Predicting Failure Before It Happens: A Breakthrough in Statistical Fracture Prediction for HPDC

This technical summary is based on the academic paper "Towards Location Specific Statistical Fracture Prediction in High Pressure Die Castings" by R. Watson, W.D. Griffiths, T. Zeguer, and S. Ruffle, published in the proceedings of the 10th European LS-DYNA Conference (2015).

Keywords

- Primary Keyword: Statistical Fracture Prediction

- Secondary Keywords: High Pressure Die Casting, HPDC defects, entrainment defects, LS-DYNA simulation, Weibull distribution, casting quality, oxide bi-films

Executive Summary

- The Challenge: The unpredictable strength of High Pressure Die Casting (HPDC) components, caused by random entrainment defects, forces engineers to use conservative, "worst-case" material properties, limiting lightweighting potential.

- The Method: Researchers used an advanced casting simulation to predict defect distribution and correlated it to experimental tensile strength data using a novel fuzzy statistical method.

- The Key Breakthrough: The study successfully mapped a location-specific, statistical strength distribution directly into an LS-DYNA model, allowing for simulations that realistically capture material variability.

- The Bottom Line: This methodology enables engineers to move beyond uniform material properties and simulate the true statistical performance of HPDC parts, paving the way for more optimized, reliable, and lightweight designs.

The Challenge: Why This Research Matters for HPDC Professionals

High Pressure Die Casting (HPDC) is a cornerstone of modern manufacturing, prized for its ability to produce complex, high-volume aluminum parts economically. However, a persistent challenge holds it back: the inherent variability in mechanical strength.

During the turbulent mould-filling process, air can become entrained in the molten metal, creating defects like oxide bi-films and pores. These defects act as stress concentrators and crack initiation sites, but their size and location are unique to each casting. Consequently, two identical parts can have different failure strengths.

To ensure safety, design engineers are often forced to rely on conservative, uniform strength estimates that account for the weakest possible outcome. This approach leads to over-engineered, heavier parts, undermining one of the key benefits of using aluminum—lightweighting. This research tackles the problem head-on by seeking a way to predict and model this strength variation on a location-specific basis.

The Approach: Unpacking the Methodology

To bridge the gap between predicted defects and actual part strength, the researchers employed a multi-stage methodology combining physical testing with advanced simulation.

Method 1: Controlled Casting and Tensile Testing

The team produced two sets of a commercial HPDC part under different process conditions to intentionally alter the defect distribution.

- "Full Gate" Castings: Produced with a standard mould geometry and a reduced shot speed.

- "Blanked Gate" Castings: Produced with one side of the in-gate blocked to significantly modify the metal flow pattern.

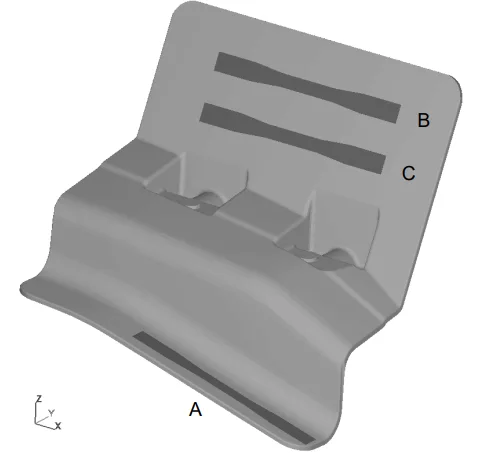

Test bars were then extracted from three specific locations (A, B, and C) on each casting and subjected to tensile testing to gather statistical data on their true fracture stress.

Method 2: Advanced Casting Simulation

Both casting variants were simulated using the commercial CFD package FLOW-3D. A crucial element was the use of the "Surface Area Entrainment Code," a user subroutine that predicts the formation of entrainment defects. The algorithm represents defects as Lagrangian particles, tracking them from their point of creation to their final solidified position in the casting.

Method 3: Statistical Mapping and LS-DYNA Integration

This is the core innovation of the study. A novel "random walk" algorithm was developed to analyze the simulation results. Instead of just counting defects at a single point, this algorithm samples the defect density in the local neighborhood of each point. This mimics real-world process variability where defects might be slightly displaced from one casting to the next.

- A 3-parameter Fréchet distribution was fitted to this sampled defect data.

- An inverse power law function was then used to transform the statistical defect distribution into a statistical strength distribution, calibrated against the experimental tensile test data.

- Finally, a PRIMER script automated the process of mapping this detailed strength data into an LS-DYNA model, assigning different material properties to different regions of the part based on the predicted local strength.

The Breakthrough: Key Findings & Data

The study's results validate the effectiveness of this integrated simulation and statistical mapping approach.

Finding 1: Simulation Accurately Captures Process-Induced Defect Changes

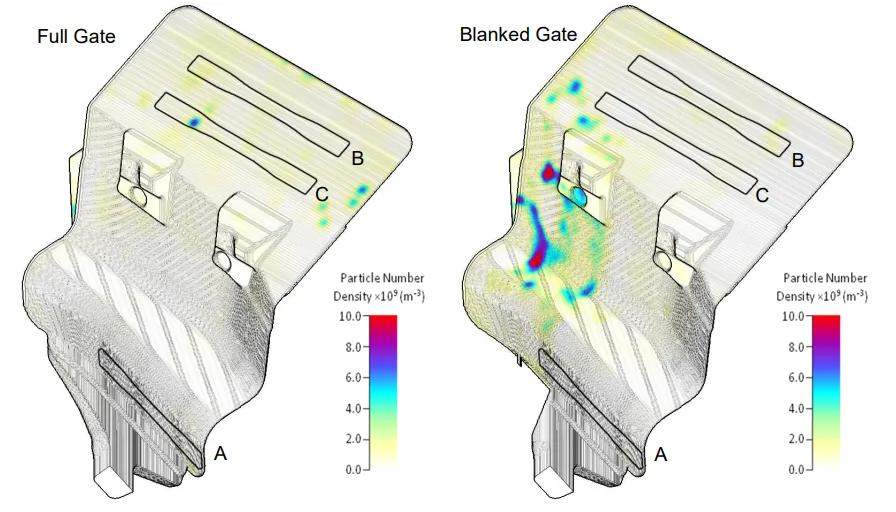

The casting simulation successfully predicted a significant difference in the final defect distribution between the two process variants. As shown in Figure 3, the "Blanked Gate" simulation shows a much higher concentration of predicted defects in specific areas compared to the more evenly distributed defects in the "Full Gate" case. This confirms the simulation's sensitivity to process modifications and its ability to predict where defects are most likely to accumulate.

Finding 2: Mapped Strength Distributions Replicate Experimental Results with High Fidelity

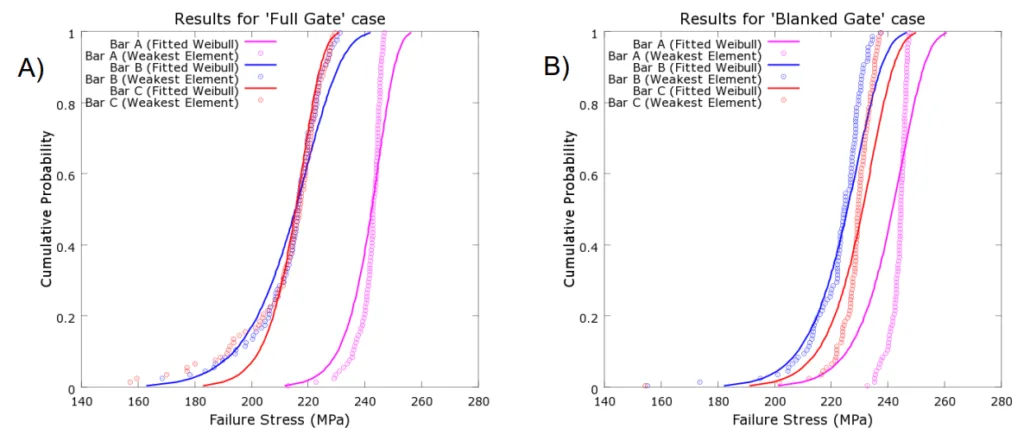

The ultimate test was whether the LS-DYNA models, now embedded with the statistical strength data, would behave like the real-world test bars. The results were compelling. As shown in Figure 5, the cumulative strength distributions produced by running 100 simulations of the virtual test bars closely matched the Weibull distributions derived from the physical tensile tests. Crucially, the model showed excellent fidelity in the "lower tail" of the distribution—the region representing the weakest samples, which is most critical for reliable engineering design.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that simulation using the Surface Area Entrainment Code can be a powerful tool to visualize the impact of process changes (e.g., gate design, shot speed) on internal quality, allowing for the optimization of casting parameters to minimize defect formation in critical areas.

- For Quality Control Teams: The data in Figure 5 of the paper illustrates the ability to predict not just average strength but the statistical spread of strength at different locations. This could inform more targeted, risk-based quality inspection strategies, focusing on regions predicted to have higher variability or lower strength.

- For Design Engineers: The findings indicate that it is now feasible to move beyond conservative, uniform material properties in FEA. By mapping a statistical strength distribution directly into an LS-DYNA simulation, designers can achieve a more realistic prediction of part performance and durability, enabling the confident design of lighter, more efficient components.

Paper Details

Towards Location Specific Statistical Fracture Prediction in High Pressure Die Castings

1. Overview:

- Title: Towards Location Specific Statistical Fracture Prediction in High Pressure Die Castings

- Author: R. Watson, W.D. Griffiths, T. Zeguer, S. Ruffle

- Year of publication: 2015

- Journal/academic society of publication: 10th European LS-DYNA Conference 2015, Würzburg, Germany

- Keywords: Statistical Fracture Prediction, High Pressure Die Casting, entrainment defects, LS-DYNA, Weibull distribution, oxide bi-films

2. Abstract:

High pressure die casting is an economical means of producing a high volume of aluminium parts, with a design freedom that can enable lighter structures to be envisioned, compared with wrought assemblies. However, cast aluminium parts have been shown to be vulnerable to damage by defects caused by the entrainment of air during the casting process.

A recently developed entrainment prediction algorithm, which is believed to more quantitatively predict the distribution of entrainment defects within a casting, was used to predict the distribution of these defects for two variants of the casting process for a commercial part. Using a novel fuzzy statistical correlation method, the predicted distribution of entrainment damage was correlated with the statistical distribution of entrainment damage, as determined by tensile testing.

This work demonstrates a verification of the mapping methodology, in which the correlated strength distribution was mapped into LS-DYNA models of the test bars used for correlation. The results showed that the fuzzy statistical entrainment damage model can be tightly fitted to tensile test data, and that this fidelity can be reproduced in LS-DYNA simulations using the methods described, however further work is required to demonstrate the method's predictive capability.

3. Introduction:

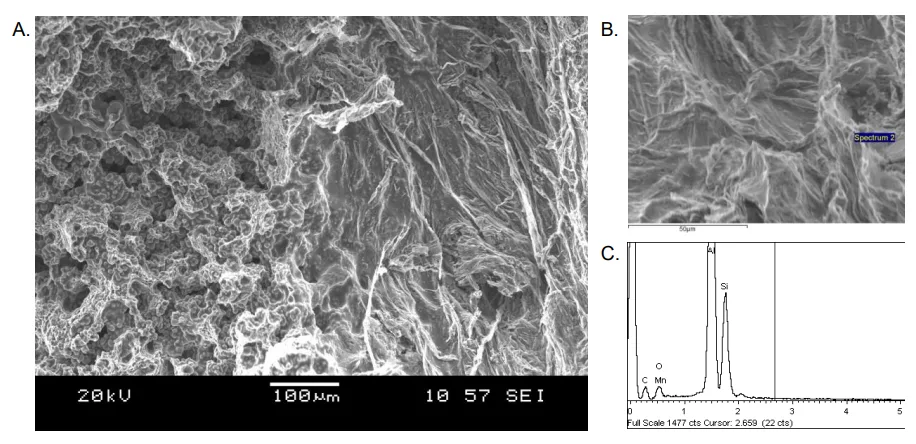

High Pressure Die Castings (HPDC) are widely used in the automotive industry for their ability to produce complex geometries in high volumes at low cost. However, their design is often based on conservative strength estimates due to the difficulty in accounting for factors like the unique distribution of entrainment defects within each casting. This work aims to apply recent developments in understanding entrainment defects to generate a map of the statistical strength distribution in a cast part. This distribution, based on simulated defect patterns, can be mapped into an LS-DYNA key-file to simulate part failure. Defects such as oxide bi-films, formed when the oxidized surface of molten metal is folded over, can significantly reduce ultimate tensile strength. While typical oxide bi-films are less common in HPDC, related defects resembling bubbles with oxidized inner surfaces are observed, suggesting they are also formed by air entrainment.

4. Summary of the study:

Background of the research topic:

The strength of cast parts is not uniform but statistical, influenced by the distribution of defects. This variability is often described by the 2-parameter Weibull distribution, where the Weibull modulus (m) describes the quality or reliability of the casting. The size distribution of defects themselves has been shown to follow log-normal or Generalised Extreme Value (GEV) distributions. A key insight is the relationship between the distribution of the most damaging "critical defect" and the bulk defect population. This study builds on the idea that strength (x) and damage (d) can be related through a negative power law, which is analogous to relationships in fracture mechanics.

Status of previous research:

Previous casting simulation models for predicting entrainment defects, such as MAGMAsoft's "air contact time" criterion or the Boolean Oxide Entrainment Code (BOEC), had limitations. Scalar transport models like "air contact time" do not robustly model defect transport, while logical models like BOEC lack a measure of severity, making it difficult to correlate particle count with damage. A more recent algorithm, the Surface Area Entrainment Code, was developed to improve robustness and provide a better basis for quantitative correlation. Previous work showed a rough location-for-location correlation was possible, but this study aims to develop a more refined statistical approach.

Purpose of the study:

The purpose of this work is to demonstrate and verify a methodology for generating a location-specific statistical strength map for an HPDC part. This involves:

1. Using an advanced entrainment prediction algorithm (Surface Area Entrainment Code) within a CFD simulation to predict the spatial distribution of defects.

2. Developing a novel fuzzy statistical correlation method to link the predicted defect distribution to the statistical strength distribution measured from experimental tensile tests.

3. Mapping the correlated strength distribution into LS-DYNA models and verifying that simulations using this map can reproduce the statistical failure behavior observed experimentally.

Core study:

The core of the study involved two variants of a commercial HPDC process: a "Full Gate" and a "Blanked Gate" configuration. Both were physically cast and simulated. Tensile bars were extracted from three locations on the physical castings and tested to determine their Weibull strength statistics. The simulations, using FLOW-3D with the entrainment prediction code, generated a 3D map of defect particles. A random walk algorithm was used to sample the simulated defect density around the locations of the test bar elements, and a 3-parameter Fréchet distribution was fitted to this data. An inverse power law transform, calibrated with four optimized parameters, was used to convert the statistical defect damage into a statistical fracture stress. This strength distribution was then mapped into LS-DYNA models of the test bars for verification.

5. Research Methodology

Research Design:

The study employed an integrated experimental and computational research design. Two distinct casting process variants were created to generate different defect populations. Experimental data from tensile testing served as the ground truth for calibrating and validating the computational model. The computational workflow involved CFD simulation for defect prediction, a statistical mapping algorithm for data correlation, and FEA simulation for verification.

Data Collection and Analysis Methods:

- Experimental Data: Tensile test data was collected from 6 groups of 30 tests each (2 casting variants x 3 locations). True fracture stresses were calculated, and the data was characterized using Maximum Likelihood Estimation (MLE) to fit a 2-parameter Weibull distribution for each group.

- Simulation Data: The FLOW-3D simulation produced spatial coordinates for Lagrangian particles representing defects.

- Statistical Correlation: A custom random walk algorithm sampled the defect number density from the simulation. This sampled data was fitted with a 3-parameter Fréchet distribution. A fitting algorithm using an arithmetic least squares solution and numerical iteration was used to find the optimal parameters for the inverse power law transform that links defect density to fracture stress.

Research Topics and Scope:

The research covers the prediction of entrainment defects in HPDC, the development of a statistical methodology to correlate predicted defect density with experimental strength data, and the implementation and verification of this statistical strength map within an LS-DYNA finite element model. The scope is limited to two process variants of a single commercial part and focuses on predicting ultimate tensile strength.

6. Key Results:

Key Results:

- The fluid simulation correctly predicted a significant difference in the geometric distribution of defects between the "Full Gate" and "Blanked Gate" cases, demonstrating the model's sensitivity to changes in the casting process.

- The mapping process generated visually distinct and non-uniform strength distributions within the virtual test bars for each case and location, reflecting the underlying predicted defect patterns.

- Repeated simulations (100 runs) of the mapped LS-DYNA test bars produced cumulative strength distributions that closely matched the experimental Weibull distributions.

- The fidelity of the fit was particularly high in the lower tail of the distributions, which is the most critical region for design against failure. The model consistently underestimated the variation in strength, especially for the strongest test pieces in the upper tail.

Figure Name List:

- Fig.1: An SEM image of an air-pore (A, right), associated with a region of micro-shrinkage porosity (A, left), alongside with a higher magnification view of the air-pore (B), showing the location that the EDX spectrum (C) was sampled from.

- Fig.2: The locations on the trial castings where the test bars were extracted from.

- Fig.3: Final time frame of "Full Gate” and “Blanked Gate" simulations, coloured by defect number density, with test bar positions overlaid.

- Fig.4: Example strength mappings of each test bar.

- Fig.5: A comparison of the cumulative distributions of true fracture stress produced by repeated evaluation of the defect mapping algorithm, and the Weibull statistics that the mapping parameters are based on.

7. Conclusion:

The results demonstrate that the defect prediction algorithm used in the fluid simulation can produce a sufficiently realistic defect distribution. This distribution can be correlated with a statistical damage function with a reasonably close fit. The methodology successfully maps this correlated strength data into LS-DYNA, and simulations can reproduce the statistical strength with high fidelity, especially in the lower tail of the distribution which is critical for design durability. Although the model tends to underestimate the strength of the strongest samples, a key advantage is that it prevents unrealistically high strength predictions for small elements. The methodology, implemented using a PRIMER script, is shown to be a viable process for application in a commercial engineering setting.

8. References:

- [1] Campbell, J: "Castings", 1, 1991

- [2] Campbell, J: "Complete Casting Handbook", issue 1, 2011

- [3] Green, N; Campbell, J: "Statistical distributions of cast Al-7Si-Mg alloy", Materials Science and Engineering A, v. 173, 1993, pp. 261-266

- [4] Weibull, W: “A Statistical Distribution of Wide Applicability", Journal of Applied Mechanics, v. 13, 1951, pp. 293–97

- [5] Nyahumwa, C: “Influence of Oxide Film Filling Defects on Fatigue Properties of Cast Al-7Si-Mg Alloy", PhD Thesis, University of Birmingham, 1997

- [6] Tiryakioğlu, M: “On the size distribution of fracture-initiating defects in Al- and Mg-alloy castings", Materials Science and Engineering A, v. 476, 2008, pp. 174-177

- [7] Chakrabarty, J: “Applied Plasticity, Second Edition", 1, 2010, p. 7

- [8] Dørum, C; Laukli, H; Hopperstad, O-S: “Through Process numerical simulations of the structural behaviour of Al-Si die-castings", Computational Materials Sceince, v. 46, 2009, pp. 100-111

- [9] Reilly, C: "Development Of Quantitative Casting Quality Assessment Criteria Using Process Modelling", PhD Thesis, University of Birmingham, 2010

- [10] Yue, Y; Green, N R: “Modelling of different entrainment mechanisms and their influences on the mechanical reliability of Al-Si castings", IOP Conf. Series: Materials Science and Engineering, v. 33, 2012, 012072

- [11] Watson, R; Zeguer, T; Ruffle, S; Griffiths, W D: "Application of a Novel Entrainment Defect Model to a High Pressure Die Casting", Advanced Materials Research, THERMEC 2013 Supplement, pp. 801-806

Expert Q&A: Your Top Questions Answered

Q1: Why was a Fréchet distribution chosen to model the defect damage?

A1: The paper notes that while previous research found the Gumbel distribution appropriate for critical defect size, the Fréchet distribution was also a possibility within the confidence intervals. The authors chose the Fréchet distribution for two key reasons: its close mathematical relationship to the Weibull distribution (used for strength), which simplifies the derivation of the power law relationship between strength and damage, and the flexibility offered by its 3-parameter form, which can account for a baseline level of damage.

Q2: What is the purpose of the "random walk algorithm" in the statistical mapping process?

A2: A single casting simulation is deterministic; it will produce the exact same defect map every time. However, real-world casting is a stochastic process with minor variations. The random walk algorithm introduces this element of variability by sampling the simulated defect density not just at a precise point, but in the local neighborhood around it. This process assumes that in reality, parcels of fluid containing defects might end up in slightly different final positions from one casting to the next, allowing the model to extrapolate a statistical variation in damage from a single simulation run.

Q3: The results in Figure 5 show the model underestimates the strength of the strongest parts (the upper tail). Why is this not a major concern?

A3: For engineering design and safety analysis, accurately predicting the strength of the weakest components (the lower tail of the distribution) is far more important than predicting the strength of the strongest ones. A design must be robust enough to withstand failure in the worst-case scenario. The model's excellent fit in the lower tail provides confidence for its use in durability and failure prediction. Furthermore, the paper notes an advantage of this characteristic: it prevents the model from assigning unrealistically high strength values to very small finite elements.

Q4: How does the "Surface Area Entrainment Code" used in this study improve upon older defect prediction models?

A4: The paper explains that older models had significant drawbacks. "Air contact time," for example, is not a robust measure of damage and doesn't directly model entrainment. The "Boolean Oxide Entrainment Code" (BOEC) was an improvement but defined entrainment with simple logical criteria (it's either happening or it's not), providing no measure of severity. The Surface Area Entrainment Code is more quantitative, creating defect particles based on the amount of new surface area created and entrained, which provides a more direct and scalable link between the fluid dynamics and the potential for damage.

Q5: How is the final statistical strength map practically implemented in the LS-DYNA simulation?

A5: The process is automated with a PRIMER script. Instead of assigning a unique strength to every single element, which would be computationally prohibitive, a binning algorithm groups elements with similar predicted strengths together. For this study, 50 bins were used. Each bin is then assigned a new *PART ID and a corresponding material ID. The average strength of the elements within that bin is then defined for that material using the *MAT_ADD_EROSION keyword in LS-DYNA, creating a detailed, location-specific map of material properties.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of unpredictable defects has long placed a ceiling on the performance of High Pressure Die Castings. This research breaks new ground by creating a robust bridge between casting process simulation and structural performance analysis. The key breakthrough is the ability to create a location-specific Statistical Fracture Prediction map and embed it directly into an LS-DYNA model. This moves the industry away from overly conservative design practices and towards a more precise, data-driven understanding of how parts will behave in the real world.

For R&D and operations teams, this means a powerful new capability to optimize designs for weight, improve casting processes to enhance quality, and simulate part durability with a much higher degree of confidence.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Towards Location Specific Statistical Fracture Prediction in High Pressure Die Castings" by "R. Watson, W.D. Griffiths, T. Zeguer, S. Ruffle".

Source: The paper was presented at the 10th European LS-DYNA Conference 2015 in Würzburg, Germany.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.