Beyond the Acid Bath: Faster, Greener Cleaning Methods for Complex Metal Sponge Castings

This technical summary is based on the academic paper "POSSIBILITIES OF CLEANING OF METAL SPONGE CASTINGS" by Václav Merta, published in METAL (2019).

![Figure 1 Principle of the two-stage investment casting process using an evaporative polyurethane (PUR) pattern [6]](https://castman.co.kr/wp-content/uploads/image-3638.webp)

Keywords

- Primary Keyword: Metal Sponge Casting Cleaning

- Secondary Keywords: Investment Casting, Gypsum Moulding, Porous Metal, Casting Cleaning Methods, Pressurized Water Cleaning, Compressed Air Cleaning

Executive Summary

- The Challenge: Removing residual gypsum moulding material from the intricate, thin-walled pores of metal sponge castings is extremely difficult and time-consuming due to the material's poor collapsibility after casting.

- The Method: The study compared the conventional chemical cleaning method (nitric acid leaching) with two alternative mechanical methods: high-pressure water washing and compressed air blasting.

- The Key Breakthrough: Both pressurized water and compressed air cleaning methods reduced the primary cleaning time from over two hours to just 2-3 minutes, removing the vast majority of the residual moulding material.

- The Bottom Line: Adopting pressurized water or compressed air cleaning can dramatically increase throughput, reduce environmental impact, and lower operational costs compared to traditional acid-based methods.

The Challenge: Why This Research Matters for HPDC Professionals

Metal sponges, a type of metal foam with fully interconnected open pores, offer unique properties for applications like heat exchangers, catalyst carriers, and lightweight structural components. They are often produced via investment casting, where a polymer foam pattern is encased in a gypsum-based moulding compound.

The problem arises after casting. The gypsum compound, essential for capturing the fine detail of the foam structure, has very poor collapsibility (high residual strength) after exposure to high casting temperatures. This makes it incredibly difficult to remove from the small, randomly distributed pores of the final metal casting. The conventional method involves a lengthy, hazardous, and environmentally burdensome process of leaching the casting in nitric acid for at least an hour, followed by another hour in an ultrasonic bath. This process creates a significant bottleneck in production and poses environmental challenges.

The Approach: Unpacking the Methodology

The research aimed to find a faster, more efficient, and ecologically sound alternative to chemical cleaning. The experiment was conducted on 50x50x20 mm metal sponge samples cast from two different alloys.

Method 1: Pressurized Water Cleaning

- Equipment: A Patriot PW 110 pressure washer.

- Key Variables: Maximum working pressure of 10 MPa.

- Materials: AlSi10MgMn and CuSn12 alloy castings with residual Eurovest gypsum compound.

Method 2: Compressed Air Cleaning

- Equipment: A standard compressed air system.

- Key Variables: Pressure of 10 bar.

- Materials: AlSi10MgMn and CuSn12 alloy castings with residual Eurovest gypsum compound.

These new methods were evaluated against the baseline chemical process and measured for efficiency (amount of gypsum removed) and time requirements.

The Breakthrough: Key Findings & Data

The experiment revealed that both pressurized water and compressed air are highly effective and significantly more time-efficient than the traditional acid leaching method.

Finding 1: Drastic Reduction in Cleaning Time from Hours to Minutes

The most significant finding was the dramatic improvement in speed. The paper states, "Instead of 2 hours of acid leaching and ultrasonic cleaning the casting can be cleaned within 2-3 minutes." This represents a time savings of over 95%, transforming a major production bottleneck into a quick, efficient step. The average cleaning time was approximately 3 minutes for pressurized water and 2 minutes for compressed air.

Finding 2: High-Efficiency Removal with Minimal Residual Material

The new methods successfully removed the bulk of the gypsum compound. As shown in Table 1, after the initial cleaning, only a very small amount of residue remained.

- For AlSi10MgMn castings, compressed air left only 1.5% of the total residue, while pressurized water left 2.2%.

- For CuSn12 castings, compressed air left 4.5% of the total residue, while pressurized water left 7%.

While a final, quick (15-minute) acid and ultrasonic clean was still needed to remove these last traces for perfect cleaning, the primary mechanical methods did the vast majority of the work in a fraction of the time.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that implementing pressurized water or compressed air systems can dramatically reduce cycle times for cleaning metal sponge castings, directly increasing throughput and operational efficiency. The choice between water and air may depend on factors like water consumption, dust management, and the specific alloy being cleaned.

- For Quality Control Teams: The data in Table 1 illustrates that while highly effective, these mechanical methods may not achieve 100% cleaning on their own, especially in areas near solid walls. QC teams should consider implementing a two-stage process where mechanical cleaning is followed by a rapid chemical/ultrasonic polish for applications requiring absolute purity.

- For Design Engineers: The findings indicate that the presence of a solid wall (part of the gating system) can create small, hard-to-clean areas. The paper notes, "in case of removing the solid wall as an element of the gating system, this problem is irrelevant." This suggests that designing components to minimize such features or planning for their removal can further simplify and improve the cleaning process.

Paper Details

POSSIBILITIES OF CLEANING OF METAL SPONGE CASTINGS

1. Overview:

- Title: POSSIBILITIES OF CLEANING OF METAL SPONGE CASTINGS

- Author: Václav MERTA

- Year of publication: 2019

- Journal/academic society of publication: METAL 2019

- Keywords: Metal sponge, investment casting, gypsum moulding materials, cleaning methods

2. Abstract:

The paper deals with methods of cleaning metal sponge castings. This type of metal foam materials, which is unique amongst other types by having fully interconnected and open pores, is produced by a two-step investment casting process using an evaporative polyurethane pattern. A special gypsum compound is used as a mould making material that is able to completely fill the complex pore system during moulding. However, after casting, the moulding material has lower collapsibility (higher residual strength). For this reason, there is a problem with the removal of mould residues from individual pores. Therefore, various alternative methods of cleaning this type of casting have been designed and tested in the experiment.

3. Introduction:

Metal foams are a progressive group of porous metallic materials with a cellular structure. Manufacturing processes have been developed to obtain foams with various pore sizes, arrangements, and levels of interconnection. These materials possess specific mechanical and functional properties, such as high specific stiffness and energy absorption, making them suitable for lightweight components in the automotive and aerospace industries. Their unique thermal properties are useful for heat exchangers, and their large specific surface area is advantageous for catalyst carriers. One production method is investment casting, where liquid metal is cast into a mould containing the pore structure. After solidification, the moulding material must be removed. While some materials like water-soluble salts are easily removed, gypsum-based compounds used for metal sponges have poor collapsibility and high residual strength, making them difficult to clean from the complex, thin-walled metal matrix structure.

4. Summary of the study:

Background of the research topic:

The production of metal sponge castings via investment casting using gypsum-based moulds presents a significant post-processing challenge: the effective and efficient removal of the residual moulding material from the intricate, open-pore structure of the casting.

Status of previous research:

Previous research and existing methods relied on chemical disruption, specifically leaching the castings in a 1M nitric acid (HNO3) solution to convert insoluble calcium sulphate dihydrate into water-soluble calcium nitrate. This was followed by cleaning in an ultrasonic bath. This entire process was identified as being very time-consuming (over two hours) and creating a significant environmental burden.

Purpose of the study:

The aim of the experiment was to find and optimize a more suitable replacement for the chemical cleaning process. The study sought to evaluate alternative methods that were more time-efficient, cost-effective, and ecologically friendly for cleaning metal sponge castings.

Core study:

The core of the study involved casting metal sponge samples from aluminum alloy (AlSi10MgMn) and copper alloy (CuSn12) using an investment casting process with a gypsum composite mould. Two alternative cleaning methods were then tested and compared: cleaning with pressurized water (10 MPa) and cleaning with compressed air (10 bar). The efficiency of these methods was quantified by measuring the mass of gypsum compound removed and the time required for the process.

5. Research Methodology

Research Design:

The study was an experimental comparison of three cleaning methods (chemical, pressurized water, compressed air) on two types of metal alloy castings (aluminum and copper). The primary metrics for comparison were the amount of residual moulding material removed and the time required for cleaning.

Data Collection and Analysis Methods:

Data was collected by weighing the castings before and after each cleaning stage to determine the mass of the removed gypsum compound residues. The results for the pressurized water and compressed air methods were tabulated (Table 1) to compare their initial effectiveness and the amount of residue remaining that required a final chemical/ultrasonic cleaning step.

Research Topics and Scope:

The research was focused on the post-casting cleaning process for open-pore metal sponges produced by investment casting. The scope included the manufacturing of test samples (50x50x20 mm) from AlSi10MgMn and CuSn12 alloys using a polyurethane foam pattern and a special gypsum composite mould (Eurovest). The investigation was limited to testing a pressure washer at 10 MPa and compressed air at 10 bar as alternatives to a 1M nitric acid solution.

6. Key Results:

Key Results:

- Both pressurized water (PW) and compressed air (CA) cleaning methods are significantly more time-efficient than the conventional chemical method. Cleaning time was reduced from approximately 2 hours to 2-3 minutes.

- The compressed air process was found to be slightly more effective than pressurized water. For AlSi10MgMn castings, CA left only 1.5% of residue, while PW left 2.2%. For CuSn12 castings, CA left 4.5% of residue, while PW left 7%.

- The difference in cleaning difficulty between the AlSi10MgMn and CuSn12 castings is likely due to the higher annealing temperature used for the copper alloy moulds, which worsened the collapsibility of the moulding material.

- A final cleaning step involving acid and ultrasonic bathing is still necessary to remove the last traces of residue, but the time required for this step is reduced to approximately 30 minutes (15 min acid, 15 min ultrasonic).

- Both new methods have disadvantages: compressed air is a very dusty process requiring a closed cabin with suction, and pressurized water has a relatively high water consumption.

Figure Name List:

- Figure 1 Principle of the two-stage investment casting process using an evaporative polyurethane (PUR) pattern [6]

- Figure 2 Prepared PUR pattern with wax solid wall

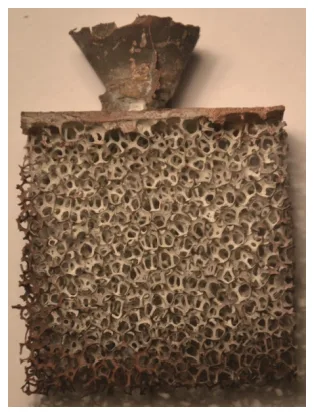

- Figure 3 AlSi10MgMn sponge casting after mould removal

- Figure 4 CuSn12 sponge casting after mould removal

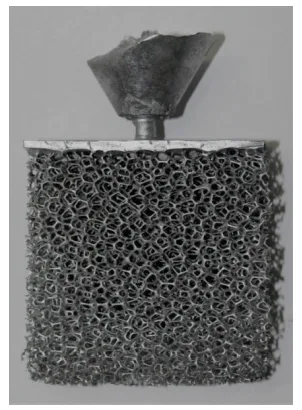

- Figure 5 CuSn12 sponge casting after 3 minutes of pressurized water cleaning, 15 min of leaching in 1M HNO3 solution and 15 min of ultrasonic cleaning

- Figure 6 AlSi10MgMn sponge casting after 2 minutes of compressed air (10 bar) cleaning, 15 min of leaching in 1M HNO3 solution and 15 min of ultrasonic cleaning

7. Conclusion:

The study tested possibilities for cleaning metal sponge castings. The previously used method of chemical disintegration with nitric acid is not entirely suitable from a technological, economic, or ecological standpoint. Tested methods of cleaning with pressurized water or compressed air proved to be very effective and time-efficient. The environmental impact of these processes is negligible compared to the use of acid. However, these methods have their own disadvantages, such as dimensional limits of cleanable castings or energy intensity. Further detailed research is recommended to gain better knowledge on this topic.

8. References:

- [1] BANHART, John. Manufacture, characterisation and application of cellular metals and metal foams. Progress in Materials Science. 2001. vol. 46, no. 6, pp. 559-632.

- [2] GARCÍA-MORENO, Francisco. Commercial Applications of Metal Foams: Their Properties and Production. Materials. 2016. vol. 85, no. 9.

- [3] ASHBY, Michael F. Metal Foams: A Design Guide. Massachusetts: Butterworth-Heinemann. 2000. p. 251, ISBN: 9781493302918.

- [4] LICHÝ, Petr, ELBEL, Tomáš, KROUPOVÁ, Ivana and RADKOVSKÝ, Filip. Preparation and evaluation of properties of cast metallic foams with regular inner structure. Archives of Metallurgy and Materials. 2017. vol. 62, no. 3, pp. 1643-1646. ISSN 1733-3490.

- [5] KROUPOVÁ, Ivana, LICHÝ, Petr, LIČEV, Lačezar, HENDRYCH, Jakub and SOUČEK, Kamil. Evaluation of Properties of Cast Metal Foams with Irregular Inner Structure. Archives of Metallurgy and Materials. 2018. vol. 63, No. 4, pp. 1845-1849. ISSN 1733-3490.

- [6] KROUPOVÁ, Ivana, LICHÝ, Petr, RADKOVSKÝ, Filip, BEÑO, Jaroslav, BEDNÁŘOVÁ, Vlasta and LÁNA, Ivo. Optimization of the annealing of plaster moulds for the manufacture of metallic foams with an irregular cell structure. Materiali in Tehnologije. 2015. vol. 49, No. 4, pp. 527-530. ISSN 1580-2949.

- [7] WANG, L., LI, H., WANG, F. and REN, J. Preparation of the open pore aluminum foams using investment casting process. Acta Metallurgica Sinica (English Letters). 2001, vol. 14, no. 1, pp. 27-32.

- [8] MATZ, A. M., MOCKER, B. S., MÜLLER, D. W., JOST, N. and EGGELER, G. Mesostructural design and manufacturing of open-pore metal foams by investment casting. Advances in Materials Science and Engineering. 2014. pp. 1-9, 421729.

Expert Q&A: Your Top Questions Answered

Q1: Why was a gypsum-based compound used for the mould if it's known to have poor collapsibility?

A1: The paper states that a "special gypsum compound is used as a mould making material that is able to completely fill the complex pore system during moulding." This implies that despite its poor collapsibility, its flowability and ability to capture the fine, intricate details of the polyurethane foam pattern are critical for successfully producing the metal sponge structure. The trade-off for high fidelity in the casting is the difficulty in cleaning.

Q2: What were the specific pressures used for the water and air cleaning tests?

A2: The study used a Patriot PW 110 pressure washer with a maximum working pressure of 10 MPa for the pressurized water cleaning. For the alternative method, compressed air was tested at a pressure of 10 bar. These parameters were chosen to provide sufficient force to mechanically dislodge the residual gypsum compound from the pores.

Q3: Was one cleaning method more effective for the aluminum alloy versus the copper alloy?

A3: The results in Table 1 show that both methods left less residual material in the aluminum alloy (AlSi10MgMn) castings compared to the copper alloy (CuSn12) castings. The paper suggests this is not due to the cleaning method itself, but because the mould for the copper alloy was annealed at a higher temperature, which "probably caused the worse collapsibility of the moulding material." The compressed air method was slightly more effective than pressurized water for both alloys.

Q4: What are the main disadvantages of these new, faster cleaning methods?

A4: The paper explicitly points out the disadvantages. The compressed air method is described as a "very dusty process" that must be performed in a closed cabin with suction to manage the airborne particulate. The pressurized water method, on the other hand, has the drawback of "relatively big consumption of water." There are also potential dimensional limits for the castings that can be effectively cleaned.

Q5: Is the final acid and ultrasonic cleaning step always necessary after using pressurized water or air?

A5: The paper suggests it is necessary for achieving a completely clean casting. While the mechanical methods remove the vast majority of the residue (over 93% in most cases), they leave small amounts, particularly in hard-to-reach areas near solid walls. The paper concludes that "the use of acid is necessary for final cleaning" to remove these last traces, though the time required for this final step is significantly reduced.

Q6: How was the initial bulk removal of the moulding material performed before these detailed cleaning methods were applied?

A6: According to the paper, the initial removal happens via thermal shock. It states, "After casting and solidification of the castings, the moulds are disrupted by thermal shock, whereby most of the moulding material is removed by immersing still warm moulds in the water bath." The cleaning methods discussed in the experiment are for removing the stubborn residue that remains after this initial step.

Q7: Did the study evaluate the energy consumption of the new methods compared to the old one?

A7: The paper mentions energy intensity as a potential disadvantage of the new methods in the conclusion, stating they have "disadvantages, such as the dimensional limits of cleanable castings, or the energy intensity." However, it does not provide a quantitative comparison of the energy consumption between the pressurized water/air methods and the original acid/ultrasonic bath method.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of efficiently cleaning complex castings is a persistent hurdle in achieving high-volume production. This research demonstrates a clear path forward for manufacturers of metal sponge components. By replacing the slow, hazardous chemical leaching process with rapid mechanical methods, companies can achieve a monumental leap in productivity. The findings on Metal Sponge Casting Cleaning show that a process that once took hours can now be accomplished in minutes, drastically reducing bottlenecks and environmental impact.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "POSSIBILITIES OF CLEANING OF METAL SPONGE CASTINGS" by "Václav MERTA".

Source: https://doi.org/10.37904/metal.2019.970

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.