Engineers: The findings, particularly the UTS model (Equation 5), provide a powerful tool for the design phase. Engineers can now use simulation not just to check for fill issues or porosity but to obtain a map of local mechanical properties, allowing them to confidently reduce thicknesses and remove weight in low-stress areas while reinforcing critical sections.

Paper Details

Development of a model for the prediction of mechanical properties for Al-Si-Mg castings

1. Overview:

- Title: Development of a model for the prediction of mechanical properties for Al-Si-Mg castings

- Author: C. Ransenigo, M. Tocci, C. Viscardi, M. Serafini, A. Pola

- Year of publication: 2022

- Journal/academic society of publication: La Metallurgia Italiana - International Journal of the Italian Association for Metallurgy

- Keywords: ALUMINUM, HEAT TREATMENT, SIMULATION, MODEL, CASTING

2. Abstract:

A356 alloy is widely used to produce structural components by means of Low Pressure Die Casting (LPDC) process. Generally, a T6 heat treatment is carried out to improve the strength of the casting. Nowadays, software simulation of casting processes is a common practice for designing sound components, but mechanical strength values and their correlation with microstructure parameters are not typically given. This study presents a model for the estimation of tensile as-cast properties based on casting simulation, validated on a 22'' wheel. Microstructural (SDAS) and mechanical properties were investigated in both as-cast and T6 conditions. Experimental data were used to verify the reliability of simulation results and to validate the as-cast model. Based on this, a mathematical model to predict the mechanical properties after T6 heat treatment was also proposed.

3. Introduction:

A356 is a widely used aluminum casting alloy due to its good castability, corrosion resistance, and high strength-to-weight ratio, making it suitable for automotive structural applications. A T6 heat treatment is generally applied to further increase strength. Casting simulation software is commonly used to improve casting quality by providing results on microstructure, defects like shrinkage porosity, and solidification phenomena. However, commercial casting software is not able to provide mechanical strength values before and after heat treatment. The ability to predict material behavior before producing the castings would be a precious tool. The aim of this work is to develop a mathematical model to predict the local mechanical strength of the casting from the main microstructural parameters.

4. Summary of the study:

Background of the research topic:

The use of A356 aluminum alloy in LPDC for structural components is well-established, as is the application of T6 heat treatment to enhance mechanical properties. Casting simulation software is a standard tool for process design, capable of predicting microstructural features and defects.

Status of previous research:

Previous research and commercial software have focused on predicting fluid flow, solidification, stresses, microstructures, and defects. However, a direct prediction of mechanical properties like yield strength and ultimate tensile strength from these simulation outputs is not a standard feature, representing a significant gap for component designers.

Purpose of the study:

The study's objective was to develop and validate a mathematical model capable of successfully predicting local mechanical strength (yield strength and ultimate tensile strength) of A356 castings from microstructural parameters obtained via casting simulation. The study aimed to create models for both as-cast and T6 heat-treated conditions.

Core study:

The core of the study involved a combined experimental and simulation-based approach. A 22'' LPDC A356 wheel was characterized in both as-cast and T6 states. Microstructural analysis (SDAS) and tensile testing were performed on samples from different locations. In parallel, a casting simulation of the wheel was conducted using ProCAST® software. The experimental SDAS data was first used to validate the simulation's accuracy. Then, simulation outputs (SDAS, shrinkage porosity) and experimental tensile data were used to develop and validate mathematical models for predicting yield strength and ultimate tensile strength.

5. Research Methodology

Research Design:

The research followed a validation-driven design. An initial experimental phase on a real industrial component (a 22'' wheel) provided baseline data on microstructure and mechanical properties. This data was then used to validate the outputs of a corresponding casting simulation. Finally, the validated simulation data and experimental results were synthesized to formulate and then validate predictive mathematical models.

Data Collection and Analysis Methods:

- Material: A356 aluminum alloy.

- Process: Low Pressure Die Casting (LPDC).

- Component: Two 22'' wheels (one as-cast, one T6 treated).

- Microstructural Analysis: Samples were taken from rim, spokes, and hub. Optical microscopy was used to observe the microstructure, and the linear intercept method was used to measure average Secondary Dendrite Arm Spacing (SDAS).

- Mechanical Testing: Brinell hardness tests and tensile tests (on an Instron 3369 machine) were performed on specimens from the rim and spokes to obtain yield strength (YS), ultimate tensile strength (UTS), and elongation (El%).

- Simulation: ProCAST® software was used to simulate the casting process, providing data on SDAS and shrinkage porosity.

Research Topics and Scope:

The research focused on A356 alloy cast via LPDC. The scope included:

1. Characterizing the microstructure (SDAS) and mechanical properties (YS, UTS) at different locations of a complex casting.

2. Validating the SDAS predictions of a commercial casting simulation software against experimental measurements.

3. Developing a mathematical model to predict YS as a function of SDAS for as-cast and T6 conditions.

4. Developing a mathematical model to predict UTS as a function of YS, SDAS, shrinkage porosity, and elongation for as-cast and T6 conditions.

5. Validating the proposed models using experimental tensile test data.

6. Key Results:

Key Results:

- A strong correlation was found between experimental SDAS values and those predicted by the casting simulation, validating the simulation's reliability (Table 1).

- A mathematical model to predict as-cast Yield Strength (YS) based on SDAS was developed:

YS = 31.6 + 16.4 * ln(ln(SDAS)). This model showed high accuracy, with a mean prediction error of approximately 2% when compared to experimental data (Table 2). - A model for T6 Yield Strength was also proposed:

YS = 135.6 + 1.67 * ln(ln(SDAS)). - An innovative model for Ultimate Tensile Strength (UTS) was developed that incorporates YS, SDAS, elongation (El%), and, crucially, the level of shrinkage porosity (%SHR.POROSITY) from the simulation.

- The UTS model was validated for the as-cast condition, with predicted values showing excellent agreement with experimental measurements. The maximum prediction error was lower than the experimental standard deviation, demonstrating the model's validity (Table 3).

Figure Name List:

- Fig.1 - Schematic representation of samples drawn from the two different spokes. For confidentiality reasons, the real wheel cannot be shown so a schematic representation is given.

- Fig.2 - Microstructure of each as cast sample. The central in-set shows the main microstructural constituents.

- Fig.3 - Tensile properties from as-cast (a) and T6 (b) wheels.

7. Conclusion:

The study successfully proposed and validated a mathematical model to predict the tensile behavior of A356 alloy for both as-cast and T6 conditions as a function of microstructural parameters. The yield strength was found to depend on SDAS, and a validated model was developed for the as-cast condition and extended to the T6 condition. The ultimate tensile strength was found to depend on SDAS, defect content, and tensile parameters. A new predictive equation, validated for the as-cast condition, was developed and proposed for T6 conditions as well. The good results suggest these models could be integrated into casting simulation software to provide local mechanical property distributions, aiding in the redesign and lightening of components to meet increasingly strict criteria.

8. References:

- [1] Kaufman J. G., Rooy E. L. Aluminium alloy castings, Properties, Processes and applications, ASM International; 2004.

- [2] Morri A. Correlations among microstructure, effect of thermal exposure and mechanical properties, in heat treated Al-Si-Mg and Al-Cu aluminium alloys. 2012; 1-2.

- [3] Abdullin A. D. New Capabilities of the ProCAST 2017 Software in Simulating Casting Processes. Metallurgist volume 61. 2017;433-438.

- [4] Ravi, B. Computer aided design and analysis for zero defects. International Conference on Aluminum. 2000; 1-6.

- [5] Aloe M., Lefebvre D., Mackenbrock A., Sholopurwalla A., Scott A. Advanced casting simulations. ESI Group, paper 30.

- [6] Chudasama B. J. Solidification Analysis and Optimization Using Pro-Cast. International Journal of Research in Modern Engineering and Emerging Technology, Vol. 1, Issue: 4. 2013

- [7] Shabani M. O., Mazaheri A. Prediction of Mechanical Properties of Cast A356 Alloy as a function of microstructure and cooling rate. Archives of Metallurgy and Materials, 2011; volume 56, issue 3.

- [8] Brusethaug S., Langsrud Y. Aluminum properties, a model for calculating mechanical properties in AlSiMgFe-foundry alloys. Metallurgical Science and Technology, Volume 18; 2000.

Expert Q&A: Your Top Questions Answered

Q1: Why was Secondary Dendrite Arm Spacing (SDAS) chosen as the primary microstructural parameter for the models?

A1: SDAS was chosen for two key reasons. First, as cited in the literature, yield strength is known to be mainly affected by microstructure, and SDAS is a direct and quantifiable measure of the fineness of that microstructure, which is controlled by the cooling rate during solidification. Second, and critically for practical application, SDAS is a standard output parameter provided by commercial casting simulation software like ProCAST®, making it a readily available input for a predictive model.

Q2: What is the most significant innovation in the Ultimate Tensile Strength (UTS) model presented in this paper?

A2: The most significant innovation is the inclusion of a shrinkage porosity term (%SHR.POROSITY) directly into the UTS equation. While standard models like the Ludwig model correlate UTS to yield strength and strain hardening, they do not account for casting defects. The authors found a clear correlation where higher shrinkage porosity led to lower mechanical strength. By incorporating this simulation-derived defect level into the model, they created a more accurate and realistic prediction of UTS in a real-world casting.

Q3: How were the models for the T6 heat-treated condition developed?

A3: The T6 models were developed as an extension of the validated as-cast models. The researchers used the same fundamental equation structures that were proven effective for the as-cast condition. They then exploited the experimental tensile test data obtained from the T6-treated wheel to define a new set of coefficients for the equations, reflecting the significant increase in strength imparted by the heat treatment.

Q4: The paper mentions the models could be integrated into simulation software. What is the main benefit of doing this?

A4: The main benefit is enabling true performance-driven design optimization. Instead of just seeing a map of potential porosity, a design engineer could see a color-coded map of predicted yield strength and tensile strength across the entire component. This allows them to make informed decisions to reduce material/weight in over-engineered areas and add material only where strength is critical, leading to lighter, more efficient, and cost-effective components.

Q5: How was the accuracy of the casting simulation itself confirmed before it was used for model development?

A5: The reliability of the simulation was confirmed by comparing one of its key microstructural outputs—SDAS—with physical measurements. As shown in Table 1, the SDAS values predicted by the ProCAST® simulation for various locations on the wheel were in very good agreement with the SDAS values measured experimentally from the actual cast wheel. This strong correlation gave the researchers confidence that the simulation's outputs were a reliable basis for developing their mechanical property models.

Conclusion: Paving the Way for Higher Quality and Productivity

This research successfully tackles a persistent challenge in the casting industry: accurately predicting final mechanical properties directly from simulation. By developing and validating a robust Predictive Modeling for Aluminum Castings approach, the authors have created a powerful tool. The models for Yield Strength and Ultimate Tensile Strength—especially the latter's inclusion of shrinkage porosity—provide a direct link between process simulation and real-world component performance.

For R&D and operations teams, this means a reduced reliance on costly and time-consuming trial-and-error. It opens the door to more advanced design optimization, significant weight reduction possibilities, and a faster path from concept to production for high-integrity cast components.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

This content is a summary and analysis based on the paper "Development of a model for the prediction of mechanical properties for Al-Si-Mg castings" by "C. Ransenigo, M. Tocci, C. Viscardi, M. Serafini, A. Pola".

Source: La Metallurgia Italiana - Marzo 2022, pages 18-23.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.