International Journal of Metalcasting (2021)Cite this article

- 38 Accesses

- Metrics

Abstract

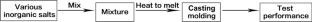

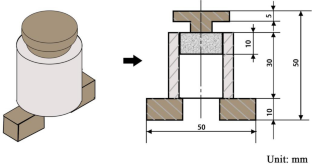

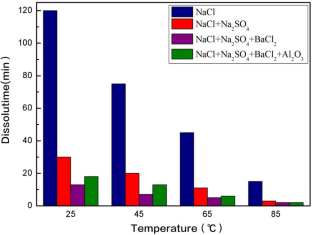

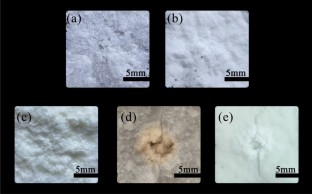

This paper aims to improve difficult cleaning and high core requirements in castings with complex internal cavities. The mixed salt was composed of NaCl, Na2SO4, BaCl2, and ceramic reinforced powder Al2O3 was added as core material. A high strength water-soluble salt core was prepared by melting gravity casting. Besides, the performance characteristics of NaCl salt core, Na2SO4 salt core, binary NaCl+Na2SO4 salt core, ternary NaCl+Na2SO4+BaCl2, and composite salt core after the addition of Al2O3 powder are compared and analyzed. The results demonstrated that the ratio of ternary salt cores was NaCl: Na2SO4: BaCl2=6:4:1; with the addition of Al2O3 powder, the bending strength of salt cores reached 27.9 MPa, and the bending strength of salt cores increased to 38.5 MPa. The composite salt core has a better water solubility than the unit NaCl salt core. Moreover, the water solubility time of the salt core can be shortened from 15 to 2 min when the water temperature was 85 °C. Scanning electron microscopy and X-ray powder diffractometer were used to analyze the microstructure and phase composition of salt cores. The composite salt core's energy during crack propagation is weakened by the deflection and passing through the composite phase, increasing the bending strength of the salt core.

Korean Abstract

이 문서는 복잡한 내부 공동이 있는 주물에서 어려운 세척 및 높은 코어 요구 사항을 개선하는 것을 목표로 합니다. 혼합염은 NaCl, Na2SO4, BaCl2로 구성되었으며, 코어재로 세라믹 강화 분말 Al2O3를 첨가하였다. 용융 중력 주조에 의해 고강도 수용성 염 코어를 제조하였다. 또한, Al2O3 분말 첨가 후 NaCl 염심, Na2SO4 염심, 2원 NaCl+Na2SO4 염심, 3원 NaCl+Na2SO4+BaCl2 및 복합 염심의 성능 특성을 비교 분석하였다. 결과는 삼원염 코어의 비율이 NaCl: Na2SO4: BaCl2=6:4:1임을 입증했습니다. Al2O3 분말을 추가하면 염심의 굽힘 강도는 27.9 MPa에 이르렀고 염심의 굽힘 강도는 38.5 MPa로 증가했습니다. 복합염 코어는 단위 NaCl 염 코어보다 더 나은 수용해도를 갖는다. 또한 염심의 수용성 시간은 수온이 85℃일 때 15분에서 2분으로 단축될 수 있다. 주사전자현미경과 X선 분말 회절분석기를 사용하여 염심의 미세구조와 상 조성을 분석하였다. 균열 전파 중 복합염 코어의 에너지는 변형 및 복합상을 통과하여 약화되어 염 코어의 굽힘 강도를 증가시킵니다.

Keywords

- water-solute salt core

- high strength

- water-solute time

- strengthening mechanism

- Figure 1

Figure 2

Figure 2 Figure 3

Figure 3 Figure 4

Figure 4 Figure 5

Figure 5 Figure 6

Figure 6 Figure 7

Figure 7 Figure 8

Figure 8

References

- L. Cao, D. Liao, F. Sun et al., Prediction of gas entrapment defects during zinc alloy high-pressure die casting based on gas-liquid multiphase flow model. Int. J. Adv. Manuf Technol. 94(1), 807–815 (2018). https://doi.org/10.1007/s00170-017-0926-5Article Google Scholar

- X. Dong, H. Yang, X. Zhu et al., High strength and ductility aluminium alloy processed by high pressure die casting. J. Alloys Compd. 773, 86–96 (2018). https://doi.org/10.1016/j.jallcom.2018.09.260CAS Article Google Scholar

- S.M. Dobosz, P. Jelinek, K. Major-Gabrys, Development tendencies of moulding and core sands. China Foundry 8(4), 438–446 (2011)CAS Google Scholar

- H. Wu, D. Li, X. Chen et al., Rapid casting of turbine blades with abnormal film cooling holes using integral ceramic casting molds. Int. J. Adv. Manuf. Technol. 50(1–4), 13–19 (2010). https://doi.org/10.1007/s00170-009-2502-0CAS Article Google Scholar

- A. Fortini, M. Merlin, G. Raminella, A comparative analysis on organic and inorganic core binders for a gravity diecasting Al alloy component. Inter Metalcast (2021). https://doi.org/10.1007/s40962-021-00628-1Article Google Scholar

- H.I. Kurt, I.H. Guzelbey, S. Salman, An experimental study of investigating the relationships between structures and properties of al alloys included with high Mg and high Ti. Int. J. Mater. Prod. Technol. 56(3), 271–283 (2018). https://doi.org/10.1504/IJMPT.2018.090819CAS Article Google Scholar

- K. Oikawa, Mechanical properties of mixed salt core made by die casting machine. J. Jpn. Foundry Eng. Soc. 81(5), 232–237 (2009)CAS Google Scholar

- P. Jelínek, E. Adámková, F. Mikšovský et al., Advances in technology of soluble cores for die castings. Arch. Foundry Eng. 15(2), 29–34 (2015). https://doi.org/10.1515/afe-2015-0032Article Google Scholar

- B. Fuchs, H. Eibisch, C. Körner, Core viability simulation for salt core technology in high-pressure die casting. Int. J. Metalcast. 7(3), 39–45 (2013). https://doi.org/10.1007/BF03355557CAS Article Google Scholar

- M. Merchán et al., Research on coatings and infiltration to strengthen ceramic lost cores used in high-pressure die casting processes. Int. J. Metalcast. 13(3), 597–603 (2019). https://doi.org/10.1007/s40962-018-00301-0CAS Article Google Scholar

- P. Jelínek, E. Adámková, Lost cores for high-pressure die casting. Arch. Foundry Eng. 14(2), 101–104 (2014). https://doi.org/10.2478/afe-2014-0045Article Google Scholar

- J. Yang, Yu. Juanli, Y. Huang, Recent developments in gelcasting of ceramics. J. Eur. Ceram. Soc. 31(14), 2569–2591 (2011). https://doi.org/10.1016/j.jeurceramsoc.2010.12.035CAS Article Google Scholar

- W. Jiang, J. Dong, L. Lou et al., Preparation and properties of a novel water soluble core material. J. Mater. Sci. Technol. 26(3), 270–275 (2010). https://doi.org/10.1016/S1005-0302(10)60045-XCAS Article Google Scholar

- J. Beňo, E. Adámková, F. Mikšovský, Development of composite salt cores for foundry applications. Materiali Tehnologije 49(4), 619–623 (2015). https://doi.org/10.17222/mit.2013.160Article Google Scholar

- P. Jiang, F. Liu, Z. Fan et al., Performance of water-soluble composite sulfate sand core for magnesium alloy castings. Arch. Civ. Mech. Eng. 16(3), 494–502 (2016). https://doi.org/10.1016/j.acme.2016.03.006Article Google Scholar

- R. Huang, B. Zhang, Study on the composition and properties of salt cores for zinc alloy die casting. Int. J. Metalcast. 11(3), 440–447 (2017)Article Google Scholar

- J. Yaokawa, D. Miura, K. Anzai et al., Strength of salt core composed of alkali carbonate and alkali chloride mixtures made by casting technique. Mater. Trans. 48(5), 1034–1041 (2007). https://doi.org/10.2320/matertrans.48.1034CAS Article Google Scholar

- Z.L. Lu, Y.X. Fan, K. Miao et al., Effects of adding aluminum oxide or zirconium oxide fibers on ceramic molds for casting hollow turbine blades. Int. J. Adv. Manuf. Technol. 72(5–8), 873–880 (2014). https://doi.org/10.1007/s00170-014-5723-9Article Google Scholar

- J. Yaokawa, K. Anzai, Y. Yamada et al., Castability and strength of potassium chloride-ceramic composite salt cores. J. Jpn. Foundry Eng. Soc. 76(10), 823–829 (2004)CAS Google Scholar

- F. Liu, S. Tu, X. Gong et al., Comparative study on performance and microstructure of composite water-soluble salt core material for manufacturing hollow zinc alloy castings. Mater. Chem. Phys. 252, 123257 (2020). https://doi.org/10.1016/j.matchemphys.2020.123257CAS Article Google Scholar

- X. Gong, W. Jiang, F. Liu et al., Effects of glass fiber size and content on microstructures and properties of KNO3-based water-soluble salt core for high pressure die casting. Inter Metalcast 15, 520–529 (2021). https://doi.org/10.1007/s40962-020-00480-9CAS Article Google Scholar

- Tu. Suo, F. Liu, G. Li et al., Fabrication and characterization of high-strength water-soluble composite salt core for zinc alloy die castings. Int. J. Adv. Manuf. Technol. 95(1), 505–512 (2018). https://doi.org/10.1007/s00170-017-1208-yArticle Google Scholar

- C. Cantas, B. Baksan, Effects of composition on the physical properties of water-soluble salt cores. Int. J. Metalcast. 6, 1–13 (2020). https://doi.org/10.1007/s40962-020-00511-5CAS Article Google Scholar