Cast vs. DMLS AlSi10Mg: A Breakthrough Study on Chip Breakability for High-Performance Machining

This technical summary is based on the academic paper "Study on Chip Breakability Index During Longitudinal Turning of Cast and DMLS Additively Manufactured AlSi10Mg Aluminum Alloy" by Grzegorz Struzikiewicz, Bogdan Słodki, Wojciech Zębala, and Emilia Franczyk, published in Advances in Science and Technology Research Journal (2022).

Keywords

- Primary Keyword: Chip Breakability

- Secondary Keywords: AlSi10Mg, Additive Manufacturing, DMLS, Longitudinal Turning, Machinability, Aluminum Alloy Machining

Executive Summary

- The Challenge: Machining aluminum alloys like AlSi10Mg is often plagued by poor chip control, leading to continuous, strong chips that can damage the workpiece and disrupt production.

- The Method: The study conducted a comparative analysis of longitudinal turning on two types of AlSi10Mg samples: traditional cast and additively manufactured via Direct Metal Laser Sintering (DMLS).

- The Key Breakthrough: Additively manufactured (DMLS) AlSi10Mg exhibits inherently superior chip breakability that is not significantly dependent on cutting parameters, unlike its cast counterpart which relies heavily on high feed rates for good chip control.

- The Bottom Line: The unique microstructure of DMLS AlSi10Mg parts allows for a more stable and predictable machining process with a wider operating window, simplifying secondary finishing operations compared to cast components.

The Challenge: Why This Research Matters for HPDC Professionals

Aluminum alloys, particularly AlSi10Mg, are workhorses in the automotive, aviation, and machinery industries due to their excellent strength-to-weight ratio. However, their machinability presents a persistent challenge. A common problem is the tendency to form long, continuous chips during turning operations. These chips can wrap around the tool and workpiece, causing surface damage, interrupting the process, and posing a safety risk.

As additive manufacturing (AM) technologies like DMLS become a viable alternative to casting for complex parts, a critical question arises: how do these new materials behave during essential finishing processes like machining? Understanding the machinability, and specifically the chip breakability, of DMLS components is crucial for developing efficient and reliable hybrid manufacturing workflows. This research directly addresses that knowledge gap, providing data-driven guidelines for turning parts made via laser powder sintering.

The Approach: Unpacking the Methodology

The research was designed as a direct comparative analysis to isolate the effects of the manufacturing method on machinability.

Method 1: Material Preparation (DMLS)

- Material: AlSi10Mg metal powder.

- Equipment: Renishaw AM 250 machine.

- Process: A cylindrical shaft (Φ 55 mm x L 140 mm) was fabricated using Direct Metal Laser Sintering (DMLS) with a laser power of 400W and a layer thickness of 25 µm.

Method 2: Material Preparation (Casting)

- Material: Cast AlSi10Mg aluminum alloy.

- Process: A second shaft of identical dimensions was produced using a traditional casting method.

Method 3: Machining and Analysis

- Process: Both shafts underwent longitudinal turning.

- Tooling: A DCGT 11T304-AS cutting insert (IC20 grade) from ISCAR was used.

- Key Variables: The experiment, designed using the Taguchi method, systematically varied cutting speed (vc), feed rate (f), and depth of cut (ap).

- Analysis: The primary metric was the Chip Breakability Index (Cin), a value from 0 (ideal, short chips) to 1 (unfavorable, long chips), calculated based on the measured length of the chips produced.

The Breakthrough: Key Findings & Data

The study revealed a stark contrast in chip formation behavior between the cast and DMLS materials.

Finding 1: Cast AlSi10Mg Machinability is Highly Dependent on Feed Rate

For the traditionally cast aluminum sample, the feed rate (f) was the dominant factor influencing chip breakability. At lower feed rates, the material produced long, unfavorable chips. A significant improvement was only observed at higher feed rates.

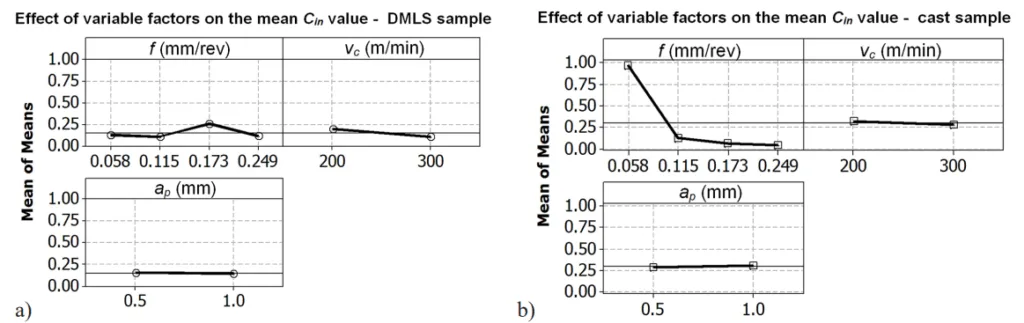

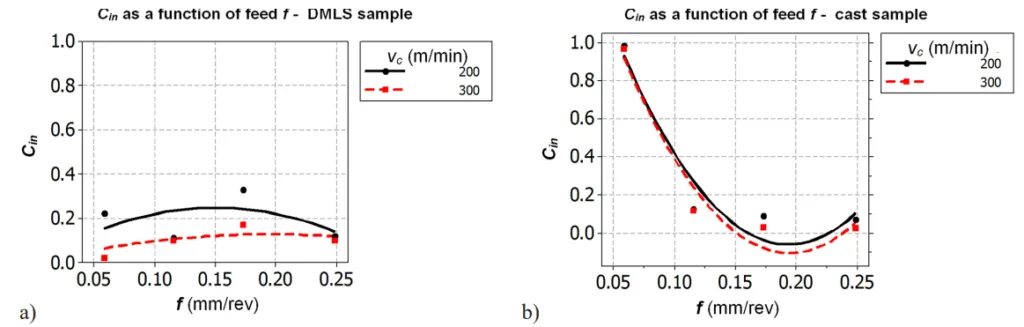

As shown in Figure 4b, the Chip Breakability Index (Cin) for the cast sample was extremely high (approximately 1.0, indicating poor breakability) at feed rates below 0.1 mm/rev. However, as the feed rate increased beyond 0.1 mm/rev, the Cin value dropped sharply to near-zero, indicating a transition to favorable, short chips.

Finding 2: DMLS AlSi10Mg Exhibits Consistently Excellent and Stable Chip Breakability

In a remarkable contrast, the DMLS sample produced favorable, short-to-acceptable chips across the entire range of tested cutting parameters. The values for feed, cutting speed, and depth of cut had no significant influence on the excellent chip breakability.

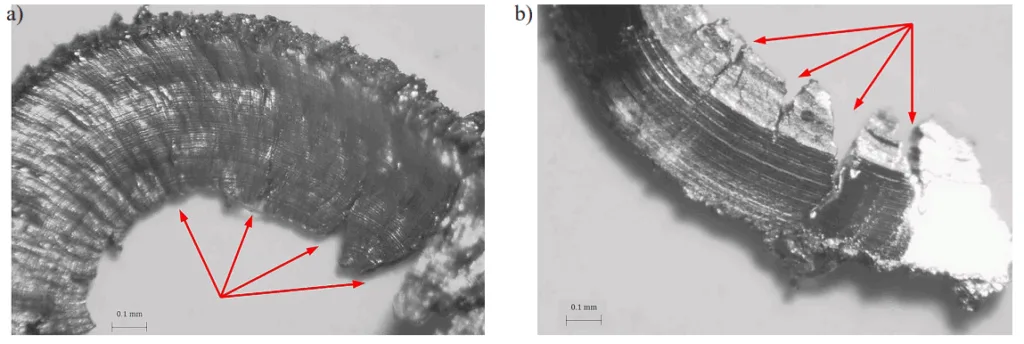

As seen in Figure 4a, the Cin value for the DMLS sample remained consistently low (below 0.4) across all feed rates. The study attributes this superior behavior to the inherent microstructure of the sintered material. Microscopic analysis (Figure 5) revealed numerous microcracks and material discontinuities, which act as natural stress risers, promoting faster and more predictable chip breaking during the cutting process.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that machining DMLS AlSi10Mg parts offers a significantly wider and more forgiving process window. The process is less sensitive to variations in cutting parameters, potentially leading to more stable and robust production with less need for fine-tuning to achieve good chip control.

- For Quality Control Teams: The data in Table 5 and Figure 5 of the paper illustrates that the chip formation mechanism is fundamentally different. The presence of microcracks and stickings on DMLS chips is not a sign of a poor cutting process but rather an indicator of the material's internal structure that aids breakability. This could inform new criteria for process monitoring.

- For Design Engineers: The findings indicate that selecting DMLS over casting for complex AlSi10Mg components can de-risk and simplify downstream machining operations. The inherent machinability of the DMLS material reduces the likelihood of surface damage from poor chip evacuation, a valuable consideration in the early design and material selection phase.

Paper Details

Study on Chip Breakability Index During Longitudinal Turning of Cast and DMLS Additively Manufactured AlSi10Mg Aluminum Alloy

1. Overview:

- Title: Study on Chip Breakability Index During Longitudinal Turning of Cast and DMLS Additively Manufactured AlSi10Mg Aluminum Alloy

- Author: Grzegorz Struzikiewicz, Bogdan Słodki, Wojciech Zębala, Emilia Franczyk

- Year of publication: 2022

- Journal/academic society of publication: Advances in Science and Technology Research Journal

- Keywords: machining, turning, AlSi10Mg aluminum alloy, additive manufacturing, DMLS, chip breakability.

2. Abstract:

The article presents selected issues related to the process of turning samples made of the AlSi10Mg alloy with the use of various manufacturing technologies, i.e. casting and DMLS (Direct Metal Laser Sintering). Machining processes of cylindrical surfaces of samples made with these two methods were subjected to a comparative analysis. The main idea behind the research was to develop guidelines for turning parts obtained using laser powder sintering. Study on the influence of cutting parameters on the value of breakability index Cin as well as the type, shape and form of chips produced during longitudinal turning is presented. The chips were also measured and the results of the microscopic analysis of the chips form are described. Results showed that the values of Cin index for turning of the cast AlSi10MG alloy depend mainly on the value of feed f. According to adopted chip classification for the feed value of f > 0.1 mm/rev the chips had a favorable, short form. In the case of turning the sample obtained by the DMLS method, the values of the chip breakability index Cin are not significantly dependent on the adopted ranges of cutting parameters. The Taguchi method was used to develop the conclusions obtained on the basis of the research results.

3. Introduction:

Just after steel, aluminum alloys are the second most used construction material, valued for properties like low density, corrosion resistance, and good strength. AlSi10Mg is a common example, used widely in automotive, aviation, and machinery industries. While generally having good machinability, aluminum alloys often present challenges such as the formation of built-up edges and low chip breakability, resulting in continuous, strong chips. Concurrently, additive manufacturing (AM) technologies like DMLS (Direct Metal Laser Sintering) are increasingly used for producing complex parts as an alternative to casting. DMLS parts often require subsequent machining to achieve final dimensional accuracy and surface finish. This creates a need for hybrid manufacturing processes, but the machinability of materials produced by AM methods is not fully understood. This study aims to address this gap by determining the influence of cutting parameters on chip form during the turning of both cast and DMLS AlSi10Mg samples.

4. Summary of the study:

Background of the research topic:

The research is situated at the intersection of traditional subtractive manufacturing (turning) and modern additive manufacturing (DMLS). It addresses a practical industrial problem: the control of chip formation when machining AlSi10Mg, a widely used aluminum alloy. Poor chip breakability is a known issue that can compromise surface quality and process stability.

Status of previous research:

Previous studies have shown that the machinability of aluminum alloys is affected by cutting parameters and material structure. Research by Segebade et al. [17] noted the influence of DMLS sinter anisotropy on chip formation, while Zimmermann et al. [13] observed differences in chips during milling of cast versus sintered samples. However, there is a need for a systematic analysis of chip breakability during turning, which combines the advantages of additive and subtractive manufacturing.

Purpose of the study:

The primary purpose was to conduct a comparative analysis of the chip form obtained during the longitudinal turning of AlSi10Mg parts made by two different methods: DMLS and casting. The study aimed to determine the influence of cutting parameters (feed, cutting speed, depth of cut) on the chip breakability index (Cin) and develop guidelines for machining parts produced by laser powder sintering.

Core study:

The core of the study involved a series of longitudinal turning experiments on cylindrical shafts of cast and DMLS AlSi10Mg. Using a Taguchi experimental design, cutting parameters were varied, and the resulting chips were collected and analyzed. The length of the chips was measured to calculate the chip breakability index (Cin), providing a quantitative measure of chip form. Microscopic analysis of the chips was also performed to understand the underlying formation mechanisms.

5. Research Methodology

Research Design:

The study employed a comparative experimental design. Two sets of identical samples (Φ 55 mm x L 140 mm shafts) were prepared, one by casting and one by DMLS. The experiment was designed according to the Taguchi method to analyze the influence of variable cutting parameters on the chip breakability index (Cin).

Data Collection and Analysis Methods:

Data was collected by performing longitudinal turning tests under a planned matrix of cutting parameters (Table 4). For each test, chips were collected, photographed, and their longitudinal dimension (Lch) was measured. The Chip Breakability Index (Cin) was calculated using formula (1), which assigns a value between 0 and 1 based on chip length. A "lower the better" analysis method for the S/N ratio was used for statistical evaluation. Microscopic analysis was performed using Bresser and Keyence microscopes.

Research Topics and Scope:

The research focused on the longitudinal turning of AlSi10Mg aluminum alloy. The scope was limited to comparing samples made by casting and DMLS. The investigated parameters were feed rate (f), cutting speed (vc), and depth of cut (ap) within ranges suitable for finishing operations. The analysis was centered on the chip breakability index (Cin) and the morphology of the resulting chips. The conclusions are specific to the cutting tool geometry used (DCGT 11T304-AS).

6. Key Results:

Key Results:

- For cast AlSi10Mg, the chip breakability index (

Cin) was found to be significantly dependent on the feed rate (f). For feed values greater than 0.1 mm/rev, the chips had a favorable, short form. Cutting speed (vc) and depth of cut (ap) had no significant effect. - For DMLS AlSi10Mg, the chip breakability index (

Cin) was not significantly dependent on any of the tested cutting parameters (f,vc,ap). The chips were consistently of a short, favorable, or acceptable form, most often arched. - Microscopic observation of chips from the DMLS sample revealed numerous microcracks, discontinuities, and deformations. This inherent material structure is identified as the reason for its superior chip breaking performance compared to the more homogeneous cast material.

Figure Name List:

- Fig. 1. Simplified classification of chip geometry (due to the length of chip (Lch)) [26]

- Fig. 2. The cutting tool

- Fig. 3. Effect of test variables on the values of Cin. Turning of (a) laser sintered aluminum (b) cast aluminum

- Fig. 4. Cin as a function of feed f. Turning of (a) laser sintered aluminum (b) cast aluminum

- Fig. 5. Cracks on the inner (a) and outer (b) surface of the chip – turning of sintered material

7. Conclusion:

The study concludes that for turning cast AlSi10Mg alloy, the chip breakability index depends mainly on the feed rate, with f > 0.1 mm/rev producing favorable, short chips. In contrast, for the AlSi10Mg sample produced by the DMLS method, the chip breakability index is not significantly dependent on the adopted ranges of cutting parameters. Chips from the DMLS material were consistently short and favorable, a behavior attributed to the presence of numerous microcracks and material discontinuities which support the chip breaking process. These findings are specific to the cutting tool with the selected geometry used in the research.

8. References:

- Olakanmi E.O., Cochrane R.F., Dalgarno K.W. A Review on Selective Laser Sintering/ Melting (SLS/SLM) of Aluminium Alloy Powders: Processing, Microstructure, and Properties. Progress in Materials Science. 2015; 74: 401-477.

- Chen J., Hou W., Wang X., Chu S., Yang Z. Microstructure, Porosity and Mechanical Properties of Selective Laser Melted AlSi10Mg. Chinese Journal of Aeronautics. 2020; 33: 2043-2054.

- Li Z., Nie Y., Liu B., Kuai Z., Zhao M., Liu F. Mechanical Properties of AlSi10Mg Lattice Structures Fabricated By Selective Laser Melting. Materials & Design. 2020; 192: 108709.

- Wanga L., Wanga S., Hong X. Pulsed SLM-manufactured AlSi10Mg Alloy: Mechanical Properties And Microstructural Effects of Designed Laser Energy Densities. Journal of Manufacturing Processes. 2018; 35: 492-499.

- Svobodová J., Luňák M., Lukáč I. Identification of the "Snowflakes" on the Machined Surface of the AlSi10Mg Alloy Casting. Manufacturing Technology. 2019; 19: 868-873.

- Santos M.C., Machado A.R., Sales W.F., Barrozo M.A.S., Ezugwu E.O. Machining of aluminum alloys: a review. The International Journal of Advanced Manufacturing Technology. 2016; 86: 3067-3080.

- Kim M.S. Effects of Processing Parameters of Selective Laser Melting Process on Thermal Conductivity of AlSi10Mg Alloy. Materials. 2021; 14(9): 2410.

- Radosh A., Kuczko W., Wichniarek R., Górski F. Prototyping of Cosmetic Prosthesis Of Upper Limb Using Additive Manufacturing Technologies. Advances in Science and Technology Research Journal. 2017; 11: 102-107.

- Struzikiewicz G., Zębala W., Słodki B. Cutting Parameters Selection for Sintered Alloy AlSi10Mg Longitudinal Turning. Measurement. 2019; 138: 39-53.

- Kim K.T. Mechanical Performance of Additively Manufactured Austenitic 316L Stainless Steel. Nuclear Engineering and Technology. DOI: 10.1016/j.net.2021.07.041.

- Walczak M., Szala M. Effect of Shot Peening on The Surface Properties, Corrosion and Wear Performance of 17-4PH Steel Produced by DMLS Additive Manufacturing. Archives of Civil and Mechanical Engineering. 2021; 21(157): 5–20.

- Żebrowski R., Walczak M. Effect of The Shot Peening on Surface Properties and Tribological Performance of Ti-6Al-4V Alloy Produced by Means of DMLS Technology. Archives of Metallurgy and Materials. 2019; 64(1): 377–386.

- Zimmermann M., Müller D., Kirsch B., Greco S., Aurich J.C. Analysis of the Machinability When Milling AlSi10Mg Additively Manufactured Via Laser-Based Powder Bed Fusion. The International Journal of Advanced Manufacturing Technology. 2021; 112: 989-1005.

- Zagórski I., Warda T. Effect of Technological Parameters on the Surface Roughness of Aluminium Alloys After Turning. Advances in Science and Technology Research Journal. 2018; 12: 144-149.

- Read N., Wang W., Essa K., Attallah M.M. Selective Laser Melting of AlSi10Mg Alloy: Process Optimisation and Mechanical Properties Development. Materials and Design. 2015; 65: 417–424.

- Yan Q., Song B., Shi Y. Comparative Study of Performance Comparison of AlSi10Mg Alloy Prepared by Selective Laser Melting and Casting. Journal of Materials Science & Technology. 2020; 41: 199-208.

- Segebade E., Gerstenmeyer M., Dietrich S., Zanger F. Schulze: Influence of Anisotropy of Additively Manufactured AlSi10Mg Parts on Chip Formation During Orthogonal Cutting. Procedia CIRP. 2019; 82: 113-118.

- Tang M., Pistorius P.C. Anisotropic Mechanical Behavior of AlSi10Mg Parts Produced by Selective Laser Melting. The Minerals, Metals & Materials Society. 2017; 69: 516–522.

- Zyguła K., Nosek B., Pasiowiec H., Szysiak N. Mechanical Properties and Microstructure of AlSi10Mg Alloy Obtained by Casting and SLM Technique. World Scientific News. 2018; 104: 462-472.

- Rosenthal I., Tiferet E., Ganor M., Stern A. Post-processing of AM-SLM AlSi10Mg specimens: Mechanical properties and fracture behaviour. The Annals of "Dunarea de Jos" University of Galati: Fascicle XII, Welding Equipment and Technology. 2015; 26: 33-38.

- Franczyk E., Machno M., Zębala W. Investigation and optimization of the SLM and WEDM processes. Parameters for the AlSi10Mg-sintered part. Materials. 2021; 14(2): 410.

- Struzikiewicz G., Sioma A. Evaluation of surface roughness and defect formation after the machining of sintered aluminum alloy AlSi10Mg. Materials. 2020; 13(7): 1662.

- Rubio E.M., Camacho A.M., Sánchez-Sola J.M., Marcos. M. Chip Arrangement in the dry cutting of aluminium alloys. Journal of Achievements in Materials and Manufacturing Engineering. 2006; 16(1-2): 164-170.

- Renishaw https://www.renishaw.pl/pl/42225.aspx (access 11.07.2021).

- Pusavec F., Deshpande A., Yang S., M'Saoubi R., Kopac J., Dillon Jr. O.W., Jawahir I.S. Sustainable machining of high temperature nickel alloy Inconel 718: Part 2. Chip breakability and optimization. Journal of Cleaner Production. 2015; 87: 941-952.

- Zębala W., Struzikiewicz G., Słodki B. Reduction of power consumption by chip breakability control in Ti6Al4V titanium alloy turning. Materials. 2020; 13(11): 2642.

- Karolczak P., Kołodziej M., Kowalski M. Effectiveness of diamond blades in the turning of aluminium composites. Advances in Science and Technology Research Journal. 2020; 14(4); 262–272.

Expert Q&A: Your Top Questions Answered

Q1: What is the primary reason for the superior chip breakability observed in the DMLS AlSi10Mg samples?

A1: The paper attributes the superior chip breakability of DMLS samples to their unique microstructure. Unlike the more homogeneous cast material, the DMLS part has a layered, porous structure with weaker bonding between material particles. As detailed in the discussion and shown in Figure 5, this leads to the formation of micro-cracks during cutting, which accelerates the chip breaking process, resulting in consistently short and manageable chips.

Q2: For the cast AlSi10Mg, what was the specific threshold for feed rate to achieve good chip control?

A2: The study clearly identifies a feed rate (f) of greater than 0.1 mm/rev as the critical threshold. The results showed that for feed values below this point, the cast material produced long, unfavorable chips (Cin ≈ 1.0). Once the feed exceeded 0.1 mm/rev, the chip form became favorable and short, demonstrating a dramatic improvement in chip breakability.

Q3: How much did cutting speed and depth of cut influence the results for either material?

A3: According to the analysis, cutting speed (vc) and depth of cut (ap) had no significant effect on the chip breakability index for either the cast or the DMLS material within the tested ranges. For the cast material, feed rate was the only dominant factor. For the DMLS material, none of the three parameters had a significant influence, highlighting its stable machining characteristics.

Q4: Do these conclusions apply to all machining operations and tool types for DMLS AlSi10Mg?

A4: The authors are careful to limit the scope of their conclusions. The paper explicitly states in the conclusion that the "presented conclusions and recommendations relate to the tested tool only" (a DCGT 11T304-AS insert). While the findings on the material's inherent properties are significant, further research would be required to determine if this behavior holds true for different tool geometries or other machining processes like milling or drilling.

Q5: What is the Chip Breakability Index (Cin) and how is it a useful metric for machinability?

A5: The Chip Breakability Index (Cin) is a quantitative metric used to evaluate the form of chips, ranging from 0 to 1. As defined by formula (1) and Figure 1, it is calculated based on the length of the chip (Lch). A lower Cin value (closer to 0) represents shorter, more desirable chips, while a value of 1.0 represents long, unfavorable chips. It provides an objective and standardized way to compare chip control under different conditions, which is a critical aspect of machinability.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a crucial insight for engineers working with modern manufacturing methods: the way a part is made fundamentally changes how it behaves in subsequent processes. The study demonstrates that additively manufactured DMLS AlSi10Mg possesses inherently excellent Chip Breakability, making it more predictable and stable to machine than its cast equivalent. This finding helps de-risk the adoption of hybrid additive-subtractive workflows.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Study on Chip Breakability Index During Longitudinal Turning of Cast and DMLS Additively Manufactured AlSi10Mg Aluminum Alloy" by "Grzegorz Struzikiewicz, Bogdan Słodki, Wojciech Zębala, Emilia Franczyk".

Source: https://doi.org/10.12913/22998624/143503

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.