Optimizing Complex Castings: A Gating System Simulation Deep Dive for Aluminum Valve Bodies

This technical summary is based on the academic paper "Simulation and Casting Process of Aluminum Alloy Multi-Way Valve Body with Various Gating Systems" by Li Rong, Chen Lunjun, Su Ming, Zeng Qi, Liu Yong, and Wang Heng, published in ARCHIVES of FOUNDRY ENGINEERING (2018).

Keywords

- Primary Keyword: Gating System Simulation

- Secondary Keywords: Aluminum Alloy Casting, Valve Body Defects, Solidification Analysis, Casting Process Optimization, Casting Simulation

Executive Summary

- The Challenge: Manufacturing complex, high-performance aluminum alloy multi-way valve bodies without critical internal defects like porosity and shrinkage is a significant industrial challenge.

- The Method: Researchers employed casting simulation software to analyze, compare, and optimize various gating systems—including single-side, twin-side, and a novel middle-pouring design—for producing the valve body.

- The Key Breakthrough: An optimized gating system featuring a single middle gate with dual-flow diversion proved superior, resulting in a gentler fill, reduced air entrapment, and controlled sequential solidification that localized defects in the disposable riser area.

- The Bottom Line: Strategic gating system design, validated by advanced Gating System Simulation, is indispensable for achieving the defect-free, high-quality internal structures required for high-performance aluminum valve bodies.

The Challenge: Why This Research Matters for HPDC Professionals

The integral hydraulic multi-way valve is a critical, high-performance component in construction machinery. Traditionally made from ductile iron, these parts suffer from high casting temperatures (approx. 1300 °C) that cause core sand to adhere to internal channels, leading to hydraulic oil system contamination.

Aluminum alloy is the superior material choice, as it allows for easier cleaning of internal passages and ensures a cleaner hydraulic system. However, the intricate internal flow channels of the multi-way valve body make it extremely difficult to cast without introducing defects. Designing a robust casting process through physical trial-and-error is costly and time-consuming. This research was necessary to leverage simulation technology to predict defect locations and design an optimal casting process from the outset, avoiding expensive and wasteful physical prototypes.

The Approach: Unpacking the Methodology

The study systematically evaluated and optimized the casting process for an aluminum alloy multi-way valve body using a combination of theoretical calculations and software simulation.

Method 1: Initial Gating System Design and Calculation

The researchers began by designing a close-open-close gating system, suitable for the valve body's thin and irregular internal runners. This design aimed to ensure effective slag removal and melt stability. Key parameters like the minimum cross-sectional flow area (Asmin) and pouring time were calculated using established foundry engineering formulas. Based on these calculations, cross-sectional area ratios of Fsprue: Frunner: Finner = 1: 3.5: 2.5 were established to ensure smooth pouring and efficient slag blocking.

Method 2: Comparative Simulation of Gating Systems

Two initial gating system configurations were modeled and simulated:

1. Twin-Side Gating System: Molten metal is poured from gates on both sides of the casting.

2. Single-Side Gating System: Molten metal is poured from gates on only one side.

The simulation software was used to analyze the filling process, gas state (air entrapment and contact time), filling speed, and turbulent flow for both configurations.

Method 3: Solidification Analysis and Optimization

Following the filling analysis, the researchers simulated the solidification process for both initial designs. They analyzed solidification temperature distribution, cooling rates, and the location of hotspots and porosity defects. Based on the defects identified, a new, optimized gating system was designed, modeled, and simulated to validate its effectiveness in resolving the issues found in the initial designs.

The Breakthrough: Key Findings & Data

The simulation results clearly demonstrated the limitations of conventional gating strategies and highlighted the significant advantages of the optimized design.

Finding 1: Initial Gating Systems Introduce Significant Filling Defects

The initial designs both presented critical flaws during the filling stage. The twin-side gating system, while faster, caused the two melt streams to collide in the product's center, creating strong turbulence and increasing air entrapment (Figure 4a). In contrast, the single-side gating system had a gentler flow but a much longer air contact time, especially on the upper surfaces, increasing the risk of oxidation (Figure 5b). The air contact time for the single-side system reached over 11 seconds in some areas, compared to a maximum of around 6.4 seconds for the twin-side system.

Finding 2: Non-Sequential Solidification Leads to Internal Defects

Both the single and twin-side gating systems failed to achieve sequential solidification. The final solidification area for both occurred at the end of the cross-flow, creating isolated hotspots (Figure 7, Figure 8). This improper solidification pattern resulted in a high potential for shrinkage porosity defects deep within the valve body's core structure, compromising the component's integrity. The simulation predicted a porosity zone (D zone) offset from the final solidification zone (E zone), indicating that molten metal replenishment was insufficient (Figure 9).

Finding 3: Optimized Gating System Eliminates Core Defects and Controls Solidification

To solve these issues, an optimized system was designed with a single straight gate at the middle and a horizontal gate diversion to both sides (Figure 11). This design achieved a much gentler, more balanced fill with lower turbulence (Figure 12). Crucially, this new design, combined with a modified riser system (Figure 13), successfully controlled the solidification pattern. The simulation showed that shrinkage cavities and defects were concentrated in the riser area, leaving the main body of the valve free of apparent defects (Figure 14). The solidification temperature distribution was more uniform and sequential, ensuring the central area was effectively fed and preventing shrinkage holes (Figure 15).

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that for complex parts like valve bodies, a central-fill, dual-diversion gating system may be far more effective at reducing turbulence and air entrapment than traditional single or twin-side systems.

- For Quality Control Teams: The data in Figure 9 and Figure 14 of the paper illustrates how simulation can accurately predict the final location of shrinkage porosity. This allows QC to focus inspections on high-risk areas or, more importantly, to confirm that process changes have successfully moved these defects out of the component and into the riser.

- For Design Engineers: The findings indicate that the location of thick sections and the overall part geometry heavily influence the final solidification zone. The simulation results underscore the importance of co-designing the component and its casting process (gating and risering) to ensure manufacturability and prevent defects.

Paper Details

Simulation and Casting Process of Aluminum Alloy Multi-Way Valve Body with Various Gating Systems

1. Overview:

- Title: Simulation and Casting Process of Aluminum Alloy Multi-Way Valve Body with Various Gating Systems

- Author: Li Rong, Chen Lunjun, Su Ming, Zeng Qi, Liu Yong, Wang Heng

- Year of publication: 2018

- Journal/academic society of publication: ARCHIVES of FOUNDRY ENGINEERING, Volume 18, Issue 2/2018

- Keywords: Casting, Aluminum alloy, Valve body, Gating system, Simulation

2. Abstract:

In order to study the effects of various gating systems on the casting of a complex aluminum alloyed multi-way valve body, both software simulation analysis and optimization were carried out. Following, the aluminum alloyed multi-way valve body was cast to check the pouring of the aluminum alloy valve body. The computer simulation results demonstrated that compared to the single side casting mode, the casting method of both sides of the gating system would reduce the filling of the external gas, while the air contact time would be lower. Adversely, due to the pouring on both sides, the melt cannot reach at the same time, leading to the liquid metal speed into the cavity to differ, which affected the liquid metal filling stability. The riser unreasonable setting led to the solidification time extension, resulting in a high amount of casting defects during solidification. Also, both gating systems led the entire casting inconsequential solidification. To overcome the latter problems, a straight gate was set at the middle pouring and the horizontal gate diversion occurred on both sides of pouring, which could provide better casting results for the aluminum alloyed multi-valve body.

3. Introduction:

The integral hydraulic multi-valve is a key component for construction machinery. Its manufacture involves material, molding, and heat treatment. Traditionally made from ductile iron, these valves have issues with high casting temperatures causing core sand to adhere to internal flows, polluting the hydraulic oil system. Aluminum alloy is chosen as an alternative to allow for easier cleaning and bear high pressure. Due to the complicated internal flow channel, designing the core and conducting pouring experiments is difficult. Casting simulation software can visualize defect locations and propose solutions without requiring actual poured castings. This study used simulation to analyze the filling process of an integral multi-way valve body under different pouring systems to predict defects and optimize the casting process.

4. Summary of the study:

Background of the research topic:

The production of high-performance, integral multi-way valve bodies for hydraulic systems faces challenges related to material choice and manufacturing complexity. While aluminum alloy offers advantages over ductile iron in terms of cleanliness for the hydraulic system, its casting process is difficult due to the component's complex internal geometry.

Status of previous research:

Previous work relies on traditional casting methods, which for complex parts like this valve body, often lead to defects. The use of casting simulation software is an established method for predicting and mitigating such defects in various casting applications, including aluminum alloys.

Purpose of the study:

The study aimed to investigate the effects of different gating systems on the casting quality of a complex aluminum alloy multi-way valve body. The goal was to use software simulation to analyze and optimize the casting process to overcome filling and solidification issues, thereby obtaining the best process for producing a high-strength, defect-free component.

Core study:

The core of the study involved the digital modeling of the valve body and the design and simulation of three different gating systems: a twin-side gating system, a single-side gating system, and an optimized middle-pouring, dual-flow system. The simulations analyzed the filling process (gas state, air contact time, flow velocity, turbulence) and the solidification process (temperature distribution, hotspots, porosity). The results were compared to identify defects and validate the effectiveness of the optimized design. Finally, experimental castings were produced to verify the simulation results.

5. Research Methodology

Research Design:

The research employed a comparative simulation-based design and optimization methodology. An initial digital model of the multi-way valve was created. Two conventional gating systems (twin-side and single-side) were designed based on theoretical calculations. These systems were then simulated to analyze their performance and identify defects. Based on this analysis, an improved, optimized gating system was designed and simulated. The performance of all three systems was compared to determine the optimal process.

Data Collection and Analysis Methods:

Data was generated and collected through casting simulation software (MAGMASOFT is indicated in the figures). The analysis focused on key output criteria:

- Filling Analysis: Tracer particle status to visualize flow, air contact time to assess oxidation risk, and filling velocity distribution to identify turbulence.

- Solidification Analysis: Solidification temperature fields to identify the last areas to solidify, hotspot detection to predict shrinkage porosity locations, and cooling rate analysis to identify areas at risk of defects.

Research Topics and Scope:

The research was scoped to the casting of a specific complex aluminum alloy multi-way valve body. The primary research topic was the effect of gating system design on casting quality. The investigation covered the entire casting process from mold filling to final solidification, focusing on the prediction and mitigation of defects such as gas entrapment, oxidation, and shrinkage porosity.

6. Key Results:

Key Results:

- The twin-side gating system resulted in lower air contact time but caused strong turbulent flows due to melt stream collision, increasing air entrapment.

- The single-side gating system produced a smoother, more stable fill but resulted in longer air contact times, increasing the risk of oxidation.

- Both initial gating systems led to non-sequential solidification, with hotspots forming at the end of the cross-flow, creating a high risk of internal shrinkage defects.

- An optimized gating system with a middle pour and dual-side diversion provided a gentler, more balanced fill with reduced turbulence.

- The optimized system, combined with a modified riser design, achieved sequential solidification and successfully moved shrinkage defects from the main casting body into the riser area.

- Experimental casting of the single-side system confirmed the simulation's prediction of significant shrinkage in the upper and central areas of the valve body.

- The final optimized cast product showed a smooth surface and clean internal channels, comparable to the cast iron version but with superior internal cleanliness.

Figure Name List:

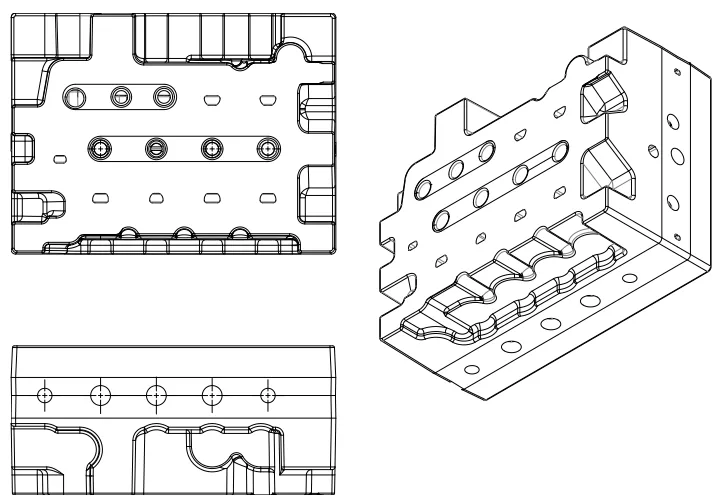

- Fig. 1. Model of multi-valve

- Fig. 2. Model of overall sand molding

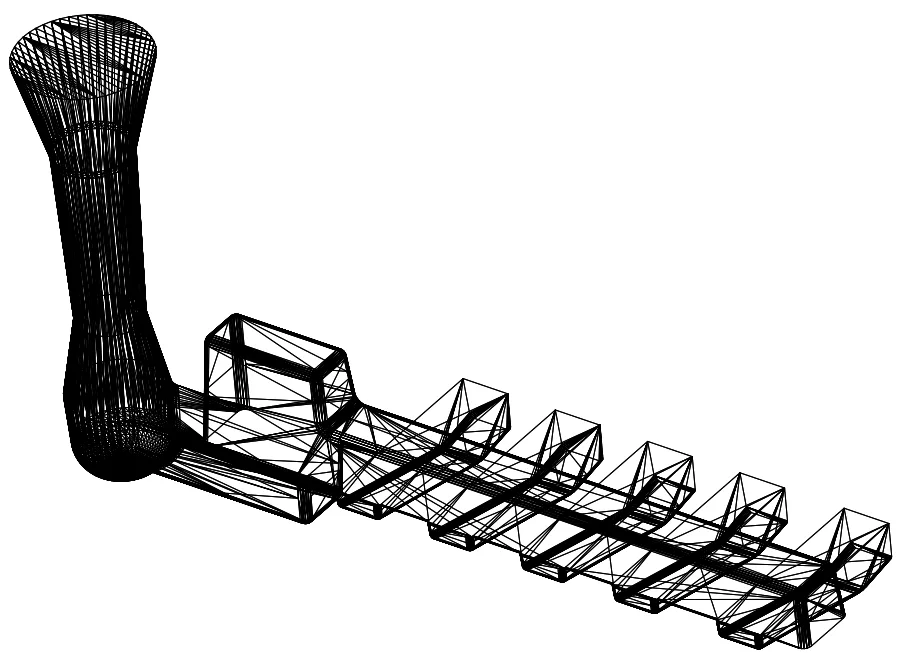

- Fig. 3. Pouring system

- Fig. 4. Tracer particle status of various gating systems: a) Twin side gating system; b) Single side gating system

- Fig. 5. Air contact times of various gating systems: a) Twin gating system; b) Single side gating system

- Fig.6. Filling speeds of various gating systems: a) Twin gating system; b) Single side gating system

- Fig. 7. Temperatures of various gating systems

- Fig. 8. Hotspots of different gating systems: a) Twin gating system; b) Single side gating system

- Fig. 9. Distribution of shrinkage and hotspots: a) Porosity; b) Hotspots; c) Time of solidification

- Fig. 10. Cooling rate of casting solidifications of various gating systems: a) Twin gating system; b) Single side gating system

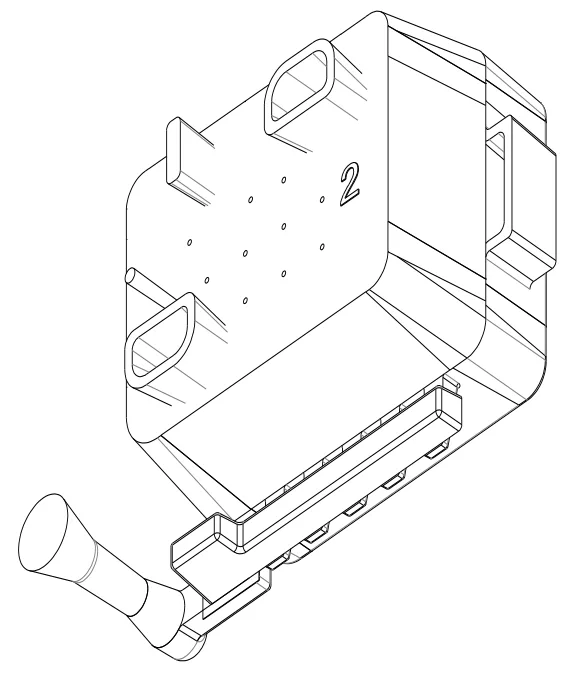

- Fig. 11. Optimized gating system

- Fig. 12. Turbulence of new gating system

- Fig. 13. Modified riser of valve body

- Fig. 14. Defects and filling rate optimization

- Fig. 15. Solidification temperature of modified gating system

- Fig. 15. Casting of single side gating system

- Fig. 16. Cutting section of aluminum alloy valve body

- Fig. 17. Comparison of aluminum alloy and iron body: a) Aluminum alloy body; b) Iron valve body; c) Partial area of Aluminum alloy body; d) Partial area of iron valve body

7. Conclusion:

- The differences in metal flow conditions were the main factors affecting filling. The twin gating system was faster but caused turbulence and air entrapment. The single-side gating system was more stable but prone to oxidation. For the multi-valve body, the core zone is a key part, and its molding should be stable with a reduced filling time.

- Neither the single nor the twin gating system could guarantee the sequential solidification of the valve body, leading to defects at the core or on the surface that would decrease strength and quality.

- The optimized gating system, based on double gates with a central pour, provided a gentler and more balanced flow. This system ensured the internal quality of the aluminum alloyed multi-valve body, achieving a quality level comparable to cast iron optimization but with a cleaner internal flow channel.

8. References:

- [1] Yanlun, X., Hongbo, W., Minchao, Z., et al. (2013). Developed Key Technologies for High-pressure Valve in Excavator. MACHINE TOOL & HYDRAULICS. 41(20), 79-81. DOI: 10.3969/j.issn. 1001-3881. 2013. 20. 026.

- [2] Zongxia, J., Chuanlong, P., Shuai, W. (2013). Progress in Construction Machinery Multi-way Valve And Future Trends. Chinese Hydraulics & Pneumatics. (11), 1-6. DOI:10. 11832/j. issn. 1000-4858. 2013. 11. 001.

- [3] Wen, H.L., Shen, R.H. & Wu, Y.W. (2014). Simulation and optimization of solidification process for large integral multiway valve body. Foundry Technology. 35(1), 182-184.

- [4] Perzyk, M. Kozlowski, J., Mazur, M., et al. (2015). Optimization of Side Feeders Systems by Means of Simulation of Solidification. Archives of Foundry Engineering. 15(1), 69-74. DOI:10.1515/afe-2015-0012.

- [5] Brůna, M., Bolibruchová, D. & Pastirčák, R. (2017). Reoxidation Processes Prediction in Gating System by Numerical Simulation for Aluminum Alloys. Archives of Foundry Engineering. 17(3), 23-26. DOI:10.1515/afe-2017-0084.

- [6] Sutiyoko, Suyitno, Mahardika, M., & Syamsudin, A. (2016). Prediction of Shrinkage Porosity in Femoral Stem of Titanium Investment Casting. Archives of Foundry Engineering. 16(4), 157-162. Retrieved 1 Nov. 2017, from doi:10.1515/afe-2016-0102.

- [7] Ke, L., Qian, W., N.G., Z., et al. (2011). Hot Cracking Behavior of A206 /1% Al2O3 Aluminum Base Nanocomposite. JOURNAL OF AERONAUTICAL MATERIALS. 31(2), 89-94. DOI: 10. 3969/j.issn. 1005-5053. 2011. 2. 017.

- [8] Shanghai Foundry Association. (1984). Concise Handbook of casting. Beijing: Machinery Industry Press.

- [9] Hongy., L., Zh., C., Z. (2005). Casting Process Design. Beijing: Machinery Industry Press: 130.

- [10] Rong, L., Qi, Z. (2015). Casting Simulation and Validation Research of MMD Crusher Teeth Plate. Foundry Technology, 36(4), 2940-2943. DOI: 10.16410/j.issn1000-8365.2015.12.039.

- [11] Wang, X.L., Zhao, Z.L., Ma, Y.X., et al. (2011). Numerical Simulation of Filling and Solidification of Large Complex ZTC4 Alloy Castings. Special Casting & Nonferrous Alloy, 31(6), 517-519. DOI: 10.3870/tzzz.2011.06.008

Expert Q&A: Your Top Questions Answered

Q1: Why was a "close-open-close" gating system chosen for the initial design?

A1: According to the paper, this type of gating system is particularly suitable for castings like the valve body which have many thin and irregular internal runners. This design, where the sprue-to-runner path is closed and the outer-to-inner runner path is open, helps ensure effective slag removal and promotes melt stability during the casting process, which is critical for complex geometries.

Q2: What was the fundamental reason both the initial single-side and twin-side gating systems failed to produce a sound casting?

A2: The core issue for both initial designs was their inability to achieve sequential solidification. The simulations (Figure 7 and 8) showed that isolated hotspots formed late in the process, particularly at the end of the cross-flow. This means these areas were cut off from the supply of molten metal from the risers as other sections solidified, inevitably leading to shrinkage porosity and defects within the main body of the casting.

Q3: How did the optimized gating system specifically address the turbulence seen in the twin-side system?

A3: The optimized system replaced the two separate-side ingates with a single, central ingate that then diverted into a horizontal runner feeding both sides of the cavity (Figure 11). This design prevents the high-velocity collision of two opposing melt fronts, which was the primary cause of turbulence in the twin-side system. The result, as shown in the simulation (Figure 12), was a much gentler, more balanced, and simultaneous filling of the cavity.

Q4: The paper recommends preheating the cores for actual production. What simulation result prompted this?

A4: The simulation results in Figure 10 showed that the areas where the sand cores were placed experienced a significantly high cooling rate, reaching up to 20 °C/s. This rapid cooling is caused by the core absorbing heat from the molten metal. An excessive cooling rate can easily lead to porosity defects. Preheating the cores before casting would ensure greater temperature uniformity throughout the mold and reduce this sharp temperature drop, slowing the solidification speed in these critical areas.

Q5: Beyond changing the ingate location, what other critical modification was made in the final optimized design?

A5: A critical part of the optimization was modifying the location and size of the risers (Figure 13). The initial simulation showed that the original risers were unsuitable and could not provide sufficient feeding to compensate for shrinkage, especially in the thick middle and top sections of the casting. The new, larger risers were redesigned and repositioned to ensure they were the last part to solidify and could effectively feed molten metal to all sections of the casting, preventing internal shrinkage.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of casting complex aluminum components like multi-way valve bodies is not insurmountable; it simply requires a more intelligent, data-driven approach. This research conclusively demonstrates that conventional gating strategies can introduce severe defects, but a well-designed process, validated by Gating System Simulation, can achieve exceptional results. By optimizing the gating and riser system, the researchers were able to control the metal flow, minimize turbulence, and ensure the sequential solidification necessary to produce a defect-free valve body with clean internal passages.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Simulation and Casting Process of Aluminum Alloy Multi-Way Valve Body with Various Gating Systems" by "Li Rong, et al.".

Source: https://doi.org/10.24425/122507

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.