This article introduces the paper "Application of Automobile Lightweight Alloys and the Development of its Die-Casting Technology".

1. Overview:

- Title: Application of Automobile Lightweight Alloys and the Development of its Die-Casting Technology

- Authors: Defang LIU, Jie TAO

- Year of Publication: 2011

- Journal/Conference: Advanced Materials Research Vols. 308-310

- Keywords: automobile, lightweight alloy, die-casting

2. Research Background:

The automotive industry increasingly utilizes lightweight alloy materials due to the development of lightweight vehicles. Auto manufacturers are seeking thinner and stronger materials, presenting a significant challenge to lightweight alloy die-casting technology. Sustainable development within the automotive industry offers substantial prospects for the lightweight alloy die-casting industry and represents a new phase for die-casting technology in China. The die casting market is largely dominated by the automotive sector, with Japan accounting for 79%, Germany 61%, and the United States 75% in market share. China maintains a 65-75% share.

3. Research Objectives and Research Questions:

This paper aims to summarize the applications of lightweight alloys in the automotive industry and the advancements in lightweight alloy die-casting technologies, including low-pressure die-casting, semi-solid die-casting, oxygenation die-casting, and combinations of different die-casting techniques. The development trends of lightweight alloy die-casting technology are also discussed. Specific research questions and hypotheses are not explicitly stated in the paper.

4. Research Methodology:

The study is based on a literature review. It analyzes existing research and literature on the applications of lightweight alloys in the automotive industry, new advancements in lightweight alloy die-casting technologies, and the development trends of this technology. The research focuses on the application and development trends of lightweight alloy die-casting technology in the automotive industry. The data collected were from existing published studies and reports.

5. Key Research Findings:

- Advantages of Lightweight Alloys: Reduce vehicle weight while maintaining stiffness and strength, leading to decreased fuel consumption and emissions. For example, the Audi A8 saw a 60% reduction in body weight using an all-aluminum body. BMW created a lightweight 3.0-liter inline six-cylinder engine (161 kg) using Mg-Al composite materials.

- Applications of Lightweight Die-Casting Components in the Automotive Industry: Aluminum alloys are preferred due to their superior properties compared to steel (1/3 the density, twice the shock absorption, and three times the heat transmission). The growth rate of aluminum alloy die-casting components is 13% annually, accounting for 75% of the overall die-casting industry. Most car manufacturers utilize all-aluminum cylinder blocks and cylinder covers; French vehicles show a 45% application rate for cylinder blocks. Magnesium alloys are even lighter (35% lighter than aluminum), further reducing vehicle weight by 15-20%. AZ91 is the primary magnesium alloy for die-casting automotive components (80% market share), with an annual growth rate exceeding 20%.

- Development of Lightweight Alloy Die-Casting Technology: New techniques such as ultra-low-speed die-casting, vacuum die-casting, oxygenation die-casting, and semi-solid die-casting improve casting quality and mechanical properties. Ultra-low-speed die-casting, for example, leads to smoother surfaces and better mechanical properties. Vacuum die-casting eliminates blowholes and enhances properties. Combining different die-casting methods maximizes the advantages of each technique.

- Figure List:

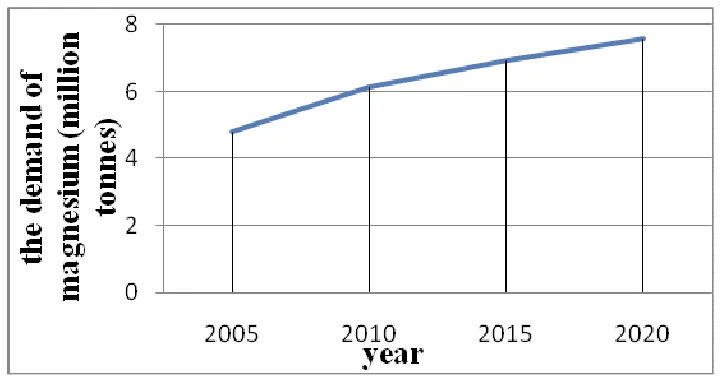

- Figure 1 (Growth trend of magnesium alloy in China's automobile industry),

- Table 1 (Application of aluminum alloy die-casting components in automobiles),

- Table 2 (Application of magnesium alloy die-casting components in automobiles).

6. Conclusion and Discussion:

This paper summarizes the applications of lightweight alloys and the development trends of lightweight alloy die-casting technologies in the automotive industry. New technologies like low-pressure die-casting, semi-solid die-casting, oxygenation die-casting, and combinations of different techniques enhance casting quality. However, the high cost of updating existing equipment limits the widespread adoption of these new technologies. The academic significance lies in the comprehensive summary of the latest trends. The practical implications involve improving productivity and quality through the application and improvement of new die-casting technologies. A limitation of this study is its reliance on a literature review.

7. Future Research:

Future research should explore cost-effective solutions for implementing new die-casting technologies and the development of smart, automated systems using artificial intelligence. Further research is needed on the properties of various lightweight alloys and their optimal die-casting parameters. For magnesium alloys, enhancing corrosion resistance and optimizing manufacturing processes are key areas for future investigation.

8. References:

- [1] Information on http://china.toocle.com

- [2] Linglin Yu: China Private Economy of Science & Technology (2010), p. 33-34

- [3] Bavarian Motor Works: International magnesium association: The global voice for magnesium. Vol. 5 (2007), p. 1–3

- [4] Dandan Sun, Wendong LI: Shandong Internal Combustion Engine, Vol. 1 (2003), p. 34–36

- [5] Mingtu Ma, Zhigang Li and Hongliang Yi: World Nonferrous Metals, (2006), p. 10-14

- [6] Mitsuguki Iisogai and Satoshi Murakami: submitted to Journal of Materials Processing Technology (1993)

- [7] Nargess Shahmanesh: Materials Advantages. Automotive Engineering, Vol. 10 (2003), p. 38-40

- [8] Zhihui Peng, Weiping Gan: Automobile Technology & Materials, Vol. 4 (1999), p. 1-6

- [9] Davies G. Magnesium: Materials for automotive bodies, Elsevier, G. London (2003)

- [10] Jun Chen: Materials Research and Application, Vol. 4 (2010), p. 81-84

- [11] Xudi Yuan: Automobile Manufacture & Equipment, Vol. 4 (2005), p. 66-69

- [12] Mustafa Kemal Kulekci: Int J Adv Manuf Technol, Vol. 39 (2008), p. 851-865

- [13] Qian Liu, Zhong-de Shan: Foundry Technology, Vol. 12 (2007), p. 1668-1671

- [14] Blawert C, Hort N, Kainer KV: Trans Indian Inst Met, Vol. 57 (2004), p. 397-408

- [15] Yizhen Lv, Liangdong Wang and Xiaoqin Zeng: Automobile Technology, Vol. 8 (1999), p. 28

- [16] Jianjun Wang, Zhiming Wang and Shan Bai: China Foundry Machinery & Technology, Vol. 4 (2006), p. 7-10

- [17] Siyuan Long, Shaoyong Xu: Modern Components, Vol. 11 (2010), p. 32-36

- [18] Hai-jun Chuan: Foundry Technology, Vol. 31 (2010), p. 625-627

- [19] Lian-qing JI: Journal of Central South University (Science and Technology), Vol. 41 (2010), p. 977-981

- [20] Lianqing Ji: Foundry, Vol. 56 (2007), p. 1057-1061

- [21] Nansheng Luo, in: Metal die-casting technology and mold design, edited by Tsinghua University Press, Beijing (2006), in press.

- [22] Jianjia Qu: Guangxi Journal of Light Industry, Vol. 9 (2008), p. 45-47

- [23] Shide Yu, Wei Tang, Zimin Zhou: Foundry Technology, Vol. 27 (2006), p. 964-967

- [24] Kim E S, Lee K H, Moon Y H: Journal of Materials Processing Technology, Vol. 105 (2000), p. 42-48

- [25] Yuanfa Li, Pingxian Su: Special Casting & Nonferrous Alloys, Vol. 26 (2006), p. 568-571

DOI References

- [24] Kim E S, Lee K H, Moon Y H: Journal of Materials Processing Technology, Vol. 105 (2000), pp.42-48. http://dx.doi.org/10.1016/S0924-0136(00)00557-4

- [12] Mustafa Kemal Kulekci: Int J Adv Manuf Technol, Vol. 39 (2008), pp.851-865. http://dx.doi.org/10.1007/s00170-007-1279-2

9. Copyright:

This summary is based on the paper "Application of Automobile Lightweight Alloys and the Development of its Die-Casting Technology" by Defang LIU and Jie TAO.

Source: DOI: 10.4028/www.scientific.net/AMR.308-310.785

This summary is for informational purposes only and cannot be used for commercial purposes without permission.

Copyright © 2023 CASTMAN. All Rights Reserved.