Eliminating Shrinkage Defects: A Casting Simulation Guide to Optimizing Riser Neck Design in Aluminium Alloys

This technical summary is based on the academic paper "Application of Simulation Softwares for Analysing the Solidification Pattern of Aluminium Alloy (LM6) Casting" by Titas Nandi, published in Scholars Journal of Engineering and Technology (SJET) (2016).

Keywords

- Primary Keyword: Casting Simulation

- Secondary Keywords: Solidification Pattern, Aluminium Alloy LM6, Shrinkage Defect, Riser Design, ProCAST software, Hot Spot

Executive Summary

- The Challenge: Achieving defect-free aluminium castings consistently is difficult, as improper riser design often leads to costly shrinkage defects and low production yields.

- The Method: The study utilized FEM-based casting simulation software (ProCAST) to analyze the solidification pattern of a stepped LM6 aluminium alloy component, varying the riser neck diameter while keeping the riser size constant.

- The Key Breakthrough: Experimental validation confirmed that an optimized riser neck geometry (specifically a diameter of 28.70mm with a height of 6.0mm) successfully eliminated shrinkage defects in the final casting.

- The Bottom Line: Casting simulation is a powerful, cost-effective tool that replaces trial-and-error on the shop floor, enabling engineers to pinpoint optimal design parameters for risering systems and ensure high-quality, defect-free components.

The Challenge: Why This Research Matters for HPDC Professionals

In any foundry, the battle against defects is constant. For aluminium alloys like LM6, one of the most persistent and costly issues is the formation of shrinkage cavities. These internal voids compromise the structural integrity and mechanical properties of the final product. The root cause often lies in the risering system, which is designed to feed molten metal to the casting as it solidifies and shrinks.

A poorly designed riser, particularly the connection point known as the "riser neck," fails to ensure directional solidification. This either traps isolated hot spots that turn into shrinkage defects or results in a low yield. Traditional methods for optimizing riser design involve numerous physical trials on the shop floor. This approach is not only expensive and time-consuming but also disrupts regular production schedules. This research addresses the critical need for a faster, more reliable method to design risering systems that guarantee casting quality from the very first run.

The Approach: Unpacking the Methodology

To find the optimal riser neck design, the researchers employed a virtual, computer-aided approach before casting any physical parts. This methodology allowed for rapid iteration and analysis without consuming materials or production time.

Method 1: 3D Modeling and Simulation Setup

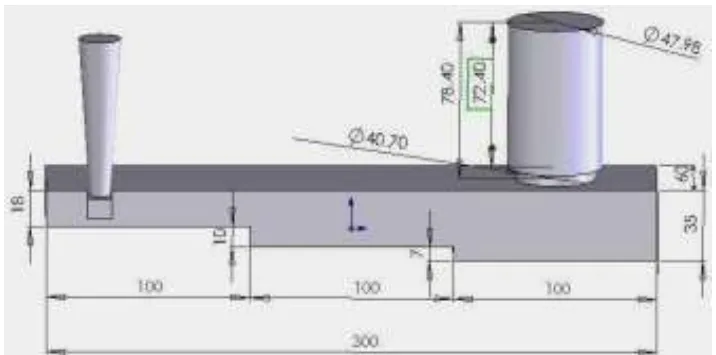

The study began by creating a 3D CAD model of a stepped component, complete with its gating and risering system. Four distinct models were developed, each with an identical riser (72.40 mm height x 47.98 mm diameter) but with different riser neck diameters: 47.98 mm (Model-1), 40.70 mm (Model-2), 28.70 mm (Model-3), and 22.00 mm (Model-4). These models were then imported into ProCAST, a Finite Element Method (FEM) based casting simulation software.

Method 2: Virtual Casting Process

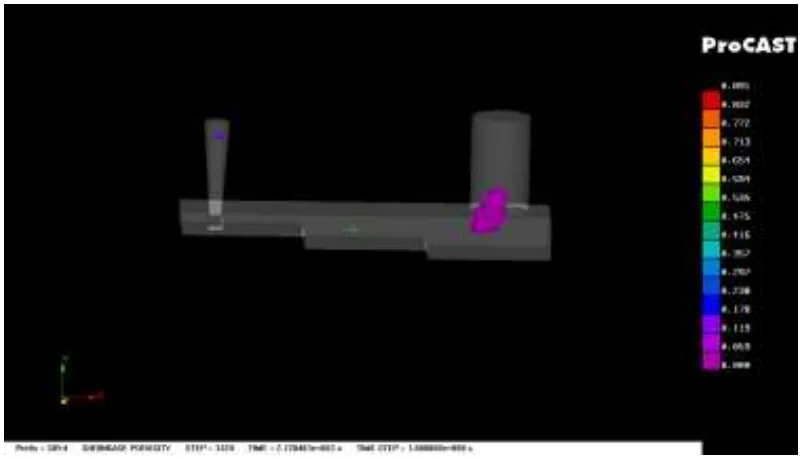

Within ProCAST, the entire casting process was simulated. This involved defining the thermo-physical properties of the LM6 aluminium alloy and the sand mould material, as well as process parameters like pouring temperature and time. The software then solved complex heat transfer equations to predict the mould filling sequence and, most importantly, the complete solidification pattern over time. This allowed the researchers to visualize temperature distribution, identify the last points to solidify (hot spots), and predict the location and severity of any resulting shrinkage porosity.

Method 3: Experimental Validation

Based on the simulation insights, physical moulds were prepared using green sand. Molten LM6 aluminium alloy was poured into these moulds, creating castings corresponding to the different riser neck designs. The finished castings were then sectioned down the middle to visually inspect for the presence of internal macro-porosity or shrinkage defects, allowing for a direct comparison between the simulated predictions and the real-world results.

The Breakthrough: Key Findings & Data

The combination of simulation and physical testing revealed a clear relationship between the riser neck geometry and the internal quality of the casting.

Finding 1: Simulation Accurately Predicts Hot Spot Location and Defect Formation

The ProCAST simulations successfully visualized the solidification process for each of the four models. The software predicted how the solidification front moved from the thinnest sections to the thickest, and critically, it identified the final hot spots. As shown in the simulation results (e.g., Figure 7 and Figure 21), certain riser neck dimensions led to the formation of isolated hot spots within the casting itself or at the neck, which are direct precursors to shrinkage defects. In contrast, other designs (e.g., Figure 14 and Figure 28) showed solidification patterns that allowed the riser to feed the casting effectively, eliminating internal defects.

Finding 2: Experimental Results Identify an Optimal Riser Neck Diameter

The physical castings provided the ultimate validation. After sectioning the parts, the researchers observed the presence or absence of shrinkage defects. As stated in the Experimental Validation section, "It has been observed that at riser neck of height (h) =6.0mm & diameter (d) =28.70mm with the same riser no shrinkage defect/ porosity is present in the casting." The study further notes that "On decreasing or increasing the diameter of riser neck from the value the shrinkage defect occurred in the casting." This confirms that an optimal geometry exists and that deviating from it reintroduces defects, proving the sensitivity of the process to this single design parameter. The experimental results were found to be "more or less matching with the simulated results," validating simulation as a predictive tool.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting the riser neck diameter is a critical lever for controlling solidification and eliminating shrinkage. Instead of relying on intuition or repeated trials, engineers can use simulation to precisely define the optimal neck dimensions for a given casting and riser combination.

- For Quality Control Teams: The data in figures like Figure 7 (casting with defect) and Figure 14 (casting without defect) of the paper illustrates the direct impact of a design choice on internal soundness. This reinforces the importance of validating the risering system design as a primary quality assurance step, rather than just inspecting final parts.

- For Design Engineers: The findings indicate that the connection point between the feeder and the casting is as important as the feeder itself. This research provides a clear case for incorporating casting simulation early in the design phase to analyze feed paths and ensure directional solidification is achieved, preventing costly redesigns later.

Paper Details

Application of Simulation Softwares for Analysing the Solidification Pattern of Aluminium Alloy (LM6) Casting

1. Overview:

- Title: Application of Simulation Softwares for Analysing the Solidification Pattern of Aluminium Alloy (LM6) Casting

- Author: Titas Nandi

- Year of publication: 2016

- Journal/academic society of publication: Scholars Journal of Engineering and Technology (SJET)

- Keywords: Simulation, solidification, casting, riser neck, hot spot, shrinkage defect.

2. Abstract:

Casting simulation is a virtual casting process that ensures the production of defect less castings in the shortest possible time. It involves computer-aided modeling, pattern design, methoding, simulation and optimization. Casting simulation technology has been proven for all major cast metals and processes, giving reliable results even for complex castings. Neither a drop of hot metal is needed nor does it hamper the regular production schedule of the concerned foundry. It however, does not replace a methods engineer or production manager. It will only assist a methods engineer to achieve the best casting design with very few or even no trial and also creates confidence to a foundry manager. In the present study, a stepped component was considered to study the solidification behavior of LM6 at different size of the riser neck, by using FEM based casting simulation software, whenever, the size of riser remains constant. The simulated results has compared with the experimental results. It has been observed that the simulated results are almost identical with the experimental data.

3. Introduction:

In manufacturing, casting is a highly economical production process involving significant metallurgical and mechanical aspects. The solidification rate critically affects the microstructure and, consequently, the mechanical properties of the cast metal. Proper design of the riser/feeder system is essential for achieving directional solidification, as an incorrect design leads to defective castings with shrinkage cavities or lower yield. While experimental routes are effective for design and optimization, they are costly and time-consuming. Casting simulation offers a convenient alternative for designing risering systems and analyzing the effect of various process parameters. The application of simulation is increasing in foundries as it minimizes or replaces shop-floor trials, helping to achieve desired internal quality efficiently.

4. Summary of the study:

Background of the research topic:

The quality of cast components is largely determined by the solidification process. Defects such as shrinkage porosity are common issues that arise from improper solidification, which is often linked to the design of the risering and feeding system. Optimizing this system is crucial for producing sound castings.

Status of previous research:

Previous research by P. Prabhakara Rao et al. and Dr. B. Ravi has demonstrated that casting simulation software like ProCAST and AUTO CAST can effectively eliminate defects like shrinkage and porosity, improve yield, and optimize gating and feeder systems. Studies have focused on various aspects, including mould filling, solidification of ductile iron, and the analysis of 3D junctions in castings to predict and correct shrinkage porosity.

Purpose of the study:

The study aimed to investigate the solidification behavior of an LM6 aluminium alloy stepped component by varying the size of the riser neck while keeping the riser dimensions constant. The primary goal was to use FEM-based casting simulation software to analyze the effect of the riser neck on defect formation and to compare these simulation results with experimental findings.

Core study:

A stepped component casting was designed with four different riser neck diameters (47.98 mm, 40.70 mm, 28.70 mm, and 22.00 mm), while the riser height (72.40 mm) and diameter (47.98 mm) were kept constant. The mould filling and solidification processes for each of these four models were simulated using ProCAST software. The simulations were used to visualize the temperature distribution, fraction of solid over time, hot spot locations, and potential porosity defects. Subsequently, physical castings were produced for each model using green sand moulds and LM6 alloy. These castings were sectioned to experimentally validate the simulation's predictions regarding the presence or absence of shrinkage defects.

5. Research Methodology

Research Design:

The research employed a comparative study design, analyzing four different models of a casting with varied riser neck dimensions. The study combined computational simulation with physical experimentation for validation.

Data Collection and Analysis Methods:

Data was generated through FEM-based simulation using ProCAST software. The outputs included visualizations of mould filling, temperature contours, fraction of solid graphs, and porosity predictions. Experimental data was collected by physically casting the components and sectioning them for visual inspection of internal defects. The simulated results were then qualitatively compared with the experimental observations.

Research Topics and Scope:

The research focused on the solidification of LM6 aluminium alloy in a sand mould. The scope was limited to studying the effect of the riser neck diameter on the formation of shrinkage defects in a specific stepped casting geometry, with a constant riser size.

6. Key Results:

Key Results:

- The simulation of mould filling showed a total fill time between 798 sec. and 803.5 sec. for all models, indicating that the riser neck dimension had a negligible effect on filling time.

- The simulation predicted the location of hotspots and shrinkage defects for different riser neck geometries. For some models, defects were predicted within the casting, while for others, the solidification pattern was sound.

- Experimental validation was conducted by producing and sectioning the castings. The study concluded that a riser neck with a height of 6.0 mm and a diameter of 28.70 mm resulted in a casting with no shrinkage defects.

- It was observed experimentally that increasing or decreasing the riser neck diameter from this optimal value (28.70 mm) led to the occurrence of shrinkage defects.

- The paper states that the simulated results were "more or less matching with the simulated results," validating the use of simulation for this application.

Figure Name List:

- Fig-1: Procedure to improve the quality of casting

- Fig-2: Flow chart of Pro CAST casting simulation

- Fig-3: 3D model of the casing part with its risering system

- Fig-4: Mould filling at different step, a- d

- Fig-5: Fraction of solid at different step, a- f

- Fig-6: Casting of model-1

- Fig-7: Section of casting with shrinkage defect

- Fig-8: Porosity in the casting

- Fig-9: Temperature Vs Time

- Fig-10: Fraction of Solid Vs Time

- Fig-11: 3D model of the casing part with its risering system

- Fig-12: Mould filling at different step, a- d

- Fig-13: Fraction of solid at different step, a- f

- Fig-14: Section of casting shows no shrinkage defect

- Fig-15: Porosity in the casting

- Fig-16: Temperature Vs Time

- Fig-17: Fraction of solid Vs Time

- Fig-18: 3D model of the casing part with its risering system

- Fig-19: Mould filling at different step, a- d

- Fig-20: Fraction of solid at different step, a- f

- Fig-21: Section of casting with shrinkage defect

- Fig-22: Porosity in the casting

- Fig-23: Temperature Vs Time

- Fig-24: Fraction of solid Vs Time

- Fig-25: 3D model of the casing part with its risering system

- Fig-26: Mould filling at different step, a- d

- Fig-27: Fraction of solid at different step, a- f

- Fig-28: Section of casting shows no shrinkage defect

- Fig-29: Porosity in the casting

- Fig-30: Temperature VS Time

- Fig-31: Fraction of solid VS Time

7. Conclusion:

The application of casting simulation software is beneficial for foundries as it minimizes the need for trial castings, thereby saving resources and enhancing the quality and yield of castings. ProCAST is a capable software that produces reliable simulation results reflecting real casting phenomena. The study demonstrated that the size of the riser neck significantly affects the solidification behavior and the formation of shrinkage defects in aluminium alloy castings. The simulated results showed a strong correlation with the experimental results, confirming the efficacy of simulation as a tool for optimizing casting design.

8. References:

- Application of Commercial Software Package Procast to the Prediction of Shrinkage Porosity in Investment Castings. www.mmat.ubc.ca/databases/Details.asp?id=354

- Viswanathan, WD, Porter; Using of Simulation in Optimizing Mould Filling. AFS Transactions, 1990; 98: 477-483.

- Ravi B, Joshi D; Feedability Analysis and Optimisation Driven by Casting Simulation. Indian Foundry Journal, 2007; 53(6): 71-78.

- Prabhakara Rao P, Chakravarthy G, Kumar ACS, Srinivasa Rao G; Computerised simulation of sand casting process 57th Indian Foundry Congress. Institute of Indian Foundry men, Kolkata, 2009.

- Ravi B; Casting method optimization driven by simulation. Minerals & Metals Review – March 2008; 39-43.

- Ravi B; Casting Simulation and Optimisation: Benefits, Bottlenecks, and Best Practices. Indian Foundry Journal, 2008; 54(1).

- Joshi D, Ravi B; Classification and simulation based design of 3d junctions in castings. American Foundry Society, 2009.

- Ravi B; Metal Casting: Computer-Aided Design and Analysis, Prentice-Hall India, New Delhi, 2005.

- Ravi B, Srinivasan MN; Hot spots in Castings- computer aided Location and Experimental Validation. Transactions of the AFS, 1990; 98: 353-357.

Expert Q&A: Your Top Questions Answered

Q1: Why was the riser size kept constant while only the neck dimension was varied in the study?

A1: The study aimed to isolate the specific effect of the riser neck on the solidification pattern and defect formation. By keeping the main riser body (height and diameter) constant, the researchers ensured that the total volume of available feed metal was the same for all four models. This experimental control allowed them to directly attribute any differences in casting quality, such as the presence of shrinkage, to the changes in the riser neck geometry alone.

Q2: What specific simulation software was used and why was it chosen?

A2: The paper specifies the use of ProCAST, which is a casting simulation software based on the Finite Element Method (FEM). ProCAST was chosen because it allows for comprehensive modeling of the casting process, including thermal heat transfer, fluid flow during mould filling, and stress analysis. Its capabilities in predicting solidification patterns, hot spots, and porosity make it a suitable tool for the study's objective of analyzing and preventing shrinkage defects.

Q3: What was the primary defect the researchers were trying to eliminate?

A3: The primary target was shrinkage defect, also referred to as shrinkage porosity or macroporosity. This defect occurs when there is insufficient molten metal to compensate for the volume reduction (shrinkage) that occurs as the metal cools from a liquid to a solid. The simulation was used to identify "hot spots"—the last regions to solidify—which are the most likely locations for these defects to form if they are isolated from the feed metal in the riser.

Q4: How did the simulation results compare to the physical casting results?

A4: The paper states that the "simulated results are almost identical with the experimental data" and that the experimental result is "more or less matching with the simulated results." This indicates a strong positive correlation. The simulations were able to successfully predict which riser neck designs would likely lead to sound castings and which would result in shrinkage defects, and these predictions were confirmed by sectioning the actual cast parts.

Q5: What is the key takeaway for a foundry manager from this study?

A5: The key takeaway is that investing in casting simulation technology can provide a significant return by drastically reducing or eliminating the need for costly and time-consuming shop-floor trials. As demonstrated, simulation can accurately predict the outcome of a specific riser design, allowing engineers to optimize the methoding virtually. This leads to higher first-time-right rates, improved casting quality, higher yield, and increased confidence in production outcomes.

Conclusion: Paving the Way for Higher Quality and Productivity

The persistent challenge of eliminating shrinkage defects in aluminium castings requires a move from traditional trial-and-error methods to more precise, predictive technologies. This study effectively demonstrates that Casting Simulation is not just an analytical tool but a practical solution for optimizing critical design elements like the riser neck. By identifying an optimal geometry that ensures directional solidification, the research proves that defect-free castings can be achieved through methodical, data-driven design.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Application of Simulation Softwares for Analysing the Solidification Pattern of Aluminium Alloy (LM6) Casting" by "Titas Nandi".

Source: DOI: 10.21276/sjet.2016.4.7.4

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.