Eliminating Voids and Pores: A Deep Dive into Rotor Casting Quality for High-Efficiency Motors

This technical summary is based on the academic paper "Analysis of the quality of squirrel cages rotor machined at Electroprecizia Electrical Motors" by Ioan MILOSAN, Gheorghe OANCEA, Adrian MIJA, and Bela VARGA, published in RECENT J. (2022).

![Fig. 2. Nomogram for the assessment of the maximum probable hydrogen content of liquid aluminium alloys, according to the elaboration conditions [8, 9]](https://castman.co.kr/wp-content/uploads/image-3120.webp)

Keywords

Primary Keyword: Rotor Casting Quality

Secondary Keywords: pressure casting, aluminium rotor, squirrel cage rotors, micro-shrinkages, casting defects, hydrogen porosity, electrical resistivity

Executive Summary

The Challenge: Non-homogeneity and internal voids in cast aluminum squirrel cage rotors create significant manufacturing issues and critically reduce the electrical efficiency of the final motor.

The Method: The study analyzed the complex interdependencies between aluminum melt quality, casting process parameters, and the resulting rotor quality using defect analysis, absorbed power measurements, and non-destructive X-ray inspection.

The Key Breakthrough: High hydrogen content in the aluminum melt—originating from ambient air humidity and inadequate refining practices—is a primary driver of porosity, which directly degrades the rotor's electrical conductivity and performance.

The Bottom Line: Rigorous optimization of the melting, refining (especially degassing), and pressure casting phases is essential for manufacturing the high-integrity rotors required for next-generation, super-premium efficiency (IE4) electric motors.

The Challenge: Why This Research Matters for HPDC Professionals

For manufacturers of industrial electric motors, achieving superior electrical efficiency is a constant battle. The heart of the issue often lies in the quality of the cast aluminum squirrel cage rotor. As this research highlights, obtaining suitable compactness and electrical conductivity in the rotor's end rings and bars is paramount. The presence of voids, pores, and micro-shrinkages creates a non-homogeneous aluminum mass. This isn't just a quality control headache; it causes a "drastic local modification of the electrical resistivity," directly undermining the motor's performance. For engineering teams striving to develop new families of super-premium energy efficiency class (IE4) motors, solving these casting defects is not just an improvement—it's a necessity.

The Approach: Unpacking the Methodology

The research team at Transilvania University of Brasov and Electroprecizia Electrical Motors conducted a multi-faceted analysis to pinpoint the root causes of poor rotor quality. Their methodology included:

- Melt Quality Analysis: The hydrogen content of the liquid aluminum alloy was assessed using the simplified "first bubble method," a practical technique for quantifying gas contamination before casting.

- Defect Characterization: Cast rotors were examined and defects were categorized according to the International Atlas of Casting Defects, specifically identifying micro-shrinkages (B221) and bubbles/pores (B111).

- Electrical Performance Testing: A specialized installation (shown in Figure 6) was used to measure the power absorbed by each rotor when placed in a stator. This test provides a direct, quantitative measure of the rotor's electrical integrity, as higher absorbed power correlates with higher resistivity and more defects.

- Non-Destructive Inspection: The internal compactness of the rotor bars and end rings was determined using X-ray analysis on a RISATTI device, allowing for the detection of internal voids, pores, and even bar breakage without destroying the part.

The Breakthrough: Key Findings & Data

The study produced clear, actionable data linking specific process variables to final part quality.

Finding 1: Hydrogen Contamination is a Critical and Quantifiable Factor

The research confirmed that ambient humidity is a major source of hydrogen in the melt. The nomogram in Figure 2 shows that at a typical summer air humidity of 25 g/m³ and a melt temperature of 730 °C, the probable hydrogen content is approximately 0.75 cm³/100 g of aluminum. This is more than double the acceptable limit of 0.3-0.4 cm³/100 g required for bubble-free castings (Figure 3). Furthermore, calculations using the "first bubble method" on a non-degassed melt yielded an even higher hydrogen content of 1.2544 cm³/100 g aluminium (Equation 5), proving that inadequate melt treatment is a primary cause of gas porosity.

Finding 2: Inconsistent Rotor Quality Directly Impacts Electrical Performance

The absorbed power test revealed significant performance variations among rotors from the same production batch. As shown in Table 1, for the 0.55/1000 rotor, the measured power varied from 5.94 [div] to 34.2 [div]—a nearly six-fold difference. This wide spread demonstrates the non-uniformity of the rotor properties (compactness) and directly translates to inconsistent motor efficiency. X-ray analysis using the RISATTI device (Figure 7) visually confirmed these issues, showing how less pronounced peaks or their absence on the recorded curve indicate internal voids or bar breaks, leading to part rejection. The study estimates the total waste from these defects to be between 0.9-1.5%.

Practical Implications for R&D and Operations

For Process Engineers: This study suggests that adjusting the melt refining process is a critical leverage point. The current practice of using degassing tablets without a proper degassing bell is identified as suboptimal. The research strongly implies that implementing a more robust technology, such as dynamic gas injection, could significantly reduce hydrogen content and improve Rotor Casting Quality.

For Quality Control Teams: The data in Table 1 (Absorbed Power) and Figure 7 (RISATTI X-ray) of the paper illustrate the direct effect of internal defects on electrical and structural integrity. These methods can be adopted as powerful tools to establish stricter, data-driven quality inspection criteria and to quickly identify when the alloy refinement or casting machine parameters have drifted out of spec.

For Design Engineers: The findings indicate that the "particularities of filling the mould cavity"—including the design of the casting grid, end rings, and channels for the bars—influence defect formation. This suggests that runner and gate design should be carefully considered during the early design phase to minimize turbulence and air entrapment, especially for new high-efficiency motor platforms.

Paper Details

Analysis of the quality of squirrel cages rotor machined at Electroprecizia Electrical Motors

1. Overview:

- Title: Analysis of the quality of squirrel cages rotor machined at Electroprecizia Electrical Motors

- Author(s): Ioan MILOSAN, Gheorghe OANCEA, Adrian MIJA, Bela VARGA

- Year of publication: 2022

- Journal/academic society of publication: RECENT J., 68:092-099

- Keywords: pressure casting, aluminium, rotor squirrel cages, micro-shrinkages, quality analysis

2. Abstract:

The paper presents methods for improving the quality of rotor squirrel cages in the casting phase at Electroprecizia Electrical Motors Săcele. For this purpose, there are analysed the results of theoretical and experimental research on the existing interdependencies between the quality of rotor squirrel cages obtained by casting and the metallurgical quality of aluminium melts, respectively the parameters of the casting process. When balancing rotor squirrel cages, the non-homogeneity of the compactness of the cast aluminium mass raises a number of technological problems. This non-homogeneity of the compactness is determined by the presence of voids (bubbles, pores) in the cast material. However, the compactness of the aluminium mass (the voids in the cast aluminium) has a decisive influence on the electrical efficiency of the electric motor due to the drastic local modification of the electrical resistivity. Based on an analysis of the results obtained, there can be concluded that the development of a new family of electric motors, of super premium energy efficiency class (IE4), also involves the analysis and detection of the causes that lead to the formation of bubbles and pores in the cast aluminium mass, on the current process flow, subsequently reducing them by improving the existing technologies or even by replacing them.

3. Introduction:

Electric motor rotors are fabricated from aluminium via various casting methods, including static, centrifugal, and pressure casting. For these components, it is critical to not only meet dimensional specifications but also to achieve suitable compactness and electrical conductivity in the aluminium mass of the end rings and bars. At Electroprecizia Electrical Motors Săcele, rotors are produced by injecting liquid aluminium into a mould containing the laminations using YIZUMI 5000 kN cold, horizontal chamber pressure casting machines. The casting phase involves a series of main and secondary operations, including preheating, melting, refining, and casting, to ensure the manufacture of quality rotor squirrel cages.

4. Summary of the study:

Background of the research topic:

The research addresses the critical need to improve the quality of cast aluminum squirrel cage rotors. The non-homogeneity of the cast aluminum, characterized by voids and pores, presents technological challenges and detrimentally affects the electrical efficiency of electric motors. This issue is a significant barrier to the development of new, super premium energy efficiency class (IE4) motors.

Status of previous research:

The paper references existing literature on casting methods [1-4], aluminum casting quality [6, 7], and the fundamental principles of aluminum metallurgy, particularly concerning hydrogen contamination and refining [8, 9, 10]. The study builds upon these established principles to analyze a specific industrial manufacturing process.

Purpose of the study:

The primary purpose is to analyze the interdependencies between the metallurgical quality of the aluminum melt, the parameters of the casting process, and the final quality of the cast rotor squirrel cages. The objective is to identify the root causes of defects that lead to the formation of bubbles and pores in the cast aluminum and to propose improvements to the existing manufacturing technologies.

Core study:

The core of the study involves a theoretical and experimental investigation into the quality of rotors produced at Electroprecizia Electrical Motors. It examines the influence of hydrogen content in the liquid alloy on defect formation, analyzes the types of defects present in the final products, and correlates these defects with the electrical properties of the rotors. The study evaluates the entire process flow, from melt preparation to final inspection, to identify opportunities for process optimization.

5. Research Methodology

Research Design:

The study employs an analytical and experimental research design. It combines theoretical calculations based on established metallurgical principles (e.g., hydrogen solubility) with empirical data collected from an industrial production environment.

Data Collection and Analysis Methods:

* Hydrogen Content Assessment: The hydrogen content in the melt was determined using the "simplified first bubble method," which involves observing the solidification of a sample and calculating the hydrogen concentration based on the temperature at which bubbles first appear.

* Defect Analysis: Cast parts were analyzed and defects were identified and classified according to the International Atlas of Casting Defects [11], specifically micro-shrinkages (B221) and bubbles/pores (B111).

* Electrical Property Measurement: The quality of the rotor bars was controlled by measuring the absorbed power. The rotor was inserted into a stator supplied with a constant current, and the power drawn was recorded as an indicator of electrical resistivity.

* Compactness Determination: The compactness of the alloy in the end rings and bars was evaluated non-destructively through X-ray analysis using a RISATTI device.

Research Topics and Scope:

The research is focused on the pressure casting process for aluminum squirrel cage rotors at Electroprecizia Electrical Motors Săcele. The scope encompasses the entire manufacturing sequence highlighted in Figure 1, including charge preparation, melting, refining (degassing and deoxidation), pressure casting, and final inspection. The analysis centers on the causes and effects of porosity and micro-shrinkages on rotor quality.

6. Key Results:

Key Results:

* The analysis indicated that ambient air humidity significantly contributes to hydrogen saturation in the aluminum melt. At 25 g/m³ air humidity and 730 °C, the probable hydrogen content is approximately 0.75 cm³/100 g, which exceeds the acceptable threshold of 0.3-0.4 cm³/100 g for preventing bubble formation.

* Experimental determination using the "first bubble method" on a non-degassed melt calculated a high hydrogen content of 1.2544 cm³ H₂/100 g aluminium, confirming the need for effective refining operations.

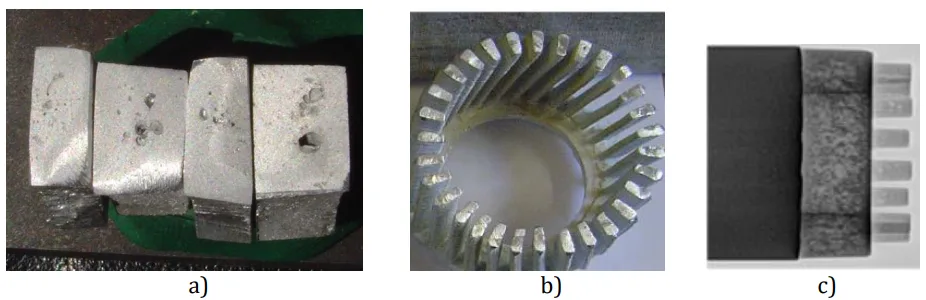

* Analysis of cast parts revealed the presence of micro-shrinkages (B221), attributed to solidification shrinkage, and bubbles/pores (B111), attributed to exogenous (air entrapment) and endogenous (dissolved hydrogen) causes.

* Measurements of absorbed power showed a wide dispersion of values (Table 1), indicating significant non-uniformity in the compactness and electrical properties of the manufactured rotors.

* X-ray analysis confirmed high levels of porosity, particularly micro-shrinkages in the end rings and voids or breaks in the bars within the laminations, leading to a total waste rate estimated between 0.9-1.5%.

Figure Name List:

* Fig. 1. The process flow for casting aluminium rotors at Electroprecizia Electrical Motors Săcele

* Fig. 2. Nomogram for the assessment of the maximum probable hydrogen content of liquid aluminium alloys, according to the elaboration conditions [8, 9]

* Fig. 3. Representation for assessing the tendency of bubble formation in castings according to the hydrogen content of the liquid metal [8, 9]

* Fig. 4. Rotor squirrel cages after casting with the casting grid

* Fig. 5. Voids in the rings of the rotor squirrel cages (a, c) and in the bars inside the laminations (b)

* Fig. 6. Simplified diagram of the installation used to examine cast rotor squirrel cages

* Fig. 7. The diagram recorded upon examining the integrity of the bars inside the rotor (laminations) on the RISATTI device

7. Conclusion:

The analysis of the experimental results demonstrates that the properties of the cast aluminum mass in the rotor—specifically compactness/porosity, density, electrical resistivity, and homogeneity—are determined by the quality of the liquid alloy (particularly its hydrogen content) and the particularities of the mould cavity filling process. The enhancement of cast rotor quality is impeded by the difficulty of assigning specific causes to casting defects. This leads to the conclusion that optimizing the melting/refining operations and the casting phase is necessary. The use of a device for determining hydrogen content via the first bubble method allows for the evaluation of degassing efficiency. The study suggests that melt degassing can be intensified by introducing degassing technology with gas injection in a dynamic regime.

8. References:

- Bonollo F., Gramegna N., Timelli G. (2015): High-Pressure Die-Casting: Contradictions and Challenges. The Journal of The Minerals, Metals & Materials Society, ISSN 1047-4838, Vol. 67, No. 5, pp. 901-908, https://link.springer.com/article/10.1007/s11837-015-1333-8

- Dargusch M.S., Dour G., Schauer N., Dinnis C.M., Savaged G. (2006): The Influence of Pressure during Solidification of High Pressure Die Cast Aluminium Telecommunication Components. Journal of Materials Processing Technology, ISSN 0924-0136, Vol. 180, is. 1-3, pp. 37-43, https://doi.org/10.1016/j.jmatprotec.2006.05.001

- Obiekea K.N., Aku S.Y., Yawas D.S. (2014): Effects of Pressure on the Mechanical Properties and Microstructure of Die Cast Aluminum A380 Alloy. Journal of Minerals and Materials Characterization and Engineering, ISSN 2327-4085, Vol. 2, pp. 248-258, http://dx.doi.org/10.4236/jmmce.2014.23029

- http://engineeringhut.blogspot.com/2010/11/special-casting-processes.html. Accessed: 2022-11-20

5.https://www.alfamm.ro/select_by_technology/Die%20Casting/Die%20Casting%20Machine/Yizumi/Standard%20Series/681/5000/. Accessed: 2022-11-20 - https://www.iqsdirectory.com/articles/die-casting/aluminum-casting.html. Accessed: 2022-11-20

- https://ramtoolinc.com/blog/intro-aluminum-die-castings/. Accessed: 2022-11-20

- Varga B. (1992): Elaborarea și turnarea aliajelor neferoase (Elaboration and casting of non-ferrous alloys). Transilvania University of Brasov, Indrumar de laborator (Laboratory guide) (in Romanian)

- Varga B. (1999): Modelarea proceselor de degazare a aliajelor de aluminiu de turnatorie prin barbotare (Modelling of the degassing processes of foundry aluminium alloys by bubbling). In: Modelarea si simularea pe calculator a procesarii materialelor (Computer modelling and simulation of material processing), U.T. Pres, ISBN 973-98701-8-Х, р. 15-38

- Sabau A.S., Vishvanathan S. (2002): Micro Porosity Prediction in Aluminum Alloy Castings. Metallurgical and Materials Transactions B, Vol. 33B, ISSN 2327-4077, p. 243-255, DOI:10.1007/s11663-002-0009-2

- ***: Atlas internațional al defectelor de turnare (International Atlas of Casting Defects) (1977): Editura Tehnică, Bucharest, p. 69-112 (in Romanian)

- Palanisamy S., Nagarajah C.R., Iovenitti P. (2007): Ultrasonic inspection of rough surface aluminium die castings. Insight, ISSN 2156-4868, Vol. 49, No. 3, pp. 160-164, DOI:10.1784/insi.2007.49.3.160, https://www.ndt.net/article/insight/papers/insi.49.3.160.pdf

EXPERT Q&A AND CONCLUSION

Expert Q&A: Your Top Questions Answered

Q1: What is the primary source of hydrogen contamination in the aluminum melt according to the study?

A1: The paper identifies two main sources. The primary source is water vapor from the ambient air, which reacts with the liquid aluminum. The second is condensation that forms on the solid metal charge and other auxiliary materials that are not properly dried before being introduced into the furnace. This highlights the critical importance of both environmental control and material preparation in the foundry.

Q2: The paper mentions the "first bubble method." How was this applied to quantify hydrogen content?

A2: The "first bubble method" is a practical test used to estimate dissolved hydrogen. A sample of the melt is cast in a small mould, and researchers observe the temperature at which the first gas bubbles appear on the surface as it solidifies. Because hydrogen's solubility in aluminum drops sharply upon solidification, this temperature corresponds to a specific hydrogen concentration. By plugging this temperature (750 °C in the experiment) into the established hydrogen solubility equation (Equation 2), the team calculated the hydrogen content in the melt.

Q3: What specific types of casting defects were identified, and what were their probable causes?

A3: The analysis identified two main defect types based on the International Atlas of Casting Defects. The first was micro-shrinkages (B221), caused by the natural volume reduction of aluminum during solidification. The second was bubbles and pores (B111), which had two distinct causes: exogenous pores from air trapped in the mould cavity during turbulent injection, and endogenous pores caused by dissolved hydrogen coming out of solution as the metal cools.

Q4: How does the absorbed power test correlate with rotor quality?

A4: The absorbed power test is an effective indirect measure of the rotor's electrical integrity. An ideal rotor has low, uniform electrical resistivity. Defects like voids, pores, micro-shrinkages, and non-metallic inclusions reduce the effective cross-sectional area of the aluminum conductors (the bars and end rings), which increases electrical resistance. Therefore, a higher absorbed power reading directly indicates a higher level of defects and poorer overall quality.

Q5: The paper criticizes the current refining method. What was the specific issue?

A5: The specific issue was the method of introducing the GASEX N3 degassing tablets. They were added using a ladle rather than a proper degassing bell. This approach is inefficient because it doesn't guarantee the tablets reach the bottom of the crucible for maximum melt interaction, nor does it provide the controlled circular movement of a bell, which is crucial for distributing the refining agent and ensuring thorough degassing throughout the entire melt.

Q6: What is the industrial impact of these defects on the final product?

A6: The industrial impact is severe. The defects result in a non-homogeneous rotor with inconsistent compactness. This leads to a "drastic local modification of the electrical resistivity," which significantly lowers the electrical efficiency of the finished motor. This quality issue not only increases product waste (estimated at 0.9-1.5%) but also serves as a major technological barrier preventing the company from successfully developing and manufacturing next-generation, super premium energy efficiency (IE4) motors.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of producing flawless aluminum rotors is a constant battle against metallurgy and physics. This research powerfully demonstrates that defects like porosity and micro-shrinkages are not random occurrences but direct results of controllable process variables, chief among them being hydrogen content in the melt. The key breakthrough is the clear link between inadequate melt refining, casting parameters, and the final electrical performance of the rotor. By focusing on optimizing these upstream processes, manufacturers can dramatically improve Rotor Casting Quality, reduce scrap, and unlock the potential to produce the high-efficiency motors the market demands.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Analysis of the quality of squirrel cages rotor machined at Electroprecizia Electrical Motors" by Ioan MILOSAN, Gheorghe OANCEA, Adrian MIJA, and Bela VARGA.

Source: https://doi.org/10.31926/RECENT.2022.68.092

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.