Revolutionizing Aluminum Casting: How Machine Learning Delivers Rapid, Accurate Melt Quality Analysis

This technical summary is based on the academic paper "Enhanced Melt Quality Rapid Analysis of Aluminum Alloy Assisted by Machine Learning" by Yunxiang Tan, Juhuai Ma, Haifeng Liu, Jianlei Jia, Liguo Yang, and Qingyan Xu, presented at The 75th World Foundry Congress (2024).

Keywords

- Primary Keyword: Aluminum Alloy Melt Quality

- Secondary Keywords: Machine Learning in Casting, Thermal Analysis, Cooling Curve Analysis, HPDC Quality Control, Foundry Technology

Executive Summary

- The Challenge: Traditional methods for inspecting the quality of aluminum alloy melts before casting are too slow, creating a critical gap between melt preparation and quality verification.

- The Method: The research team conducted thermal analysis by recording the cooling curves of aluminum alloy melts and applied machine learning algorithms to rapidly identify key characteristics of the solidification process.

- The Key Breakthrough: A new, rapid melt quality criterion was developed that accurately and stably reflects the quality of the melt, proving significantly faster than conventional inspection techniques.

- The Bottom Line: This machine learning-assisted approach enables foundries to perform near real-time quality checks, facilitating process optimization and enhancing the final quality of aluminum castings.

The Challenge: Why This Research Matters for HPDC Professionals

In the quest for automotive lightweighting, the performance of aluminum alloy castings is paramount. The quality of the liquid metal before it's even poured is a critical factor that directly dictates the final microstructure and mechanical properties of the component. A poor-quality melt can lead to defects like shrinkage porosity, inconsistent grain size, and poor mechanical performance.

While treatments like refining and degassing are standard practice, verifying their effectiveness quickly is a major industry pain point. Traditional quality analysis methods are often performed after the fact, making it impossible to correct a sub-par melt before casting. This research addresses the urgent need for a rapid, accurate, and reliable pre-pour inspection system to ensure melt quality and prevent costly defects downstream.

The Approach: Unpacking the Methodology

The study was grounded in a practical, industrial setting at CITIC Dicastal Co., Ltd., using a low-pressure die casting melting furnace. The methodology combined physical experimentation with advanced data analysis.

Method 1: Thermal Analysis Experimentation

The core of the data collection involved a classic thermal analysis technique.

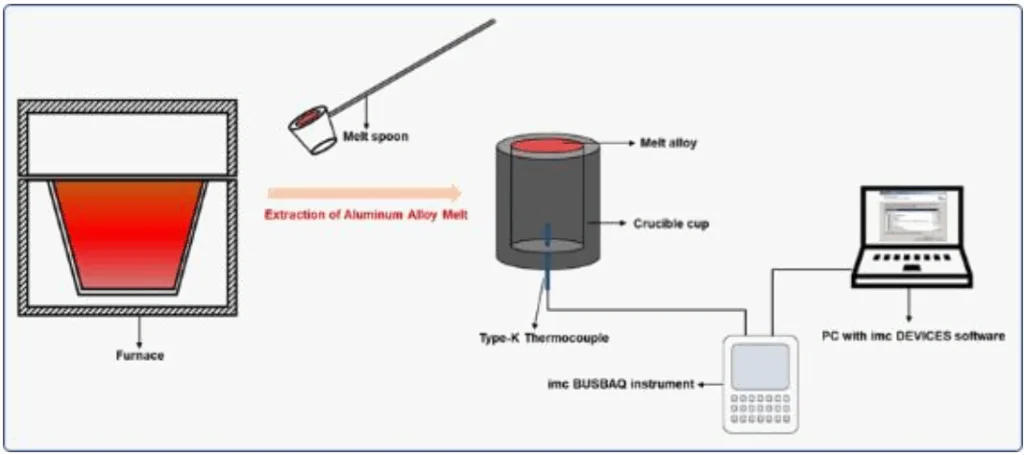

- Equipment: A low-pressure die casting melting furnace, a preheated test cup, K-type thermocouples, and an IMC temperature acquisition device.

- Process: A sample of the aluminum alloy melt was carefully extracted from the furnace at an ideal pouring temperature and poured into the test cup. Thermocouples recorded the temperature drop from the liquid state to room temperature.

- Output: This process generated a "cooling curve"—a graph of temperature versus time that serves as a unique fingerprint of the melt's solidification behavior.

Method 2: Data Processing and Machine Learning

The raw cooling curve data was then fed into a sophisticated analysis program.

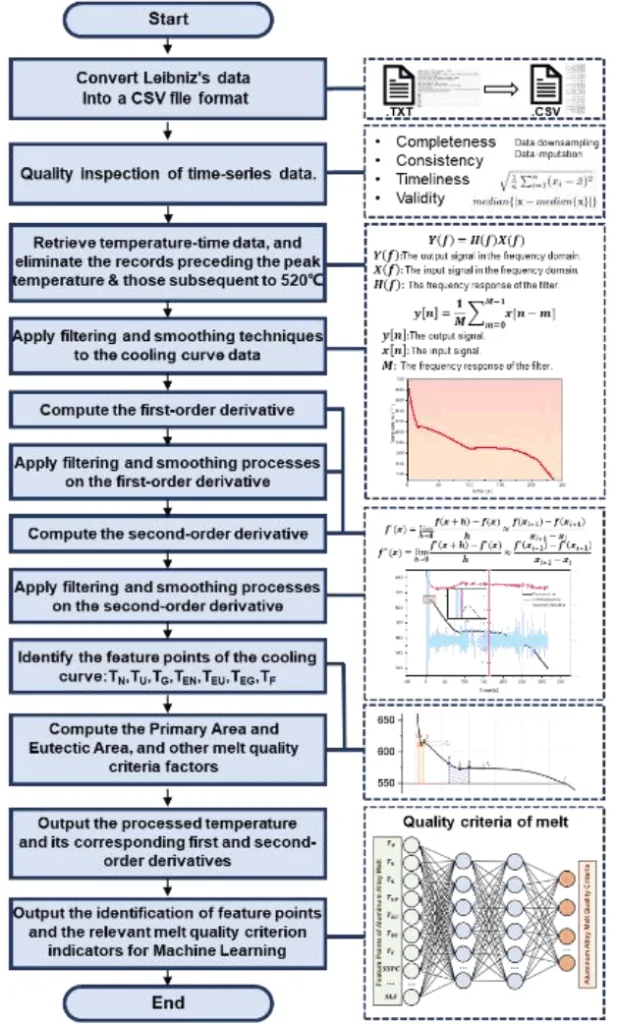

- Algorithm Development: The researchers developed algorithms to automatically process the cooling curve data. This included filtering noise, smoothing the curve, and calculating its first and second-order derivatives to pinpoint critical events during solidification.

- Feature Extraction: Key characteristic values were identified from the curves, such as the start and end temperatures of phase transformations and the rate of cooling (indicated by the curve's slope).

- Model Training: This data, combined with results from thermodynamic calculations and numerical simulations, was used to train machine learning models (including random forests, support vector machines, and deep neural networks) to build a new, comprehensive criterion for melt quality.

The Breakthrough: Key Findings & Data

The research delivered a powerful new tool for foundries, moving melt quality analysis from a slow, reactive process to a fast, predictive one.

Finding 1: Cooling Curves as a Rich Source of Quality Data

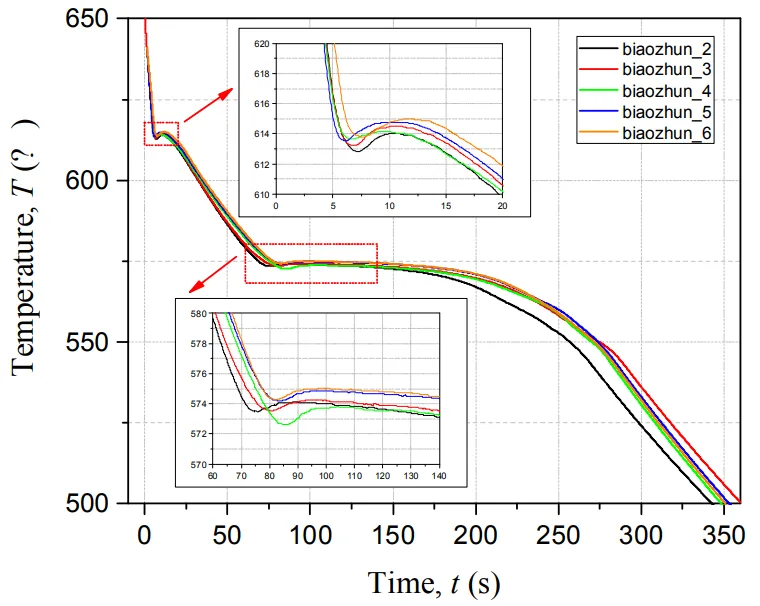

The study reaffirmed that the cooling curve and its derivatives are packed with information about melt quality. As shown in the representative data in Figure 2, the shape of the curve reveals critical solidification characteristics. A larger slope (first derivative) indicates faster cooling, which can influence grain size and porosity. Furthermore, the stability of the temperature during phase transformations (the flat portions of the curve) reflects the uniformity of the process, which is essential for achieving a desirable microstructure.

Finding 2: An Automated Program for Rapid, Data-Driven Analysis

The most significant breakthrough is the development of an automated analysis program, outlined in the flow chart in Figure 3. This program systematically:

1. Imports and cleans the raw temperature-time data.

2. Applies filtering and smoothing techniques.

3. Computes first and second-order derivatives to precisely identify feature points like the start of nucleation (TN), eutectic growth (TEU), and end of solidification.

4. Calculates key quality criteria factors, such as the area under the curve during primary and eutectic solidification.

5. Outputs these indicators for machine learning models to score the melt quality.

This automated workflow is "significantly faster than traditional methods," enabling operators to make informed decisions about the melt before casting begins.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that the cooling curve's slope can be used as a real-time proxy for the cooling rate. By monitoring this, engineers can fine-tune process parameters to achieve the ideal solidification conditions for minimizing defects like shrinkage porosity.

- For Quality Control Teams: The data in Figure 3 outlines a new set of quantifiable criteria for melt quality (e.g., Primary Area, Eutectic Area, specific transformation temperatures). These can be used to establish faster, more accurate, and automated go/no-go criteria for melts, replacing slower, subjective methods.

- For Design Engineers: The findings indicate that the solidification pathway, which is heavily influenced by melt quality, affects defect formation. Understanding a melt's inherent solidification characteristics can inform the design of castings to be more robust against potential process variations.

Paper Details

Enhanced Melt Quality Rapid Analysis of Aluminum Alloy Assisted by Machine Learning

1. Overview:

- Title: Enhanced Melt Quality Rapid Analysis of Aluminum Alloy Assisted by Machine Learning

- Author: Yunxiang Tan¹, Juhuai Ma¹, Haifeng Liu², Jianlei Jia², Liguo Yang², Qingyan Xu¹, *

- Year of publication: 2024

- Journal/academic society of publication: The 75th World Foundry Congress

- Keywords: aluminum alloy; melt quality; melt quality criterion; machine learning

2. Abstract:

The quality of aluminum alloy melts decisively influences the molding process and mechanical properties of castings. Rapid and accurate pre-pour inspection of melt quality has significant engineering value and scientific significance. This research conducts temperature measurement experiments on aluminum alloy melts to obtain cooling curves. Algorithms to identify characteristic values during the solidification process of aluminum alloy melts are proposed and developed. A database on the quality of aluminum alloy melts is established. Data including cooling curves and characteristic values obtained during the solidification process of the aluminum alloy melts utilizing algorithms such as random forests, support vector machines, and deep neural networks, combined with results from thermodynamic calculations and numerical simulations of the solidification process of aluminum alloy melts with inclusions. This research identifies factors affecting melt quality and proposes a new criterion for melt quality assessment. Results demonstrate that the melt quality analysis method developed in this study is significantly faster than traditional methods. The proposed melt quality criterion accurately and stably reflects the quality of the melt, facilitating the optimization of production processes and enhancing the quality of castings.

3. Introduction:

Aluminum alloys play a pivotal role in the lightweighting of automobiles. The quality of the liquid aluminum alloy before casting is a critical factor influencing the microstructure and mechanical characteristics of the final castings. To enhance the overall performance, improving the quality of the liquid melt is essential. Numerous factors affect melt quality, including the cooling rate, which can improve shrinkage porosity, dendritic spacing, and grain size. However, production limitations prevent infinite increases in cooling rates, necessitating the introduction of advanced methods like machine learning for melt quality analysis. Typically, treatments such as refining, degassing, grain refinement, and modification are employed to improve the quality of the aluminum alloy.

4. Summary of the study:

Background of the research topic:

The performance of aluminum alloy castings is heavily dependent on the quality of the melt prior to pouring. There is a significant need in the foundry industry for a method that can rapidly and accurately assess this quality to prevent defects and ensure consistent mechanical properties in the final product.

Status of previous research:

Previous work has established the importance of factors like cooling rate on the final microstructure. Traditional quality improvement methods include refining, degassing, and modification treatments. However, a gap exists in the ability to quickly verify the efficacy of these treatments and the overall quality of the melt before casting.

Purpose of the study:

The primary purpose of this research was to develop and propose a new, rapid criterion for aluminum alloy melt quality assessment. This was achieved by leveraging thermal analysis (cooling curves) and applying machine learning algorithms to create a faster and more accurate analysis method than traditional approaches.

Core study:

The core of the study involved conducting thermal analysis experiments on aluminum alloy melts to capture cooling curve data. Algorithms were developed to process this data and identify key characteristic values related to the solidification process. A database of melt quality was established, and machine learning models (random forests, SVM, deep neural networks) were used, in conjunction with thermodynamic calculations and numerical simulations, to identify factors affecting melt quality and formulate a new assessment criterion.

5. Research Methodology

Research Design:

The study employed an experimental research design. The primary experiment was the thermal analysis of aluminum alloy melts conducted in an industrial setting at CITIC Dicastal Co., Ltd., using a low-pressure die casting melting furnace.

Data Collection and Analysis Methods:

Data collection involved measuring the temperature of an aluminum alloy melt sample as it cooled from pouring temperature to room temperature using thermocouples and an IMC temperature acquisition device. The collected time-series data (cooling curves) was then processed using smoothing and filtering methods. Algorithms were developed to compute first and second-order derivatives to identify characteristic points. Machine learning models and linear regression were used to analyze the extracted features and develop criteria for melt quality assessment.

Research Topics and Scope:

The research is focused on the rapid quality analysis of aluminum alloy melts. The scope includes experimental temperature measurement, cooling curve analysis, feature extraction via custom algorithms, and the application of machine learning to establish a new melt quality criterion.

6. Key Results:

Key Results:

- A new set of melt quality criteria was defined based on features extracted from the cooling curve and its higher-order derivatives, including the area under the curve within specific phase transformation ranges and the slopes of the curve, which reflect the cooling rate.

- An automated melt quality analysis program was developed, as shown in Figure 3, which standardizes the process from data acquisition to feature extraction and output for machine learning analysis.

- The study demonstrated that the developed melt quality analysis method is significantly faster, more accurate, and more stable than traditional methods, enabling real-time process optimization.

Figure Name List:

- Figure 1 Experimental schematic diagram of aluminum alloy melt quality analysis

- Figure 2 Cooling curve and its higher-order derivatives

- Figure 3 Melt quality analysis program flow chart

7. Conclusion:

An experiment was conducted to measure the temperature of aluminum alloy melts, and the resulting raw cooling curve data was processed through smoothing and filtering. An algorithm for identifying characteristic values during the primary and eutectic solidification stages was established. Based on these extracted values, criteria for melt quality assessment were developed using machine learning and linear regression, which enables the quantitative scoring of melt quality.

8. References:

- [1] LuoAA, SachdevAK,ApelianD. Alloy development and process innovations for light metals casting. Journal of Materials Processing Technology, 2022,306:117606.

- [2] Stefanescu D M, Suarez R, Kim S B.90 years of thermal analysis as a control tool in the melting of cast iron. China Foundry, 2020, 17(2):69-84.

- [3] Li Y X, Hu X,Xu X R. Pattern recognition of thermal analysis cooling curves and quality evaluation of melt cast alloys.2001, 17(1): 73-74.

- [4] Yi W, Liu G, Gao J,et al.Boosting for concept design of casting aluminum alloys driven by combining computational thermodynamics and machine learning techniques. Journal of Materials Informatics, 2021, 1(2).

Expert Q&A: Your Top Questions Answered

Q1: Why was thermal analysis using cooling curves chosen as the primary method for data collection?

A1: Thermal analysis was chosen because the cooling curve provides a dynamic fingerprint of the entire solidification process. Unlike a static chemical analysis, it captures critical information about phase transformations, cooling rates, and nucleation events in real-time. This makes it an ideal data source for a rapid, pre-pour quality assessment system.

Q2: What specific "characteristic values" are extracted from the cooling curve for analysis?

A2: The analysis program, as depicted in Figure 3, identifies several key feature points. These include the temperatures at the start of nucleation (TN), eutectic undershoot (TU), start of eutectic growth (TG), minimum eutectic temperature (TEU), and the end of solidification (TF). Additionally, the program calculates the slopes (first derivatives) at various points and the area under the curve for the primary and eutectic solidification stages.

Q3: How exactly does machine learning enhance this analysis compared to just looking at the cooling curve?

A3: While a human can interpret a single cooling curve, machine learning models can analyze vast datasets containing thousands of curves, along with corresponding simulation and thermodynamic data. The models can identify complex, non-linear relationships between subtle variations in the curve's shape and the final melt quality that would be impossible for a human to detect. This leads to a more robust, accurate, and stable quality criterion.

Q4: What is the significance of calculating the first and second-order derivatives of the cooling curve?

A4: The derivatives are crucial for precise feature extraction. The first derivative represents the cooling rate (the slope of the curve), which is a key process parameter. The second derivative helps to pinpoint the exact start and end times of phase transformations, as these events correspond to points of inflection on the cooling curve, making the identification of points like TN and TG more accurate and automated.

Q5: The paper claims the method is "significantly faster." Can you quantify this improvement?

A5: The paper doesn't provide specific time values, but the speed improvement comes from the automation of the entire process. Traditional methods, like metallographic analysis, require cutting a sample, polishing it, and examining it under a microscope, which can take hours. This new method provides a quality score within minutes of taking the melt sample, allowing for immediate corrective action before the entire batch is cast.

Q6: What types of aluminum alloys was this method tested on?

A6: The paper mentions the experiment was conducted on "aluminum alloy melts" in a low-pressure die casting furnace at CITIC Dicastal, a major producer of aluminum automotive wheels. While a specific alloy isn't named, the context suggests it is relevant to common aluminum-silicon casting alloys used in high-volume manufacturing.

Q7: How can a foundry implement this technology?

A7: Implementation would require setting up a thermal analysis station next to the melting furnace, consisting of a sampling tool, standardized test cups, thermocouples, and a data acquisition device connected to a PC. The core of the system is the analysis software, which incorporates the algorithms described in the paper. The system would need to be calibrated and the machine learning model trained on the specific alloys used at the foundry to ensure maximum accuracy.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of ensuring Aluminum Alloy Melt Quality before casting has long been a hurdle for foundries aiming for zero-defect production. This research presents a significant leap forward, replacing slow, reactive quality checks with a rapid, predictive, and data-driven approach. By combining thermal analysis with the power of machine learning, this method provides the critical, real-time insights needed to optimize processes, reduce scrap, and consistently produce high-performance castings.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Enhanced Melt Quality Rapid Analysis of Aluminum Alloy Assisted by Machine Learning" by "Yunxiang Tan, Juhuai Ma, Haifeng Liu, Jianlei Jia, Liguo Yang, Qingyan Xu".

Source: The 75th World Foundry Congress, October 25-30, 2024, Deyang, Sichuan, China

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.