Unlocking Complex HPDC: How 0.3% Glass Fiber Creates a High-Strength Salt Core

This technical summary is based on the academic paper "Improving the Mechanical Properties of Salt Core through Reinforcing Fibers" by Ahrom Ryu, Soyeon Yoo, Min-Seok Jeon, Dongkyun Kim, Kiwon Hong, Sahn Nahm, and Ji-Won Choi, published in the Journal of Sensor Science and Technology (2023).

Keywords

- Primary Keyword: High-Strength Salt Core

- Secondary Keywords: High-Pressure Die Casting (HPDC), Bending Strength, Glass Fiber Reinforcement, KCl-based Salt Core, Complex Internal Geometries

Executive Summary

- The Challenge: Standard salt cores lack the mechanical strength required for the high-pressure die casting of complex parts, leading to fractures and production limitations.

- The Method: A potassium chloride (KCl) based salt core was reinforced with varying small amounts of glass and carbon fibers to evaluate improvements in mechanical properties.

- The Key Breakthrough: Adding just 0.3 wt% glass fiber more than doubled the salt core's bending strength from 22 MPa to an impressive 49.3 MPa.

- The Bottom Line: This new fiber-reinforced salt core composition enables the reliable, high-quality production of complex aluminum parts with intricate internal geometries using HPDC.

The Challenge: Why This Research Matters for HPDC Professionals

In the world of High-Pressure Die Casting (HPDC), particularly for advanced applications in the automotive and electronics industries, creating parts with complex internal geometries is a major hurdle. Salt cores offer a promising solution, as they can form intricate shapes and then be easily dissolved. However, their widespread adoption has been hindered by a critical flaw: low mechanical strength.

Traditional inorganic salt cores are brittle. During the intense pressure of the die-casting process, they are highly susceptible to cracking and deformation. This not only leads to high scrap rates but also limits the complexity of parts that can be reliably manufactured. As the industry pushes for lighter, more integrated components (e.g., for electric vehicles), the need for a robust, high-strength salt core has become more critical than ever.

The Approach: Unpacking the Methodology

To address the challenge of low core strength, the researchers developed and tested a new fiber-reinforced salt core. The methodology was systematic and focused on quantifiable performance metrics.

Method 1: Materials and Composition

The core matrix consisted of potassium chloride (KCl) and sodium carbonate (Na2CO3) powders, with a molar ratio of KCl:Na2CO3:MgCl2 set at 30:60:10. Two types of reinforcing materials were investigated:

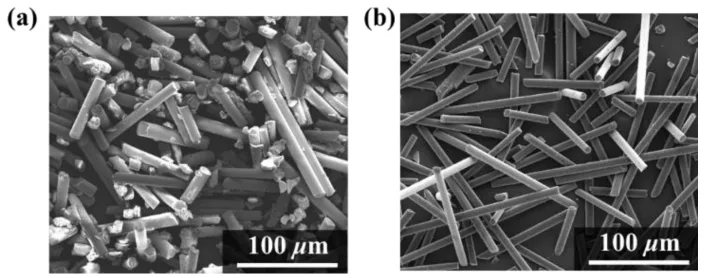

* Glass Fibers: Average particle size of 20 µm with a diameter of 3 µm.

* Carbon Fibers: Average particle size of 100 µm with a diameter of 7.2 µm.

The content of these reinforcing fibers was varied from 0.1 wt% to 0.7 wt%.

Method 2: Fabrication Process

As illustrated in the paper's process diagram (Fig. 2), the fabrication involved several key steps:

1. Mixing & Drying: The salt powders and reinforcing fibers were mixed and dried.

2. Melting: The mixture was placed in an alumina crucible and melted in a furnace at 750 °C, followed by 10 minutes of stirring.

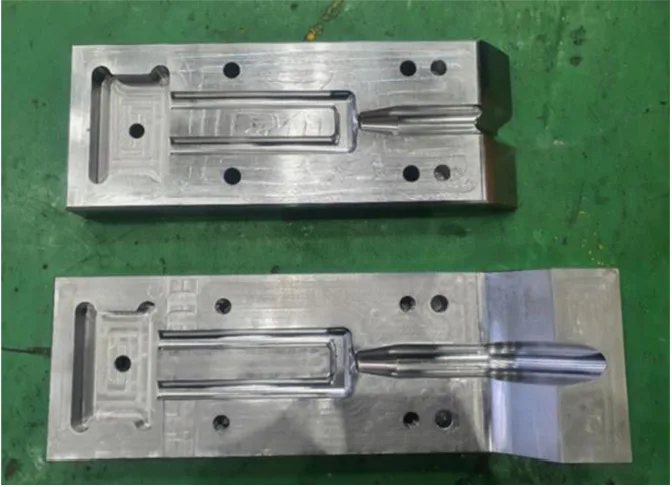

3. Casting: The molten salt was rapidly poured into a preheated (220 °C) SKD61 steel mold.

4. Solidification: After 55 seconds of cooling, the finished salt core was removed from the mold and cooled to room temperature.

Method 3: Performance Characterization

The resulting salt cores were subjected to a battery of tests to evaluate their properties:

* Bending Strength: A three-point bending test was performed to measure the core's ability to withstand pressure.

* Physical Properties: Linear shrinkage, water solubility rate, and hygroscopic (moisture absorption) rate were calculated.

* Microstructure Analysis: A scanning electron microscope (SEM) was used to observe the fractured surfaces and understand the reinforcing mechanism.

The Breakthrough: Key Findings & Data

The experimental results demonstrated a significant improvement in the salt core's performance, particularly with the addition of glass fibers.

Finding 1: Bending Strength More Than Doubled with Minimal Reinforcement

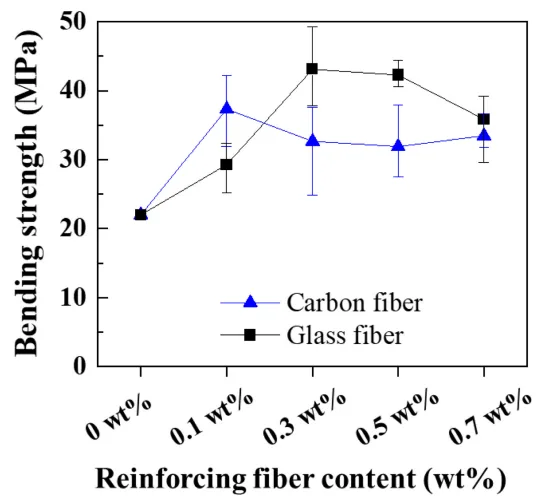

The most significant finding was the dramatic increase in bending strength. As shown in Figure 4, the unreinforced salt core had a baseline bending strength of approximately 22 MPa. The addition of glass fiber produced a remarkable improvement:

* At just 0.3 wt% glass fiber content, the bending strength reached a maximum of 49.3 MPa.

This represents a greater than 120% increase in strength with an ultra-low amount of reinforcing material. While carbon fibers also improved strength, glass fibers proved more effective at this optimal low concentration.

Finding 2: Improved Microstructure and Balanced Physical Properties

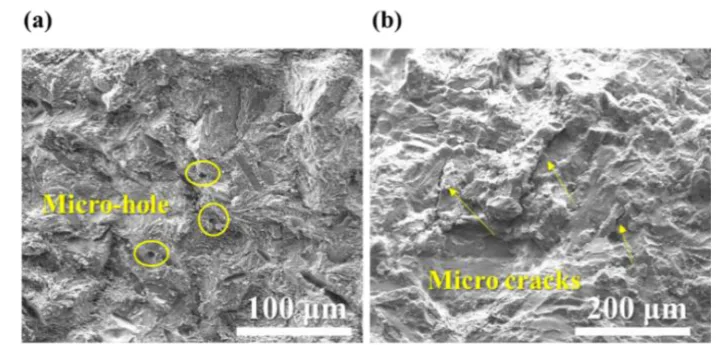

The SEM analysis revealed why the reinforced core was stronger. As shown in Figure 6, the unreinforced core (Fig. 6a) exhibits micro-holes and loose adhesion between grains. In contrast, the salt core reinforced with 0.3 wt% glass fiber (Fig. 6b) is visibly more compact. The fibers are well-embedded in the salt matrix, acting as barriers that impede the propagation of micro-cracks and require more energy to fracture the core.

Furthermore, the optimized core demonstrated a balanced set of physical properties. According to Table 1, the salt core with 0.3 wt% glass fiber achieved:

* Linear Shrinkage: 1.5%

* Hygroscopic Rate: 0.058% (indicating good moisture resistance)

* Water Solubility Rate: 16.25 g/min·m² (ensuring easy removal after casting)

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that incorporating a small, precise amount (0.3 wt%) of glass fiber into the salt core mixture can significantly enhance core strength, which may contribute to reducing core breakage during the high-pressure injection phase and lowering scrap rates.

- For Quality Control Teams: The data in Figure 4 and Table 1 of the paper illustrates the effect of fiber reinforcement on key mechanical and physical properties. These values can serve as new benchmarks for quality inspection criteria for high-performance salt cores.

- For Design Engineers: The findings indicate that the enhanced strength of these reinforced cores could enable the design of components with more complex and delicate internal passages, which were previously not feasible with weaker, standard salt cores.

Paper Details

Improving the Mechanical Properties of Salt Core through Reinforcing Fibers

1. Overview:

- Title: Improving the Mechanical Properties of Salt Core through Reinforcing Fibers

- Author: Ahrom Ryu, Soyeon Yoo, Min-Seok Jeon, Dongkyun Kim, Kiwon Hong, Sahn Nahm, and Ji-Won Choi

- Year of publication: 2023

- Journal/academic society of publication: Journal of Sensor Science and Technology, Vol. 32, No. 3

- Keywords: Salt core, Reinforcing fiber, Bending strength, Eco-friendly, High-pressure die casting

2. Abstract:

Salt cores have attracted considerable attention for their application to the casting process of electric vehicle parts as a solution to ecological issues. However, the salt core still has low mechanical strength for use in high-pressure die casting. In this study, we investigated the improvements in the bending strength of KCl-based salt cores resulting from the use of reinforcing materials. KCl and Na2CO3 powders were used as matrix materials, and glass fiber and carbon fiber were used as reinforcing materials. The effects of carbon fiber and glass fiber contents on the bending strength properties were investigated. Here, we obtained a new fiber-reinforced salt core composition with improved bending strength for high-pressure die casting by adding a relatively small amount of glass fiber (0.3 wt%). The reinforced salt core indicates the improved properties, including a bending strength of 49.3 Mpa, linear shrinkage of 1.5%, water solubility rate of 16.25 g/min.m² in distilled water, and hygroscopic rate of 0.058%.

3. Introduction:

Aluminum high-pressure die-casting (HPDC) alloys are widely used in electronics and automotive industries due to their favorable properties. The use of salt cores in the casting process has been proposed to fabricate parts with complex internal geometries and high-quality requirements, as the salt can be easily dissolved after casting. Salt cores, composed of inorganic salts like KCl, NaCl, and Na2CO3, offer advantages in strength, dimensional accuracy, and removability. However, limitations exist, including the inherent brittleness and susceptibility to cracking of the salt material, which reduces strength. To overcome this, research has focused on improving the manufacturing process and using reinforcing materials. This study investigates the use of inexpensive glass and carbon fibers to reinforce a KCl-based salt core to improve its mechanical properties for HPDC applications.

4. Summary of the study:

Background of the research topic:

Salt cores are a critical technology for producing complex aluminum HPDC parts, but their application is limited by low mechanical strength. Improving this strength is essential for enabling the mass production of advanced components, such as those for electric vehicles.

Status of previous research:

Previous studies have utilized reinforcing materials like aluminum borate whiskers and various powders to improve salt core properties, but these can limit the liquidity of the molten salt. Research by Gong et al. on KNO3-based cores demonstrated that glass fibers could improve bending strength and reduce hygroscopicity. However, high contents of reinforcing material can lead to casting defects.

Purpose of the study:

The purpose of this study was to improve the bending strength of a KCl-based (KCl-60 mol%Na2CO3) salt core by incorporating low-cost glass and carbon fibers as reinforcements. The study aimed to identify an optimized composition that enhances mechanical properties for use in high-pressure die casting.

Core study:

The study involved the fabrication of KCl-based salt cores with varying contents of glass fiber and carbon fiber (0.1 wt% to 0.7 wt%). The mechanical and physical properties—including bending strength, linear shrinkage, water solubility, and hygroscopic rate—were systematically measured and compared. The microstructure of the fractured cores was analyzed using scanning electron microscopy (SEM) to understand the reinforcement mechanism.

5. Research Methodology

Research Design:

The study employed an experimental design to compare the properties of unreinforced KCl-based salt cores with those of cores reinforced with different types and concentrations of fibers. The primary independent variables were the type (glass or carbon) and content (0, 0.1, 0.3, 0.5, 0.7 wt%) of the reinforcing fiber. The dependent variables were bending strength, linear shrinkage, hygroscopic rate, and water solubility.

Data Collection and Analysis Methods:

The salt core matrix was composed of KCl, Na2CO3, and MgCl2 in a 30:60:10 molar ratio. Cores were fabricated by melting the mixture at 750 °C and casting it into a preheated SKD61 steel mold. Bending strength was measured using a three-point bending test on a universal testing machine. Linear shrinkage, water solubility, and hygroscopic rate were calculated using standardized equations (Eq. 1-3). The microstructure of fractured samples was analyzed using an SEM after platinum sputtering.

Research Topics and Scope:

The research was focused on a KCl-based salt core system reinforced with commercially available glass and carbon fibers. The scope was limited to fiber contents up to 0.7 wt% to investigate the effects of low-level additions on the core's properties relevant to high-pressure die casting.

6. Key Results:

Key Results:

- The addition of reinforcing fibers significantly increased the bending strength of the KCl-based salt core. The strength increased from 22 MPa for the unreinforced core to a maximum of 49.3 MPa with the addition of 0.3 wt% glass fiber.

- The optimized salt core (0.3 wt% glass fiber) exhibited a linear shrinkage of 1.5%, a hygroscopic rate of 0.058%, and a water solubility rate of 16.25 g/(min·m²).

- Microstructural analysis revealed that the reinforced salt core had a more compact structure compared to the unreinforced core. The fibers were observed to impede crack propagation.

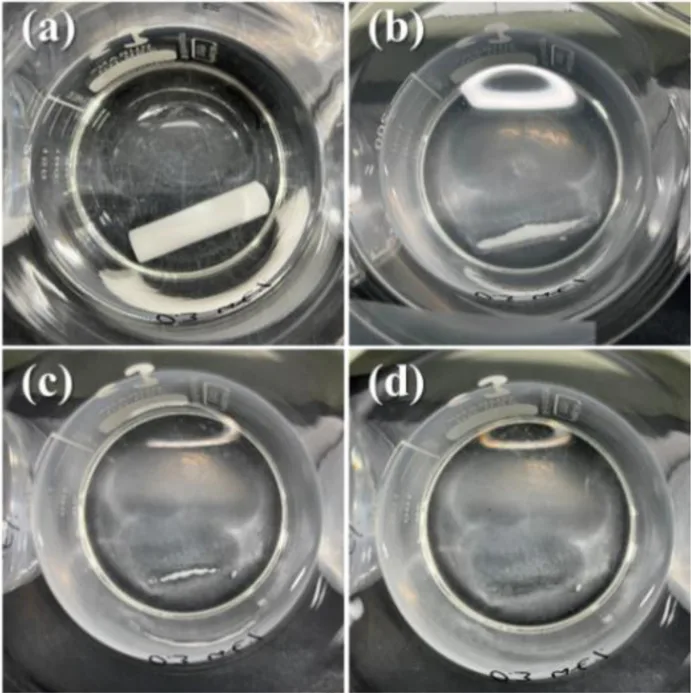

- The reinforced salt core maintained excellent water solubility, completely dissolving in room-temperature water within 6 hours, which facilitates easy removal from the final cast part and allows for the recycling of the glass fiber reinforcement.

Figure Name List:

- Fig. 1. SEM morphologies of the (a) glass fibers and (b) carbon fibers.

- Fig. 2. Preparation process of KCl-based salt core.

- Fig. 3. SKD61 steel salt core mold.

- Fig. 4. Effect of the content of reinforcing fibers on the bending strength of KCl-based salt cores.

- Fig. 5. Water soluble experiments of the KCl-based salt core reinforced by 0.3 wt% glass fiber in room temperature: (a) 0 h, (b) 2 h, (c) 4 h, (d) 6 h.

- Fig. 6. SEM micrographs of the fractured salt core: (a) unreinforced, (b) with 0.3 wt% glass fiber

7. Conclusion:

This study successfully demonstrated that the bending strength of a KCl-based salt core can be significantly improved by adding a very small content (0.3 wt%) of glass fiber. A complex, high-strength salt core was fabricated, with its bending strength increasing from 22 MPa to 49 MPa. Investigation of the fractured surface microstructure confirmed that the fibers inhibit crack propagation. The water solubility, hygroscopic rate, and shrinkage properties of the reinforced core were also characterized, confirming its suitability for high-pressure die casting applications.

8. References:

- [1] J. Bedmar, B. Torres, and J. Rams, "Manufacturing of Aluminum Matrix Composites Reinforced with Carbon Fiber Fabrics by High Pressure Die Casting, Mater., Vol. 15, No. 9, pp. 3400(1)-3400(18), 2022.

- [2] S. O. Akinwamide, O. J. Akinribide, and P. A. Olubambi, "Microstructural evolution, mechanical and nanoindentation studies of stir cast binary and ternary aluminium based composites, J. Alloys Compd., Vol. 850, pp. 156586(1)-156586(3), 2021.

- [3] S. O. Akinwamide, B. T. Abe, O. J. Akinribide, B. А. Obadele, and P. A. Olubambi, "Characterization of microstructure, mechanical properties and corrosion response of aluminium-based composites fabricated via casting-a review,J. Adv. Manuf. Technol., Vol. 109, pp. 975-991, 2020.

- [4] J. Weise, J. Hilbers, F. Handels, D. Lehmhus, M. Busse, and M. Heuser, "New Core Technology for Light Metal Casting, Adv. Eng. Mater., Vol. 21, No. 4, p. 1800608, 2019.

- [5] M. Gromada, A. Świeca, M. Kostecki, A. Olszyna, and R. Cygan, "Ceramic cores for turbine blades via injection moulding, J. Mater. Process Technol., Vol. 220, pp. 107-112, 2015.

- [6] H. Khandelwal and B. Ravi, "Effect of Binder Composition on the Shrinkage of Chemically Bonded Sand Cores, Mater. Manuf. Process., Vol. 30, No. 12, pp. 1465-1470, 2015.

- [7] P. Jelinek, E. Adamkov, F. Miksovsky, and J. Beno, "Advances in Technology of Soluble cores for Die Castings, Arch. Foundry Eng., Vol. 15, pp. 29-34, 2015.

- [8] P. P. Zhou, G. Q. Wu, Y. Tao, X. Cheng, J. Q. Zhao, and H. Nan, "Optimization of the injection molding process for development of high performance calcium oxide -based ceramic cores, Mater. Res. Express, Vol. 5, No. 2, p. 025208, 2018.

- [9] R. Huang and B. Zhang, "Study on the Composition and Properties of Salt Cores for Zinc Alloy Die Casting, Int. J. Metalcasting, Vol. 11, pp. 440-447, 2017.

- [10] M. Lagler, “Use of Simulation to predict the Viabilirt of Salt Cores in the HPDC Process-Shot Curve as a Decisive Criterion, Die Casitng Eng., Vol. 57, No. 4, pp. 16-17, 2013.

- [11] B. Fuchs, H. Eibisch, and C. Körner, "Core Viability Simulation for Salt Core Technology in High-Pressure Die Casting, Int. J. Metalcasting, Vol. 7, pp. 39-45, 2013.

- [12] J. Yaokawa, K. Anzai, Y. Yamada, H. Yoshii, and H. Fukui, "Castability and Strength of Potassium Chloride-Ceramic Composite Salt Cores, J. Japan Foundry Eng., Vol. 76, No. 10, pp. 823-829, 2004.

- [13] J. Beòo, E. Adámkov, F. Mikovsk, and P. Jelínek, "Development of composite salt cores for foundry applications, Mater. Technol., Vol. 49, No. 4, pp. 619-623, 2015.

- [14] J. Yaokawa, D. Miura, K. Anzai, Y. Yamada, and H. Yoshii, "Strength of Salt Core Composed of Alkali Carbonate and Alkali Chloride Mixtures Made by Casting Technique, Mater. Trans., Vol. 48, No. 5, pp. 1034-1041, 2007.

- [15] F. Liu, S. Tu, X. Gong, G. Li, W. Jiang, X. Liu, and Z. Fan, "Comparative study on performance and microstructure of composite water-soluble salt core material for manufacturing hollow zinc alloy castings, Mater. Chem. Phys., Vol. 252, p.123257, 2020.

- [16] X. Gong, W. Jiang, F. Liu, Z. Yang, F. Guan, and Z. Fan, "Effects of glass fiber size and content on microstructures and properties of KNO3-based water-soluble salt core for high pressure die casting, Int. J. Metalcasting, Vol. 15, pp. 520-529, 2021.

- [17] S. Tu, F. Liu, G. Li, W. Jiang, X. Liu, and Z. Fan, “Fabrication and characterization of high-strength water-soluble composite salt core for zinc alloy die castings, Int. J. Adv. Manuf. Tech, Vol. 95, pp. 505-512, 2018.

Expert Q&A: Your Top Questions Answered

Q1: Why were glass fibers more effective than carbon fibers at the optimal 0.3 wt% concentration?

A1: The paper's data in Figure 4 clearly shows glass fibers yielding a higher bending strength (49.3 MPa) compared to carbon fibers at the 0.3 wt% level. While the paper does not specify the exact reason, it could be related to the different physical dimensions of the fibers. The glass fibers were significantly shorter and thinner (20 µm length, 3 µm diameter) than the carbon fibers (100 µm length, 7.2 µm diameter), which may have allowed for a more uniform dispersion and a more effective reinforcement network within the salt matrix at this very low concentration.

Q2: The paper mentions that the hygroscopic rate increased with fiber content. Is this a concern for practical use?

A2: While the hygroscopic rate did increase from 0.036% (unreinforced) to 0.058% for the optimized core with 0.3 wt% glass fiber, this value is still extremely low. The authors note in the paper that for contents up to 0.3 wt%, the rate remains below 0.1%, which indicates the core "still possesses moisture resistance." Therefore, this minor increase is considered acceptable and should not pose a significant problem for storage or handling in a typical production environment.

Q3: The linear shrinkage also increased from 1.03% to 1.5% for the optimized core. Doesn't this negatively impact dimensional accuracy?

A3: It is true that lower shrinkage is generally preferred for dimensional precision. However, the primary challenge this research addresses is the core's mechanical failure during casting. The more than 120% increase in bending strength is a substantial gain that likely outweighs the modest 0.47 percentage point increase in shrinkage. This predictable shrinkage can be compensated for in the initial mold design, whereas a fractured core results in a complete part failure.

Q4: What is the proposed mechanism that allows such a small amount of fiber to increase strength so dramatically?

A4: The paper suggests a dual mechanism based on the microstructure analysis in Figure 6. First, the well-embedded fibers act as physical obstacles that impede the propagation of micro-cracks, essentially holding the salt matrix together and requiring more energy to cause a fracture. Second, the authors cite that reinforcing fibers with a high melting point can act as "foreign crystal nuclei," which increases the number of nucleation sites during solidification. This leads to a finer, more refined grain structure, which is inherently stronger than a structure with large, columnar grains.

Q5: How does the addition of fibers impact the liquidity of the molten salt during the core casting process?

A5: The paper acknowledges that adding reinforcing materials can decrease the liquidity of molten salt, which can lead to casting defects like misruns, especially at higher concentrations. The key breakthrough of this study is achieving a massive strength improvement at an "ultra-low" fiber content of only 0.3 wt%. This approach is designed to minimize the negative impact on liquidity, avoiding the defects that have been a problem in previous attempts that used higher levels of reinforcement.

Conclusion: Paving the Way for Higher Quality and Productivity

The fundamental challenge of low mechanical strength has long been a barrier to the full potential of salt cores in High-Pressure Die Casting. This research provides a practical and effective solution: a High-Strength Salt Core created by reinforcing a KCl-based matrix with just 0.3 wt% of glass fiber. The resulting 120% increase in bending strength to 49.3 MPa enables the reliable production of complex components that were previously prone to failure.

This breakthrough paves the way for greater design freedom, reduced scrap rates, and higher overall productivity in the manufacturing of advanced aluminum parts.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

This content is a summary and analysis based on the paper "Improving the Mechanical Properties of Salt Core through Reinforcing Fibers" by "Ahrom Ryu, Soyeon Yoo, Min-Seok Jeon, Dongkyun Kim, Kiwon Hong, Sahn Nahm, and Ji-Won Choi".

Source: http://dx.doi.org/10.46670/JSST.2023.32.3.159

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.