Sitao Chen1 and Feng Zhou1

Published under licence by IOP Publishing Ltd

Journal of Physics: Conference Series, Volume 2044, The 2nd International Conference on Advanced Materials and Intelligent Manufacturing (ICAMIM 2021) 20-22 August 2021, Nanning, ChinaCitation Sitao Chen and Feng Zhou 2021 J. Phys.: Conf. Ser. 2044 012144

Abstract

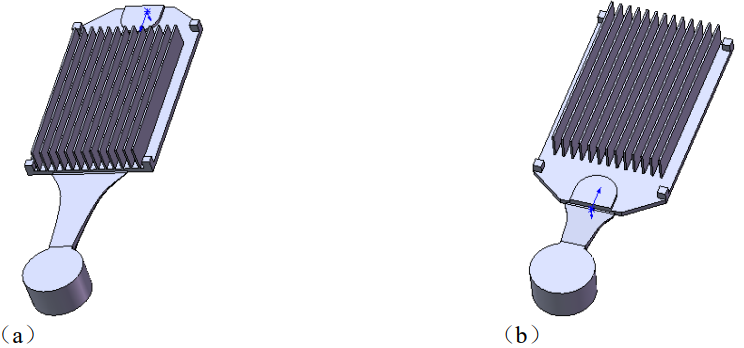

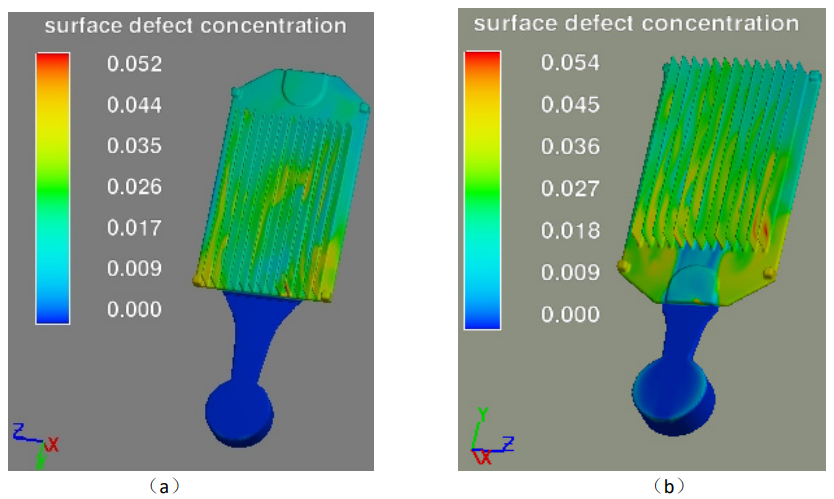

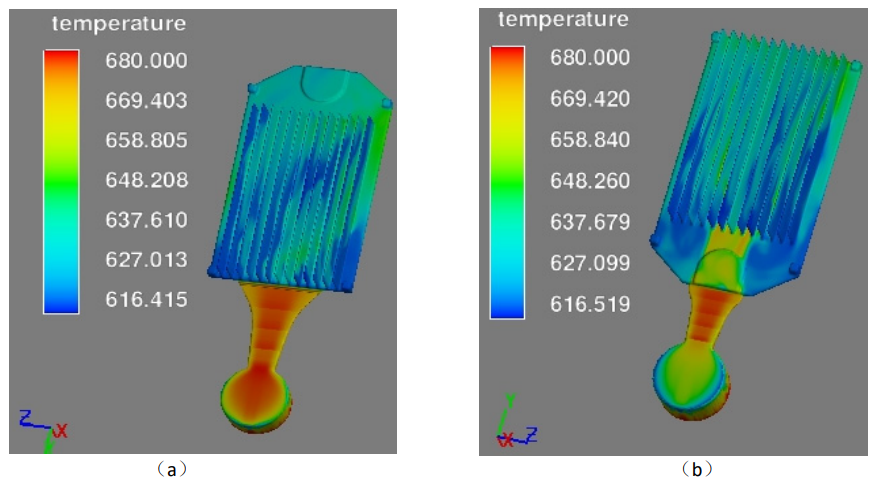

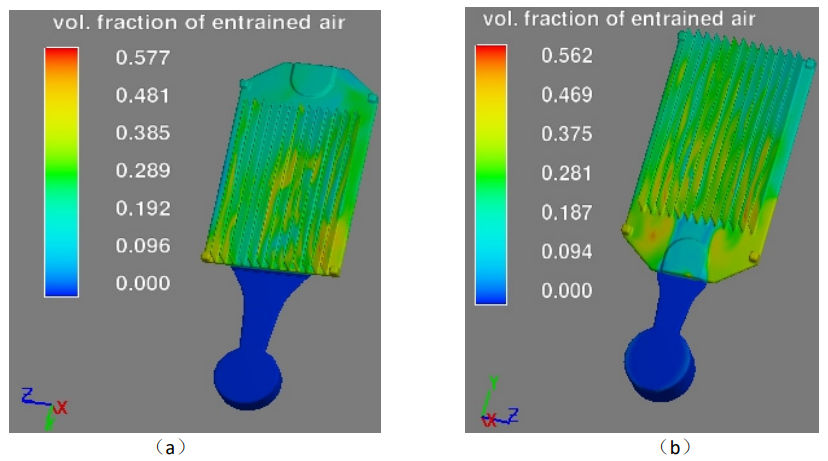

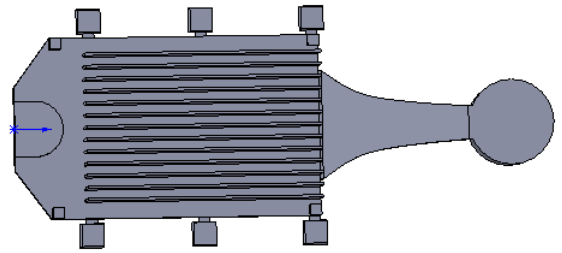

According to the structural characteristics of the radiator, two different gate structures were designed. The filling process of metal liquid in different gate structures was simulated by using the simulation software FLOW-3D, the size and location of possible defects in die casting were predicted, and the best design scheme of gate and overflow trough was put forward. The results show that under the conditions of pouring temperature of 680°C, preheating temperature of mold of 220°C and pouring speed of 60m/s, the most reasonable design scheme is that the whole casting can be filled with molten metal evenly and the concentration of surface defects is low.

References

- [1]Peng Y., Wang S.C. and Zheng K.H. 2013 Research progress of high performance magnesium alloy casting technology J. Casting Technology 34 203-204Go to reference in articleGoogle Scholar

- [2]Chen X.H., Geng Y.X. and Liu J. 2013 Research progress of functional materials of magnesium and magnesium alloys.J Journal of Materials Science and Engineering 31 148-152Go to reference in articleGoogle Scholar

- [3]An S.J. 2015 Mg-Al-Mn alloy by super vacuum die casting J. Scripta Material 67 879-882Go to reference in articleGoogle Scholar

- [4]Qi W.J., Song D.F. and Cai C. 2014 Research on vacuum technology for vacuum die casting of magnesium alloy radiators J. Casting 63 328-329Go to reference in articleGoogle Scholar

- [5]Chen S.T., Qi W.J. and Song D.F. 2013 Optimization of pouring system for magnesium alloy radiator die casting J. Special casting and non-ferrous alloys 33 1134-1136Go to reference in articleGoogle Scholar

- [6]Song D.F., Qi W.J., Wang H.Y. et al. 2015 Study on die-casting process of magnesium alloy heat sink for LED J.Casting 64 403-404Go to reference in articleGoogle Scholar

- [7]Li X.B., Cao W.T. and Bai J.Y. 2010 Study on the heat dissipation performance of AZ91D J. Journal of Henan University of Technology 29 685-688Go to reference in articleGoogle Scholar