Unlocking New Potential in Thin-Walled Gray Cast Iron Casting: A Proven Method to Boost Fluidity and Extend Service Life by 30%

This technical summary is based on the academic paper "Development of Technology for Obtaining Thin-Walled Details from Gray Cast Iron in Sand-Clay Moulds" by Jamshidbek Khasanov et al., published in the International Journal of Mechatronics and Applied Mechanics (2024).

Keywords

- Primary Keyword: Thin-Walled Gray Cast Iron Casting

- Secondary Keywords: Gray Cast Iron, Sand-Clay Moulds, Casting Modifiers, Liquid Fluidity, Mechanical Properties, Microstructure Analysis, Brittleness, Perlite, Ferrite, Graphite

Executive Summary

- The Challenge: Manufacturing complex, thin-walled gray cast iron components is often hindered by poor liquid fluidity and insufficient hardness, leading to defects and reduced service life.

- The Method: Researchers developed a comprehensive technology involving the precise addition of modifiers (copper phosphide and ferromolybdenum) to G24 gray cast iron and utilized modern 3D-printed polystyrene models for sand-clay molds.

- The Key Breakthrough: This integrated approach increased the liquid alloy's fluidity by up to 11% and the final casting's hardness by 12%, enabling the successful production of high-quality, defect-free thin-walled parts.

- The Bottom Line: The developed technology and optimized alloy composition increased the service life of the resulting thin-walled castings by 1.3 times, offering a significant and measurable improvement in durability and performance for industrial applications.

The Challenge: Why This Research Matters for HPDC Professionals

In today's engineering landscape, the demand for lightweight, high-strength, and cost-effective components is relentless. Gray cast iron is a compelling material, particularly in the automotive industry, where it can reduce vehicle costs by nearly 15% compared to steel or aluminum alloys. However, its application in producing thin-walled, complex parts presents significant manufacturing challenges.

The core problem lies in the inherent properties of the molten alloy. Achieving complete mold fill for intricate, thin sections requires exceptional liquid fluidity. Simultaneously, the final part must possess sufficient hardness and strength to withstand operational stresses. Traditional methods often struggle to balance these requirements, leading to misruns, cold shuts, and parts with suboptimal mechanical properties. This research directly addresses this critical industry pain point by developing a repeatable, technology-driven solution to enhance the castability and performance of gray cast iron for demanding thin-walled applications.

The Approach: Unpacking the Methodology

The study was built on a systematic, multi-faceted approach to improve every critical stage of the casting process, from alloy preparation to mold creation and final pouring.

Method 1: Strategic Alloy Modification

The base material was G24 gray cast iron. To enhance its properties, researchers introduced specific modifiers both in the furnace and out-of-furnace.

- Materials: G24 gray cast iron, ferromolybdenum (FeMo70), and copper phosphide (CuP2).

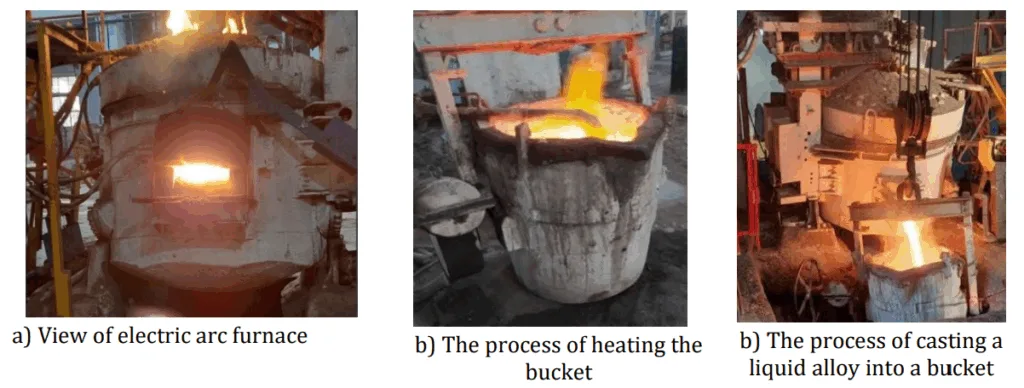

- Equipment: A DSP-0.5 electric arc furnace was used for melting and alloying.

- Key Variables: The mass percentages of CuP2 and FeMo70 were systematically varied to determine their effect on fluidity, hardness, and brittleness.

Method 2: Advanced Modeling and Molding Technology

To overcome the limitations of traditional pattern making, the team integrated modern digital design and manufacturing techniques.

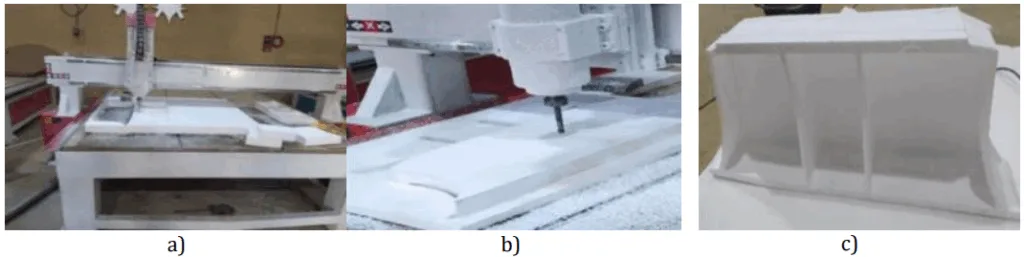

- Modeling: 3D models of the thin-walled "lifting roof" detail were created using Solidworks software. These digital designs were then used to machine patterns from flammable polystyrene material on a CNC ROUTER machine.

- Molding: A vacuum mold was prepared using a composition of 80-84% quartz sand, 5-6% bentonite clay, and 6-7% water. This method, combined with the precise polystyrene models, allowed for the creation of highly detailed and complex mold cavities.

Method 3: Rigorous Property Testing and Analysis

The effectiveness of the new technology was validated through comprehensive material testing.

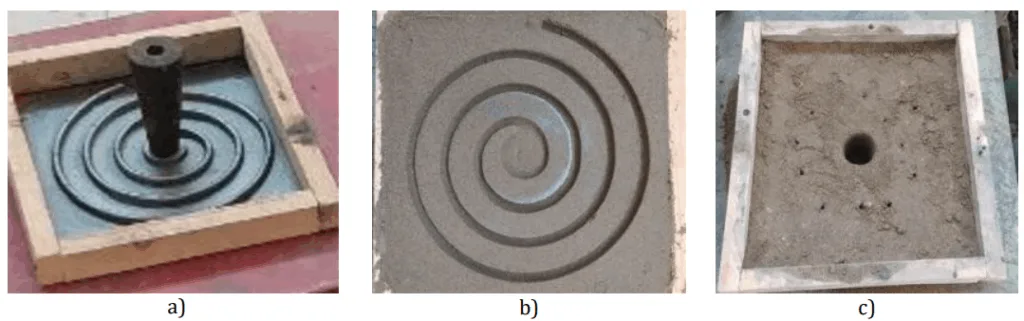

- Fluidity Testing: A standardized spiral sample mold (Figure 6) was used to quantitatively measure the liquid flow length of different alloy compositions at various temperatures.

- Mechanical Testing: A ZWICK/ROELL Z600 universal testing machine was used to determine the compressive strength and brittleness of the cast samples.

- Microstructural Analysis: A Carl Zeiss Ultra Plus Field Emission scanning electron microscope (SEM) was employed to examine the microstructure of the resulting castings, identifying the phases of graphite, perlite, and ferrite.

The Breakthrough: Key Findings & Data

The experimental results demonstrated clear and significant improvements in the properties of the gray cast iron, directly attributable to the new technology.

Finding 1: Copper Phosphide Dramatically Increases Liquid Fluidity

The addition of copper phosphide (CuP2) was identified as a critical factor in improving the alloy's ability to fill thin sections. The study found that 0.5% CuP2 was the optimal amount.

- As shown in Table 4, at a casting temperature of 1450°C, the fluidity length increased from 230 mm for the unmodified alloy to 560 mm with the addition of 0.5% CuP2. This represents a more than two-fold increase in flowability, which is essential for thin-walled casting. While higher amounts (0.7%) increased fluidity further to 600 mm, they also induced excessive brittleness.

Finding 2: Molybdenum Enhances Hardness and Refines Microstructure

While CuP2 improved fluidity, ferromolybdenum (FeMo70) was added to increase hardness and corrosion resistance.

- The research determined that an optimal amount of 0.3% molybdenum provided the desired increase in hardness without significantly compromising fluidity or causing excessive brittleness. As detailed in the paper, molybdenum modifies the microstructure by promoting the transformation of austenite from pearlite to bainite, contributing to improved mechanical properties. The microstructural images in Figure 17 clearly show the resulting refined structure of perlite, ferrite, and well-distributed graphite flakes.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting the alloy composition with a combination of ~0.5% copper phosphide and ~0.3% molybdenum may be a highly effective strategy for overcoming mold-filling issues in thin-walled gray cast iron casting, directly contributing to a reduction in scrap rate.

- For Quality Control Teams: The data in Figure 13 and Table 4 of the paper illustrates the direct effect of modifier additions on compressive strength and fluidity. These findings could inform new quality inspection criteria for critical thin-walled components, linking specific alloy compositions to measurable performance metrics.

- For Design Engineers: The findings indicate that the successful casting of complex, thin-walled geometries is achievable with optimized material chemistry. This allows for greater design freedom, enabling the creation of more lightweight and intricate components without compromising manufacturability. The use of CNC-machined polystyrene patterns from 3D models further supports this, saving 13-15% in resources.

Paper Details

Development of Technology for Obtaining Thin-Walled Details from Gray Cast Iron in Sand-Clay Moulds

1. Overview:

- Title: Development of Technology for Obtaining Thin-Walled Details from Gray Cast Iron in Sand-Clay Moulds

- Author: Jamshidbek Khasanov, Nozimjon Kholmirzaev, Nosir Saidmakhamadov, Begijon Tojiboev, Ergashev Dilshodbek, Khusanboy Makhammadjanov, Abdujalol Bektemirov, Firyuza Arabbaeva, Akramjon Otakuziev

- Year of publication: 2024

- Journal/academic society of publication: International Journal of Mechatronics and Applied Mechanics, Issue 18

- Keywords: Gray cast iron, Thin-walled details, Sand-clay moulds, Brittleness, Perlite, Ferrite, Graphite.

2. Abstract:

In this article, the technology of casting thin-walled details into sand-clay molds has been developed based on the analysis of existing problems in casting detail manufacturing enterprises. In order to increase the liquid fluidity and hardness properties of G24 gray cast iron alloy, the technology of adding modifiers to the liquid alloy in the furnace and outside the furnace was developed. In addition, the composition of the sand-clay mold material and the technology of the processes of pouring the liquefied gray cast iron alloy into the mold were developed. Also, the technologies of using models made of modern ABS (acrylonitrile butadiene styrene) material have been improved in obtaining casting details of thin-walled parts in a sand-clay mold. Microstructural images of gray cast iron alloy samples cast on the basis of the used technologies were obtained and interpreted. As a result of the introduction of the developed technologies, it was possible to obtain high-quality thin-walled details. Based on the developed technologies and the modifiers included in the liquid alloy, the service life of cast thin casting has increased by 1.3 times.

3. Introduction:

The paper addresses the industrial need for high-quality, inexpensive, thin-walled cast products with improved mechanical and operational properties. It highlights the increasing demand for lightweight products to reduce energy and fuel consumption. Gray cast iron is presented as a cost-effective alternative to steel and aluminum alloys, particularly in the automotive industry, due to its low cost and ease of mass production. The research is motivated by the challenges in producing durable, thin-walled, high-construction details from gray cast iron. It builds upon existing knowledge that modifying the composition of gray cast iron with various elements can improve its properties such as corrosion resistance, hardness, and fluidity. The study aims to develop and improve casting technologies to overcome these challenges.

4. Summary of the study:

Background of the research topic:

The research is set against the backdrop of a growing global demand for thin-walled cast products in the engineering and automotive industries. The focus is on gray cast iron, which holds a significant market share (37% in 2021) due to its low cost, low melting point, and ease of production compared to steel. However, producing complex, thin-walled parts from this inherently brittle material presents significant technological hurdles.

Status of previous research:

The paper acknowledges that leading scientists have previously studied the modification of gray cast iron's composition to obtain cheaper, more durable details. It is known that adding modifiers and alloying elements can improve properties like corrosion resistance, hardness, and fluidity, and that controlling the cooling rate is critical.

Purpose of the study:

The primary purpose was to develop a comprehensive technology for obtaining high-quality, thin-walled details from G24 gray cast iron in sand-clay molds. This involved increasing the liquid fluidity and hardness of the alloy through the addition of modifiers, optimizing the mold material composition, and improving the model-making process.

Core study:

The core of the study involved a series of experiments focused on a specific industrial part: a "lifting roof detail" used in metallurgical enterprises. The research developed in-furnace and out-of-furnace modification technologies using ferromolybdenum (FeMo70) and copper phosphide (CuP2). It also developed an improved molding process using combustible polystyrene models created from 3D CAD files on a CNC machine. The effects of these modifications on the fluidity, mechanical properties (compressive strength, brittleness), and microstructure of the G24 gray cast iron were systematically analyzed.

5. Research Methodology

Research Design:

The study employed an experimental research design to investigate the effects of specific modifiers on the physical and mechanical properties of G24 gray cast iron. The chemical composition of multiple samples was varied by adding different percentages of copper phosphide and molybdenum. The resulting properties were then measured and compared to a baseline unmodified sample.

Data Collection and Analysis Methods:

- Chemical Composition: Determined using an emission spectroscopy device.

- Microstructure Analysis: Analyzed using fast metallurgical microscopes and a Carl Zeiss Ultra Plus Field Emission scanning electron microscope (SEM).

- Fluidity Measurement: Assessed by casting spiral samples and measuring the length of the filled spiral.

- Mechanical Properties: Compressive strength and brittleness were determined using a ZWICK/ROELL Z600 testing machine.

- Process Observation: The casting process, from melting in a DSP-0.5 electric arc furnace to pouring, was conducted and documented at the "Uzmetkombinat" JSC enterprise and in a laboratory setting.

Research Topics and Scope:

The research was focused on G24 gray cast iron and its application for producing thin-walled "lifting roof" details. The scope included the development of alloy modification techniques, sand-clay mold composition, modern model-making using polystyrene, and analysis of the resulting material's fluidity, hardness, compressive strength, and microstructure.

6. Key Results:

Key Results:

- The technology of out-of-furnace processing of the liquid alloy was developed, increasing its fluidity by 9-11%.

- The technology of in-furnace processing of the liquid alloy was developed, increasing the hardness of the cast product by 10-12%.

- The use of model preparation technology based on 3D technology allowed for resource savings of 13-15%.

- An efficient casting technology was developed through modification with CuP2 and Mo elements, allowing for savings in modifiers.

- A scheme for the placement of the detail in the casting mold was developed to ensure uniform distribution of corrosion resistance.

- The technology successfully increased the fluidity of gray cast iron, enabling the production of thin-walled details with a complex shape.

- As a result of the developed technologies, the service life of the cast thin casting was increased by 1.3 times.

Figure Name List:

- Figure 1: A detail of the lifting roof used by the enterprise "Uzmetkombinat" JSC. a) Rear view of the lifting roof detail b) Front view of the lifting roof detail

- Figure 2: Three views of the 3D model of the lifting roof detail drawn in the Compass program based on the SP-1037 drawing

- Figure 3: Models of lifting roof detail made of polystyrene material using a CNC ROUTER machine a) making from polystyrene on the CNC ROUTER device b) semi-finished model c) finished model

- Figure 4: Models prepared for casting in a vacuum mold based on a drawing a) SP-1037 is a model of a raised roof detail based on the drawing b) SP-1033 is a model of a raised window detail based on the drawing c) models of lifting roof details based on drawings SP-1037 and SP-1033

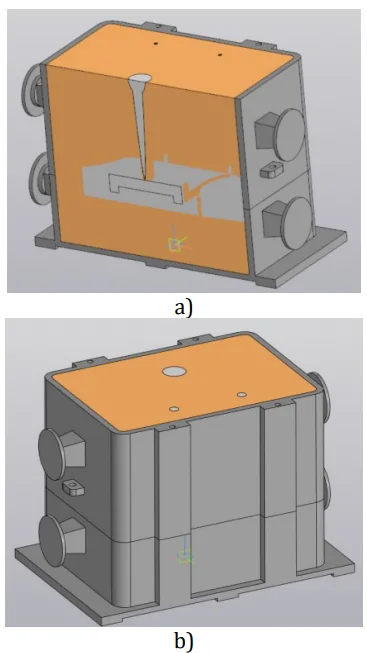

- Figure 5: A figure of the placement of the mold of the lifting roof detail a) a cropped image of the placement of the models in the mold b) flasks layout of models

- Figure 6: Spiral sample for fluidity determination a) spiral sample 3D view b) spiral sample dimensions

- Figure 7: A mold made using a spiral model to determine the ductility of modified gray cast iron a) model ready for rammering with sand b) the inner part of the mold based on the prepared spiral pattern c) mold ready for casting.

- Figure 8: The process of liquefaction of gray cast iron in the BF-TB2 induction furnace a) The process of loading charges into the furnace crucible b) the process of adding a modifier to the alloy being liquefied c) the process of casting a liquid alloy into a spiral mold

- Figure 9: Processes of de-molding from the mold and measuring the length of samples cast with copper phosphide as a modifier in gray cast iron a) separating the cast samples from the mold b) the process of measuring various samples c) the process of measuring the length of a cast sample without the addition of a modifier.

- Figure 10: Proportion of lengths to the amount of copper phosphide as a modifier for gray cast iron.

- Figure 11: Copper phosphide and temperature dependence graph of fluidity length (1.1450 °C, 2.1430 °C, 3. 1400°C).

- Figure 12: The graph of the dependence of the fluidity length of gray cast iron on the amount of molybdenum added to it as a modifier.

- Figure 13: Graph of dependence of copper phosphide and ferromolybdenum added as modifiers to gray cast iron samples on its brittleness property.

- Figure 14: Determining the compressive strength properties of gray cast iron samples a) ZWICK/ROELL Z600 laboratory equipment b) a sample prepared for testing the property of brittleness c).

- Figure 15: Casting process of liquefied gray cast iron alloy in an electric arc furnace.

- Figure 16: Detail of a thin-walled high-rise construction raised roof cast in gray cast iron in sand-clay moulds.

- Figure 17: Microstructures of copper phosphide 0.5% and molybdenum 0.3% in Carl Zeiss Ultra Plus Field Emission scanning electron microscope in the laboratory of "Iron and Steel" Institute of Karabuk University a) image magnified x500 times b) image magnified x2000.

- Figure 28: Volume distribution of elements in gray cast iron samples taken by Carl Zeiss Ultra Plus Field Emission scanning electron microscope in the laboratory of the Iron and Steel Institute of Karabuk University.

7. Conclusion:

The paper presents six main conclusions from the work on developing technology for obtaining thin-walled details from gray cast iron:

1. A technology for out-of-furnace processing was developed, increasing liquid alloy fluidity by 9-11%.

2. A technology for in-furnace processing was developed, increasing the cast product's hardness by 10-12%.

3. A model preparation technology based on 3D technology was developed, allowing for resource savings of 13-15%.

4. An efficient casting technology was developed using CuP2 and Mo modification, leading to savings in modifiers.

5. A placement scheme for the detail within the casting mold was developed to ensure uniform corrosion resistance.

6. The overall technology for increasing gray cast iron fluidity was developed, enabling the production of complex-shaped, thin-walled details.

8. References:

- [1] https://www.sphericalinsights.com/reports/iron-steel-casting-market

- [2] https://www.caef.eu/statistics/

- [3] Khasanov, J., Turakhodjaev, N., Abdukarimov, A., & Mirkamalov, S. (2022). Microstructural Analysis of Details Obtained by Liquefying Gray Cast Iron in a Sand Clay Mold. Central Asian Journal of Theoretical and Applied Science, 3(12), 107-112. https://doi.org/10.17605/OSF.IO/BS4W2

- [4] International Journal of Cast Metals Research Relationship between matrix-microstructure and mechanical properties of copper alloyed thin wall austempered gray cast iron (TWAGI) Tanmoy Sarkar & Goutam Sutradhar (2017): Relationship between matrixmicrostructure and mechanical properties of copper alloyed thin wall austempered gray cast iron (TWAGI), International Journal of Cast Metals Research, DOI: 10.1080/13640461.2017.1351705 17 Jul 2017.

- [5] Nosir, S.., Nodir, T. ., Jamshidbek, K. ., Nilufar, Z. ., & Anvar, Τ. (2022). Improvement of the Technology of Pouring Thin - Walled Gray Cast Iron into a Sand Clay Mold. European Multidisciplinary Journal of Modern Science, 9, 90– 96. Retrieved from https://emjms.academicjournal.io/index.php/emjms/article/view/747

- [6] Saidmakhamadov Nosir, Turakhodjaev Nodir, Abdullaev Kamol, Khasanov Jamshidbek, & Tadjiev Nuritdin. (2022). Improvement of Technology of Liquefaction of Gray Cast Iron Alloy. Global Scientific Review, 6, 19-28. Retrieved from https://scienticreview.com/index.php/gsr/article/view/40

- [7] Khasanov, J., Turakhodjaev, N., Makhmudov, F., Turakhujaeva, S., Ermanov, O., & Ibragimov, A. (2023). Improvements in Obtaining Thin-Walled Casting Details Through Liquid Glass Mixtures. Central Asian Journal of Theoretical and Applied Science, 4(4), 51-54. https://doi.org/10.17605/OSF.IO/6T843

- [8] E. Heidari, S. M. A. Boutorabi, and M. T. Ablation casting of thin-wall ductile iron. Honaramooz School of Metallurgy and Materials Engineering, Iran University of Science and Technology, Tehran, Iran J. Campbell School of Metallurgy and Materials Engineering, The University of Birmingham, Edgbaston B152TT, UK Copyright 2021 American Foundry Society, 37-43 pages. May 2020. https://doi.org/10.1007/s40962-021-00579-7.

- [9] Agus Yulianto, Rudy Soenoko, Wahyono Suprapto, As'ad Sonief, Agung Setyo Darmawan, Muhammad Debi Setiawan.; Microstructure and Hardness of Gray Cast Iron as a Product of Solidification in Permanent Mold. Materials Science Forum (Volume 991) https://doi.org/10.4028/www.scientific.net/MSF.991.37

- [10] J. O. Agunsoye, S. A. Bello, S. B. Hassan, R. G. Adeyemo, J. M. The Effect of Copper Addition on the Mechanical and Wear Properties of Grey Cast Iron. Odii Journal of Minerals and Materials Characterization and Engineering, 2014.

- [11] Nodir, T., Nosir, S., Shokhista, S., Furkat, O., Nozimjon, K., & Valida, B. (2021). Development of 280x29nl alloy liquefaction technology to increase the hardness and corrosion resistance of cast products. International Journal of Mechatronics and Applied Mechanics, 1(10), 154-159. https://doi.org/10.17683/IJOMAM/ISSUE10/V1.19

- [12] Kidao, "Application of copper in Automotive Iron Castings", Copper in Cast Iron, 1970, pp 13-18.

- [13] http://w3.bilecik.edu.tr/wp-content/uploads/sites/119/2016/12/Basma Deneyi.pdf

- [14] Kholmirzaev, N., Turakhodjaev, N., Saidmakhamadov, N., Khasanov, J., Saidkhodjaeva, S., & Sadikova, N. (2023). Development of Technology of Making Shafts from Steel Alloy 35XGCL. Lecture Notes in Networks and Systems, 762 LNNS. https://doi.org/10.1007/978-3-031-40628-7 18

- [15] Kholmirzaev, N., Turakhodjaev, N., Saidmakhamadov, N., Khasanov, J., Bektemirov, A., & Sadikova, N. (2024). Effects of titanium (Ti) contents on the wear resistance of low-alloy steel alloys. In E3S Web of Conferences (Vol. 525, p. 03003). EDP Sciences.

- [16] Xiao, Z., Lv, Z., Zhou, X. et al. Numerical Simulation and Optimization of Investment Casting for Complex Thin-walled Castings. Inter Metalcast 18, 159-179 (2024). https://doi.org/10.1007/s40962-023-00990-2

- [17] Łukasz Rakoczy, Rafał Cygan, Analysis of temperature distribution in shell mould during thin-wall superalloy casting and its effect on the resultant microstructure, Archives of Civil and Mechanical Engineering, Volume 18, Issue 4, 2018, Pages 1441-1450, ISSN 1644-9665, https://doi.org/10.1016/j.acme.2018.05.008.

- [18] Krutiš V, Novosad P, Záděra A, Kaňa V. Requirements for Hybrid Technology Enabling the Production of High-Precision Thin-Wall Castings. Materials. 2022; 15(11):3805. https://doi.org/10.3390/ma15113805

- [19] Bingxu Wang, Yuming Pan, Yu Liu, Gary C. Barber, Feng Qiu, Ming Hu, Wear behavior of composite strengthened gray cast iron by austempering and laser hardening treatment, Journal of Materials Research and Technology, Volume 9, Issue 2, 2020, Pages 2037-2043, ISSN 2238-7854, https://doi.org/10.1016/j.jmrt.2019.12.036.

- [20] Ibrahim, M. (2023). An overview on Thin Wall Cast Iron Castings and its Applications in Automotive Industry. International Journal of Materials Technology and Innovation, 3(1), 57-69. doi: https://doi.org/10.21608/ijmti.2022.153909.1056

- [21] Y.W. Dong, X.L. Li, Qi Zhao, Jun Yang, Ming Dao, Modeling of shrinkage during investment casting of thin-walled hollow turbine blades, Journal of Materials Processing Technology, Volume 244, 2017, Pages 190-203, ISSN 0924-0136, https://doi.org/10.1016/j.jmatprotec.2017.01.005.

- [22] Lu, Y., Lü, K., Li, Y. et al. Effect of Wall Thickness on Properties of Multilayer Composite Plaster Mold for Investment Casting. Inter Metalcast (2024). https://doi.org/10.1007/s40962-024-01350-4.

- [23] V. Lopes, H. Puga, I.V. Gomes, N. Peixinho, J.C. Teixeira, J. Barbosa, Magnesium stents manufacturing: Experimental application of a novel hybrid thin-walled investment casting approach, Journal of Materials Processing Technology, Volume 299, 2022, 117339, ISSN 0924-0136, https://doi.org/10.1016/j.jmatprotec.2021.117339.

- [24] Nosir, S., & Bokhodir, K. (2023). Development of Liquefaction Technology 280X29NL to Increase the Strength and Brittleness of Castings. In Lecture Notes in Networks and Systems: Vol. 534 LNNS. https://doi.org/10.1007/978-3-031-15944-2_10.

- [25] Baode Sun, Jun Wang, Da Shu Precision Forming Technology of Large Superalloy Castings for Aircraft Engines DOI: https://doi.org/10.1007/978-981-33-6220-8

- [26] Ren, J., Chen, X., Li, Yx. et al. Properties of fiber reinforced plaster molds for investment casting. China Foundry 17, 332-340 (2020). https://doi.org/10.1007/s41230-020-0056-9.

- [27] Mardonov, U., Meliboyev, Y., & Shaozimova, U. S. (2023). Effect of Static Magnetic and Pulsated Electromagnetic Fields On the Dynamic and Kinematic Viscosity of Metal Cutting Fluids. International Journal of Integrated Engineering, 15(1), pp: 203-212. doi: https://doi.org/10.30880/ijie.2023.15.01.018

- [28] Lu, Y., Liu, X., Li, Y. et al. Effect of Ball Milling Time on Strengths of Hybrid Fiber-reinforced Plaster Molds for Investment Casting. Inter Metalcast 15, 864-873 (2021). https://doi.org/10.1007/s40962-020-00522-2.

- [29] Lynch, P., Hasbrouck, C.R., Wilck, J., Kay, M. and Manogharan, G. (2020), "Challenges and opportunities to integrate the oldest and newest manufacturing processes: metal casting and additive manufacturing", Rapid Prototyping Journal, Vol. 26 No. 6, pp. 1145-1154. https://doi.org/10.1108/RPJ-10-2019-0277.

Expert Q&A: Your Top Questions Answered

Q1: Why was copper phosphide (CuP2) chosen as the primary modifier to improve fluidity?

A1: Copper phosphide was selected because phosphorus is known to significantly improve the fluidity of cast iron. According to the paper, phosphorus forms a ternary eutectic (a mixture of high-phosphorus austenite, carbide Fe3C, and phosphide Fe3P) that has a relatively low liquefaction point of 950°C. This easily fluidized eutectic phase persists longer during solidification, allowing the molten metal to fill intricate and thin sections of the mold more completely before solidifying.

Q2: The study identified 0.5% as the optimal amount of copper phosphide. What were the negative consequences of adding more?

A2: While adding more CuP2 (in the 0.6-0.9% range) did continue to increase fluidity, it came at the cost of increased brittleness. Phosphorus, while beneficial for fluidity, is generally considered a harmful element in cast iron's mechanical properties. The paper's compressive strength tests (Figure 13) showed that brittleness increases significantly as the amount of copper phosphide rises. Therefore, 0.5% was determined to be the optimal balance, providing a substantial fluidity boost without compromising the final part's structural integrity.

Q3: What was the specific role of molybdenum (FeMo70) in the alloy, and how did it complement the copper phosphide?

A3: Molybdenum was added primarily to increase the hardness and corrosion resistance of the gray cast iron. It functions as a carbide-forming element and refines the microstructure by promoting the transformation of austenite from pearlite to bainite. While copper phosphide addressed the casting challenge (fluidity), molybdenum addressed the in-service performance requirements (hardness and durability). The study found an optimal amount of 0.3% to achieve these benefits without negatively impacting fluidity to an unacceptable degree.

Q4: How did the use of 3D-printed polystyrene models improve the overall manufacturing process compared to traditional methods?

A4: The paper highlights that using CNC-machined polystyrene models based on 3D CAD files offered several advantages over traditional wooden models. This modern approach is faster and more precise, allowing for the creation of complex, high-construction geometries. The paper explicitly states that this technology provides a resource saving of 13-15% by reducing time, raw material consumption, and energy usage associated with conventional pattern making.

Q5: The paper concludes that the service life of the casting increased by 1.3 times. What specific technological changes were most responsible for this significant improvement?

A5: This 30% increase in service life was not due to a single change but rather the synergistic effect of the entire developed technology. The key contributors were: 1) The optimized alloy composition with CuP2, which ensured a complete, defect-free casting by improving fluidity, and 2) The addition of molybdenum, which increased the part's intrinsic hardness and corrosion resistance. This combination resulted in a higher-quality part that was both perfectly formed and materially stronger, leading directly to enhanced durability and a longer operational lifespan.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of producing high-quality, complex components via Thin-Walled Gray Cast Iron Casting has been a persistent hurdle for engineers. This research provides a clear and actionable technological pathway to overcome these limitations. By strategically modifying G24 gray cast iron with copper phosphide and molybdenum and integrating modern 3D modeling techniques, it is possible to dramatically improve liquid fluidity, enhance mechanical hardness, and ultimately produce defect-free parts with a 30% longer service life. These findings offer a significant opportunity for manufacturers to improve quality, reduce scrap, and expand the design possibilities for cost-effective cast iron components.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Development of Technology for Obtaining Thin-Walled Details from Gray Cast Iron in Sand-Clay Moulds" by "Jamshidbek Khasanov, Nozimjon Kholmirzaev, Nosir Saidmakhamadov, Begijon Tojiboev, Ergashev Dilshodbek, Khusanboy Makhammadjanov, Abdujalol Bektemirov, Firyuza Arabbaeva, Akramjon Otakuziev".

Source: The paper was published in the International Journal of Mechatronics and Applied Mechanics, 2024, Issue 18, pages 199-209.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.