Unlocking Casting Excellence: A Review of Machine Learning Applications for Defect Reduction and Automation

This technical summary is based on the academic paper "AN OVERVIEW OF MACHINE LEARNING APPLICATIONS IN METAL CASTING INDUSTRIES" by VISHAL B. BHAGWAT, DHANPAL A. KAMBLE, and SANDEEP S. KORE, published in Arch. Metall. Mater. (2024).

Keywords

- Primary Keyword: Machine Learning in Metal Casting

- Secondary Keywords: Casting Defect Prediction, Foundry Automation, Quality Control in Casting, Process Optimization, Artificial Intelligence in Manufacturing

Executive Summary

- The Challenge: The metal casting process is inherently complex and prone to failures, leading to product rejections, wasted resources, and increased costs.

- The Method: This paper provides a comprehensive literature review of machine learning (ML) models implemented between 2010 and 2023 to address challenges in the sand-casting industry.

- The Key Breakthrough: The review identifies specific ML models—notably Artificial Neural Networks (ANN), Support Vector Machines (SVM), and Bayesian Networks—as consistently effective tools for predicting material properties, automating quality control, and forecasting defects.

- The Bottom Line: Machine Learning in Metal Casting is no longer theoretical; it is a proven set of tools that can significantly enhance efficiency, reduce scrap, and ensure consistent product quality by moving from reactive problem-solving to proactive, data-driven prediction.

The Challenge: Why This Research Matters for HPDC Professionals

Even with modern advancements, the idea of a completely automated "Smart Factory" foundry remains out of reach. Casting involves numerous transformations and variables—from pattern material and sand type to pouring temperature—each posing a risk of failure that can lead to product rejection. This gap between a foundry's current capabilities and the techniques available to produce defect-free castings creates a persistent need for support systems that minimize reliance on human intervention and reduce costly trial-and-error experimentation.

This research matters because it consolidates over a decade of academic and industrial efforts to solve this problem. It demonstrates how Machine Learning in Metal Casting provides a pathway to integrate predictive intelligence into production, enabling the acquisition of new, optimized production parameters without the need for extensive physical testing. For HPDC professionals, this translates directly to lower development costs, faster cycle times, and a more robust, reliable manufacturing process.

The Approach: Unpacking the Methodology

This study is a systematic literature review that analyzes and synthesizes high-quality research papers on ML applications in metal casting published from 2010 to 2023. The authors' methodology involved two key steps:

Method 1: Categorization of Research

The collected papers were divided into two primary categories to provide a structured overview:

1. Automation and Quality Control: Research focused on optimizing processes, predicting equipment failures, and ensuring consistent product quality.

2. Material and Defect Prediction: Research focused on predicting material melting compositions, designing materials with desired properties, and predicting the occurrence of specific defects.

Method 2: Analysis of ML Model Implementation

The authors meticulously documented the types of ML algorithms used in the reviewed studies. They analyzed the frequency of use for various models—such as Artificial Neural Networks (ANN), Support Vector Machines (SVM), K-Nearest Neighbour (KNN), and Decision Trees—to identify which techniques are most commonly and successfully applied to specific challenges within the sand-casting application area.

The Breakthrough: Key Findings & Data

The comprehensive review revealed clear trends in the application and effectiveness of different ML models for solving critical foundry challenges.

Finding 1: Dominant Models for Foundry Automation and Quality Control

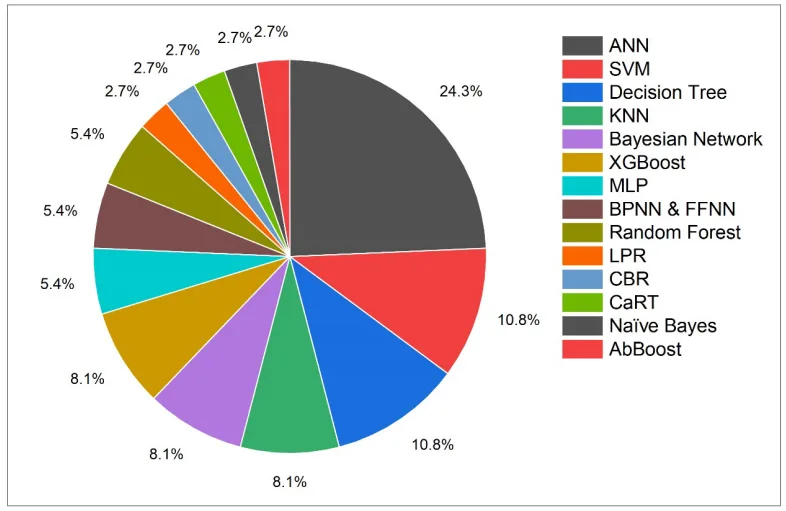

The analysis of ML models used for automation and quality control showed a distinct pattern of preference. As shown in Figure 1, the Artificial Neural Network (ANN) is the most prevalent model, used in 24.3% of the reviewed studies. Following ANN, Support Vector Machine (SVM) and Decision Tree models are also frequently used, each accounting for 10.8% of applications. This indicates that for tasks related to process control and quality assurance, these models have proven to be robust and reliable tools.

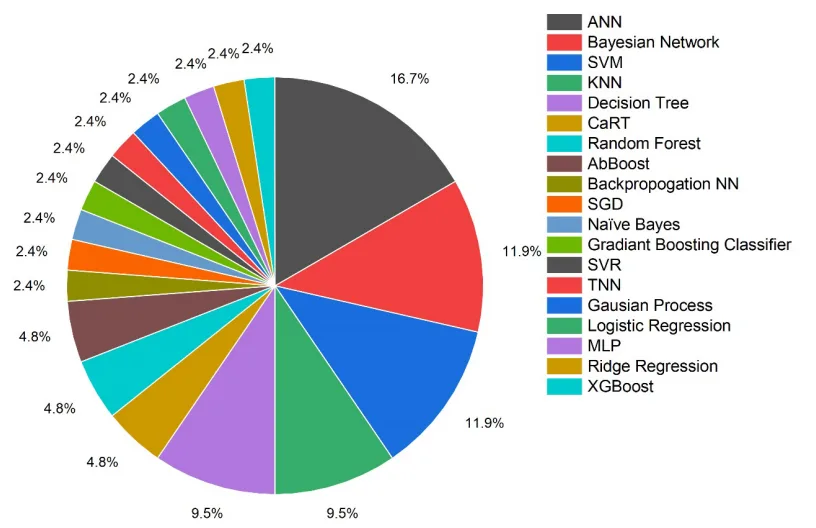

Finding 2: Proven Models for Material Design and Defect Prediction

When focusing on the more complex tasks of material design, melting, and defect prediction, a similar set of powerful models emerges. The paper's conclusion highlights that ANN, Bayesian Network, and SVM are the most commonly used models in this category. The study provides numerous examples of their success, including predicting microshrinkage defects with 82% accuracy using Bayesian networks, identifying subsurface defects from X-ray images using SVM, and modeling alloy solidification using deep neural networks. The review concludes that ANN and SVM are the most suitable ML techniques for confirming desired material properties and predicting defects in sand-casting processes.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that implementing ML models like ANN and SVM can help predict the time-dependent heat transfer coefficient (HTC) between the mold and the alloy, or determine optimal wall temperatures in low-pressure die casting to maximize final product quality, reducing the need for trial-and-error.

- For Quality Control Teams: The data in Table 2 shows that ML algorithms can automatically detect surface defects (inclusions, cold laps) and internal flaws from X-ray images. Models like SVM and KNN have demonstrated high classification accuracy, which could inform the development of automated, real-time inspection systems.

- For Design Engineers: The findings indicate that ML can predict the ultimate tensile strength (UTS) and hot ductility of cast steel based on chemical composition and thermal data. This allows for the computational design of alloys and components with specific mechanical properties, reducing reliance on costly and time-consuming physical prototyping.

Paper Details

AN OVERVIEW OF MACHINE LEARNING APPLICATIONS IN METAL CASTING INDUSTRIES

1. Overview:

- Title: AN OVERVIEW OF MACHINE LEARNING APPLICATIONS IN METAL CASTING INDUSTRIES

- Author: VISHAL B. BHAGWAT, DHANPAL A. KAMBLE, SANDEEP S. KORE

- Year of publication: 2024

- Journal/academic society of publication: Arch. Metall. Mater. 69 (4), 1577-1584

- Keywords: Metal casting; Machine learning; artificial intelligence; quality control; defects prediction

2. Abstract:

This paper presents an overview of different machine learning (ML) techniques and algorithms implemented in metal casting industries. ML has made significant contributions to the field of metal casting by improving various aspects of the casting process. In this work, referred quality research papers are divided into two categories. Firstly, work reviewed for the automation in foundry and quality control. Secondly, the raw material melting, material designs and defect predictions in the metal casting. The literature is extensively studied for types of ML models implemented from 2010 to 2023 for the sand-casting application area especially in the prediction of material melting compositions, desired material properties and occurrence of defects along with involvement of advanced foundry technologies.

3. Introduction:

The paper highlights that a completely automated foundry based on the Smart Factory concept is currently implausible, as humans remain a crucial component in decision-making. The demand for metal casting is growing, particularly in India, which is becoming a hub for manufacturing casting components. Machine learning (ML) has significantly enhanced the metal casting industry by improving defect detection, process optimization, predictive maintenance, and quality control, leading to higher efficiency and product quality. This paper serves as a review of ML applications in this field.

4. Summary of the study:

Background of the research topic:

The metal casting process is complex, involves numerous transformations, and carries a significant risk of failure, which can lead to defects and product rejection. There is a recognized need for a support system in the industry to minimize human intervention and improve outcomes. ML offers a powerful toolset for process optimization, quality control, and defect prediction, thereby addressing these long-standing industrial challenges.

Status of previous research:

The literature from 2010 to 2023 demonstrates widespread application of various ML models in casting. Researchers have successfully used techniques such as Artificial Neural Networks (ANN), Support Vector Machines (SVM), K-Nearest Neighbour (KNN), Bayesian networks, and Decision Trees to address specific problems. These include predicting mechanical properties like ultimate tensile strength (UTS), detecting defects such as microshrinkage and centerline segregation, and optimizing process parameters like heat transfer coefficients and pouring temperatures.

Purpose of the study:

The primary purpose of this study is to present a systematic overview of the different machine learning techniques and algorithms that have been implemented in the metal casting industry. The work categorizes the reviewed literature into two main areas: (1) automation in foundry and quality control, and (2) raw material melting, material design, and defect prediction.

Core study:

The core of the study is an extensive review of quality research papers from 2010 to 2023 concerning ML applications in sand-casting. The study analyzes the types of ML models implemented for predicting material melting compositions, achieving desired material properties, and forecasting the occurrence of defects. It synthesizes the findings to identify the most commonly used and effective ML models for various applications within the casting process, supported by graphical representations of model frequency.

5. Research Methodology

Research Design:

The research is designed as a systematic literature review.

Data Collection and Analysis Methods:

The authors collected and studied quality research papers published between 2010 and 2023. The literature was divided into two distinct categories for analysis: automation/quality control and material/defect prediction. The frequency of application for various ML algorithms within these categories was analyzed to identify trends and common practices. The results of this frequency analysis are presented in pie charts.

Research Topics and Scope:

The scope of the review is centered on the application of machine learning in the metal casting industry, with a particular focus on sand-casting. The topics covered include foundry automation, quality control, raw material melting, material design, process optimization, and defect prediction.

6. Key Results:

Key Results:

- For foundry automation and quality control, Artificial Neural Networks (ANN) are the most frequently used model (24.3%), followed by Support Vector Machines (SVM) and Decision Trees (10.8% each), as depicted in Figure 1.

- For material melting, design, and defect prediction, the review identifies ANN, Bayesian Network, and SVM as the most commonly utilized models.

- The paper concludes that ANN and SVM are the most suitable ML techniques for both confirming desired material properties and predicting defects within the sand-casting process.

- The review highlights specific successful applications, such as using Bayesian networks to predict microshrinkage, SVM to classify X-ray images for subsurface defects, and deep neural networks for modeling alloy solidification.

Figure Name List:

- Fig. 1. Types of ML models used foundry automation and quality control

- Fig. 2. Types of ML models used in material design, melting and defect prediction

7. Conclusion:

The review concludes that a variety of machine learning techniques are employed by researchers for quality checking, process optimization, material design, and defect prediction in foundries. Based on the literature, ANN, SVM, and Decision Tree are the most common models for automation and quality control, while ANN, Bayesian Network, and SVM are prevalent for material design and defect prediction. It is determined that ANN and SVM are the most suitable overall techniques for confirming material properties and predicting defects in sand-casting. Future work should involve checking data fitness with applicable kernels (e.g., RBF, MLP), using techniques like SMOTE to handle imbalanced datasets, and extending studies to special casting processes.

8. References:

- [1] J. Kozłowski, R. Sika, F. Górski, O. Ciszak, Modeling of foundry processes in the era of industry 4.0. In: Ivanov V., et al. Adv. Des. Simul. Manuf. DSMIE 2019. Springer Cham. 62-71 (2019). DOI: https://doi.org/10.1007/978-3-319-93587-4_7

- [2] N.D. Mehta, A.V. Gohil, S.J. Doshi, Innovative Support System for Casting Defect Analysis - A Need of Time. Mater. Today Proc. 5 (2), 4156-4161 (2018). DOI: https://doi.org/10.1016/j.matpr.2017.11.677

- [3] B. Hazela, Machine Learning: Supervised Algorithms to Determine the Defect in High-Precision Foundry Operation. J. Nanomater. 2022 (2022). DOI: https://doi.org/10.1155/2022/1732441

- [4] D. Wilk-Kołodziejczyk, M. Małysza, K. Jaśkowiec, A. Bitka, M. Głowacki, Modification of Casting Production Parameters in Order to Obtain Products with the Assumed Parameters with Using Machine Learning. Int. J. Met. 17 (4), 2680-268 (2023). DOI: https://doi.org/10.1007/s40962-023-01076-9

- [5] Y. Santos, I. Nieves, J. Bringas, P.Y. Penya, Machine-Learning-Based Defect Prediction in High-Precision Foundry. Struct. Steel Cast. Shapes Stand. Prop. Appl. L. M. Becker (Ed). 259-276 (2010).

- [6] P.J. García Nieto, E. García-Gonzalo, J.C. Álvarez Antón, V.M. González Suárez, R. Mayo Bayón, F. Mateos Martín, A comparison of several machine learning techniques for the centerline segregation prediction in continuous cast steel slabs and evaluation of its performance, J. Comput. Appl. Math. 330. 877-895 (2018) DOI: https://doi.org/10.1016/j.cam.2017.02.031

- ... [and all other references up to 32 as listed in the paper] ...

- [32] J. Suthar, J. Persis, R. Gupta, Predictive modeling of quality characteristics - A case study with the casting industry. Comput. Ind. 146, (2023). DOI: https://doi.org/10.1016/j.compind.2023.103855

Expert Q&A: Your Top Questions Answered

Q1: According to this review, which specific machine learning models are most consistently used for improving quality control in foundries?

A1: The paper's analysis, summarized in Figure 1, shows that Artificial Neural Networks (ANN) are the most widely applied model for automation and quality control, appearing in 24.3% of the reviewed studies. Following ANNs, Support Vector Machines (SVM) and Decision Trees are also prominent, each used in 10.8% of cases. These models are favored for their ability to analyze historical data and predict the quality of castings, ensuring consistency.

Q2: How does machine learning help in predicting a casting's mechanical properties before it's even made?

A2: The paper cites several studies where ML models were trained to predict mechanical properties based on input parameters. For example, researchers have successfully predicted ultimate tensile strength (UTS) and hot ductility of cast steel by feeding models with data on chemical composition and thermal conditions. This allows engineers to computationally design and verify material properties without costly and time-consuming physical experiments.

Q3: Can these ML techniques detect internal defects that aren't visible on the surface, such as those found in HPDC parts?

A3: Yes. The paper specifically discusses the use of ML for analyzing X-ray images, which is the primary non-destructive method for finding internal flaws. One study reviewed 24 different methods for computer-aided X-ray defect detection. It found that an ensemble learning model combined with LBP (Local Binary Patterns) feature engineering achieved the best performance, demonstrating that ML can be effectively used to automate the detection of subsurface defects.

Q4: The paper's conclusion mentions "not balanced classes" and "SMOTE." What does this mean in a practical foundry setting?

A4: In a foundry, "not balanced classes" refers to a dataset where defect-free parts vastly outnumber parts with a specific defect. If a model is trained on such data, it can become very good at identifying good parts but poor at identifying the rare defects. The paper suggests using aids like SMOTE (Synthetic Minority Over-sampling Technique), which is an algorithm that creates new, synthetic examples of the minority class (the defects) to create a more balanced dataset for training a more accurate prediction model.

Q5: What is the primary advantage of using these data-driven ML models compared to traditional physics-based simulation software?

A5: While simulation is powerful, it often requires extensive setup and computational resources. The paper highlights that ML models, once trained on historical production data, can provide rapid predictions. For instance, a study created a model that could reproduce a set of production process parameters with a smaller number of test results, lowering the need for genuine tests. This reduces costs, speeds up decision-making, and can capture complex variable interactions that may be difficult to define in a purely physics-based model.

Conclusion: Paving the Way for Higher Quality and Productivity

The core challenge in metal casting has always been managing a multitude of variables to consistently produce defect-free parts. This comprehensive review demonstrates that Machine Learning in Metal Casting offers a powerful solution. By leveraging historical data, models like ANN and SVM can predict outcomes, identify potential defects before they occur, and optimize processes for greater efficiency and quality. The key breakthrough is the shift from a reactive, experience-based approach to a proactive, data-driven one.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "AN OVERVIEW OF MACHINE LEARNING APPLICATIONS IN METAL CASTING INDUSTRIES" by "VISHAL B. BHAGWAT, DHANPAL A. KAMBLE, and SANDEEP S. KORE".

Source: https://doi.org/10.24425/amm.2024.151428

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.