Beyond the Surface: Why CT Scanning is the Gold Standard for Detecting Defects in Automotive Cast-Steel Parts

This technical summary is based on the academic paper "Flaw Detection of Cast-Steel Safety Parts in Automotive Application" by K.C. Dizdar, H. Sahin, M. Ardicli, D. Dispinar, published in ARCHIVES of FOUNDRY ENGINEERING (2022).

Keywords

- Primary Keyword: CT Scan for Casting Defects

- Secondary Keywords: Flaw Detection, Cast-Steel, Automotive Safety Parts, NDT (Non-Destructive Testing), Porosity Detection, Foundry Engineering

Executive Summary

- The Challenge: Ensuring zero defects in critical cast-steel automotive safety components to prevent catastrophic failures like fuel leaks.

- The Method: An evaluation of various non-destructive testing (NDT) methods, including Eddy-current, Ultrasonic Testing, Magnetic Particle Testing, and CT-Scan, on a 1.4308 stainless steel function block.

- The Key Breakthrough: CT-Scan proved to be the only effective method for comprehensively identifying the size, shape, and location of internal porosity in the complex part.

- The Bottom Line: For complex, critical cast-steel components, CT-Scan is the most reliable NDT method for ensuring part integrity and safety.

The Challenge: Why This Research Matters for HPDC Professionals

Casting is one of the most economical ways to mass-produce complex metal parts for the automotive industry. However, the very nature of solidification can introduce defects like shrinkage and gas porosity. While some minor defects may be tolerable in non-critical parts, they are unacceptable in functional safety components.

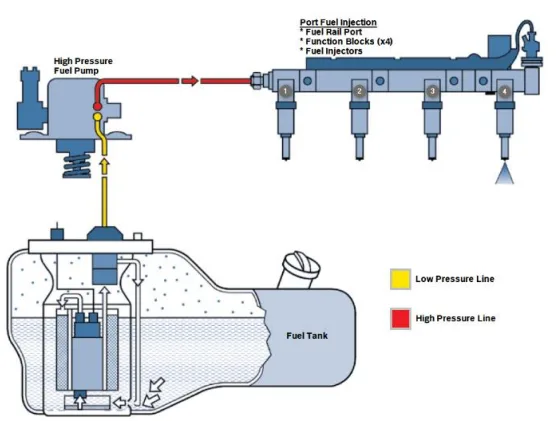

This study focuses on a cast-steel function block for a fuel injection unit—a part where failure is not an option. A defect leading to a fuel leak could cause a vehicle fire. The challenge for foundries and automotive suppliers is to implement a reliable, non-destructive inspection method that can be used in mass production to guarantee that every single part is free from critical flaws. Traditional NDT methods often fall short when faced with complex geometries and specific material properties, creating a critical gap in quality assurance.

The Approach: Unpacking the Methodology

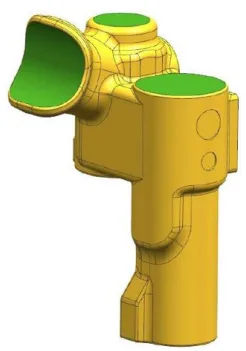

The research team investigated a 1.4308 cast stainless steel function block (20x65x40 mm) used in a high-pressure fuel pump system. To find the most effective inspection method, they systematically applied several NDT techniques.

Method 1: Eddy-Current and Ultrasonic Testing (UT)

An initial attempt was made using an Eddyliner device and ultrasonic probes. However, both methods failed to produce a reliable measurement. The complex geometry of the part prevented proper probe contact and rotation, while the large wall thickness and austenitic material structure resulted in low signal penetration, making it impossible to detect internal pores.

Method 2: Magnetic Particle Testing (MT)

This method was also attempted. MT relies on magnetic particles clinging to flux leakage fields at surface or near-surface defects. However, the function block is made of 1.4308 stainless steel, a non-magnetic material. Consequently, the magnetic particles did not adhere to the surface, rendering the test inapplicable.

Method 3: Radiography (X-Ray and Computed Tomography - CT)

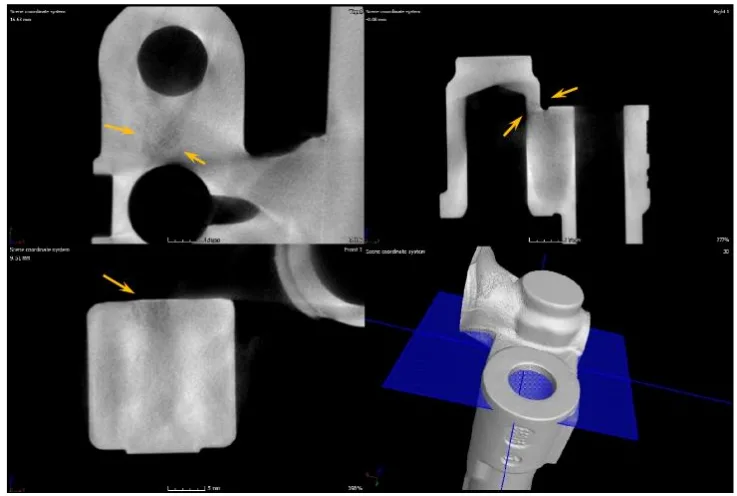

With other methods ruled out, the team turned to X-ray based inspection using YXLON MU-2000 and GE Phoenix v|tome|x s systems. The CT machine required careful fine-tuning of parameters (power in kV, current in μA, projection time, and filters) to achieve deep beam penetration and clear images, a process that took three hours for the initial setup. This approach proved successful in visualizing the part's internal structure.

The Breakthrough: Key Findings & Data

The evaluation clearly demonstrated the superiority of Computed Tomography for this application. Unlike other methods that failed entirely, CT-Scan provided a complete and detailed picture of internal defects.

Finding 1: Successful Detection of Internal Porosity

2D X-ray and CT scans successfully identified porosity within the cast sample, particularly in the thickest sections where solidification defects are common. As shown in Figures 3 and 5, porosity was clearly visible at the top of the part. This confirmed that radiography was a viable method for seeing through the material where other methods could not.

Fig. 3 & 5 from the paper illustrate the initial detection of porosity in the thickest section of the part.

Finding 2: Detailed 3D Characterization of Defect Shape and Location

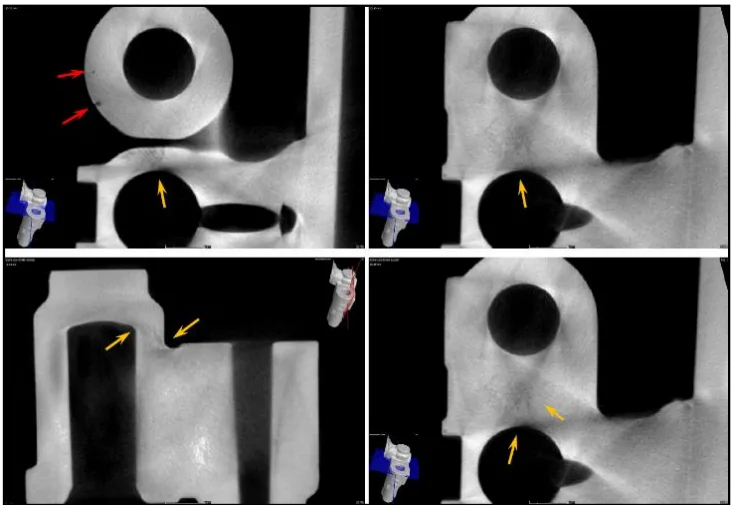

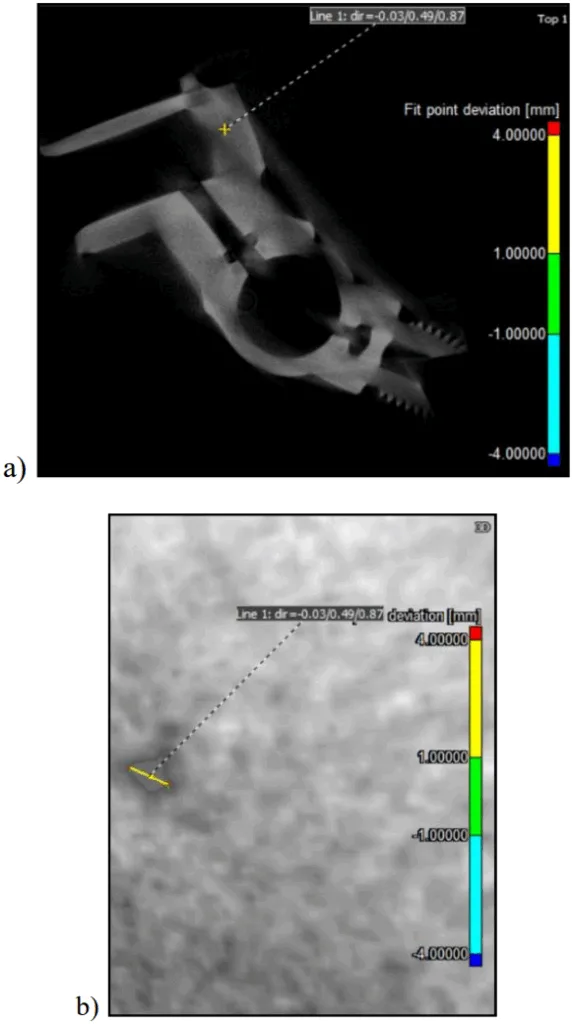

The true breakthrough came from the 3D capabilities of the CT-Scan. While a 2D X-ray can show that a pore exists, it cannot accurately determine its depth, shape, or volume. As seen in Figure 7, the CT data allows the part to be digitally sliced and cross-examined from any angle. This revealed not only spherical porosity but also sponge-type porosity, providing crucial information for understanding the defect's origin and its potential impact on the part's mechanical integrity. This level of detail is impossible to achieve with other non-destructive methods.

Fig. 7 from the paper shows a digital cross-section, allowing for precise measurement and characterization of the internal porosity.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that for complex cast-steel parts, relying on traditional NDT may provide a false sense of security. Implementing CT-Scan as a process validation tool can offer direct feedback on how changes in runner design, feeding, or melt quality affect the formation of internal porosity.

- For Quality Control Teams: The data in Figures 6 and 7 of the paper illustrates that CT-Scan enables a more sophisticated quality standard. Instead of a simple "defect/no defect" check, criteria can be based on the precise size, location, and type of porosity, ensuring that critical areas are 100% free of flaws while potentially accepting minor, non-critical indications elsewhere.

- For Design Engineers: The findings indicate that part geometry, particularly thick sections, directly influences both defect formation and the ability to inspect for those defects. This highlights the importance of considering inspectability during the initial design phase, ensuring that critical safety parts can be reliably validated with advanced NDT methods like CT.

Paper Details

Flaw Detection of Cast-Steel Safety Parts in Automotive Application

1. Overview:

- Title: Flaw Detection of Cast-Steel Safety Parts in Automotive Application

- Author(s): K.C. Dizdar, H. Sahin, M. Ardicli, D. Dispinar

- Year of publication: 2022

- Journal/academic society of publication: ARCHIVES of FOUNDRY ENGINEERING (Volume 2022, Issue 1/2022)

- Keywords: NDT, Cast steel, CT, Porosity, Leakage

2. Abstract:

Casting is the most economical way of producing parts for many industries ranging from automotive, aerospace to construction towards small appliances in many shares. One of the challenges is the achievement of defect-free cast parts. There are many ways to do this which starts with calculation and design of proper runner system with correct size and number of feeders. The first rule suggests starting with clean melt. Yet, rejected parts can still be found. Although depending on the requirement from the parts, some defects can be tolerated, but in critical applications, it is crucial that no defect should exist that would deteriorate the performance of the part. Several methods exist on the foundry floor to detect these defects. Functional safety criteria, for example, are a must for today's automotive industry. These are not compromised under any circumstances. In this study, based on the D-FMEA (Design Failure Mode and Effect Analysis) study of a functional safety criterion against fuel leakage, one 1.4308 cast steel function block, which brazed-on fuel rail port in fuel injection unit, was investigated. Porosity, buckling, inclusion and detection for leak were carried out by non-destructive test (NDT) methods. It was found that the best practice was the CT-Scan (Computed Tomography) for such applications.

3. Introduction:

Casting is an economical mass-production process involving pouring liquid alloy into a mould. During solidification, volumetric changes can lead to shrinkage porosity, while dissolved gases can cause gas porosity. These defects are a major cause for part rejection and economic loss. Proper design of feeders and runners, along with ensuring melt cleanliness, can mitigate these issues, but defects can still appear randomly. Cast steel is widely used in automotive applications for its toughness and ductility. Given its continued use, achieving low defect rates (ppm) is critical. Inspection is performed using destructive or non-destructive methods. This paper focuses on non-destructive tests (NDT) for flaw detection, such as cracks and porosity, in cast materials.

4. Summary of the study:

Background of the research topic:

The study is grounded in the stringent functional safety requirements of the modern automotive industry. For critical components like fuel system parts, defects such as porosity can lead to fuel leakage, posing a significant fire risk. Therefore, reliable and comprehensive flaw detection is not just a quality issue but a critical safety imperative.

Status of previous research:

The paper acknowledges the existence of various NDT methods, including Ultrasonic Testing (UT), Computed Tomography (CT), Magnetic Particle Testing (MT), and Penetrant Testing (PT). It cites existing literature on the application of these methods for detecting flaws like cracks and porosity and for characterizing material properties in different contexts.

Purpose of the study:

The primary objective was to evaluate several NDT methods to determine the most suitable and effective technique for detecting internal defects in a specific 1.4308 cast steel function block used in an automotive fuel injection system. The ultimate goal was to identify a method that could be reliably implemented for inspection in a mass production environment.

Core study:

The core of the study involved the systematic application of Eddy-current, Ultrasonic wave, Magnetic field imaging, and Radiography (X-ray and CT) to the cast steel function block. The applicability and results of each method were analyzed to compare their effectiveness in identifying porosity and other potential flaws within the complex geometry of the part.

5. Research Methodology

Research Design:

The study employed a comparative experimental design to evaluate the performance of different NDT methods on a single, industrially relevant component. The research was structured to first test common NDT methods and proceed to more advanced techniques based on the results.

Data Collection and Analysis Methods:

Data was collected using various NDT instruments. The final and most significant data was acquired using YXLON MU-2000 & GE Phoenix v|tome|x s X-ray and CT systems. The analysis involved fine-tuning machine parameters (e.g., power in kV, current in μΑ, projection time, pixel size, and filters) to optimize image quality for deep penetration and accurate pore detection. The collected 3D CT data was then analyzed by creating digital cross-sections to examine the size, shape, and location of the detected porosity.

Research Topics and Scope:

The research was focused on a 1.4308 stainless steel function block with dimensions of 20x65x40 mm, produced via investment casting. The scope was limited to the detection of flaws (primarily porosity) using non-destructive methods. The study did not include destructive testing, mechanical property analysis, or microstructural examination.

6. Key Results:

Key Results:

- Eddy-current and ultrasonic testing were determined to be ineffective for this part due to its complex geometry, large wall thickness, and the material's austenitic structure, which limited signal penetration.

- Magnetic particle testing was inapplicable because the 1.4308 stainless steel material is non-magnetic.

- Radiography, specifically 2D X-ray and 3D Computed Tomography (CT), successfully detected internal porosity.

- CT-Scan provided a comprehensive volumetric analysis, enabling detailed characterization of the porosity's location, size, and shape (including spherical and sponge-type defects), which is not possible with 2D X-ray or the other tested NDT methods.

Figure Name List:

- Fig. 1. Fuel pump system

- Fig. 2. The geometry of the tested part (20x65x40 mm)

- Fig. 3. X-ray images of porosity that is detected in the cast sample

- Fig. 4. Close-up X-Ray images of porosity region in Fig 3.

- Fig. 5. Observation of porosity on top of the part in the thickest section

- Fig. 6. Detection of two spherical porosity on the edges with sponge type porosity on the second section

- Fig. 7. Cross-examination of the porosity

7. Conclusion:

The size, geometry, and complexity of cast parts can present challenges for many analysis techniques. The volumetric analysis using CT Scan reveals detailed information about volumetric porosity, including the shape and distribution of pores. This non-destructive method provides solid information about internal defects that can be observed in cast materials. The method yields useful data in a short duration, making it a good option for rapid defect detection. This paper presented the adaptation of CT Scan for the detection of porosity in cast steel parts as a quick assessment tool.

8. References:

- [1] Stefanescu, D.M. (2005). Computer simulation of shrinkage related defects in metal castings-a review. International Journal of Cast Metals Research. 18(3), 129-143.

- [2] Kweon, E.S., Roh, D.H., Kim, S.B. & Stefanescu, D.M. (2020). Computational modeling of shrinkage porosity formation in spheroidal graphite iron: a proof of concept and experimental validation. International Journal of Metalcasting. 14, 601-609.

- [3] Campbell, J. (2015). Complete casting handbook: metal casting processes, metallurgy, techniques and design. Butterworth-Heinemann.

- [4] Duckers, (2015). AISI Materials Content Analysis: Final Report.

- [5] Meola, C., Squillace, A., Minutolo, F.M.C. & Morace, R.E. (2004). Analysis of stainless steel welded joints: a comparison between destructive and non-destructive techniques. Journal of Materials Processing Technology. 155, 1893-1899.

- [6] Menzies I. & Koshy, P. (2009). In-process detection of surface porosity in machined castings. International Journal of Machine Tools and Manufacture. 49(6), 530-535.

- [7] Ushakov, V.M., Davydov, D.M. & Domozhirov, L.I. (2011). Detection and measurement of surface cracks by the ultrasonic method for evaluating fatigue failure of metals. Russian Journal of Nondestructive Testing. 47(9), 631-641.

- [8] Vazdirvanidis, A., Pantazopoulos, G. & Louvaris, A. (2009). Failure analysis of a hardened and tempered structural steel (42CrMo4) bar for automotive applications. Engineering Failure Analysis. 16(4), 1033-1038.

- [9] Gupta, R.K., Ramkumar, P. & Ghosh, B.R. (2006). Investigation of internal cracks in aluminium alloy AA7075 forging. Engineering Failure Analysis. 13(1), 1-8.

- [10] Smokvina Hanza S. & Dabo, D. (2017). Characterization of cast iron using ultrasonic testing, HDKBR INFO Mag. 7(1), 3-7.

- [11] Krautkrämer, J. & Krautkrämer, H. (1990). Ultrasonic Testing of Materials” Springer-Verlag.

- [12] Ziółkowski, G., Chlebus, E., Szymczyk, P. & Kurzac, J. (2014). Application of X-ray CT method for discontinuity and porosity detection in 316L stainless steel parts produced with SLM technology. Archives of Civil and Mechanical Engineering. 14(4), 608-614.

- [13] A. du Plessis, A., le Roux, S.G. & Guelpa, A. (2016). Comparison of medical and industrial X-ray computed tomography for non-destructive testing. Case Studies in Nondestructive Testing and Evaluation. 6(A), 17-25.

- [14] Kurz, J.H., Jüngert, A., Dugan, S., Dobmann, G. & Boller, C. (2013). Reliability considerations of NDT by probability of detection (POD) determination using ultrasound phased array. Engineering Failure Analysis. 35, 609-617.

- [15] Sika, R., Rogalewicz, M., Kroma, A. & Ignaszak, Z. (2020). Open atlas of defects as a supporting knowledge base for cast iron defects analysis. Archives of Foundry Engineering. 20(1), 55-60.

Expert Q&A: Your Top Questions Answered

Q1: Why did standard NDT methods like Ultrasonic and Eddy Current fail for this specific part?

A1: According to the paper's discussion, these methods failed for two main reasons. First, the part's complex geometry and large wall thickness prevented effective application of the probes and limited the penetration of the ultrasonic waves. Second, the austenitic nature of the cast steel also contributed to low penetration levels for the ultrasonic test, making it insufficient to detect internal pores.

Q2: What specific material was tested and why is it challenging for some NDT methods?

A2: The part was a function block produced by casting from 1.4308 stainless steel. This material contains 18-20% chromium and around 10% nickel, making it non-magnetic. This non-magnetic property rendered Magnetic Particle Testing (MT), a common method for detecting surface flaws in ferrous materials, completely inapplicable.

Q3: What makes CT-Scan superior to a simple 2D X-ray for this application?

A3: While a 2D X-ray can show the presence of porosity, it cannot determine its precise location along the beam's path (depth). The paper's discussion implies this limitation: "the porosity can be observed but its location may vary which may not be known." CT-Scan overcomes this by creating a full 3D volumetric model, allowing for digital slicing (as seen in Figure 7) to pinpoint the exact location, size, and shape of the defect, which is critical for assessing its impact on a safety part.

Q4: What were the key parameters that needed to be tuned for the CT-Scan to be effective?

A4: The paper states that the pore detection job required "fine-tuning of some parameters." These included the power (in kV) and current (in μA) to ensure deep penetration of the X-ray beams, as well as projection time and pixel size. Additionally, a tin (Sn) filter was employed during the rendering process to obtain better and more accurate images from the machine.

Q5: What is the real-world safety implication of the defects found in this part?

A5: The part investigated is a function block for a fuel rail port in a vehicle's fuel injection unit. The paper states that problems with this part could "cause the high-pressure gasoline to leak out of the engine block... and subsequently cause the vehicle to catch fire." Therefore, the porosity detected by the CT-Scan represents a potential leak path, making its detection and elimination a critical safety requirement.

Conclusion: Paving the Way for Higher Quality and Productivity

Ensuring the absolute integrity of critical automotive components is a non-negotiable requirement. This research clearly demonstrates that for complex cast-steel safety parts, conventional NDT methods can be inadequate, creating unacceptable risks. The key breakthrough is the validation of CT Scan for Casting Defects as the most robust and reliable inspection tool. By providing a complete 3D view of a part's internal structure, CT-Scan empowers engineers to not only catch critical flaws but also to gain insights that can be used to refine the entire casting process.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Flaw Detection of Cast-Steel Safety Parts in Automotive Application" by "K.C. Dizdar, H. Sahin, M. Ardicli, D. Dispinar".

Source: https://doi.org/10.24425/afe.2022.140211

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.